Electric motor power calculation

Calculation of electric motor power by current can be done using our online calculator:

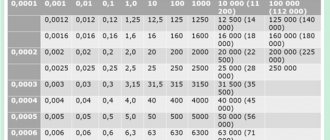

The result obtained can be rounded to the nearest standard power value.

Standard values of electric motor power : 0.25; 0.37; 0.55; 0.75; 1.1; 1.5; 2.2; 3.0; 4.0; 5.5; 7.5; eleven; 15; 18.5; 22; thirty; 37; 45; 55; 75 kW, etc.

Engine power is calculated using the following formula:

P=√3UIcosφη

- U - Rated voltage (voltage to which the electric motor is connected);

- I - Rated current of the electric motor (taken from the passport data of the electric motor , and in their absence is determined by calculation);

- cosφ - Power factor - the ratio of active power to total power (taken from 0.75 to 0.9 depending on the power of the electric motor);

- η - Efficiency factor - the ratio of the electrical power consumed by the electric motor from the network to the mechanical power on the motor shaft (taken from 0.7 to 0.85 depending on the power of the electric motor);

How to determine the power of an electric motor

The easiest way is to look at the plate and find the value in kilowatts. For example, in the picture it is 45 kW.

Please note that this value on the plate indicates the active power consumed from the electrical network.

The total power will be equal to the sum of active and reactive power. Electric meters in a house or garage count only the consumption of active electricity, and reactive energy is recorded only in enterprises using special meters. The higher the cos(fi) of an electric motor, the lower the reactive energy component of total power will be. Do not confuse cos(fi) with efficiency. This indicator shows how much electricity is converted into useful mechanical work, and how much into useless heat. For example, an efficiency of 90 percent means that a tenth of the electricity consumed is spent on heat losses and friction in the bearings. You should keep in mind that the passport or plate indicates the rated power, which will be equal to this value only if the optimal load on the shaft is achieved. However, you should not overload the shaft for a number of reasons; it is better to choose a more powerful motor. At idle, the current will be much lower than the nominal value.

How to determine the rated power of an electric motor? On the Internet you will find many different formulas and calculations. For some, you need to measure the dimensions of the stator, for other formulas you will need to know the current value, efficiency and cos(fi). My advice is don't bother with all this. Practical measurements will still be better than these calculations. And you won’t need anything at all to carry them out.

How to determine the power of any electrical appliance in the house or garage? Of course, using an electricity meter. Before starting the measurement, unplug all electrical appliances from the sockets, lighting and everything connected to the electrical panel.

Next, if you have an electronic meter of the Mercury type, everything is very simple: you just need to turn on the motor under load and drive for about 5 minutes. The electronic display should display the load value in kW currently connected to the meter.

If you have a disk induction meter, keep in mind that it keeps records in kilowatt/hours. Write down the latest readings before starting measurements, turn on the engine strictly second per second for exactly 10 minutes, then after stopping, subtract the new readings from the previous ones and multiply kWh by 6. The result obtained will be the active power of this engine in Kilowatts; to convert to Watts, divide by 1000 I recommend reading the article: how to take electric meter readings.

If the engine is low-power , then for higher accuracy you can count the disk revolutions. For example, in one minute it made 10 full revolutions, and the meter says 1200 revolutions = 1 kW/h. We multiply 10 by the number of minutes in an hour and get 600 revolutions per hour. Divide 1200 by 600 and we get 500 watts or 0.5 kW. The longer you measure, the more accurate the data will be. But the time must always be a multiple of a full minute. Then divide 60 by the number of minutes of measurement and multiply by the counted revolutions. After this, we divide the value of revolutions equal to one Kilowatt/hour for your electric meter model by the result obtained and obtain the required amount of power.

Motor current calculation

The rated and starting current of an electric motor can be calculated by power using our online calculator:

The rated motor current is calculated using the following formula:

Inom=P/√3Ucosφη

- P - Rated power of the electric motor (taken from the motor’s passport data or determined by calculation);

- U - Rated voltage (voltage to which the electric motor is connected);

- cosφ - Power factor - the ratio of active power to total power (taken from 0.75 to 0.9 depending on the power of the electric motor);

- η - Efficiency factor - the ratio of the electrical power consumed by the electric motor from the network to the mechanical power on the motor shaft (taken from 0.7 to 0.85 depending on the power of the electric motor);

The starting current of the electric motor is calculated using the formula:

Istart=Inom* K

- K - Starting current multiplicity, this value is taken from the electric motor passport, or from catalog data (in the above online calculator, the starting current multiplicity is determined approximately based on the other specified characteristics of the electric motor).

11kW 3000 rpm DIN

- Send a request

Print version

Technical characteristics of an 11 kW DIN standard electric motor with a shaft speed of 3000 rpm

| power, kWt | Dimensions | Nom. Cool. mom. (Nm) | Il/In | Tl/Tn | Tb/Tn | Moment of inertia kgm2 | Weight, kg | Noise, dB | Speed, rpm | Efficiency 100% load | Nom current, A |

| 11 | 160M | 35,9 | 6,8 | 2 | 2,7 | 0,28200 | 97 | 67 | 2920 | 88,1 | 21,600 |

Dimensions of the DIN standard electric motor with a power of 11 kW with a shaft speed of 3000 rpm, mounting version on feet

| Dimensions | A | A.A. | AB | A.C. | AD*** | AD' | B | B.A. | BB | C | C.A. | D | D.A. | E | E.A. | ES | F | F.A. | G | G.B. | G.D. | GF | T.S. |

| 160M | 254 | 64 | 308 | 329 | 264 | 264 | 210 | 63 | 254 | 108 | 174 | 42k6 | 42k6 | 110 | 110 | 80 | 12 | 12 | 37 | 37 | 8 | 8 | 80 |

| H | H.A. | HB*** | HC | HD*** | HF*** | HH | H.K. | K | L | L.C. | LL | L.M. | S1 | d1 | d2 |

| 160 | 22 | 79 | 327 | 374 | 168 | 213 | 100 | 14,5 | 598 | 712 | 198 | 188 | 2xM40x1.5 | M16 | M16 |

***- dimensions apply to terminal boxes for right and left mounting

Dimensions of the large FF flange of a DIN standard electric motor with a power of 11 kW and a shaft speed of 3000 rpm

| Dimensions | Flange | L.A. | M | N | P | S | T | A, deg | Number of holes |

| 160 | FF-300 | 18 | 300 | 250 | 350 | 19 | 5 | 45 | 4 |

see also

:

- Technical characteristics of DIN electric motors

- 0.12 kW 3000 rpm DIN

- 0.18 kW 3000 rpm DIN

- 0.25 kW 3000 rpm DIN

- 0.37 kW 3000 rpm DIN

- 0.55 kW 3000 rpm DIN

- 0.75kW 3000 rpm DIN

- 1.1kW 3000 rpm DIN

- 1.5kW 3000 rpm DIN

- 2.2kW 3000 rpm DIN

- 3kW 3000 rpm DIN

- 4kW 3000 rpm DIN

- 5.5kW 3000 rpm DIN

- 7.5kW 3000 rpm DIN

- 9.2kW 3000 rpm DIN

- 15kW 3000 rpm DIN

- 18.5kW 3000 rpm DIN

- 22kW 3000 rpm DIN

- 30kW 3000 rpm DIN

- 37kW 3000 rpm DIN

- 45kW 3000 rpm DIN

- 55kW 3000 rpm DIN

- 75kW 3000 rpm DIN

- 90kW 3000 rpm DIN

- 110kW 3000 rpm DIN

- 132kW 3000 rpm DIN

- 150kW 3000 rpm DIN

- 160kW 3000 rpm DIN

- 185kW 3000 rpm DIN

- 200kW 3000 rpm DIN

- 220kW 3000 rpm DIN

- 250kW 3000 rpm DIN

- 260kW 3000 rpm DIN

- 280kW 3000 rpm DIN

- 300kW 3000 rpm DIN

- 315kW 3000 rpm DIN

- 0.12kW 1500 rpm DIN

- 0.18kW 1500 rpm DIN

- 0.25kW 1500 rpm DIN

- 0.37kW 1500 rpm DIN

- 0.55kW 1500 rpm DIN

- 0.75kW 1500 rpm DIN

- 1.1kW 1500 rpm DIN

- 1.5kW 1500 rpm DIN

- 2.2kW 1500 rpm DIN

- 3kW 1500 rpm DIN

- 4kW 1500 rpm DIN

- 5.5kW 1500 rpm DIN

- 7.5kW 1500 rpm DIN

- 9.2kW 1500 rpm DIN

- 11kW 1500 rpm DIN

- 15kW 1500 rpm DIN

- 18.5kW 1500 rpm DIN

- 22kW 1500 rpm DIN

- 30kW 1500 rpm DIN

- 37kW 1500 rpm DIN

- 45kW 1500 rpm DIN

- 55kW 1500 rpm DIN

- 75kW 1500 rpm DIN

- 90kW 1500 rpm DIN

- 110kW 1500 rpm DIN

- 132kW 1500 rpm DIN

- 150kW 1500 rpm DIN

- 160kW 1500 rpm DIN

- 185kW 1500 rpm DIN

- 200kW 1500 rpm DIN

- 220kW 1500 rpm DIN

- 250kW 1500 rpm DIN

- 260kW 1500 rpm DIN

- 280kW 1500 rpm DIN

- 300kW 1500 rpm DIN

- 315kW 1500 rpm DIN

- 330kW 1500 rpm DIN

- 355kW 1500 rpm DIN

- 370kW 1500 rpm DIN

- 400kW 1500 rpm DIN

- 0.12kW 1000 rpm DIN

- 0.18kW 1000 rpm DIN

- 0.25kW 1000 rpm DIN

- 0.37kW 1000 rpm DIN

- 0.55kW 1000 rpm DIN

- 0.75kW 1000 rpm DIN

- 1.1kW 1000 rpm DIN

- 1.5kW 1000 rpm DIN

- 2.2kW 1000 rpm DIN

- 3kW 1000 rpm DIN

- 4kW 1000 rpm DIN

- 5.5kW 1000 rpm DIN

- 7.5kW 1000 rpm DIN

- 9.2kW 1000 rpm DIN

- 11kW 1000 rpm DIN

- 15kW 1000 rpm DIN

- 18.5kW 1000 rpm DIN

- 22kW 1000 rpm DIN

- 30kW 1000 rpm DIN

- 37kW 1000 rpm DIN

- 45kW 1000 rpm DIN

- 55kW 1000 rpm DIN

- 75kW 1000 rpm DIN

- 90kW 1000 rpm DIN

- 110kW 1000 rpm DIN

- 132kW 1000 rpm DIN

- 160kW 1000 rpm DIN

- 185kW 1000 rpm DIN

- 200kW 1000 rpm DIN

- 220kW 1000 rpm DIN

- 250kW 1000 rpm DIN

- 260kW 1000 rpm DIN

- 280kW 1000 rpm DIN

- 300kW 1000 rpm DIN

- 315kW 1000 rpm DIN

- 0.12kW 750rpm DIN

- 0.18kW 750 rpm DIN

- 0.25kW 750rpm DIN

- 0.37kW 750 rpm DIN

- 0.55kW 750 rpm DIN

- 0.75kW 750 rpm DIN

- 1.1kW 750 rpm DIN

- 1.5kW 750 rpm DIN

- 2.2kW 750 rpm DIN

- 3kW 750 rpm DIN

- 4kW 750 rpm DIN

- 5.5kW 750 rpm DIN

- 7.5kW 750 rpm DIN

- 9.2kW 750 rpm DIN

- 11kW 750 rpm DIN

- 15kW 750 rpm DIN

- 18.5kW 750 rpm DIN

- 22kW 750 rpm DIN

- 30kW 750 rpm DIN

- 37kW 750 rpm DIN

- 45kW 750 rpm DIN

- 55kW 750 rpm DIN

- 75kW 750 rpm DIN

- 90kW 750 rpm DIN

- 110kW 750 rpm DIN

- 132kW 750 rpm DIN

- 150kW 750 rpm DIN

- 160kW 750 rpm DIN

- 185kW 750 rpm DIN

- 200kW 750 rpm DIN

- 220kW 750 rpm DIN

We work only with legal entities of the Russian Federation

Calculation of electric motor power factor

Online calculation of power factor (cosφ) of an electric motor

Calculation of cosφ (cosine phi) of the engine is carried out using the following formula:

cosφ=P/√3UIη

- P - Rated power of the electric motor (taken from the motor’s passport data or determined by calculation);

- U - Rated voltage (voltage to which the electric motor is connected);

- I - Rated current of the electric motor (taken from the passport data of the electric motor , and in their absence is determined by calculation);

- η - Efficiency factor - the ratio of the electrical power consumed by the electric motor from the network to the mechanical power on the motor shaft (taken from 0.7 to 0.85 depending on the power of the electric motor);

What current does the motor consume from the network during startup and operation?

The passport of the electric motor indicates the current at the rated load on the shaft.

If, for example, 13.8/8 A is indicated, then this means that when the engine is connected to a 220 V network and at a rated load, the current consumed from the network will be equal to 13.8 A. When connected to a 380 V network, there will be a current of 8 A is consumed, that is, the power equality is valid: √ 3 x 380 x 8 = √ 3 x 220 x 13.8. Knowing the rated power of the motor (from the passport), you can determine its rated current. When the motor is connected to a three-phase 380 V network, the rated current can be calculated using the following formula:

I n = P n/ ( √3 U n x η x s osφ),

where P n is the rated power of the engine in kW, U n is the network voltage, in kV (0.38 kV). Efficiency factor (η) and power factor (with osφ) are the motor’s nameplate values, which are written on the shield in the form of a metal plate. See also - What passport data are indicated on the shield of an asynchronous motor.

Rice. 1. Electric motor passport. Rated power 1.5 kV, rated current at voltage 380 V – 3.4 A.

If the efficiency is not known. and the power factor of the engine, for example, if there is no passport plate on the engine, then its rated current with a small error can be determined by the ratio “two amperes per kilowatt”, i.e. If the rated power of the motor is 10 kW, then the current consumed by it will be approximately 20 A.

For the motor shown in the figure, this ratio also holds (3.4 A ≈ 2 x 1.5). More accurate current values when using this ratio are obtained with motor powers of 3 kW and above.

When the electric motor is idling, a small current is consumed from the network (no-load current). As the load increases, the current consumption also increases. As the current increases, the heating of the windings increases. Large overload leads to the fact that the increased current causes overheating of the motor windings, and there is a danger of charring of the insulation (burning out of the electric motor).

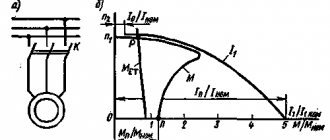

At the moment of starting from the network, the electric motor consumes the so-called starting current, which can be 3 to 8 times more than the rated current. The nature of the current change is presented on the graph (Fig. 2, a).

Rice. 2. The nature of the change in the current consumed by the motor from the network (a), and the effect of high current on voltage fluctuations in the network (b)

The exact value of the starting current for each specific engine can be determined by knowing the value of the starting current multiplicity - I start / I nom. The starting current multiplicity is one of the technical characteristics of the motor, which can be found in catalogs. The starting current is determined by the following formula: I start = I n x (I start / I nom). For example, with a rated motor current of 20 A and a starting current multiple of 6, the starting current is 20 x 6 = 120 A.

Knowing the actual value of the starting current is necessary for selecting fuses, checking the operation of electromagnetic releases during engine starting when selecting circuit breakers, and for determining the amount of voltage reduction in the network during startup.

Calculation of electric motor efficiency

Online calculation of efficiency (efficiency) of an electric motor

The efficiency of the electric motor is calculated using the following formula:

η=P/√3UIcosφ

- P - Rated power of the electric motor (taken from the motor’s passport data or determined by calculation);

- U - Rated voltage (voltage to which the electric motor is connected);

- I - Rated current of the electric motor (taken from the passport data of the electric motor , and in their absence is determined by calculation);

- cosφ - Power factor - the ratio of active power to total power (taken from 0.75 to 0.9 depending on the power of the electric motor);

Did you find these online calculators useful? Or maybe you still have questions ? Write to us in the comments!

Didn’t find an article on the website on a topic that interests you regarding electrical engineering? Write to us here. We will definitely answer you.

Source

Calculation of basic engine parameters from the nameplate

Electric motors are found everywhere in industry and everyday life. If you haven’t paid attention, I’ll give you a couple of photo examples:

Sometimes a need arises, born of everyday curiosity, or a production need, to determine the power of an electric motor by its appearance, or the permissible operating temperature, not to mention the current and voltage values.

Here it is possible that the plate on which the nominal parameters are written has been torn off, or the nameplate is in such a state that it is impossible to distinguish anything. How to be in such a situation...

Electric motor label

Having examined any electric motor, with rare exceptions, you can find a plate screwed onto bolts, screws or rivets. What is written on this piece of metal? Let's take a nameplate, replacing the serial number on it with the name of the site.

By the way, it rarely happens that a plate for electrical equipment is in such almost perfect condition. Often the data is faded or covered with paint, because the task is for the maintenance personnel to paint the engine, and not to paint the engine, leaving the plate untouched. But we were lucky. Let's go in order.

First line

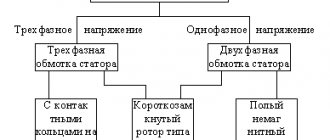

- number of phases and type of current (3

), serial number, network frequency, design and installation form, insulation class

Second line

— type of electric motor, cosine phi, possible connection diagrams, rated speed

Third line

- possible rated voltages, rated power, IP - degree of protection of the electric motor, weight, operating mode of the electric motor (S1).

Fourth line

- rated currents depending on the winding connection circuit, then which guest the ed corresponds to.

Let's look at the individual parameters in more detail.

Electric motor power: total, active and shaft

Formula for calculating the power of a three-phase asynchronous motor:

S1 - total power consumed by the motor from the network

P1 - active power consumed by the electric motor from the network (indicated on the nameplate)

P is the active power on the EM shaft.

cosf - cosine phi, power factor - phase angle between active (P) and total power (S).

In the formulas above, the power value is obtained in W, the total power value in VA. To convert to kilowatts, you need to divide the resulting value by a thousand. The value of current and voltage, respectively, in the formula above is in amperes and volts.

I1 and U1 are linear values of current and voltage, they are also called phase-to-phase. Not to be confused with phase ones. Linear ones are AB, BC, SA (380); phase - AO, VO, SO (220). If we express the power formulas in terms of the phase values of current and voltage, then instead of the root of three there will initially be a coefficient of 3. This coefficient is determined visually through the vector diagram of the three-phase voltage.

For DC motors, the formula will simply be the voltage at the motor terminals multiplied by the current drawn by the motor from the network.

Power consumption p1 is greater than the power on the EM shaft due to losses that arise when converting electrical energy into mechanical energy.

Star/Delta and 220/380, 380/660

See all the values in order as they go through the fraction. That is, it is written on the nameplate Y/D (triangle/star), which means that the currents and voltages will accordingly be first for Y, and after the fraction for the star. The only caveat is that at 220/380 the triangle will be 220, and at 380/660 the triangle will be 380. That is, to say that 380 is always a star is incorrect.

Always read the label on the engine before connecting.

The advantages of star and delta connections are abstract, since each circuit has its own areas of application:

- Y - less operating and starting current, more voltage, less starting torque, less heat

- D - higher starting torque, starting current, but also heats up more.

There are two-speed engines, where they first start on a star, and then switch to a triangle. In this case, the mechanism starts up easier and then works with more power.

Motor current calculation

Hello visitors to the site fazanet.ru, and in today’s article we will figure out how to do this incomprehensible calculation of the electric motor current. Every self-respecting electrician whose work involves servicing electrical machines simply must know this. I also remember at one time that I was very interested in this when I was transferred from one workshop to another. Specifically, working as an electrician.

Before this, I already touched a little on the topic of electric motors, when I wrote about how to start asynchronous motors, and when I wrote what the ratings of electric motors are.

Well, now let's get down to the calculation itself. Let's say: you have a three-phase asynchronous AC electric motor, the rated power of which is 25 kW, and you want to know what its rated current will be.

There is a special formula for this: In = 1000Pн /√3•(ηн • Un · cosφн),

Where Pн is the power of the electric motor; measured in kW

Un is the voltage at which the electric motor operates; IN

ηн is the efficiency factor, usually this value is 0.9

Well, cosφн is the engine power factor, usually 0.8.

The last two values are usually written on the factory tag, although they are almost the same for all engines. But you still need to take the data from the factory tag on the engine.

This is how in this picture all the values are visible, but the current is not. Only if the efficiency is written as 81%, then for the calculation you need to take 0.81.

How to calculate the starting current of an electric motor

In order to objectively assess the complexity of the engine starting conditions, it is necessary to first know the amount of starting current required for this. The main calculation steps are as follows:

- calculation of rated current;

- determination of the starting current value (in amperes).

In order to obtain the value of the rated current for the used electric motor model, use a formula that has the form Iн=1000Pн / (Un*cosφ*√ηн). Pн and Un are the rated power and voltage indicators, cosφ and ηн are the rated power and efficiency factors.

The actual starting current, which is designated as Iп, is determined using the formula Iп = Iн * Kп, where Kп is the multiple of the direct current in relation to its rated value (Iн). All information necessary for calculations (values of Kp, Pn, ηn, cosφ, Un) can be found in the technical documentation that comes with the electric motor.

Correct calculation of the motor starting current facilitates the correct selection of circuit breakers designed to protect the switching line, as well as the purchase of additional equipment (generators, etc.) with suitable parameters.

Source

How to determine the current of an electric motor in practice.

Lastly, I wanted to share with you how I determine the approximate current value without any calculations. If you really look at what we got in the calculation, it really looks like the rated current is approximately twice as large as its power. This is how I determine current in practice, I multiply the power by two. But this is only an approximate value.

And the no-load current will usually be two times less than its power. But we will talk to you about how to determine these values in the following articles. So subscribe to updates and don’t forget to share this article with your friends on social networks.

Source

How to determine the rated current of a three-phase motor

Motor current calculation

Calculation of the rated current of a three-phase asynchronous electric motor

To correctly select the electrification system for a lifting and transport mechanism, be it a trolley busbar or cable supply, you need to know the rated current of the electrical installation.

Below is the calculation form for a three-phase AC induction motor:

In=Pn/√3*Un*cosφн*ηн or Pн/1.73*Un*cosφн*ηн,

where Рн is the rated power of the electric motor (W),

Un — rated voltage of the electric motor (V),

ηн - nominal efficiency of the engine,

cos φн is the rated power factor of the motor.

The rated data of the electric motor are indicated on the nameplate or in other technical documentation attached to the electric motor.

For convenience, here is an example of a calculation:

It is necessary to determine the rated current of a three-phase asynchronous AC electric motor if Рн = 25 kW, rated voltage Un = 380 V, rated efficiency ηн = 0.9, rated power factor cos φн = 0.8.

The rated voltage of the three-phase network is 380 V - the motor windings are connected in a star configuration. The rated voltage of a three-phase network is 220 V - the connection of the motor windings is in a delta pattern.

We convert the rated power from kW to Watts: Pn = 25 kW = 1000*25 = 25000 W

Next: In = 25000/√3*380 * 0.8 * 0.9 = 25000/1.73*380*0.8*0.9 = 52.8 A.

Share link:

- We recommend

- Comments

IP65 degree of tightness of equipment

IP rating (Ingress Protection Rating, input protection) is a system for classifying the degree of protection of the electrical equipment shell from the penetration of solid objects and water in accordance with the international standard IEC 60529 (DIN 40050, GOST 14254-96). For example, the radio control for the F21-E1B crane has a sealing class of IP-65. The first digit means

COPPER and COPPER ROLLED

Copper grades and their chemical composition are defined in GOST 859-2001. Brief information about copper grades is given below (the minimum copper content and the maximum content of only two impurities - oxygen and phosphorus are indicated): Grade Copper O2 P Production method, main impurities M00k 99.98 0.01 - Copper cathodes: product of electrolytic refiner.

Transferring the crane to control from the floor

Transferring the crane to control from the floor. When transferring overhead or gantry cranes to remote control from the floor, cable control panels or mongrel crane control panels can be used. The full list of operations and control systems of the crane cabin must correspond to the functionality of the console, in accordance with RD 24.09.

Starting current.

The electric motor's passport indicates the current at the rated load on the shaft; it is less than the starting current. If 13.8/8 A is marked, this means that when the motor is connected to a 220 V network and the rated load, the motor current will be equal to 13.8 A. When connected to a 380 V network, the current is 8 A, thus the power equality is correct: √3 x 380 x 8 = √3 x 220 x 13.8.

Knowing the rated power of the motor, its rated current is determined. When connecting the motor to a three-phase 380 V distribution network, the rated current is calculated as follows:

In = Pн/(√3Uн x сosφ), kA

where Pn is the rated power of the engine, kW, Un is the network voltage, kV (0.38 kV). Power factor (cosφ) - engine nameplate values.

Rice. 1. Electric motor passport.

If the power factor of the motor is not known, then its rated current with a small error is determined by the ratio “two amperes per kilowatt,” i.e. If the rated power of the motor is 10 kW, then the current it consumes from the network will be approximately 20 A.

For the motor mentioned in the figure, this ratio also holds (3.4 A ≈ 2 x 1.5). More accurate current values when applying this ratio are obtained with electric motor powers of 3 kW and above.