Not only the car should feel comfortable in this place (not damp and safe), but also its owner. Why is expanded clay concrete the right option for building a garage in this regard?

And if the choice fell on this material, how to build a garage with its help? Practical advice and high-quality theory is what the reader will receive from this article.

Is it worth making a building from such material?

When deciding whether to choose expanded clay concrete as a building material for a garage, it is important to consider several points :

Expanded clay concrete, unlike brick, allows walls to “breathe” due to its porous structure. Therefore, moisture will not accumulate in the walls, but will go outside.- Expanded clay concrete does not like humid climates.

Therefore, if the garage will be built in such an area, then it needs to be additionally finished (at least with plaster). If the owner does not have extra money for additional protection, then it is better to think about using another material that would be less susceptible to moisture and could stand without external finishing. - Expanded clay concrete is a fairly durable and frost-resistant material. Therefore, in harsh climates its use is recommended by experienced builders. Expanded clay concrete products are not deformed and will not be destroyed by cold, frost, or wind. The service life of such a garage will be tens of years.

- This is a relatively cheap and economical option. Therefore, for a small budget, expanded clay concrete is what you need.

- In the event of a fire, you can be sure that the garage walls will withstand open fire for 8 hours and will not collapse. This is especially true if a lot of flammable substances (gasoline, varnishes, paints, etc.) will be stored in the garage. The amount of flammable objects will not affect the fire resistance of expanded clay concrete.

- If the car owner spends a lot of time in the garage, then he may not worry about his safety from the environmental side. Expanded clay concrete is a safe material and does not emit toxic and toxic substances (which cannot be guaranteed when using cinder blocks).

Requirements for walls and stone

It is recommended that the construction of load-bearing external walls be carried out in 2 blocks. If we are talking about internal load-bearing structures and partitions, then you can build in 1 block.

Blocks can be of different sizes, both standard and non-standard. But the most popular dimensions are:

- 200×200×400 mm;

- 200×300×600 mm;

- 100×300×600 mm.

The first two options are suitable for the construction of external walls, and the last - for internal walls and partitions.

The strength grade that blocks for garages should have can vary from M50 to M75. Only in the first case, expanded clay concrete M50 is used for garages with a 1st floor, and in the second - for the construction of garages up to 2 floors.

The strength grade affects the energy efficiency of the building, its durability, sound insulation of the constructed walls and the reliability of the garage. The higher the strength grade, the higher these performance indicators.

The density must be at least D600 . The higher the density of expanded clay concrete, the fewer air pores it will have, so the material will be stronger, but its thermal insulation properties will be weaker.

Frost resistance for blocks used in the construction of a garage must be at least F75, i.e. 75 freeze-thaw cycles.

Rules for drafting a project

Construction must begin with drawing up a project. Working without a drawing is the same as going to your destination in an unfamiliar city without a map. You can get lost and spend a lot of time and effort trying to reach your final goal. It's the same with the garage. If you do not have clear dimensions and guidelines in construction, then it is impossible to erect a reliable and strong building.

On paper or in a computer program you need to draw a plan that takes everything into account:

- Garage dimensions.

- Type and dimensions of the base.

- Roof type.

- Calculation of the amount of expanded clay concrete.

- The presence of an inspection pit, cellar and other utility rooms inside the garage.

- The size of the car so that it fits into the garage and the doors can be opened without hindrance.

For modern cars, it is enough to build a garage approximately 4 m wide, 7 m long and 3 m high. This room will fit a car and other useful things (tires, spare parts, racks with tools).

In order to calculate the number of expanded clay products required for the construction of a structure, it is necessary:

- Calculate the area of all walls being built. If we take into account the parameters mentioned above, then the area is: (4×3)+(7×3)+(4×3)+(7×3)=66 m2.

- Calculate the area of window openings and gates. Let's say the windows are 1 m wide and 1 m high, and the gates are 2.5 m wide and 2.5 m high. It turns out that the window area is 1×1=1 m2, and the gate area is 2.5×2.5=6.25 m2.

- Now you need to subtract the area of all openings from the previously calculated area of the walls: 66-1-6.25 = 58.75 m2.

- Next, you need to find out the area of one block, depending on its dimensions. If products with dimensions of 200 × 200 × 400 mm are taken, then the area is 0.2 × 0.4 = 0.08 m2.

- The last step is to calculate the number of elements to build a garage. For this purpose, the area of walls without openings must be divided by the area of one element, i.e. 58.75/0.08=735 blocks.

- If the laying of external walls will be carried out in 2 blocks, then the resulting figure should be multiplied by 2 and another 5% added to it - for possible defective products or for broken blocks during work. It turns out that about 1545 blocks are needed to lay the garage. And if there are additional rooms or partitions inside the garage, then their number is added to the resulting number.

The number of blocks for internal masonry is calculated according to the same scheme as for external masonry . The only exception is the 6th point, because the masonry will be carried out in 1 block, so there is no need to add anything.

The garage layout may look like it has other dimensions, depending on what the owner wants from the garage. Some options are shown in the photo below.

Typical projects with photos and drawings

In order to choose a suitable project for a bathhouse made of foam blocks, you must first decide on the site that is at your disposal, as well as what you expect from your structure. Meticulous planning is a mandatory item in the “preparatory” program, but if you do not want to deal with the distribution of key zones, then use ready-made projects. They already provide for the separation of a sink and a steam room, and there is also an allocation of space for a relaxation room, a dressing room, and in some cases a veranda. Information on how many foam blocks are needed for a bath is in each size section.

3x3

How many foam blocks are needed: 134 pcs. (4.82 cubic meters)

Project options for those who want to build a compact bathhouse. Both separate washing and steam rooms are allowed, as well as combining two zones into one.

4x4

How many foam blocks are needed: 196 pcs. (7.06 cubic meters)

A selection of bathhouse projects with one of the most common sizes. The square base allows you to make good use of every centimeter of usable space.

3x4

How many foam blocks are needed: 172 pcs. (6.19 cubic meters)

A very viable rectangular and quite compact solution will undoubtedly appeal to those who do not have a reserve of square meters at their disposal.

6x4

How many foam blocks are needed: 245 pcs. (8.82 cubic meters)

An excellent selection of bathhouse projects that provide literally everything: a spacious dressing room, a relaxation room, and a veranda. The layout of bathhouses with an attic allows you to include in some cases a games room with a billiard table.

5x5

How many foam blocks are needed: 267 pcs. (9.61 cubic meters)

A project with the placement of functional areas for a spacious square bath.

Materials and tools

Having dealt with the garage project, you need to move on to collecting and purchasing consumables and equipment for the job.

The builder will need the following:

- expanded clay concrete products;

- adhesive mixture or cement-sand mortar, which includes cement, sand, water and expanded clay (if necessary, additives are also added);

- reinforcing mesh or reinforcement;

- waterproofing material;

- shovel, trowel, spatula and comb - for mixing the solution and applying it;

- mixer or drill with a whisk - for mixing the components of the mortar mixture;

- level, square, tape measure, fishing line, cord, pencil and marker - for marking and checking the evenness of the masonry;

- wall chaser - for cutting grooves for reinforcement;

- a hacksaw, a grinder with a stone disc - for cutting elements into the required sizes and shapes;

- mallet with a rubber head - for tapping the elements in order to shrink them into the correct position;

- bucket, basins - for transporting and storing the solution;

- concrete mixer - for mixing the solution.

Required Tools

When building a garage from expanded clay concrete blocks, you should take care in advance of such tools as:

- Bulgarian;

- perforator;

- electric drill;

- screwdriver;

- construction mixer;

- vibrator;

- shovel;

- scrap;

- hammer;

- sledgehammer;

- rubber hammer;

- Master OK;

- putty knife;

- paint brush;

- roller;

- knife;

- scissors;

- hacksaw for metal;

- pliers;

- roulette;

- plumb line;

- building level.

DIY masonry instructions

The process of laying a garage from expanded clay concrete blocks is not much different from laying other buildings made of the same material, for example, a house.

But there are still some nuances that need to be taken into account and additionally done :

- Prepare the area for pouring and laying. The area must be thoroughly cleared of trees, tree and plant roots, stumps, grass, and debris. This stage is extremely important, especially if an inspection hole is being built in the garage, which will go several meters deep into the ground. Therefore, the area needs to be well cleaned and leveled. If you cannot do this manually, then it is better to hire special equipment. Deep holes are filled up, and excess mounds are leveled to the ground.

- Prepare the base for pouring the foundation. To do this, a trench 30 cm wide is dug. The soil is compacted and a film is laid on top of it, onto which sand and gravel are poured (layer thickness 10 cm). Then concrete solution is poured into this trench.

After the perimeter of the base has been poured, the floors themselves are poured. At the same time, the concrete must be strong to withstand the weight of the car and other items that will be stored in the garage.The load experienced by the garage foundation is several times stronger than that experienced by the foundation of a living space. A strip rather than a column foundation is suitable for a garage. When building a foundation, it is important not to forget to make an inspection hole, if it was provided for by the project.

- After the foundation has dried (and this will take 3-4 weeks), you can begin laying the walls. To protect the walls of the garage from dampness, you need to lay waterproofing (several layers) on top of the base to the width of the wall. You can use roofing felt - it is a cheap and reliable material.

Masonry starts from the corners. The first row is always mounted on a cement-sand mixture, and then, to reduce cold bridges, you can use an adhesive mixture. Then the seam thickness will be 2-3 mm. Each row must be checked with a plumb line, level and line so that the garage is level and the last row is level on all 4 corners.The second and every even row begins with laying a half block. You should not build more than 3-4 rows around the perimeter per day, otherwise the walls will shrink greatly from the total weight of the structure.

- Don’t forget to leave space for window openings and gates during construction.

- Build a roof. Any roof is suitable for a garage (gable, single-pitched and flat).

- Complete the construction by finishing the exterior walls (and, if desired, interior walls).

Construction technology

First, we clear the necessary space, get rid of bushes, stumps and small trees.

Foundation and floor

A trench is dug around the perimeter of the proposed garage, 30 cm wide, and a film is laid along the even walls of the trench. A sand and gravel cushion is laid out at the bottom of the trench in layers and filled with water, the height of each layer is about 10 cm. At the final stage, the concrete mixture is poured until it dries completely.

The floor must support the weight of the car; it is laid in almost the same way as the foundation. To begin with, the soil is compacted, covered with film, and a sand and gravel cushion is poured. To increase strength, a reinforcing mesh is laid and filled with a sand-cement mixture, preferably with the addition of crushed stone.

Walls and roof

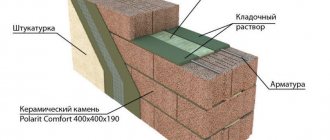

When constructing garage walls, the technology for laying expanded clay concrete blocks is almost the same as for bricks. A cement-sand mixture with a reinforced mesh along the width of the wall is applied to the finished foundation; the mesh is necessary to ensure that the solution does not leak outside the block. Next, a block is placed, a mixture is applied at the junction with another, and so on. The next row is placed offset by half a block so that the pressure of the wall mass is distributed evenly. Particular attention should be paid to external seams, distributing the mortar evenly between the blocks.

To cut blocks, it is better to use specialized equipment, for example, a grinder. Openings for windows should be reinforced with wooden boards. If desired, you can insulate the expanded clay concrete walls of the garage with polystyrene foam from the inside, and the outside can be covered with a cement coat. You need to make a hole on the back wall for natural ventilation.

The roof is installed according to the specified design. To begin with, load-bearing beams are installed along the walls, then the frame itself, which is covered with boards and roofing felt on top to prevent water from entering.

Insulation of the garage

The most optimal insulation option is a multilayer system, which involves laying three layers. For the first layer, foam or fiberglass is used. The second layer is polyethylene, which protects from moisture. And the third layer is a finishing material, for example, drywall.

The final stage of building a car garage from expanded clay concrete blocks is the plastering process, after which detailed finishing is performed, for which all kinds of materials are used and the most daring creative ideas are embodied.

Advantages and disadvantages of expanded clay concrete

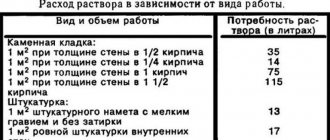

Laying expanded clay concrete blocks requires 2 times less mortar than similar brick laying .

And the construction time is several times faster than when using brick. This plus is especially important both when doing the masonry yourself and when using specialists, where each of their working days must be paid.

Due to the porous structure of the elements, the optimal temperature and humidity coefficient are maintained in the room . Therefore, the car owner will feel comfortable staying in this room. The thermal insulation properties of expanded clay concrete are several times higher than those of brick or concrete walls.

Some even additionally insulate an already built garage with a wall of 1 expanded clay concrete block, and then finish the material.

Additional advantages of the material:

- fireproof;

- not subject to rot (unlike wood);

- non-toxic (unlike panels or cinder concrete);

- resistant to temperature changes;

- requires special care.

In addition, the products are lightweight and inexpensive. Moreover, the first indicator pleases the builders, and the second – the car owner.

On blocks made of expanded clay concrete, you can freely fix hanging shelves and cabinets with tools with dowels. The walls will withstand such a load, cracks will not appear on them, and they will not deform over time.

The downside is that the expanded clay walls of the structure cannot be left without finishing (although in the case of other building materials this point could be skipped). And the point is not that the look will be considered unfinished, but that expanded clay concrete does not tolerate direct exposure to moisture.

Rain and snow will simply fill the pores of the product and begin to destroy it from the inside. Therefore, walls necessarily require additional finishing cladding (siding, lining, plastic panels, decorative plaster or stone, ceramic tiles).

Foundation for a garage made of expanded clay concrete blocks

The advantages of expanded clay determine its choice as a material for the construction of buildings for residential, commercial and technical purposes. To build a garage, you can use one of two types of foundations made from the same building materials. The use of foamed baked clay filler in combination with sand and cement gives the product the specified parameters of thermal conductivity, resistance to external influences, and sound insulation. Expanded clay concrete products serve effectively in low-rise buildings. Let's consider the construction of a garage from cinder blocks sequentially.

What to consider in the project

The process of digging a trench for the foundation

Difficulties in work and mistakes of builders

It is better to carry out construction work from expanded clay concrete in the warm season - from late April to early October, when the thaw has already ended and the ground is ready for digging trenches, and the walls are not threatened by temperature changes and frequent rains with snow. As a result, the foundation will be strong and the walls in the structure will be reliable.

During the work process, there may not be enough expanded clay concrete blocks. And you'll have to buy them again. But only a new batch may differ in color and texture.

To prevent this from happening, it is worth remembering a simple rule: professional builders need to order 5% more blocks than indicated in the project calculations, and beginners and those who do everything with their own hands - 10% more (taking into account inexperience and defects in the finished product) .

The lack of a drainage and ventilation system is another mistake when building a garage.

The drainage system is especially important if the garage has a viewing hole or cellar. To do this, special drainage gutters with a slope are laid along the entire perimeter of the building so that the water flows into a common collector or sewer. And the ventilation system needs to be thought out at the construction stage, leaving several holes in the wall.

Construction project

A garage made of expanded clay concrete blocks with your own hands should have optimal dimensions, i.e. allow you to comfortably keep your car in the smallest room dimensions. The design of a future garage begins with determining its size. How to calculate them correctly and rationally?

In the old days, this problem was easily dealt with: the standard garage size was 3x6 m, which made it possible to comfortably service a domestic car. Currently, the range of automobiles has expanded significantly, and more and more people want to have a spacious car for the whole family. Naturally, the previous standards can no longer satisfy the new needs of car enthusiasts.

When calculating the size of a garage, the following factors are taken into account: the size of the car, taking into account open doors; the presence of shelving, a workbench and other equipment, as well as furniture; the need to store other large items and small vehicles (bicycles, mopeds, scooters, etc.); planning of highways (ventilation, water supply). Dimensions must take into account space for passage, maintenance and repair of the machine. Taking into account these circumstances, it is generally accepted that the average size of a modern garage is 4x7x2.8 m.

Prices for professional work

Not everyone has the desire, skills and ability to carry out masonry work themselves. Therefore, some hire workers so that specialists can do everything themselves. You will have to pay for such work. On average, the price in Russia ranges from 1,500 rubles. up to 2,000 rub. for 1 m3 or from 12,500 rub. for 1 m2 .

There are also construction teams that build a garage from scratch and do it for 112,500 rubles. This cost includes pouring a strip foundation (RUB 18,000), block laying (RUB 39,000), roof installation (RUB 48,000), wall finishing with facing bricks (RUB 15,000) and other work (installation of a ventilation system, drainage, installation of windows and gates).

Photo

What kind of garage can be built from expanded clay concrete can be seen in the photo: