Wooden foundations are used for the construction of lightweight wooden buildings. Since the building material - wood - has a weak load-bearing capacity, and products made from it have a limited service life, the scope of application of wooden load-bearing base structures is very limited. When choosing wood as a material for a load-bearing foundation, individual developers must remember that it is necessary to correctly take into account the categories of soil and the type of soil on the building site, since not every type of earthen soil is suitable for the construction of wooden foundations.

Types of wooden foundations

A wooden foundation can be classified as a pile foundation, in which the support piles are made of wood. Piles made of wood differ in the type of installation:

- Hanging piles, the installation of which is provided at great depths in soft soils.

- Piles in the form of racks, used to pass through weak soil layers until they stop at a solid foundation.

Wooden hanging piles and piles - racks differ from each other in the depth of penetration of soil layers and the depth of support on a dense, durable base.

The main task when constructing a wooden foundation is to create a support for the piled wooden structure to a depth not exceeding its total length.

Types of foundations

Building a foundation with your own hands involves the use of several technologies:

- pillars;

- piles;

- ribbon;

- plate;

- combined options.

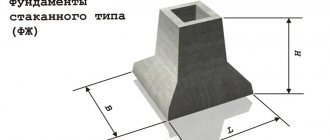

Columnar supports have a low load-bearing capacity. It is possible to install monolithic pillars or assemble them into compact concrete blocks. Both options are great for DIY projects.

There are three types of pile foundation for a house:

- driven (not recommended for private buildings due to the need to attract equipment);

- bored (suitable for building a brick or concrete house);

- screw (ideal for light wooden buildings).

Piles make it possible to reduce the amount of excavation work. There is no need to dig trenches or a foundation pit or transport large amounts of soil outside the site. Thanks to this quality, installing this type of foundation is a very economical choice. The main disadvantage will be the impossibility of equipping a basement or underground for utilities. In this case, the base of the building is covered with decorative materials.

Another advantage of piles is their ability to be used in wetlands. Even if the groundwater level is located close to the ground surface, the supports provide the necessary load-bearing capacity.

The next option is tape. It can be made monolithic or from blocks. The second option is rational to use for mass construction. Strip foundations are:

- recessed (for buildings with a basement, brick and concrete structures);

- shallow (for wooden and frame houses);

- non-buried (technology of pouring foundations for small buildings on a solid foundation).

Before making a tape, it is worth checking the groundwater level and compliance with the rule that the sole cannot be closer than 50 cm to the groundwater horizon. Otherwise, there is a high probability of flooding of the basement, reducing the load-bearing capacity of the foundation and destruction of the materials of the supporting part of the building.

Advantages of wooden foundations

There are many positive characteristics in using wood for the foundation of a wooden house or other building. These include:

- Simple and affordable technology for the work.

- The ability to build a wooden foundation independently and with your own hands without the involvement of specialists.

- Low cost of material.

- Possibility of using manual labor for installation without the use of expensive construction equipment.

- The distinctive ability of wood to resist significant bending and tensile loads.

- The heat capacity of wood, due to which the heat losses of a wooden house or building will be insignificant.

Type of wooden foundation

The fragility of wooden foundations is their main drawback, especially in cases of construction on soils with variable humidity levels.

A good and interesting alternative to a concrete strip foundation would be to lay wooden sleepers as a continuous load-bearing foundation for the structure.

Advantages and disadvantages of wooden foundations

Wood is a unique building material that has a number of advantages when used as a foundation:

1.

The property of elastic deformation, that is, the ability to recover after the perception of some excess pressure, while other types of materials are deformed or destroyed;

2.

Natural heat insulator.

The building does not lose heat and does not “pull” cold through the foundation; 3.

Low cost;

4.

Simple installation technology.

The main disadvantage of wooden pile foundations is their fragility. Especially in soils where humidity changes frequently. We consider other types of foundations in other materials: do-it-yourself pile foundation, columnar foundation, shallow foundation, do-it-yourself strip foundation and in the material on how to lay a foundation.

Requirements for the construction of wooden foundations

Suitable structures for wooden piles are rectangular wooden posts or the bottom (butt) part of a tree with a diameter of at least 200 mm. The estimated length of the pillars and the required number are taken on the basis of calculated data depending on the characteristics of the soil at the building site.

At the intersection of internal and external walls, as well as at the corners of the building, it is necessary to provide for the installation of wooden piles. When constructing a large building, it is recommended to place additional piles between the main design supports.

Piles need to be installed in holes or holes with a diameter slightly larger than the diameter of the wooden support itself.

If you strengthen the base under the pillars with a concrete mixture, stones or wooden crosses, you can significantly increase the load-bearing capacity of a wooden foundation. When installing pillars in a concrete mixture to a depth of 100 to 150 mm, the fixation of structures is significantly enhanced, which will make the subsidence of the foundation minimal.

Wooden columnar foundations

For foundations made of wooden pillars, it is best to use oak or pine logs with a diameter of 250 to 300 mm, located under the main walls and along the perimeter of the building. Wooden pillars were called “chairs” due to their external resemblance to this piece of furniture. The chairs are installed directly into the ground to a depth below the freezing level. Typically, the lower level for installing pillars is 1.5 or 2 m below ground level.

If the base soil has a significant strength and density, it is allowed to install chairs directly into the ground. In case of weak soils, to increase the support area, wooden posts are installed on special beds made of wooden plates or rectangular log linings. Connecting struts significantly increase the stability of wooden pillars - chairs. Typically, the installation depth of wooden poles is from 1.25 to 2 m, the height of the chairs above ground level is 0.75 - 0.8 m.

When installing chairs, it is recommended to leave a slightly higher height above the ground for possible cutting when creating the overall upper design level of the foundations

The procedure for reinforcing a strip foundation

The existing scheme for reinforcing a strip foundation for building a house requires following several mandatory rules:

- Application when carrying out reinforcement of rods of class A400

- Minimizing the use of welding when connecting rods, as this technology helps to weaken the sections

- At the corners, the frame can only be tied; the use of welding at the corners is not recommended

- The protective layer of concrete used in a particular situation must be at least 4 centimeters to protect metal elements from the negative effects of the environment and corrosion

- The use of smooth reinforcement is not recommended

- During laying, concrete must not be able to get stuck between the rods, which will eliminate control over failure due to too frequent placement of metal rods

Detailed step-by-step instructions with photos and videos provided for clarity will help you create a reinforcement frame. A significant advantage of reinforced strip foundations is the combination of high reliability and affordable cost. Steel and concrete are high-strength materials.

This is important for creating a foundation for construction on any soil, except for naturally stable and reliable rocks. In other situations, reinforcement of any foundation will eliminate damage caused by stress

How is it formed

When carrying out work such as reinforcing a strip foundation, the drawings include three groups of rods:

- Working rods used for laying along the belt

- Horizontal elements arranged transversely

- Vertical options, transverse

The task of transverse reinforcement is to connect all working elements into a single unit of reliable, innovative working rods that is stable in use. They are often called clamps.

An important feature of the work is the use of SNP and other regulatory specialized documents for activities such as reinforcement of strip foundations. When calculating, SNiP 52-01-2203 is used

In this regulatory document it is easy to find all the necessary calculations for creating reinforcement for the strip foundation of a small country house.

What requirements for concrete are determined by regulatory documents?

If you follow the order of creating reinforcement, it is important to comply with the mandatory requirements for the concrete used in a particular work. When creating a strip foundation with your own hands at the site of future construction, it is worth considering that the main characteristics of the strength of concrete structures include resistance to axial compression, readiness to withstand tension and not respond to transverse fracture

Reliability correction factors can vary from 1 to 1.5

When creating a strip foundation with your own hands at the site of future construction, it is worth considering that the main characteristics of the strength of concrete structures include resistance to axial compression, readiness to withstand tension and not respond to transverse fracture. Reliability correction factors can vary from 1 to 1.5.

Protective measures for wood processing

High-quality wooden piles for foundations are the key to the durability and reliability of the supporting structures of a house or other structure. If for some reason the wood material was not treated before installation in the ground, such a wooden pile foundation will be susceptible to rotting under the influence of moisture and freeze-thaw cycles and will become unusable after a few years.

Wood processing must be carried out before it is installed in the ground.

Treatment of wooden piles with antiseptics

The modern building materials market has a large assortment of factory-made liquid antiseptics, which have different price characteristics. Preparations for protecting wood from rotting are classified by type:

- Water soluble.

- With an organic oil or alcohol base.

- Combined.

Antiseptic compositions are available in the form of solutions or concentrates, applied with brushes or mechanical sprayers.

Treating wood with antiseptic

Alternative wood processing

In order not to spend significant amounts of money on the purchase of ready-made antiseptics, you can remember and apply ancient methods of treating wood against rotting:

- Charring of wooden foundation structures. The wooden post or pile must be cleared of bark and after sanding, the lower part is carefully charred with a blowtorch or propane torch.

- Treatment of poles with birch tar, waste machine oil or molten petroleum bitumen. This method of creating protection is considered the simplest and cheapest.

- Wrapping wooden foundation structures with sheets of roofing material. The log or post is first coated with molten bitumen and then wrapped in roofing material. Most often, roofing felt is used for this purpose.

Experts recommend using wood harvested in winter for wooden foundations.

It is believed that winter wood has increased resistance to destructive rotting processes and is better able to withstand temperature changes and precipitation than others.

Methods for treating wood against rotting can be seen in the video:

Wooden larch foundation

A high-quality wooden foundation can be made from certain types of wood: these can be deciduous or coniferous trees. If it is possible to use larch for the material of wooden posts and piles, then this will be the best ideal solution.

Larch timber is the best material for constructing a reliable and durable wooden foundation

A larch foundation can withstand any load and has excellent bacterial resistance. In addition, the fiber of this wonderful type of wood contains many essential resins, which themselves are natural preservatives.

Larch wood has a high density, which makes its processing difficult and time-consuming.

The procedure for constructing a wooden foundation

A wooden foundation for building a house can be done using 2 methods: by installing wooden piles and laying sleepers from logs. The most common and reliable method is a pile foundation.

Pile wooden foundation

Wooden piles are installed in prepared earthen trenches, which look like pits and are located over the entire area of the building site. The width of the trench must be 1.5 times the diameter of the wooden pile. Piles are placed at all external corners of the building, at the intersections and junctions of walls. For corner supports, logs with a diameter of at least 300 mm are used.

Scheme of wooden piles arrangement

Intermediate supports are installed between the corner piles in increments of 1.5 - 2 m. After installation, all piles are combined with a wooden grillage into a single strong supporting structure.

After installing the wooden piles, the pits are backfilled using medium-fraction crushed stone.

Strip wooden foundation made of wooden sleepers

If you need to make a wooden strip foundation for lightweight buildings, then the most suitable material for these purposes would be to use old railway wooden sleepers with a cross-section of 200 x 200 mm. The work is performed in the following sequence:

- First, you need to mark the foundation and dig earthen trenches with a depth of about 400 mm.

- A drainage layer of crushed stone or gravel up to 200 mm high is laid at the bottom of the trench.

- Wooden sleepers are laid on top of the drainage, fastened at the corners into prepared grooves.

- When installing additional rows of wooden sleepers, it is necessary to fasten them together.

- To fasten rows of sleepers, it is recommended to drill through holes and drive in reinforcing bars.

Watch a video example of a wooden foundation:

The construction of a strip wooden foundation made from sleepers is the simplest and most inexpensive type of load-bearing foundation. Since railway sleepers are initially impregnated with a powerful antiseptic, creosote, such a wooden foundation can last for decades.

Ways to protect wooden foundations

Unprepared wood quickly rots from contact with water and soil, and the part of the pile that is close to the surface is first affected by rot. To avoid this, the pile tree requires protection. We begin preparing wood for pile foundations with sanding.

Then we treat the wood with special antiseptic compounds. A simple but effective remedy is the following solution: dissolve 950 g of table salt and 50 g of boric acid in five liters of boiling water. We treat the piles with the resulting solution 2-3 times. This simple treatment of a wooden foundation will triple its service life.

The modern antiseptic industry offers more effective products. When using them, you must strictly follow the instructions and carefully observe safety precautions.

Regardless of the compositions used, home treatment has a serious drawback: the thickness of the protected wood layer does not exceed a few millimeters. Therefore, when deciding how best to make a wooden foundation with your own hands, you should use industrial pressure impregnated wood.

In addition, for additional protection, the wood can be coated with tar. Or, use the recipe of ancient architects, burning wooden pillars over low heat until the top layer of wood is charred. The sintered crust prevented the wood from rotting, extending the service life of the wood by one and a half to two times. At home, firing can be done with a blowtorch.

Service life and their changes during processing, depending on the type of wood, can be seen in the table.

| Wood species | Standard service life, years | |

| unprocessed | processed | |

| Larch | ||

The numbers in the table are guidelines and are approximate downwards. It is known that most of the buildings in Venice have stood on the water for centuries. And it stands on wooden stilts made of larch. St. Petersburg is built on swampy soil, where most of the buildings, including the beautiful St. Isaac's Cathedral, stand on wooden ridges.

To conclude this section, some advice: our wise grandfathers and great-grandfathers harvested wood for buildings only in winter, when there is no sap flow in the tree, and the available moisture partially freezes out. This wood dries faster and lasts much longer.