Car engine power calculator

Let's look at 5 popular ways to calculate the power of a car engine using data such as:

- engine speed,

- engine volume,

- torque,

- effective pressure in the combustion chamber,

- fuel consumption,

- injector performance,

- machine weight

- acceleration time to 100 km.

Each of the formulas used to calculate the power of a car engine is quite relative and cannot determine with 100% accuracy the real horsepower of the driving car. But by making calculations for each of the above garage options, based on certain indicators, you can calculate at least the average value, whether it’s a stock or tuned engine, literally with a 10 percent error .

Power is the energy generated by the engine, it is converted into torque on the output shaft of the internal combustion engine. This is not a constant value. Next to the maximum power values, the speed at which it can be achieved is always indicated. The maximum point is reached at the highest average effective pressure in the cylinder (depending on the quality of filling with fresh fuel mixture, combustion completeness and heat losses). Modern engines produce the greatest power on average at 5500–6500 rpm. In the automotive industry, engine power is measured in horsepower. Therefore, since most results are displayed in kilowatts, you will need a kW to hp conversion calculator.

The role of engine power and torque

To ensure better engine dynamic performance, manufacturers are trying to provide the power unit with maximum torque, which will be achieved at a wider engine speed.

To correctly assess the role of these two concepts, it is worth paying attention to the following facts:

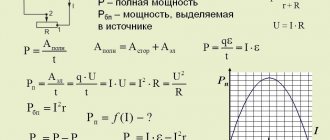

- The relationship between power and torque can be expressed in the formula: P = 2P*M*n , where P is power, M is the torque indicator, and n is the number of crankshaft revolutions per unit time.

- Torque is a more specific indicator of engine performance. Low torque (even with high power) will not allow the engine to realize its potential: while being able to accelerate to high speed, the car will take an incredibly long time to reach this speed.

- Engine power will increase with increasing speed: the higher the speed, the more power, but up to certain limits.

- Torque increases with increasing speed, but when the maximum value is reached, torque figures decrease.

- Given equal power and torque, the engine with lower fuel consumption will be more efficient.

Let's look at 5 popular ways to calculate the power of a car engine using data such as:

- engine speed,

- engine volume,

- torque,

- effective pressure in the combustion chamber,

- fuel consumption,

- injector performance,

- machine weight

- acceleration time to 100 km.

Each of the formulas used to calculate the power of a car engine is quite relative and cannot determine with 100% accuracy the real horsepower of the driving car. But by making calculations for each of the above garage options, relying on one or another indicator, you can calculate, at least, the average value for a stock or tuned engine, literally with a 10 percent error .

Power is the energy generated by the engine, it is converted into torque on the output shaft of the internal combustion engine. This is not a constant value. Next to the maximum power values, the speed at which it can be achieved is always indicated. The maximum point is reached at the highest average effective pressure in the cylinder (depending on the quality of filling with fresh fuel mixture, combustion completeness and heat losses). Modern engines produce the greatest power on average at 5500–6500 rpm. In the automotive industry, engine power is measured in horsepower. Therefore, since most results are displayed in kilowatts, you will need a kW to hp conversion calculator.

How to calculate power through torque

The simplest calculation of car engine power can be determined by the relationship between torque and revolutions .

Torque

The force multiplied by the leverage of its application, which the engine can produce to overcome certain resistance to movement. Determines how quickly the motor reaches maximum power. Calculation formula for torque based on engine volume:

Micro = VHxPE/0.12566

, Where

- VH – engine displacement (l),

- PE – average effective pressure in the combustion chamber (bar).

Engine speed

Crankshaft rotation speed.

The formula for calculating the power of an internal combustion engine of a car is as follows:

P = Mkr * n/9549 [kW]

, Where:

- Mcr – engine torque (Nm),

- n – crankshaft speed (rpm),

- 9549 is a coefficient so that the revolutions can be substituted in rpm, and not in alpha cosines.

Since according to the formula, we get the result in kW, then, if necessary, you can also convert to horsepower or simply multiply by a factor of 1.36.

Using these formulas is the easiest way to convert torque to power.

And in order not to go into all these details, a quick calculation of the power of an internal combustion engine online can be done using our calculator.

But, unfortunately, this formula reflects only the effective power of the motor, which does not all reach the wheels of the car. After all, there are losses in the transmission, transfer case, parasitic consumers (air conditioning, generator, power steering, etc.) and this does not take into account such forces as rolling resistance, lifting resistance, aerodynamic resistance.

Power via torque

One way to calculate power is to determine the relationship between engine torque and RPM.

Any torque in physics is the result of a force acting on its arm. Torque is the product of the force that an engine can produce to overcome the resistance of a load multiplied by the arm of its application. It is this parameter that determines the speed at which the engine reaches maximum power.

Torque can be defined as the ratio of the product of the working volume to the average effective pressure in the combustion chamber and 0.12566 (constant):

- M = (V working * P efficiency)/0.12566, where V working – engine volume [l], P efficiency – effective pressure in the combustion chamber [bar].

Engine speed describes the speed of the engine shaft.

Using the torque and engine speed values, you can calculate the engine power using the following formula:

- P = (M * n)/9549, where M is torque [Nm], n is shaft rotation speed [rpm], 9549 is aspect ratio.

Design power is measured in kilowatts. To convert the calculated value to horsepower, multiply the result by a proportionality factor of 1.36.

This calculation method consists of using only two elementary formulas, so it is considered one of the simplest. However, this can be made even simpler and use an online calculator, where you need to enter some data about the car and its engine unit.

It's worth noting that this engine power formula only calculates the power that comes out of the engine, not the power that actually reaches the wheels of the car. Who cares? While the power (if you think of it as a flow) reaches the wheels, it experiences losses, such as in the case of transmission. Side loads such as the air conditioner or alternator also play a role. Overflow losses, rolling resistance and drag resistance should not be overlooked.

This disadvantage is partially compensated by the use of other calculation formulas.

How to calculate power by engine volume

If you do not know the torque of your car’s engine, then to determine its power in kilowatts you can also use a formula of this type:

Ne = Vh * pe * n/120

(kW), where:

- Vh — engine volume, cm³

- n — rotation speed, rpm

- pe is the average effective pressure, MPa (for conventional gasoline engines it is about 0.82 - 0.85 MPa, for forced ones - 0.9 MPa, and for diesel engines from 0.9 and to 2.5 MPa, respectively).

To obtain engine power in “horses” rather than kilowatts, the result should be divided by 0.735.

Calculation of power by engine volume

The attentive reader will probably have noticed that the first formula can be replaced directly with the second to simplify the calculations. The force in this case can be expressed as follows:

M = (KM x OD)/9549 = (O x L x OD)/(9549 x 0.0126) = (O x L x OD)/120.3.

The interpretation of this formula will be standard:

Note that the combustion chamber pressure (variable D) in the case of a standard gasoline engine is usually between 0.8-0.85 MPa . In the case of a modernized engine, this figure will be 0.9 MPa in the case of a diesel engine. 1-2 MPa .

Calculation of engine power based on air flow

The same approximate calculation of engine power can be determined by air flow. The function of such a calculation is available to those who have an on-board computer installed, since it is necessary to record the flow rate when the car engine, in third gear, is spun up to 5.5 thousand revolutions. We divide the resulting value from the mass air flow sensor by 3 and get the result.

The formula for calculating the power of an internal combustion engine based on air flow ultimately looks like this:

This calculation, like the previous one, shows gross power (bench test of the engine without taking into account losses), which is 10-20% higher than the actual one. It is also worth considering that the readings of the mass air flow sensor are highly dependent on its contamination and calibrations.

Calculation of power by weight and acceleration time to hundreds

Another interesting way to calculate engine power using any type of fuel, be it gasoline, diesel or gas, is by acceleration dynamics. To do this, using the weight of the car (including the pilot) and acceleration time to 100 km. And in order for the Power Calculation Formula to be as close to the truth as possible, it is also necessary to take into account slipping losses depending on the type of drive and the speed of reaction of different gearboxes. The approximate loss at start for front-wheel drive will be 0.5 seconds. and 0.3-0.4 for rear-wheel drive cars.

Calculation of weight and acceleration time from zero to hundreds

You can also determine how engine power is measured by the total weight of the car and the time it takes to accelerate to 100 kilometers per hour. Unfortunately, this method has a big drawback - the final formula is quite complex and can vary greatly depending on the technical characteristics of the car (type of drive, nature of the transmission, etc.).

Optimal action algorithm:

- Accelerate your car from 0 to 60 kilometers per hour. Determine the acceleration time in any convenient way (usually this is done using the on-board computer).

- Find out the weight of your car - this can be done using the same on-board computer, technical documentation, and so on.

- Use our calculator - enter weight and acceleration time, select drive type, select gear.

Calculation of internal combustion engine power based on injector performance

An equally effective indicator of the power of a car engine is the performance of the injectors. Previously, we looked at its calculation and relationship, therefore, it will not be difficult to calculate the amount of horsepower using the formula. The estimated power is calculated according to the following scheme:

Where, the load factor is no more than 75-80% (0.75...0.8), the mixture composition at maximum performance is somewhere around 12.5 (rich), and the BSFC coefficient will depend on what kind of engine you have, naturally aspirated or turbocharged (atmo - 0.4-0.52, for turbo - 0.6-0.75).

Having found out all the necessary data, enter the indicators into the appropriate cells of the calculator and by clicking the “Calculate” button you will immediately receive a result that will show the real engine power of your car with a slight error. Please note that you do not necessarily need to know all the parameters presented; you can clear the power of the internal combustion engine using a separate method.

The value of the functionality of this calculator lies not in calculating the power of a stock car, but if your car has been tuned and its weight and power have undergone some changes.

Shaft calculation

The task:

Four concentrated moments M1...M4 are applied to a steel shaft consisting of 4 sections of length l1...l4 (see Fig. 1).

Required:

Construct a diagram of torques Mkr, select the shaft diameter based on strength, construct a diagram of maximum tangential stresses τmax, construct a diagram of shaft twist angles φ and determine the largest relative shaft twist angle.

Loads, kN×m:

- M1 = -4.5;

- M2 = -2.6;

- M3 = -3.1;

- M4 = -2.0;

Length of sections, m:

- l1 = 0.9;

- l2 = 0.6;

- l3 = 0.9;

- l4 = 0.4;

Directions:

Draw a diagram of the shaft in accordance with the original data. The signs of the moments in the source data mean: plus - the moment acts counterclockwise relative to the Z axis, minus - clockwise (see towards the Z axis). In the future, the values of the moments are taken in absolute value. The sections are numbered from the support. The permissible tangential stress for steel is taken equal to 100 MPa.

Solution:

1. Let us determine the values of torques at each power section from the free end of the shaft using the cross-section method. The torque is equal to the algebraic sum of the external moments acting on the shaft on one side of the section.

- MIV = -M1 = -4.5 (kN×m);

- MIII = -M1 - M2 = -4.5 - 2.6 = -7.1 (kN×m);

- MII = -M1 - M2 - M3 = -4.5 - 2.6 - 3.1 = -10.2 (kN×m);

- МI = -М1 – М2 – М3 – М4 = -4.5 – 2.6 – 3.1 – 2.0 = -12.2 (kN×m).

2. Let us select the shaft cross-section based on the torsional strength according to the polar moment of resistance for the section where the torque value is maximum (ignoring the sign):

WP≥ Mkr/ .

Since for a circular section the polar moment is equal to: Wр = πD3/16, we can write:

D ≥ 3√(16Mkr/π) ≥ 3√(16×12.2×103/3.14×) = 0.0855 m or D ≥ 85.5 mm. (Hereinafter, the sign “√” means the square root from expression)

In accordance with the standard series provided by GOST 12080-66, we accept shaft diameter D = 90 mm.

3. Determine the angle of twist for each section of the shaft using the formula:

φ = Mkr×l/G×Iр,

where G is the modulus of elasticity of the 2nd kind; for steel G = 8×1010 Pa; Ip – polar moment of inertia (for a circular section Iр = πD4/32 ≈ 0.1D4, m4). The product G×Iр = 8×1010×0.1×0.094 ≈ 524880 N×m2 is the torsional rigidity of the section of this shaft.

We calculate the twist angles in each section:

- φI = -12.2×103×0.9/524880 = -0.0209 rad;

- φII = -10.2×103×0.6/524880 = -0.0116 rad;

- φIII = -7.1×103×0.9/524880 = -0.0122 rad;

- φIV = -4.5×103×0.4/524880 = -0.0034 rad.

4. Determine the angles of twist of the shaft sections, starting from the rigid seal (support):

- φ0-0 = 0 rad;

- φ1-1 = φI= -0.0209 rad;

- φ2-2 = φI + φII= -0.0209 - 0.0116 = -0.0325 rad;

- φ3-3 = φI + φII + φIII= -0.0209 - 0.0116 - 0.0122 = -0.0447 rad;

- φ4-4 = φI + φII + φIII + φIV = -0.0209 - 0.0116 - 0.0122 -0.0034 = -0.0481 rad.

5. Determine the maximum shear stress at each force section using the formula:

τmax = Mkr/Wp = 16 Mkr/πD3≈ 5 Mkr/D3.

Then:

- τmaxIV = 5×-4.5×103/0.093 = -30864197 Pa ≈ -30.086 MPa;

- τmaxIII = 5×-7.1×103/0.093 = -48696844 Pa ≈ -48.700 MPa;

- τmaxII = 5×-10.2×103/0.093 = -69958847 Pa ≈ -69.959 MPa;

- τmaxI = 5×-12.2×103/0.093 = -83676268 Pa ≈ -83.676 MPa.

6. The largest relative twist angle Θmax is determined by the formula:

Θmax = MKRmax/G×Iр = -12.2×103/524880 = 0.0232 rad/m.

7. Based on the calculation results, we construct diagrams of torques Mkr, tangential stresses τmax and twist angles φ (see Fig. 2).

***

Academic disciplines

- Engineering graphics

- MDK.01.01. "Car design"

- General structure of the car

- car engine

- Car transmission

- Steering

- Brake system

- Suspension

- Wheels

- Body

- Car electrical equipment

- Basic car theory

- Basics of technical diagnostics

- Fundamentals of hydraulics and heat engineering

- Metrology and standardization

- Agreecultural machines. Agreecultural equipment

- Basics of agronomy

- Transportation of dangerous goods

- Materials Science

- Management

- Technical mechanics

- Tips for graduate student

Olympics and tests

- "Engineering graphics"

- "Technical Mechanics"

- "Engine and its systems"

- "Car chassis"

- "Car electrical equipment"

FAQ

How to calculate the power of an internal combustion engine?

Engine power in kW can be calculated from engine size and crankshaft speed. The formula for calculating engine power is: Ne = Vh * Pe * n / 120 (kW), where: Vh - engine volume, cm³ n - number of crankshaft revolutions per minute Pe - average effective pressure, MPa

What coefficient should be taken into account when calculating engine power?

The power factor (cosϕ) for calculating the power of an electric motor is taken equal to 0.8 for low-power motors (less than 5.5 kW) or 0.9 for motors with a power of over 15 kW.

How to calculate engine power from torque?

To determine the engine power in kilowatts, when the torque is known, you can use the following formula: P = Mcr * n/9549, where: Mcr – torque (Nm), n – crankshaft speed (rpm), 9549 – coefficient for converting revolutions to rpm.

How to calculate engine power based on air flow?

You can calculate the engine power in kW knowing its air consumption (if you have an on-board computer) using a simple diagram. It is necessary to spin the engine in third gear to 5500 rpm (peak torque) and, according to the readings at that time, record the air flow, and then divide that value by three. As a result of such a mathematical calculation, you can find out the approximate engine power with a small error.

Source

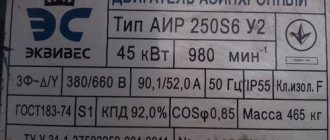

Determining the power of an electric motor without a tag

If there is no technical certificate or tag on the engine, the question arises: how to find out the power of an electric motor without a plate or technical documentation? The most common and fastest methods, which we will discuss in the article:

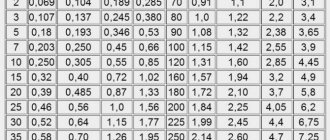

Determining engine power by shaft diameter and length

The simplest ways to determine the power and brand of an engine are the overall dimensions - shaft or mounting holes. The table shows the lengths and diameters of the shafts (D1) and length (L1) for each model of an asynchronous industrial three-phase motor. Go to detailed overall dimensions of AIR electric motors

| R, kW | 3000 rpm min | 1500 rpm min | 1000 rpm min | 750 rpm min | ||||

| D1, mm | L1, mm | D1, mm | L1, mm | >D1, mm | L1, mm | D1, mm | L1, mm | |

| 1,5 | 22 | 50 | 22 | 50 | 24 | 50 | 28 | 60 |

| 2,2 | 24 | 28 | 60 | 32 | 80 | |||

| 3 | 24 | 32 | 80 | |||||

| 4 | 28 | 60 | 28 | 60 | 38 | |||

| 5,5 | 32 | 80 | 38 | |||||

| 7,5 | 32 | 80 | 38 | 48 | 110 | |||

| 11 | 38 | 48 | 110 | |||||

| 15 | 42 | 110 | 48 | 110 | 55 | |||

| 18,5 | 55 | 60 | 140 | |||||

| 22 | 48 | 55 | 60 | >140 | ||||

| 30 | 65 | |||||||

| 37 | 55 | >60 | 140 | 65 | 75 | |||

| 45 | 75 | 75 | ||||||

| 55 | 65 | 80 | 170 | |||||

| 75 | 65 | 140 | 75 | 80 | 170 | |||

| 90 | 90 | |||||||

| 110 | 70 | 80 | 170 | 90 | ||||

| 132 | 100 | 210 | ||||||

| 160 | 75 | 90 | 100 | 210 | ||||

| 200 | ||||||||

| 250 | 85 | 170 | 100 | 210 | ||||

| 315 | — | — | ||||||

Check power by dimensions and mounting dimensions

Table for selecting engine power based on mounting holes on the feet (L10 and B10):

Source

Car engine power

How much actual power does your car's engine produce under different driving modes and conditions? More often than not, it is not at all what is written on the vehicle registration certificate. Let's find out the answer to this question by remembering elementary physics...

...and perform a simple calculation in Excel.

It is known that the coefficient of performance (COP) of a new modern gasoline automobile engine continues to remain very low. Its value is only 20...25% and is achieved only during the optimal operating mode - when reaching maximum power at rated speed!

Losses of about 80% arise as a result of:

— incomplete combustion of gasoline (about 25%);

— friction losses in the moving parts of the motor (about 5%);

— heat loss through the cooling system and exhaust gas removal system (about 50%).

Efficiency is directly (but not linearly) proportional to the developed power of the car engine. When the engine operates at a frequency of 2500...3500 rpm, its real efficiency does not reach 10%.

It’s hard to imagine, but every nine liters of fuel out of ten are dissipated as heat in the surrounding space and “fly down the drain” in the literal sense of the word. And only one liter of gasoline in ten, when burned, does useful work - it moves the car in space.

The efficiency of a modern diesel engine in optimal mode reaches a slightly higher value - 40%. Therefore, diesel engines are significantly more economical than their gasoline counterparts.

What you need to know about power and torque in a car

Content

- How is engine power calculated?

- Video: In simple words without complex formulas and calculations, what is power, torque and engine speed.

- What is torque

- Which is better: power or torque?

Engine power is a quantity that shows how much work a motor can do per unit time. That is, the amount of energy that the engine transmits to the transmission over a certain period of time. Measured in kilowatts (kW) or horsepower (hp).

How is engine power calculated?

Motor power is calculated in several ways. The most accessible way is through torque. We multiply the torque by the angular velocity and get the engine power.

N_eng – engine power, kW;

M – torque, Nm;

ω – angular speed of rotation of the crankshaft, rad/sec;

π – mathematical constant equal to 3.14;

n_eng – engine rotation speed, min-1.

Power is also calculated using the average effective pressure. The combustion chamber has a certain volume. Heated gases act on the piston in the cylinder with a certain pressure. The motor rotates at a certain frequency. The product of engine displacement, mean effective pressure and rotational speed, divided by 120, will give the theoretical engine power in kW.

V_dv – engine volume, cm3;

P_eff – effective pressure in the cylinders, MPa;

120 is the coefficient used to calculate the power of a four-stroke engine (for two-stroke internal combustion engines this coefficient is 60).

To calculate horsepower, kilowatts are multiplied by 0.74.

N_dv hp – engine power in horsepower, l. With.

Other engine power formulas are used less frequently in real calculations. These formulas include specific variables. And in order to measure engine power using other methods, you need to know the performance of the injectors or the mass of air consumed by the engine.

In practice, car manufacturers perform power calculations empirically, that is, they measure it on a bench and build a graph of the dependence in fact, based on the indicators obtained during testing.

Engine power is not a constant quantity. For each motor there is a curve that displays on a graph the dependence of power on crankshaft speed. Up to a certain peak, up to approximately 4-5 thousand rpm, power increases in proportion to the rpm. Next there is a smooth lag in power growth, the curve slopes. At about 7-8 thousand rpm, the power begins to decline. This affects valve overlap at high crankshaft speeds and a drop in engine efficiency due to insufficiently intense gas exchange.

What is engine power

Power should be understood as a physical quantity that shows the work performed by the engine per unit of time. In rotational motion, power is defined as the product of torque and the angular speed of rotation of the crankshaft. It is usually indicated in horsepower (hp), but it can also be measured in kW.

There are several units of measurement called "horsepower", but, as a rule, what is meant is the so-called "metric horsepower", which is equal to ≈ 0.7354 kW. But in the USA and Great Britain, horsepower in cars is equal to 0.7456 kW, that is, 75 kgf*m/s, which is approximately equal to 1.0138 metric.

- 1 kW = 1.3596 hp (for metric calculus);

- 1 kW = 1.3783 hp (English standard);

- 1 kW = 1.34048 hp (electric “horse”).

If we convert the power of 1 horsepower into kilowatts (in industry or energy), then it will be approximately equal to 0.746 kW. The concept of horsepower is not included in the International System of Measurements (SI), so measuring power in kW will be more correct.

The more power, the higher the speed the car can develop.

Types of power

To determine engine characteristics, power concepts such as:

- indicator;

- effective;

- liter

The indicator power is the power with which the gases press on the piston. That is, no other factors are taken into account, but only the pressure of the gases at the moment of their combustion. Effective power is the force that is transferred to the crankshaft and transmission. The indicator will be proportional to the engine displacement and the average gas pressure on the piston.

The effective engine power will always be lower than the indicated one.

There is also a parameter called liter engine power. This is the ratio of engine volume to its maximum power. For gasoline engines, the liter power is on average 30-45 kW/l, and for diesel engines - 10-15 kW/l.

How to find out the power of a car engine

Of course, the value can be found in the documents for the car, but sometimes you need to find out the power of a car that has been tuned or has been in operation for a long time. In such cases, you cannot do without a dynamometer. It can be found in specialized organizations and at service stations. The car's wheels are placed between drums that create resistance to rotation. Next, movement with different loads is simulated. The computer itself will determine the engine power. It may take several attempts for a more accurate result.

What is torque

Torque in a car engine is a rotating force that is numerically equal to the product of the applied force (the pressure of hot gases on the piston) and the shoulder (the distance between the axes of the main and connecting rod journals of the crankshaft in the projection perpendicular to the axis of rotation of the crankshaft). Torque is measured in newtons per meter (Nm).

The torque of the internal combustion engine depends on the pressure on the piston and the distance between the main and connecting rod journals. The dependence here is direct. The larger the shoulder and the greater the pressure on the piston, the greater the engine torque.

Diesel engines have a higher compression ratio. The piston stroke in the cylinder is also longer (with the same cylinder diameter as a gasoline engine). This means that the distance between the main and connecting rod journals will be greater. That is, the shoulder is longer. Due to the higher degree of compression during the power stroke, diesel engines have a higher force pressing on the piston. The torque in diesel engines, all other things being equal, is greater than in gasoline engines.

Torque affects how much energy the motor delivers at the current time. Torque is the quantity that determines the energy actually transmitted to the transmission at a given moment in time. The greater the torque, the stronger the engine thrust at the current speed.

Calculation via torque

This calculation method is basic. To measure power, you need to know two technical parameters: torque and engine speed. Therefore, the calculation is performed in two stages.

What is torque

Torque is the force applied to a rigid body during rotation. The higher it is, the more powerful your car's engine will be. The following formula is used to calculate torque:

The formula can be deciphered as follows:

How are engine speeds calculated?

To calculate operating power, not only torque is required, but also engine speed. Simply put, RPM is the speed at which the crankshaft rotates. Again, the correlation is direct: the higher the revs, the more powerful and productive your car will be.

To calculate power per revolution, use the following formula:

Please note that this formula is suitable for calculating the maximum engine power .

Unfortunately, when the internal combustion engine is running, part of the power is “eaten up” by certain elements of the car (transmission, transfer case, air conditioning, etc.).

So, in reality, the actual engine power measurement will be 10-15% less depending on the type of vehicle and how it is currently being used.