How to choose the best boiler?

When choosing a boiler with which you plan to heat the greenhouse, it is necessary to take into account the footage and cubic capacity of the room, as well as material costs associated with purchase, installation, etc. Preferable is equipment that uses long-burning technology - in this case, two boilers are produced per day. fuel bookmarks.

However, the cost of such boilers is high. The larger the area of the heated room, the sooner the payback period will occur. In small greenhouses (about 20 sq. m.), the payback period for technical equipment can last up to 10 years. In these circumstances, it is recommended to install solid fuel or gas devices, which, for greater efficiency, are equipped with a system for pumping water through pipes, which will allow the room to be evenly heated.

An electric boiler is not economical, consuming a large amount of electricity. When using it, the upper part of the greenhouse room warms up, but the lower part does not receive full heating, which causes the plants to freeze. Combined long-burning models are industrial and operate on gas or liquid fuel.

Did you know? The cauldron is depicted on the coat of arms of the city of Kronstadt. This is due to the fact that the mentioned city is located on the island of Kotlin.

The cost of such equipment is high and economically justified for large greenhouses when growing plants that are extremely demanding on temperature changes (strawberries, raspberries, eggplants). A long-burning pyrolysis solid fuel boiler has high heat transfer, is economical and at the same time highly productive.

However, it is large in size: due to the high heat transfer, plants must be planted at a distance of more than half a meter from the boiler. Therefore, it cannot be installed in small greenhouses. In case of unforeseen circumstances, a stationary wood stove or a mobile pellet boiler will come to the rescue, which, if necessary, is heated with any solid fuel (wood, corn cobs, etc.).

Infrared heaters

If you have already built it, then it is impossible to heat the greenhouse using a heating cable. In this case, ceiling infrared heaters are suitable for you. They are capable of not only warming up the room, but also doing it in a semi-automatic mode. A typical infrared heating scheme in a greenhouse looks like this:

If necessary, you can place the heating of the greenhouse using infrared heaters on the wall.

Greenhouse heating methods

To maintain the temperature regime, the following types of heating are applicable:

- steam, water;

- air;

- gas;

- electric;

- stove

Air

Air heating is carried out in two ways:

- heated air is taken from the external environment and heated in the supply ventilation system;

- Using gas convectors or fan ovens, the internal volume of air is heated.

Water

Water heating is the most popular type of heating in winter. Possessing unique physical and chemical properties, water is a coolant for most heating systems. Units to which cool-water systems are connected can operate on any type of fuel. In this case, it is possible to equip the stoves with a water circuit, and, therefore, the system functions according to all the principles of water heating.

The most economical greenhouse heating. Heating options and methods

Experienced gardeners share their inventions and experience in using commercially available devices for heating a film greenhouse. The most common of them include the following:

- stove heating;

- water heating from a boiler;

- use of a gas gun;

- IR heaters and convectors;

- heating the soil using cables or water pipes.

The possibility of using one or another method of heating a greenhouse depends on having access to an appropriate source of thermal energy. For example, when creating a water heating system for a greenhouse with walls made of polycarbonate or film, access to a central water supply is required. The type of fuel for operating the boiler can be any: gas, electric, liquid or solid fuel.

Each of the above methods of heating a greenhouse has its own advantages and disadvantages. The use of gas guns is considered quite effective and resource-saving, gas consumption is minimal. When choosing guns, the area of the rectangular space of the greenhouse and the required power are taken into account.

If we consider electric as the main source of energy, it is best to purchase an infrared heater. Such a system effectively increases the temperature of the air space in the room, without drying out the air and the plants themselves.

In addition to IR heaters, infrared films are used to heat the soil. For plant growth and maturation, soil heating is most important. The film is easy to install with your own hands; it is placed under the ground, thereby heating the soil and the air above it. The disadvantage is the need for electrical wiring.

The stove device is considered an economical way to heat a greenhouse. The disadvantage of this option is the need to manually maintain the desired temperature in the oven. In addition, stoves dry the air space of greenhouses.

Types of boilers

Below is a more detailed description of the various devices.

Important! If a cyclic heating mode is used, then it is recommended to use a non-freezing liquid or antifreeze as a coolant liquid.

Gas

It operates using liquefied or natural gas, and water of any quality is used. The boiler is installed in a greenhouse in a free space. The device includes a heat exchanger, an atmospheric burner, a pump, an expander (tank), and a safety valve. A working boiler heats water in a heat exchanger and uses a pump to supply it to the system circuit. The smoke is diverted and removed through a chimney or pipe.

Register - heating equipment consisting of smooth-walled pipes connected to each other by welding. Typically, the tubes are arranged horizontally and secured to each other by vertical jumpers, through which the coolant also moves. Registers are often installed in heating systems intended for technical and industrial premises.

Algorithm for connecting the register to the main unit:

- Understand where the hot and cold water inlet and outlet are located in the water circuit.

- In the end parts of the register, holes are drilled for threaded couplings, which are the basis for fittings connecting the heat exchanger to the water circuit.

- Using a welding machine, the air vent is secured (from the supply - on the opposite side). The optimal location for attaching the valve is the top.

- Considering the large mass of the register, a reliable fastening system should be provided. When placed on the floor, these are stable legs and additional fixation to the wall.

- A distance of at least 25 cm is maintained between the register and the surrounding walls or objects.

Did you know? The first armored car in history was designed in 1916

—

the basis of its body was a boiler brought from the Guinness brewery.

- Advantages of heating a greenhouse using a gas boiler:

- ease of maintenance;

- very fast heating and uniform distribution of warm air inside the greenhouse.

- Flaws:

- Since the installation of the above-described equipment is advisable in large-volume greenhouses, the price of the system will be high.

- Approval is required for connecting equipment and gas supply, which also involves significant material costs.

Solid fuel or pyrolysis

Pyrolysis is a chemical process that occurs at high temperatures and low oxygen content in the combustion chamber, which releases excess thermal energy. In solid fuel pyrolysis boilers, wood (or other solid fuel) is burned with the release of pyrolysis gas and the formation of coal residues. In boilers of this type, the generated gas is subsequently burned. During the combustion process, carbon is oxidized not to CO², but to CO (carbon monoxide).

List of fuel types for pyrolysis boilers:

- firewood

- briquettes;

- sawdust, chopped branches;

- pellets;

- coke;

- coal;

- peat.

Wood is most preferable, since the process proceeds with the maximum release of pyrolysis gas.

You can use a combination of firewood with sawdust, branches and pellets. It is not worth burning with sawdust or finely chopped branches, as the boiler will not work or the efficiency will be extremely low. Important! In rooms with large heat losses (solid glazing, drafts, high ceilings), it is necessary to install a boiler with increased power. If the generation of hot water supply equipment is implied , the calculated

power increases by another 20

-

50%.

The sequence of operating processes for a solid fuel (wood) pyrolysis boiler:

- Firewood is loaded onto the grate.

- After igniting the fuel, close the door tightly and open the smoke exhauster.

- Air begins to flow into the upper chamber due to the pressure difference.

- The resulting pyrolysis gas falls into the lower furnace, in which it burns.

- After a period of time, the air circulation stabilizes, combustion in the fireboxes proceeds evenly. It is necessary to monitor the stability of the processes occurring in the upper and lower furnaces, and promptly remove ash from the lower chamber.

- During the combustion of the top layer of fuel, the funnel-shaped distributor is lowered, thereby supplying air for permanent combustion.

- Gases formed during the combustion process are discharged through the chimney.

- Advantages:

- Efficiency reaches 90%;

- long interval between fuel loadings (up to several days);

- combustion is constant, therefore, the temperature of the coolant is stable;

- comfort in equipment maintenance.

- Flaws:

- considerable dimensions. The height of a pyrolysis oven is higher than that of a conventional wood-burning oven;

- the loaded fuel must be completely dry;

- During the combustion process, carbon monoxide is released - it is necessary to carefully monitor the CO level sensors;

- high price.

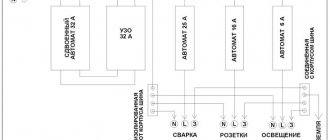

Electrical

Electric boilers in small greenhouses are connected to a 220 V network. For greenhouses with large areas - from 100 sq. m and above, the project provides for three-phase high-power units that are powered from a 380 V network. Equipment (pipes, radiators, etc.) is usually connected to the electric boiler so that additional water and electric heating of the entire volume of the greenhouse is possible.

- The undoubted advantages of this type of system include the following:

- ease of installation, operation and maintenance;

- environmental friendliness (no waste from the combustion process, as well as noise during operation);

- small sizes;

- reliability.

- The disadvantages include the following factors:

- high cost of energy;

- constant electrical power is required.

Diesel

Diesel boilers are rarely used to maintain the temperature inside the greenhouse. This is due to the fact that in addition to the large dimensions of the unit itself, it is necessary to provide an additional location for the fuel tank. In addition, additional equipment with convectors and (or) pipelines will be required.

Important! If you plan to connect a gas boiler to a homemade heating system, the participation of a gas technician is required. In this case, independent work is prohibited!

- The undoubted advantages are:

- high efficiency;

- automatic fuel supply;

- relatively low price of the boiler.

- Flaws:

- high cost of fuel;

- large dimensions;

- noise during operation, the unit emits a persistent specific odor;

- the need to install a chimney;

- fire hazard.

Waste oil devices

Installing a heat generator that works using any available waste oil (machine, pyrolysis, animal and vegetable oils, crude oil, kerosene, etc.) allows you to heat the room using hot air. A stove of this operating principle is also installed as an additional heat source for an existing one. When used independently, this type of device requires the installation of a chimney and a fuel tank, which is not a costly undertaking.

- Pros:

- low cost of fuel raw materials. “Exhaust” devices are especially beneficial for those who have constant access to a fuel resource (pizzerias, fast food restaurants, service stations);

- rapid heating of the room due to high heat transfer;

- low cost of the repair kit.

- Minuses:

- increased oxygen consumption.

Combined

Boilers of this type allow the use of various types of fuel in any combination (depending on the model and manufacturer). Initially, it is necessary to decide which type of fuel will be a priority and which will be a secondary one. This type of equipment is often formed according to the principle of a designer.

Just like a single-fuel boiler, the main elements of a combined boiler are a heat exchanger, a reliably insulated casing (minimizing heat loss), and an automatic control system. For household needs, when operating in small spaces, the choice is a double-circuit boiler with the ability to operate on two types of fuel.

- Positive points:

- uninterrupted operation;

- selection of the preferred fuel at the time of operation of the unit;

- ease of use.

- Flaws:

- high price;

- complex setup;

- expensive repairs;

- the need to store several types of fuel raw materials.

Heating device options

You should choose the type of greenhouse heating based on your personal needs and capabilities, technical and financial. You can choose not just one system, but combine several that complement each other.

Purpose and need for heating greenhouses

Heating of greenhouses is organized in two cases:

- For growing herbs, vegetables or berries in winter.

- For earlier planting. For example, if we start work in a greenhouse without heating in early May, then in a heated winter greenhouse - already in early April.

The question of the need for heating in a greenhouse is not even raised. Even if you don't plan to do gardening in the winter, starting it a little earlier in the spring won't hurt in any case. Therefore, you should at least arrange heating of the greenhouse yourself with a potbelly stove.

How to build a winter greenhouse with heating: using a stove-stove

Stove heating

Let's start with the most economical stove heating, both in price and in terms of consumables. Its meaning is that hot smoke from the stove passes through a system of pipes removed from it, giving off heat into space. The greenhouse is heated with wood, coal, waste lumber, waste oil and diesel fuel.

The main advantage of a heated greenhouse of this type is its low cost. You can even assemble the system from used materials. These are liquid fuel barrels, sheets of metal, pipes and bricks. The design is simple: the stove itself, the pipes through which the smoke will flow, and the smoke exhaust pipe. The number of stoves is calculated based on the area of the greenhouse: one for every 15 m2. Fuel consumption depends on what temperature should be maintained in the room.

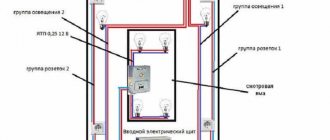

Drawing of a heated polycarbonate greenhouse; you can assemble a system of one or more stoves with your own hands

Useful information on how to heat a greenhouse with your own hands; the video describes the principle of operation of a waste oil stove.

Solid fuel convector

This type of heating can also be classified as stove heating, but heat transfer occurs according to a different principle. The design includes a firebox enclosed on both sides in non-communicating tubes that are open at both ends. When the walls of the firebox are heated, the lower ends of the tubes begin to draw air into them. The latter, through natural convection, comes out of the upper ends heated to 50 - 60 degrees.

Such heating loses to that described in the previous subsection in only one way - the heat sources are installed in the center of the greenhouse. Which means:

- There is no thermal barrier created from the walls, whose temperature is always lower.

- The passage between the beds becomes cluttered, which can make caring for the plants a little difficult. For example, you can’t get through with a wheelbarrow.

How to heat a greenhouse in winter: solid fuel convector Buleryan

How you can organize heating of a polycarbonate greenhouse in winter; the video shows the rules for handling a solid fuel stove.

Heating with infrared radiators

They come in two types. The first one I would like to mention is pendant lamps for winter greenhouses made of polycarbonate with heating, mounted on the greenhouse ceiling. They consist of an emitter of electromagnetic waves and a reflector that reflects them and directs them to the heating zone. There are three types of such heating:

- Electrical. The radiation is short-wave, so such heat sources are used to heat small and medium-sized greenhouses.

- Gas. The radiation here is long-wave, which allows one device, depending on the model, to cover an area of up to 25 m2. Such equipment is suitable for large greenhouses with an area of 30 m2 or more.

- Diesel. The area coverage here is the same as that of gas ones, but the equipment, unlike the first two options, is mobile. Heating points can be moved arbitrarily around the room.

The main advantage of heating polycarbonate greenhouses with an infrared heater is that it remains effective even when drafts in the room cannot be completely eliminated. This is due to the fact that it is not the air that is heated, but the plants and soil underneath them. It is difficult to talk about the cost of devices and their operation. Expensive equipment will last a long time and consume little electricity; cheap equipment will do the opposite.

Please note: infrared heaters for greenhouses cannot harm the walls of greenhouses. Radiation does not heat translucent media, so polycarbonate and film are not in danger, even if the rays fall on them from a short distance.

Hanging infrared lamps

Electric emitters of electromagnetic waves are produced not only in the form of lamps. It can also be carbon tapes with a filament, covered with film on both sides. They provide a very low temperature, up to 60 degrees, but they also consume very little electricity. In addition, full heating power is not required - plant roots cannot tolerate temperatures above 30 degrees.

Placing infrared tape under seedling boxes

Laying infrared tape in the ground

Electrical cable for under-ground heating

Also, in heating greenhouses, a system similar to the electric “warm floor” that we make at home is used. It is organized by laying a heating cable in the soil. To do this, a kind of cake is made, the layers of which will be like this:

- Compacted sand.

- Safety net.

- Heating cable.

- Compacted sand.

- Safety net.

- Planting soil.

Additionally, a thermostat and a relay responsible for turning the heating on/off are mounted on the wall of the greenhouse.

There are three disadvantages to heating a greenhouse with a cable: the impossibility of using it as the only type of heating if the greenhouse is used in winter; in the event of damage at one point, the entire system fails, whereas the infrared tape would continue to function effectively; high consumption of electricity.

Heat guns

A heat gun consists of a heating element and a powerful fan located behind it. The heated air comes out under high pressure, spreads far, and the temperature in the greenhouse rises very quickly. These devices are produced in different capacities, which allows you to select them according to the size of the greenhouse. Can be suspended or floor-mounted.

Disadvantages of heating with heat guns:

- High electricity consumption.

- High temperature of the exhaust air, which makes it necessary to carefully choose the location of the equipment.

- The heating element strongly burns oxygen in the room.

On the last point, these heaters for greenhouses are much inferior to infrared and water heating, described below.

Heating with a heat gun

Electric convector

An electric convector consists of a casing with holes, a heating element and a thermostat, just like a heat gun. However, if the first one has forced air supply into and out of the casing, then here the convection is natural: the gas is drawn in from below and, warming up, exits through the upper holes. The temperature in the room does not rise too quickly, however, the loss of oxygen during heating is relatively small.

Solid fuel convectors can be used either independently or in combination with other types of heating. The devices can be placed on the ceiling, walls of the greenhouse or on the ground. The number of points is determined based on their power and the area of the greenhouse. The only significant disadvantage of this type of heating is the high electricity consumption of the equipment.

Heating with electric convector

Water heating

It consists of a water heating boiler powered by electricity, gas or diesel fuel, piping and automation: thermostats, relays and temperature sensors. The system is organized as follows:

- Laying large diameter pipes or installing radiators along the walls of the greenhouse.

- Heating the greenhouse with a warm floor made of small diameter polypropylene pipes.

Making a greenhouse boiler with your own hands

The first step towards self-installation of heating equipment in order to create a heated greenhouse in a personal household should be a detailed drawing of the planned heating installation. The required power is also calculated based on the area and volume of the room, type of boiler, type of fuel, operating time, etc. After a painstaking process of theoretical pre-preparation, one should proceed to the main stages of creating a boiler.

You will be interested to know how to insulate a greenhouse for the winter with your own hands.

Materials and tools

For a simple solid fuel boiler model you will need:

- A metal barrel with holes or an old gas cylinder, sawn in half.

- Water circuit or coil.

- Hinges, metal handles, matching latches, etc.

- Welding machine.

- Cutting tools.

Construction and connection

The most common model of a homemade boiler looks like this:

- The cylinder (barrel) is placed in a metal oven.

- A chimney pipe is welded to the resulting structure, through which gases will be discharged from the greenhouse premises to the outside.

- The last stage is welding pipes (plastic, metal) together and their further installation.

Video: how to make a solid fuel boiler with your own hands

DIY heating sources

Simple heating boilers for a greenhouse can be assembled and installed with your own hands. For implementation, you can use metal sheets, an old barrel or an empty gas cylinder.

Boiler for a greenhouse from a gas cylinder

- empty gas cylinder;

- metal grill;

- door latch;

- handles and hinges;

- U-shaped metal pipe – water circuit coil;

- steel plate and chimney pipe.

Step-by-step progress of work on manufacturing a heating boiler for a greenhouse:

Cut the balloon in half. One hemisphere is the furnace body, the second is the ash tank.

Insert the grate into the body and secure it with welding - the grate should divide the space into 1/3 and 2/3 parts.

Cut 1/3 off the circle. For the most part, prepare a rectangular hole. Weld fittings to the door (latch, hinges, handle).

Cut the bottom of the ash pan from the second half of the cylinder and connect it to the end - the door.

Weld the coil to the inner surface of the furnace by threading the ends of the pipes through the holes. To secure the fastening, you can place a metal sheet.

- At the top of the boiler, cut a hole for the pipe and weld the pipe. The chimney should pass through the greenhouse at an angle of 20°, and the exit should be through the back wall. The height of the pipe is equal to the height of the greenhouse plus 1 m.

- Connect the chimney to the pipe using a coupling and sheet asbestos.

Connecting the chimney to the combustion chamber

When connecting the boiler, it is important to ensure reliable thermal insulation of the area where the chimney comes into contact with the roof of the building.

Video: greenhouse heating system

The proposed videos demonstrate the features of organizing and operating various methods of heating country greenhouses.

Option 1. Water circuit: connection through a Zhukovsky gas boiler, exhaust - galvanized pipe 15 mm, installation method - combined (at the top and bottom of the greenhouse). Coolant circulation is forced through a pump.

Video: Water system

Option 2. Stove heating. The use of two types of wood stoves in the greenhouse: brick and metal, the chimney is laid horizontally. Recommendations for choosing wood for kindling.

Video: Stove heating

Video: boilers for greenhouses

Video: Technology for assembling a pyrolysis boiler for a greenhouse, installation, connection and operation

Video: Transformation of a wood-burning stove into a water boiler

Possible problems with a homemade device

- The most common problems when operating a homemade heating unit are:

- uneven heating of the internal space;

- excessive dry air.

Both factors negatively affect the condition of the plants in the greenhouse, so you should be especially careful when laying air pipes and providing additional air humidification. Undoubtedly, the selection and installation of technically complex, expensive equipment requires a considerable amount of time and effort to study the issue. However, these efforts can be attributed to a prolonged investment in a future rich harvest, which will delight you both morally and materially for more than one season.