Purpose and application

High-voltage transformers (HV) belong to the group of voltage converters. Their purpose is to convert high-voltage voltage into low-voltage to power various devices. According to the principle of operation, voltage converters differ little from power transformers. The secondary winding always has fewer turns than the primary if the converter is a step-down converter, and vice versa if the device is a step-up one.

HV transformers are classified according to:

- number of phases (single- or three-phase);

- number of windings (two, three or four);

- permissible errors;

- installation method (indoor or outdoor);

- purpose (general or special).

Special purpose converters are used in various electrical equipment:

- televisions and radios;

- communication devices;

- household appliances (for example, power supplies for lighting systems).

Most converters of this type are low-power (no more than a few kilovolt-amperes), frequency from 50 Hz, and are intended for indoor installation. The number of windings depends on the equipment in which the transformer will be installed. The insulation is filled with epoxy resin.

Calculation of electrical parameters

To calculate power, use a formula based on output voltage and current:

Powers are added if there are two (or more) secondary windings.

The efficiency of the converter cannot be higher than 80%, so the primary power is:

The current from the primary winding to the secondary is transmitted through a core, the area of which depends entirely on the power of the primary winding. For a core made of transformer steel, the area is calculated by the formula:

Number of turns of the primary winding:

When using a core made of a different material (some use tin, baked wire, roofing iron), then S must be increased by a third.

Number of turns of secondary windings:

Since part of the voltage is lost due to resistance, it is advisable to increase the calculated amount by 5-10%.

DIY winding machine

One possible option is to make a machine equipped with an adjustable stacker and a thread counter, using the principle of a bicycle wheel.

The wheel is placed on a pin in the wall, and its rim is equipped with a rubber ring. In order to put the core on the rim, you will first need to cut it and then fasten it again, obtaining a solid circle. Having wound the required length of wire around it, one end of it is connected to a core freely located on the rim. The coil moves along the rim in complete circles, as a result of which the wire is laid on the frame. In this case, a bicycle counter is used to count revolutions.

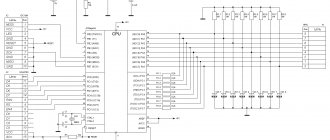

Creating a more advanced device will require the use of stepper motors with positioning of their position. For this, microcontrollers and an electronic counter are used. Such design requires certain skills in radio electronics.

Originally posted 2018-07-04 07:14:26.

Source

Selection of magnetic core material

A low-power converter can be made using an armored or rod magnetic core. In armor, rods with a rectangular cross-section are arranged horizontally. This is a relatively complex design and is therefore rarely used. In a core magnetic circuit, the rods are arranged vertically, the windings are cylindrical.

For a step-up transformer, it is better to use an W-shaped ferrite magnetic core. It is important to select the dimensions accurately (the required number of turns must fit on the rod). If the core needs to be disassembled to make another of the resulting plates, the thickness of the package is selected based on the power. The plates are inserted into the coil and tightened using pins and nuts.

Winding insulation

In certain cases, when making a step-up or step-down transformer yourself, insulating spacers should be inserted between the wires. For these purposes, cable or capacitor paper is used.

In the middle, the windings are insulated as tightly as possible. For insulation, as well as to level the surface being constructed, a varnished cloth wrapped in paper on both sides is needed. If there is no varnished fabric, you can solve the problem with folded paper.

To check the operating condition of the device, it is necessary to determine the terminals of the windings.

Core design

To make a step-down converter with two windings with your own hands, you need to find a round ferrite magnetic core.

These are found in old TVs and computer power supplies. In the case of a computer, the central core of the power transformer serves as the rod (it needs to be cut out). Length 2.1 cm, diameter 1.1 cm.

Most often these converters are coated with epoxy resin. In order to disassemble them, heating is required with a hair dryer. The cores are cut out with a grinder (no need to chop). The surface is usually uneven, so the posts are wrapped with tape. If the length is not enough, you can glue the two together with super glue.

Winding instructions

The core must be wrapped with tape (5 layers), a wire with the calculated diameter must be inserted into the groove, and the number of turns calculated for the primary winding must be wound along the entire length. Both ends of the winding are brought out to one side and insulated with vinyl.

The last turn must be secured (simple threads will do) to prevent unwinding.

Next, 4-5 layers of tape are wound, the structure is placed in the body of a disposable syringe 3 cm long. 2 rows of tape and the number of turns calculated for the secondary are wound on the syringe, the width of the winding is approximately 1.5 cm. Each layer must be insulated with tape or two layers of fluoroplastic tape. The ends of the second winding are brought out on both sides. As a result, three outputs are obtained from one end, and one from the other.

The finished structure is insulated with tape (5 layers), flexible wires (leads) are soldered, and another 5 layers of tape are wound.

If the wire breaks during the winding process, the ends must be stripped, twisted, soldered and insulated. The electrical strength is increased by impregnation of each layer of winding with varnish based on acrylic or epoxy resin.

In order to make a transformer with your own hands, it is not necessary to buy a new wire. The old one is also suitable if the segments are connected correctly (twisted and soldered). When winding, the turns should be pressed tightly against each other. It is not advisable to lay them perpendicular to the core (a slight tilt is required). Kinks and folds are not allowed, so a certain amount of tension is required. The insulation tape should be cut into 1.5 cm wide strips to make it easier to cover the wire.

Step-up transformer assembly

A feature of a step-up transformer is the larger cross-section of the cores of the primary winding of the transformer in relation to the secondary. A striking example is any unit that increases the supply voltage of 220 Volts to 400, 500, 1000 V, etc., accordingly, the insulation class of the transformer is selected according to the rating of the secondary winding, as in network transformers.

Please note that a large cross-sectional conductor cannot be wound with a homemade machine, since you will not be able to produce enough force. This is quite easy to determine - if the first turns move freely along the coil frame, or worse, you see a clear gap between the core and the frame, proceed to manual winding.

To assemble you will need to perform the following sequence of actions:

- Assemble the base from a dielectric material; to do this, you can cut it according to a cardboard pattern. The frame is assembled overlapping using glue.

Rice. 2: Make a frame for the transformer

If you have a ready-made sample, you can move on to the next step.

- Make holes in the cheek of the coil for the leads to the electrical network and to the consumer. Thread the conclusions through them.

Rice. 3: thread the primary winding lead - Place the first layer of insulation under the primary.

Rice. 4: Apply a layer of insulation to the coil - Wind the primary winding of the transformer - if thickness allows, use a machine, otherwise, do it by hand. When winding, every 4-5 turns, check the rigidity of the fixation and the tightness of the fit.

Rice. 5: wind the primary

If there are visible gaps, it is recommended to press down the coils with a wooden press die or nail them through the die with a hammer.

- Count the number of turns, it should correspond to the calculated one, insert the leads into the holes. Place a layer of insulation on the primary.

- After the insulation layer, wind the secondary, since a thinner wire will be used here; this procedure is easier to perform on the machine.

Rice. 6: wind the secondary winding

Periodically check the tightness of the turns and their fixation on the rod. A good fixation should not sag or deform when pressed with your fingers.

- If all the turns do not fit in one layer, they are laid out in several, then it is important to maintain the same number of turns in each of them. The layers are layered with dielectric material; note that the thickness of the insulation should not significantly affect the overall dimensions of the coils.

Rice. 7: Insulate the first layer - Bring the ends of the secondary winding to the cheek of the frame.

- Place the magnetic core in the window of the frame, the core is assembled alternately on each side, otherwise the losses will be too large. Then the core expands for tight fixation.

Rice. 8: Place the coils on the core

Powerful transformers with high voltage ratings are additionally impregnated with paraffin insulation. This procedure leads to increased capacitive losses, but creates additional protection against electric current.