Today there are many methods for heating residential premises and other objects. Therefore, it is not surprising that the consumer is already trying to choose exactly those technologies that are most suitable in a given situation, and are also the least expensive for him. And one of the effective methods of heating is the use of a hydrogen generator for heating residential buildings.

What is hydrogen heating?

Hydrogen today is used for a variety of needs, including space heating. Modern technologies are being introduced into many areas of human life every day. And hydrogen heating is also a similar useful innovation. It has already interested many consumers in the West, and is now gaining popularity in our country.

In fact, hydrogen is the most common substance in the Universe, which means it is a practically inexhaustible source of energy. However, for the most part it is still extracted from water - this technology is the least expensive to date.

Components of a hydrogen plant

The design of a heating system operating on hydrogen is quite simple.

The boiler , which plays the role of a heat exchanger, is the main element where hydrogen production occurs.

A boiler operating on hydrogen can be assembled from available elements, and for its operation only ordinary or distilled water is required (+)

The electrolyser is the main operating part of the boiler, where the electrolytic reaction occurs, leading to the decomposition of water into H2 and O2. The element is a reservoir filled with water into which metal electrodes are placed that have maximum current conductivity.

The plates are connected to wires through which electricity is supplied.

A burner is a device that helps heat the coolant in the heating system. Located in the combustion chamber, a spark is supplied to ignite it.

The burner valve is a special part located at the top of the device. Thanks to this part, the H2 that rises to the top easily overcomes the barrier inaccessible to other released substances and enters directly into the burner.

Factory hydrogen boilers are equipped with a control unit. The panel displays voltage and current indicators, a power regulator and levers for setting other operating parameters

We recommend: Calculation of heating radiators, number of sections and battery power

Pipeline – communications that extend from the unit and are used to supply heat to all rooms of the house. For piping, heating pipes with a diameter of 25-32 mm are used. When laying, the fundamental rule is observed: the diameter of each subsequent branch should be smaller than that of the previous one.

Hydrogen generators: features

The maximum power of a hydrogen generator is 6. However, the optimal burner power is calculated based on the area of the living space. In addition, a mandatory condition for the operation of such equipment is a constant supply of electrical energy.

Hydrogen burners are used for heating homes and industrial facilities, both as independent heating systems and to complement existing heat sources. It is important to ensure that such equipment operates normally at low temperatures. Most often, to heat a house, such units are connected to “warm floor” systems.

Operating principle of a hydrogen generator

The device generates heat using the process of electrolysis of water in the presence of a special catalyst. At the same time, normal and safe operation of the generator is possible only if, as a result of such an electrochemical process, the reaction of hydrogen and oxygen does not occur, because their combination is explosive. Therefore, modern devices of this type produce another substance – Brown’s gas. It is also called water gas.

This substance is greenish or brown in color and is absolutely non-explosive.

The resulting gas is heated to forty degrees Celsius and then enters the heat exchanger, which is essentially a combustion chamber. And there it is mixed with the air-fuel element. Next we will talk about the design of a hydrogen generator for heating.

The main elements of such heating devices are a boiler and various tubes. In principle, no additional technical accessories are required for normal operation.

The same applies to equipment for removing combustion products. This is due to the fact that as a result of this process, only water vapor is formed, which is absolutely safe for humans due to its purity.

To make such units more efficient, their design is often made modular: special catalysts are placed in each part. If we talk about the tubes used, then it is advisable to use those whose diameter is in the range of 1-2.5 inches.

This parameter may, of course, differ slightly, but for maximum efficiency it is still better to use tubes with the above values.

When installing heating pipes, do not forget that each previous branch is made larger in diameter than the next one.

How to make hydrogen heating with your own hands

Before making a hydrogen generator for heating a house, the master needs to take care of the materials that will come in handy:

- sheet of stainless steel metal with dimensions 50x50 cm;

- two 6x150 bolts with nuts and washers;

- flow filter (can be taken from a washing machine);

- hollow transparent tube, for example, 10 m water level;

- 1.5 liter plastic food container with an airtight lid;

- fittings with a diameter of 8 mm with a herringbone pattern;

- Bulgarian.

Steel 03Х16Н1 is well suited for the manufacture of the unit; alkali instead of water is also useful in order to provide a more aggressive environment for current, but at the same time extend the service life of the steel sheet. To make high-quality home heating with hydrogen, you need to first select a layout scheme (warm floors, layout on baseboards, etc.), and calculate the length of the pipelines.

And now about how to make a hydrogen stove:

- Place the sheet of metal on a flat plane and cut it into 16 rectangles (calculation for a sheet of metal 50x50 cm). This is the future burner. Cut the pieces with a grinder.

- Cut off one corner of each of the 16 pieces in order to connect the plates later.

- Drill a hole for a bolt on the back of each plate.

- To ensure the principle of operation, which looks like the passage of electric current through plates immersed in an electrolyte to decompose the liquid into hydrogen and oxygen, it is necessary to have two plates simultaneously, one of which is the anode, the second is the cathode. In this case, it turns out to be 8 pieces. anodes and 8 pcs. cathodes.

- Place the plates in a plastic container, taking into account their polarity and alternating plus, minus, plus and so on. The elements should be insulated with a transparent tube, cutting it into rings, and then into strips 1 mm thick.

- Secure the plates together with washers. First, the washer is put on the bolt, then there is a plate, then 3 more washers, again a plate, so you need to hang 8 pieces. for anode and 8 pcs. to the cathode.

- Determine the bolt stop point in the container and drill a hole in this area. If the bolts do not fit into the container, they must be cut to the required length. Then insert the bolts into the holes, put washers on them, and tighten them with nuts to seal.

- Make a hole in the lid of the container for the fitting, insert the fitting into the hole, coat the joint area with silicone sealant to seal it. Now you need to check the tightness of the hole by blowing out the fitting. If air escapes, seal the lid with the same silicone sealant.

- Test the generator by connecting any current source to it and filling the container with water. Now you need to put a hose on the fitting, the end of which is lowered into the container. If air bubbles appear in the water, then the system works; if there are no bubbles, the source is not powerful enough, but don’t be upset, bubbles will appear in the electrolyzer.

All that remains is to increase the intensity of gas production and output by increasing the voltage level in the electrolyte. To do this, add alkali to the water, for example, sodium hydroxide from the Mole cleaning product. Now you need to reconnect the power source and evaluate the capabilities of the electrolyzer.

The final stage is connecting the burner to a heating pipeline, for example, a heated floor system, sealing the joints and the unit can be put into operation.

In order for heating with hydrogen to be done efficiently with your own hands, you should install a filter and valve. The valve is installed at the point of hydrogen release, preventing the accumulation and combustion of gas under the lid of the container, and the filter is needed to create a water seal, which also prevents an explosion. If you have any questions, a video from professionals will help solve all the problems.

Electrolytic hydrogen generators

Generators that operate on the principle of electrolysis are usually manufactured in the form of containers. When purchasing such a device, be sure to inquire about the package of permitting documents:

- Certificate of conformity GOSTR.

- Hygienic certificate.

- Permission from Rostechnadzor.

Electrolytic generators usually consist of such basic structural elements as:

- control Panel;

- automatic control system;

- water replenishment and demineralization unit;

- electrolyzer (unit for separate production of oxygen and hydrogen);

- gas analysis system;

- liquid cooling devices;

- hydrogen leak detection system;

- transformer and rectifier;

- junction box.

To increase the electrical conductivity of water, lye is usually added to it. For the latter there is a special reservoir, which is replenished, as a rule, no more than once a year. Modern industrial hydrogen generators are manufactured in accordance with European safety and environmental standards.

Experiments with eternal logs

An everlasting log is a small metal tank with small holes to allow water vapor to escape. This container is filled with water, the neck is screwed on, and placed on the bottom of the oven. The container heats up to a high temperature, water vapor comes out of it, going directly onto the burning coals.

We recommend: Do-it-yourself potbelly stove drawings (The most effective) photo + video

As a result, according to the experimenters, black soot disappears in the smoke. Those. supposedly the carbon particles normally carried away into the pipe now all react with oxygen. The flame becomes saturated with long tongues, etc.

But it’s true that measurements of the actual heat received were not carried out, it is impossible to measure it at home, but all the signs of high energy output are present...

Feasibility of using hydrogen generators

If we compare hydrogen heating of buildings, for example, with the regular purchase of gas, the first will be much more profitable. So, in order to get one cubic meter of Brown's gas, you need only half a liter of demineralized water and 3.5 kilowatts of electrical energy. But this is not all the advantages of such a hydrogen unit.

We must not forget that hydrogen generators for heating a home have such advantages as:

- High efficiency - up to 90 percent, which is on par with the latest household appliances for home and industrial use.

- There is no need to use an open flame.

- The process is based on the use of a chemical reaction involving catalysts.

- Such devices are absolutely harmless.

- Sources of practically inexhaustible energy are used.

- The exploitation of classical energy resources, the extraction of which is associated with high costs, is reduced.

- Quiet operation.

- No separate chimney required.

But such systems also have their disadvantages, the main of which are:

- Improper use of such units can lead to a fuel explosion in a residential building.

- There are still few hydrogen generators for space heating on the Russian market, and therefore there are not enough professionals to install and maintain them.

- It is still difficult to certify devices of this class.

Making a generator in-house

On the Internet you can find many instructions on how to make a hydrogen generator. It should be noted that it is quite possible to assemble such an installation for your home yourself - the design is quite simple.

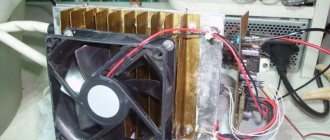

DIY hydrogen generator components for heating in a private home

But what will you do with the resulting hydrogen? Once again, pay attention to the combustion temperature of this fuel in the air. It is 2800-3000°C

If you consider that metals and other solid materials are cut with the help of burning hydrogen, it becomes clear that installing the burner in a regular gas, liquid fuel or solid fuel boiler with a water jacket will not work - it will simply burn out.

Craftsmen on the forums advise lining the inside of the firebox with fireclay bricks. But the melting point of even the best materials of this type does not exceed 1600°C; such a firebox will not last long. The second option is to use a special burner that can reduce the flame temperature to acceptable values. Thus, until you find such a burner, you should not start installing a homemade hydrogen generator.

Tips for assembling and operating a generator

Having solved the issue with the boiler, choose a suitable diagram and instructions on how to make a hydrogen generator for heating a private house.

A homemade device will be effective only if

:

- sufficient surface area of the plate electrodes;

- correct choice of material for the manufacture of electrodes;

- high quality liquid for electrolysis.

What size should be the unit that generates hydrogen in sufficient quantities to heat a house will have to be determined “by eye” (based on other people’s experience), or by first assembling a small installation. The second option is more practical - it will allow you to understand whether it is worth spending money and time on installing a full-fledged generator.

Rare metals are ideally used as electrodes, but this is too expensive for a home unit. It is recommended to choose stainless steel plates, preferably ferromagnetic.

Hydrogen generator design

There are certain requirements for water quality. It should not contain mechanical impurities and heavy metals. The generator operates most efficiently on distilled water, but to reduce the cost of design, you can limit yourself to filters to purify water from unnecessary impurities. To make the electrical reaction more intense, sodium hydroxide is added to the water in a ratio of 1 tablespoon per 10 liters of water.