Building a garage on screw piles - a step-by-step guide

Having purchased a plot for the construction of a garage, the last thing car owners think about is the stability of the soil. And subsequently there is a need for additional expenses to build a stable foundation. In this situation, you should not save money, because poor quality garage construction can lead to disastrous results. Therefore, if your garage site is located on wet or shifting soil, you should choose a foundation that will be attached to solid layers of soil.

Which foundation to choose

Construction of a garage on screw piles in this case will be the best option both in terms of the cost of construction and in terms of its quality. The price of the structure is affordable; laying the foundation does not require global excavations

And most importantly, the garage owner can be sure that the foundation of his building is reliable and of high quality

A screw foundation can be laid at any time of the year; frozen soil is not a problem.

Above ground, a pile foundation is practically no different from a classic pillar foundation, which is used in the construction of light structures. But underground, the length of piles can reach up to 20 m. It is thanks to the ability to penetrate to such a depth that the structure will always be protected from ground vibrations.

Tips for working

If you decide to lay a pile-strip foundation with your own hands, professionals recommend choosing piles with a large cross-section. Since, in this case, in order to lower the pile into the ground, you only need a construction drill.

When drilling wells and sewers, you should remember that under the piles there is a sand cushion, which occupies about 3 cm.

In a pile-strip foundation, the piles are located at the base of the walls and in the corners. The distance from one pile to another is approximately 2 m.

To carry out waterproofing, you can use asbestos-cement pipes, the diameter of which is 15-20 cm. You can make waterproofing using roofing felt. To do this, roll it up into a tube and tie it with fishing line.

After the strip foundation formwork has been constructed, it is necessary to proceed to the reinforcement of the strip and piles. You fill the entire structure with concrete. Construction vibration equipment is best suited for this procedure.

The process of screwing in a pile should not be simplified by digging holes or different holes. The screw pile enters the ground at a right angle, from scratch. The further stability of the structure being built depends on this.

Advantages and disadvantages

Experienced builders know that the foundation is installed at a soil depth below freezing. If you do not follow this technology, the structure will become warped over time, and cracks will form on the walls. And in the case of erecting an expensive strip-monolithic foundation during the construction of a garage or other light structure, the expenses will be unreasonable, since the foundation will be very powerful for such a building. The best option in this case is to build a screw foundation. It has a number of advantages:

- there is no need to clear the site to build the foundation;

- construction is possible in any weather;

- acceptable price;

- simple installation; building such a foundation manually is not difficult;

- the work takes several days; with a small building area and work experience, one day is enough;

- There is no need to wait until the foundation is strong to build walls.

The advantages of a screw foundation are undeniable, but along with them, there are a number of disadvantages:

- Under the influence of corrosion, metal piles sooner or later collapse. Therefore, this type of foundation cannot be classified as long-term.

- When driving piles into the ground, there is no way to control the integrity of the anti-corrosion coating on them. There are hard rocks in the ground that can damage the coating.

- There is a need to install a base. Not everyone likes the look of buildings on a screw foundation. And processing the base is a difficult and sometimes expensive task.

- During winter, the sewer system may freeze. Because with such a foundation there is no question of a warm underground.

- Cases have been recorded when piles installed in the cold season begin to wobble by spring.

It should be noted that all problems with foundations on screws arise only in cases of incompetence of specialists or when using piles of poor quality. In order to build a long-term and reliable foundation, pay close attention to the work process and maintain accuracy when working with screw piles. If you decide to use the services of a construction company, before starting work, be sure to sign a contract and make sure that it contains a clause on compliance with construction technology.

Quick construction of a garage on screw piles with your own hands: stages of work and photos

It happens that when purchasing a country house with beautiful views and nature, the owners end up with a plot with unstable soil.

Such soil, having high mobility, does not allow the owner of the site to make do with little effort when laying the foundation . Insufficient research of the site and saving money on strengthening the foundation sometimes lead to disastrous results.

Therefore, when constructing on shaky soil, it is necessary to get to the solid layer located underneath it. A significant difficulty in this matter can be the large depth of solid rock, which can be located at a depth of 5 to 20 meters .

Step-by-step instructions for building a garage

Building a frame garage with your own hands is very easy if you follow the detailed instructions.

Technology for constructing columnar and pile foundations

The foundation for a frame garage can be made of concrete blocks or screw piles. The process of creating a concrete block foundation consists of the following steps:

- You can buy ready-made concrete blocks or cast them yourself. For this you will need forms and fittings. To prepare the solution, use cement, river sand, crushed stone, and water. Forms can be made from boards or plywood. They are boxes without a bottom with an aspect ratio of 2:1. The forms are placed on a table covered with polyethylene.

- Filling of forms occurs in two stages. First, they are filled halfway, then cut reinforcement mesh is laid, and the molds are filled to the end. After removing from the molds, the blocks need to be dried for several weeks.

- Now you need to prepare the site for the garage. It is cleaned of debris and roots, slightly buried and leveled. After this, it is recommended to fill the site with sand and make markings along the perimeter of the future garage.

- Concrete blocks are laid in two rows, tied together with cement mortar and masonry mesh. The first row is buried in the ground, the second is placed on top of it. Then you need to let the solution dry for several days.

- The outer side of the foundation must be waterproofed with bitumen mastic, which is applied in 2-3 layers (each of them must be given time to dry).

- After this, you can backfill the sand to the level of the soil surface.

You can make concrete blocks for the foundation for a frame garage yourself

It’s also easy to build a foundation on screw piles with your own hands:

- In the places where the piles are installed, shallow holes need to be dug.

- The piles must be inserted into them and screwed into the ground using levers. In this case, you need to align them vertically.

- After installing all the supports, the tops need to be trimmed horizontally.

- Fill the cavities inside the piles with concrete.

- Install the headbands to which the grillage is attached.

Detailed instructions for assembling a wooden frame

To do this you need:

- Waterproof the foundation surface with roofing felt in 1–2 layers. This is done to prevent wood rotting.

- Lay the bottom trim beam around the perimeter of the structure on the roofing felt. In the corners, connect it with notches and dowels.

- Install corner and side posts. The minimum distance between them is 2 m. The racks are attached to the bottom trim on metal corners with dowels and self-tapping screws. After installing the racks, the upper frame beam is placed on them and secured.

- Install intermediate racks made of boards at a distance of 0.5 m from each other. Attach horizontal jumpers between them using corners and self-tapping screws. It is convenient to select the distance between the racks and the height of the fastening of horizontal ties according to the size of the insulation, so that later you do not have to install additional sheathing for it.

Since the garage will have a pitched roof, one of the walls should be higher. This is taken into account when installing vertical posts, which need to be made of different heights.

Installing a roof on a wooden building

Installation of a pitched roof for a frame garage is carried out in the following sequence:

- The floor beams are attached to the top frame beam using dowels or nails.

- A vapor barrier film is laid on the beams. It does not need to be pulled tightly, it should sag slightly - no more than 0.5 cm.

- A sheathing of boards is attached on top of the film in increments of 0.5 m.

- The roof you have chosen for the garage is being laid - slate, metal profile, etc.

Most often, a pitched roof is chosen for a garage.

What type of cladding is needed?

Garage lining can be made from:

- metal profiles;

- OSB sheets.

For a wooden frame, the second option is more often used.

The sheets are fastened on the outside with self-tapping screws. You need to leave a small gap between them (2–3 mm). Over time, the sheets can change sizes due to temperature changes and high humidity, and the gaps will not allow them to push each other out.

Stone wool can be used as insulation. It must be laid between the racks, not forgetting to fix it with the inner lining. Before laying the wool, you can attach a windproof film to the walls.

If desired, the frame garage can be insulated from the inside

Finishing

External and internal decoration of the walls of a frame garage can be any:

- plaster;

- painting;

- facing with siding.

This is done to protect the wall from atmospheric influences. Before applying plaster, OSB sheets must be treated with a special primer.

Do-it-yourself grillage in a separate line

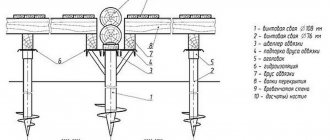

The grillage is the ground part of the driven structure (lintel), which connects the piles to each other, removes unnecessary stress and vibration, and gives the structure rigidity and stability. The joints with the rods are called nodes. These gaps are important because they take on a significant load of the garage.

There are different grillage designs:

Formwork is constructed, filled with reinforcement and filled with cement mortar.

Above-ground finishing consists of solid wooden or reinforced concrete structures that are fastened together at the top point of the underground support and form the entire structure.

In this case, the pile foundation (its supports) is buried to the required depth and fastened with strip foundations, which are also partially hidden in the ground. The method is effective for a garage in wetlands, since a pile-screw foundation of this type effectively combats the shrinkage of the building.

- Monolithic mechanism.

- Prefabricated grillage.

- Hybrid option.

Another design deserves attention: a rib-shaped rod is rigidly attached to the tile base.

Performing calculations

The foundation of such a garage must last a long time and first it is necessary to make an accurate calculation, which concerns the choice of material, determining the actual loads on the soil and its individual layers, the dimensions and weight of the future garage.

Find out exactly what communications are going on at the construction site in order to avoid future problems with neighbors and utility services. It is better to make calculations according to SNiP 2.02.03-85 Pile foundations. During the calculation, the bearing capacity and strength of the foundation are determined.

Values and characteristics taken into account:

- bases of piles and their shells;

- the values of the horizontal load when combined with the slopes of the structure;

- design features of concrete supports and foundation grillage.

Types of screw piles.

A very important part of the calculations is the calculation of loads:

- The weight of snow on the garage roof, which is recommended to be 190 kg/m2 for the northern regions, 50 kg/m2 for the southern regions and 100 kg/m2 for the middle zone.

- Load from façade insulation and wall finishing.

- The load from the structure, not only from the roof covering, but also from the weight of the sheathing, insulation, rafters and other materials. Ceramic tiles - 60-80 kg/m2, asbestos-cement material - 40-50 kg/m2, roofing felt 30-50 kg/m2, sheet steel 20-30 kg/m2.

- Floor load, taking into account the weight of the insulation.

- Overall weight of the structure.

- Operating loads. This takes into account the availability of furniture, equipment, appliances, etc.

Calculating the foundation is a very complex matter, associated with a large number of formulas, calculation of dynamic loads, deformation and settlement, seasonal loads, the weight of the garage along with its contents.

And even a small mistake can lead to a big disaster, so to start quickly building supports with your own hands, you should entrust the calculations to professionals.

Technology of building a house on stilts

The foundation serves as an integral part of any building and is designed to transfer loads to the base. With a pile-screw foundation, each individual pile can be screwed to a different depth, depending on the type of soil in a certain area. Construction can be carried out even on an uneven site; all technology for constructing the foundation must be done strictly according to the created project. Step-by-step algorithm for building a foundation on screw piles:

- It is necessary to obtain a design solution for the future structure;

- The piles are verified by load tests;

- After the screw piles have passed the tests, a protocol is drawn up;

- Mark the area for construction;

- The foundation is divided into axes;

- The material is accepted, all necessary components and parts are checked to ensure that everything is in accordance with the specifications;

- In the places where screw piles are installed, holes are made; in summer the depth is 50 cm, and in winter it is necessary to take into account the level of frozen soil; the width is made according to the diameter of the blade;

- The piles are immersed to the design mark;

- The piles are cut along one level of the horizontal plane;

- The cavity is concreted;

- Using a welding machine, the heads and grillage are welded;

- An act of hidden work for immersion is created;

- The quality of work on the construction of a pile-screw foundation occurs in accordance with SP 50-102-2003;

- At the last stage, an act for the construction of the object is drawn up.

Rice . Screw pile for house on stilts

Installation of piles can occur in several ways:

- Geared;

- Mechanical;

- Manual method.

The manual installation method is usually used when it is not possible for special equipment to arrive or if the method is more cost-effective. But mostly specialized equipment is used, since it greatly reduces the construction time of the object. After screwing in the piles, the pillars are concreted; this construction process is carried out to increase the service life of the foundation and to prevent the formation of corrosion and water ingress. Using a welding machine, specialized structures are welded to the top of the pile, and then the strapping is performed. To extend the service life, upon completion of all work, all structural elements are painted.

Garage on a pile-screw foundation

Foundations on screw piles are erected in areas with moving soil

When intending to build a garage on stilts, the design of its base is planned taking into account its functional purpose. Supporting elements are placed along the perimeter of the rear and side walls. The facade side needs additional elements for installing the gate.

Before work, you need to calculate the number of piles for the base of the garage, the distance between them and the depth of immersion. These parameters depend on the mass of the building, which is determined by its material. If the structure is heavy (for example, made of brick or sandwich), more piles will be required. To make such a foundation more reliable, the supporting elements should be combined with a concrete grillage.

More often, lightweight frame structures are chosen for garage space. If the building is small (6 by 3 meters or less), there is no need to make a viewing hole. In other cases, it must be taken into account that the distance between the piles and the walls of the cellar must be at least 2 m. Ignoring this rule will negatively affect the stability and verticality of the supports. This is especially dangerous when constructing a building on heaving soil.

A garage on a pile foundation is easy to build without special skills. The work is completed quickly and does not require significant financial costs. The largest expense item in this case will be the purchase of the supports themselves. Other advantages of arranging a garage on a pile-screw foundation include:

- possibility of installation on problematic soils - heaving, mobile, wet;

- no need for perfect leveling of the site;

- convenience of carrying out construction work immediately after installing the piles;

- the possibility of creating a garage in a tight area, next to another building;

- compatibility with different types of building materials.

The disadvantage of the design is one serious limitation it imposes. In such a garage it is problematic (and sometimes even impossible in principle) to organize a basement.

Description of the construction of a foundation on screw piles for a garage

In our area, the construction of garages on screw piles has become common. If the plan involves the construction of a 6x4.5 m garage, then you should decide on the number of piles required. Many owners rely on accurate calculations from design documentation, and rightly so. However, in our garage cooperative, all garages are built of brick. The garages also have the same size of 6x4.5m. The weight of the load on the foundation is approximately the same for all. Therefore, you should not spend extra money on design developments, but do it as other people do. Experienced garage owners said that the installation of pile structures with a diameter of 89 mm or 108 mm was carried out every 1.5-2.5 meters, depending on who you are. The main thing is that there are no problems yet in those garages where the support was installed every 1.5 m and in those where the pile elements were screwed in after 2.5 m. In our case, it turns out that 12-14 screw piles with a length of 1.5 m are needed. Before moving on to the immediate stages, we should dwell on the design features of the screwed elements we have chosen.

Do-it-yourself construction of a pile foundation for a garage

A pile foundation for a garage can be erected with the help of professional builders. In this case, the result will be a reliable foundation, performed according to all the rules. However, the cost of such a foundation will be quite high. If you build a pile foundation yourself, listening to the advice and recommendations of experienced craftsmen, you can build an equally strong and high-quality foundation at minimal cost.

Preparatory stage

Any work begins with the preparation of materials and tools. To build a pile foundation for a garage, you need the following tools:

- Shovel.

- Plumb and building level.

- Roulette.

- Pencil or marker.

- Lever for screwing piles.

- Bulgarian.

- Pegs and cord for marking.

- Sledgehammer.

It is impossible to imagine the construction of a foundation on piles without the following materials:

Marking and excavation work

Despite the fact that a flat surface is not required for screwing in piles, you will still have to remove excess vegetation and large debris. This will greatly facilitate the process of marking the area and screwing in the supports.

Site marking

In the cleared area, the ground is marked for a foundation for the garage. To do this, pegs are installed at the corners of the future building and along the perimeter of the building. The distance between the pegs should not exceed 1.5-2 meters, and they should be evenly spaced around the entire perimeter. When installing the pegs, it is necessary to check the evenness of the corners and diagonals using known methods.

Next, small holes are made in the places designated for the piles, for which, using a shovel, the soil is removed to a depth of 10-15 cm, since a pit that is too deep reduces the stability of the pile. The width of the hole should be 2-3 cm greater than the diameter of the screw pile blade.

Installation of piles

Installation of piles for the foundation of a garage is best done with assistants: two people directly screw in the piles, one person controls the vertical position of the pile. To immerse the pile into the ground, a lever is inserted into the technological hole in the upper part of the rod, which can be a piece of pipe or scrap iron. The length of the lever is selected individually, but it should be remembered that the longer the lever, the easier the pile sinks into the ground.

Installation of piles

The twisted pile must pass the lower freezing point of the soil and rest against a dense load-bearing layer. This is evidenced by difficult screwing.

All foundation piles are installed in a similar manner.

Reinforcement and concreting of piles

After installing all the supports, the piles are leveled in height; for this, a building level or level is used. On each pile, make a corresponding mark with a marker and, using a grinder, cut off the upper part of each support.

To increase the strength of the pile, you can additionally install a frame of reinforcement inside the pile. Although, if you take into account the insignificant weight of the garage, you can skip the reinforcement stage.

But concreting the piles cannot be neglected! The concrete solution inside the pile core helps increase the strength of the support and prevents rapid corrosion of the metal.

Concreting is carried out with a standard solution, piercing the poured mass with a piece of reinforcement to remove air bubbles.

Installation of heads

To conveniently attach the grillage to each support, it is necessary to weld the head. To do this, you can take a metal plate 8-10 mm thick, the size of which exceeds the diameter of the pile by 2-3 cm on each side.

Grillage installation

To create a complete support for the garage, all piles must be connected to each other. To do this, you need to make a grillage. This structure is a horizontal frame at the top of a pile-screw foundation. In most cases, there is free space between the grillage and the ground.

The grillage can be made in the form of a monolithic reinforced concrete strip, which is performed in a similar way to pouring a strip foundation. Also, a wooden beam, channel or I-beam can act as a grillage.

The metal grillage is fastened by welding; the wooden elements are attached to the heads using bolts.

Features of installing screw piles under a garage

First of all, you need to decide on the method of driving the piles. Since the garage is usually located on the site and is not always located directly at the entrance, access of large equipment to the construction site can be difficult. This means that the use of technology is not possible in all cases, and the piles must be screwed in manually. This is especially true for garages attached to the house.

Secondly, depending on the size of the garage, the number of piles required to lay the foundation may be small, and the use of a pile drill is not economically profitable.

In this regard, the installation of the foundation may involve a large proportion of manual labor.

Manual installation is labor-intensive

Another feature could be piling for garage doors. They can have significant dimensions and are usually made of metal and have a lot of weight. Piles for them can be wrapped in cramped conditions - next to the wall. This also imposes its own limitations on the use of technology.

A few words about laying screw piles under garage doors. Typically garages use heavy metal gates. They can be

- Swing

- On casters (suspended and rail type)

- Rolled

- Console

Only if the gate is installed on rail-type rollers, the piles are installed under the beam lying across the entrance. In all other cases, the piles are screwed under the support pillars. More details about this are written in a separate article about installing a pile-screw foundation for different types of gates.

Roller garage doors

Construction technology

It is possible to build a pile foundation for a garage using a team of experienced builders. As a result, you will receive a reliable foundation prepared in accordance with the requirements. But at the same time, you will have to pay not only the cost of building materials, but also the services of specialists. But if you follow all the recommendations. It is quite possible to carry out such work on your own, while incurring minimal financial costs.

Building a garage is a serious task. The fact is that the garage must provide reliable protection for your vehicle from moisture and corrosion.

Preparation

When performing any construction work, preparatory measures are carried out. First of all, you should prepare certain tools:

- shovels;

- level and plumb;

- tape measure, level and plumb line;

- pencil;

- levers necessary for screwing in pile pillars;

- grinder;

- wooden pegs and cord;

- sledgehammer

In addition, you will need screw pile supports, grillage caps, metal reinforcement, cement, crushed stone and sand.

The construction of a pile foundation does not involve preliminary leveling of the ground surface on the site, but for the convenience of performing the work, it is recommended to remove turf and debris. After this, we determine the corner areas of the object and install pegs in these places. The recommended interval between pile supports is from one and a half to two meters, while the piles are distributed evenly throughout the area.

It remains to make pits in the places designated for installation with a depth of ten to fifteen centimeters and a width slightly exceeding the diameter of the blade of the pile support.

Installation of piles

If small-sized supports are chosen for the construction of a foundation on screw piles for a garage, then they can be installed using an ordinary crowbar inserted into the technological hole of the pile and extended with pieces of steel pipes.

As a rule, piles whose length reaches five meters are used for the construction of a garage.

Installation of support elements is carried out using one of the convenient options:

- drilling - a well is manually drilled, a pile support is immersed;

- screwing - the pile column is screwed directly into the soil composition. The support is positioned vertically, twisting is performed in the direction of the clock hand until the tip of the pile reaches a dense soil layer. To install correctly, rotate the pile below the freezing point of the soil until rotation becomes difficult.

Reinforcement

Once the installation of pile supports is completed, their upper parts are leveled. Each pile is checked with a level and cut with a grinder.

To increase the strength indicator, a reinforcement cage is installed in each support. Some people neglect this condition, because the garage does not create serious loads.

Concreting

A mandatory event. Concrete poured into the support adds strength to it and creates reliable protection for the internal walls from corrosion.

The concreting process is carried out according to the standard scheme: liquid concrete is fed into the support in a thin stream and periodically pierced with a piece of reinforcement to remove air bubbles.

Installation of heads

A head is attached to each pile. It is recommended to use welded structures, placing them on the same level. The parameters of the heads are determined by the specific gravity of the garage and the cross-section of the pile supports. It is easier and more convenient to make the heads from metal plates with a thickness of 0.8 - 1 cm and a diameter that exceeds the same size of the pile by three to four millimeters.

Grillage arrangement

This is the upper part of the pile-screw foundation in the form of a horizontal frame, designed to redistribute load effects and perform load-bearing functions.

Types of grillages according to materials used:

- wooden - the beams are attached to the plates with bolts or welded with metal clamps. A gap is left between such a grillage and the soil;

- concrete - a formwork structure is installed, a waterproofing layer and a reinforcing frame are installed from the inside, after which the concrete mixture is poured;

- reinforced concrete - the width of the formwork should be greater than the thickness of the proposed walls. After this, we arrange waterproofing, install the frame and fill the formwork with concrete;

- metal - the frame is made of a channel or angle.

Bored foundation

This type of foundation for a garage with your own hands is relevant in the case when it is impossible for a simple platform to reach the incompressible layer of soil. This technique is also relevant when building on steep slopes. The process of drilling wells under a bored foundation

Marking for bored piles

Drilling wells in various ways: using a hand drill or special equipment. Recently, do-it-yourself TISE drilling technology has been in demand. The presence of a plow on the device allows you to make the necessary expansion below under the pile support. With this approach, the load-bearing capacity of a large screw increases many times over. The important expansion also prevents the supports from being pushed out when the ground freezes.

The minimum length of the well is two meters. The diameter of the hole is at least 20 cm. At important corners of the building, wells are installed below the freezing level. A well is installed between the wells. This drainage mechanism is effective.

Factory bored piles are being poured

If builders are dealing with dense soil, the concrete mixture is poured into the well. Wooden forms are constructed only to frame the pile heads. When activities are carried out on loose soil, formwork is required. Ruberoid or asbestos pipes will serve as a frame.

Stages of work:

- an asbestos pipe is placed in the well where the bored piles are located;

- cavities are filled with liquid concrete with your own hands;

- then the hose is raised so that the mixture fills the vacated lower space of the well for additional stability of the point foundation.

Reinforcement

Any bored foundation and its components work under tension and compression. The load from the garage is directed towards compression. It is important to lay the piles below the frost layers so that the structure can withstand any mechanical pressure. Heaving soil, on the contrary, causes piles to break. In this case, carry out vertical reinforcement of the foundation.

Ribbed reinforcement, rods (8 cm) of which are held together by a smooth surface, is ideal as a “skeleton”. During pouring, the rigid structure is immersed into the wells.

If you plan to create a poured grillage, leave the metal ends visible above the piles. The rods will firmly tie the grillages to the platform posts.

Advantages

Garages on pile-screw foundations are usually built in areas with difficult terrain. Leveling the terrain is not always possible or requires significant financial investments. If there are underground communications and groundwater nearby, it is often impossible to build a conventional foundation. Pile-screw structures have many advantages, due to which they are often used in garage construction.

- Affordable price. Foundations on screw piles are usually much cheaper than traditional counterparts. But the final cost can vary significantly. The price is affected by the depth, weight and dimensions of the garage. Typically the savings are at least 20-40% compared to a strip foundation.

- Ease and simplicity of installation. You can install your own without the use of special equipment, especially at shallow installation depths. A team of several people can install the foundation. The garage itself is built very quickly, since it has a frame structure. As a rule, installation of screw piles takes 1-2 days. Other types of foundations take much longer to construct.

- Possibility of construction on a site with a slope. Screw piles are one of the best solutions for areas with significant differences in terrain. Even with a significant slope, you can build a strong and durable foundation, on which you can then build a garage of almost any size. It is often impossible to install a reinforced concrete foundation on a site with a difference of several meters. Piles can be installed even if the difference exceeds 5 meters. You can also resort to tape technology, but the final price of such a garage will be several times higher.

- Construction at any time of the year. You can work with piles even in winter. There is no need to heat the concrete and use special additives to protect it from low temperatures. Even in severe frosts, you can continue installing the foundation from screw piles. The structure is ready for use immediately after installation. Therefore, after deepening the piles, you can begin assembling the frame garage.

- Possibility of modernization and repair. If in the future there is a need to change the size of the garage, this can be done without significant costs. The foundation can be easily expanded by adding new screw piles. If the garage is assembled incorrectly or the foundation is installed, repairs can be made quickly.

Main types of garages on individual plots

Construction of a garage is an integral attribute of a suburban area, especially for temporary residence - after all, today the majority of owners of private country houses have a car. The only question is which garage is preferable for the owner - based on the available land holdings and the functions that are superimposed on the garage building.

Of course, sometimes the car is simply parked on a free “patch” on the site, but this option is more suitable for summer residents who come to their lands at the end of the week for one or two days. If you live in your home permanently, it is preferable to install a garage or at least a carport for your car - this will protect your car both from unpleasant attacks and from atmospheric influences. In addition, it is convenient to store any accessories for car repair and operation in the garage.

So, different types of garages can be built on the site:

- Simple canopy with protection from rain and sun rays

- Factory-made prefabricated metal garage, like a “shell”

- Light frame garage

- Finally, a large garage made of bricks or blocks

Almost any type of garage requires the construction of a foundation, except perhaps a metal one installed directly on the ground. Even a canopy requires a reliable foundation for supporting pillars, not to mention capital foundations for a large garage made of brick or reinforced concrete panels. In addition, the garage can be built into a house with a single foundation or serve as an extension to the house on a separate foundation.

You can read more about the types of garages and the features of their construction on the site on our website, here.

Metal garage frame on screw piles