Home / House / Porch

Back

Published: 03/29/2021

Reading time: 14 min

0

If there is a house, there must be a porch. This is an axiom and until people have learned to fly like birds, it does not need proof. But even today experts have not come to a consensus about the architecture of the porch and the most suitable materials for its manufacture.

Therefore, in this review, we will first look at what options are generally possible here, and then we will go through in detail one idea that, in our opinion, deserves attention. And we’ll even show you how to build a semicircular porch with your own hands.

So, Wikipedia states that a porch is an external extension that has an overhang and steps. It serves to protect the front door area from bad weather and at the same time performs decorative functions.

And now, this last point is important for us now. After all, in fact, if you don’t think about beauty, then it becomes unclear why these round steps are needed at all?

They are more difficult to manufacture and operate and are much more dangerous than their rectangular counterparts. In addition, the form imposes some restrictions on the list of structural and finishing materials. In a word, for the sake of a design you like, you will have to suffer a lot.

But let’s be consistent and briefly go over the entire range of possible options, focusing only on those products that allow us to make a staircase in the shape of a semicircle.

- 1 Wooden porches

- 2 Metal porch

- 3 Stone porch

- 4 Round porch and its disadvantages

- 5 How to make a semicircular porch from concrete

- 6 Laying tiles on a round porch

Wooden porches

Wood is traditionally considered a universal building material and, of course, it is used in the construction of a porch. At the same time, it can perform both structural and finishing functions there.

In the first option, timber and boards are used to create a supporting frame. In the second - for covering ready-made metal and stone bases. But in both cases, the master gets the opportunity to work not only a rectangular, but also a round porch.

Metal porch

A worthy analogue of wood is iron. To process it, however, a plane and an ax will not be enough, but hand-held power tools have long ceased to be in short supply. An inverter welding machine or grinder is probably in the workshop of every self-respecting summer resident.

And even if you have to buy all this from scratch, it's worth it. After all, steel has an order of magnitude greater strength and structural flexibility than wood, and therefore it is also possible to make a nice, semicircular porch or at least its frame from it for a private home.

How to make a foundation

Heavy concrete semicircular steps need a solid foundation, which is equipped as follows:

- The area under the foundation is cleared, a pit is dug 20-30 cm deep.

- It is filled to the middle with sand and compacted.

- Geotextiles are laid on top, the space remaining to ground level is filled with crushed stone, and on top with cement mortar.

- If the porch is small (two steps), they limit themselves to filling the pit halfway with medium-fraction crushed stone, and filling the remaining space with cement mortar.

A neat semicircular porch in front of a small terrace Source dekoriko.ru

Stone porch

And finally, the third most common building product in the field of porch construction is stone. Moreover, both natural and artificial. Rubble, concrete, marble and porcelain stoneware - all these materials have enviable strength, wear resistance and considerable weight in common.

To work with them you will also need glue and solutions. That is, water will necessarily be present, which in turn will require some time for its evaporation. Perhaps this is why impatient summer residents prefer faster technologies.

But this is if we mean an ordinary open veranda. If we consider a porch made of stone in a semicircle, then these will account for about 90% of all figured steps. Remember how often you have seen an oval porch made of wood or metal?

But tiled radial staircases will probably decorate a familiar store, hairdresser or porch of a massage parlor. So in this article we will consider just such semicircular steps. For a private home, a threshold cast from concrete and tiled will serve as an excellent decoration.

Installation

All work can be divided into three stages:

Stage No. 1: selection of material

Above, we have already determined a priori that we will consider a concrete structure, but it is worth considering that a semicircular porch can also be made of wood or brick:

Advice: if you decide to make semicircular steps from wood, then be sure to take care of creating a canopy of a sufficiently large size and treating it with moisture-proofing agents. Such measures will maximize the protection of the structure from premature rotting and destruction.

As you can see, concrete is the ideal option for accomplishing your plans on your own. In addition, it should also be noted that it can then be “dressed up” with almost any decorative finish suitable for the occasion, which will make the design also unusually beautiful.

Stage No. 2: calculations

Before you build a porch in the form of a semicircle, you need to perform the necessary calculations. At the same time, the definition of some parameters does not differ from classic rectangular structures:

| Parameter name | Approximate value |

| Width | At least 30 cm, but more is quite acceptable, since the staircase in this case is external. |

| Height | No more than 18 cm, as then it will simply become uncomfortable to raise your leg. |

| Number of steps | It is found by dividing the total height of the porch from the ground to the platform by the size of the tread. Perform calculations until the value is an integer. |

- We create a drawing in real scale, setting the height, width and even the radius of curvature of future steps.

- We determine the center of the circle enclosing the future construction. It is usually located on the threshold of the doorway.

Stage No. 3: construction

Advice: cement, sand, reinforcement and other materials used are not particularly light, so it is recommended to enlist an assistant before starting work. This will not only speed up the process, but will also allow you to preserve your own health.

The porch in a semicircle begins to be built with your own hands from the foundation:

- We apply markings on the ground in accordance with the created drawing.

- We dig a pit with a depth of 50-70 cm according to the marks.

- We fill the bottom with a 20 cm thick cushion of sand mixed with crushed stone and compact it thoroughly.

- We create a waterproofing layer from roofing felt or other material suitable in its qualities.

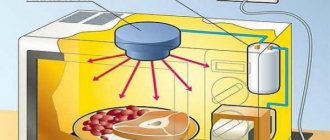

- We construct formwork from plastic lining or flexible sheets of metal, which repeats the outlines of the future porch conceived in the diagram. Traditional boards and plywood may not fit rounded shapes and will crack if you try to bend them enough. We support the structure along the edges with vertical reinforced rods.

Formwork made from flexible sheet metal strips

- In the place where the array of steps will come into contact with the foundation of the house, we also lay a waterproofing layer. This is necessary to compensate for the shrinkage process of the porch.

- We reinforce all treads with a metal mesh, tying it together with wire. This will allow the screed to strengthen properly.

Round porch and its disadvantages

And yet, before you start pounding sand and cement with your own hands and knitting reinforcement, I would like to remind you that a round porch, especially one cast from concrete, is not without its drawbacks.

- Injury hazard. We associate the circle with freedom and lack of boundaries. But where there are none, there are no landmarks, and therefore it is easy to fall from the semicircular steps not only in winter, but also in the dark season, especially when the “client” is drunk.

- Overuse of material. Tiles, boards, panels - most traditional building materials are rectangular in shape and when building smooth lines from them, unclaimed trim will inevitably remain.

- Technology limitation. For example, you do not use aluminum anti-slip strips on oval steps, nor do you use abrasive tapes. More precisely, you can, of course, glue them there, but they will look terrible.

- Increased demands on the professionalism of the master. Not every tiler will take on tiling a semicircular staircase. More precisely, not everyone has the necessary experience for this.

Aren't you scared? Then let's move on to step-by-step instructions.

Stages of work on pouring a round porch

The whole process is divided into several stages, each of which is important. So:

Preparing the base

The area must take on a large load - a concrete platform and several tiers of steps, so neglecting preparation means dooming the porch to rapid destruction from freezing and moisture. The preparation of the common platform is as follows:

- A pit is dug up to 120 cm deep, taking into account soil freezing. You can focus on the foundation of the house. The bottom should be carefully leveled and spilled with cold water. This will retain moisture approaching the concrete base from the inside.

- Sand and crushed stone layers are compacted to the bottom. Each of them should be at least 15 cm. In addition to protecting the concrete platform from moisture, the layers will act as the necessary insulation of the concrete and cushion subsequent loads, preventing the porch foundation from cracking.

Now you need to install the formwork for the concrete rectangular porch platform. For this purpose, shields and supports are used. We must not forget about reinforcement - steel rods are simply stuck into the ground. After this, the site can be filled.

- Installation of formwork for a round porch. In general, pouring a completely round porch into several tiers occurs in multiple stages - this is easier for novice craftsmen. First the first ring is poured, then the second and so on.

- Reinforcement. For this, a rod and wire are used for tying. Vertical elements are simply stuck into the ground through protective layers.

So, formwork: for this purpose, a strip of plywood is used 3-5 cm wider than the step. It is soaked in water to give the material flexibility and is fixed with a small block. Then it is installed in the ground - for convenience, you can put several pegs on the surface and sink them together with the plywood into the ground.

Horizontal rods are tied with wire in appropriate places. The fixation must be rigid to support the mass of concrete. It is impossible to weld the reinforcement together, since high temperatures have a destructive effect on it.

Actually, the preparation of the structure for pouring is completed. You can start preparing the solution.

For self-mixing, a home construction mixer is advisable - it will make the solution plastic and save its own strength.

However, buying it for a one-time job is impractical. You will have to acquire a suitable container, shovels and considerable patience - you should mix the concrete solution carefully and for a long time.

Fill

How to determine if the solution is ready for pouring? The mass, naturally, must be plastic and viscous, and before you make a round porch with your own hands, you should make sure that it is ready - the concrete collected in a handful does not fall apart when opened and does not leave dirty marks on rubber gloves. If the condition is achieved, then the concrete is ready.

Filling should be done evenly over the entire prepared area, not in bulk. Periodically, the entire thickness of concrete should be pierced with a rod to expel air and prevent the formation of voids, otherwise the steps will lose strength.

If the work is carried out in hot weather, then the finished surface is spilled with a large amount of cold water until white foam - milk - forms on the surface. This will prevent the platform from cracking and indicate that the mass has sunk to the bottom. The filling is left until completely hardened.

Arrangement of steps-tiers

After final hardening, the remaining tiers are made similarly to the first, only with a smaller diameter, taking into account the width of future steps. Each time a fresh strip of plywood is cut for a new ring.

To facilitate its separation from hardened concrete, the plywood is wrapped in film or rubbed with drying oil. Important - the vertical reinforced rods from the first ring must be of sufficient length for the entire structure.

Typically, a concrete exterior porch consists of three, rarely five, steps. This amount will not require handrails. If a canopy is initially planned, then holes must be made in the concrete area in advance for glasses to insert racks with a canopy, or they must be poured immediately, having previously wrapped the ends with waterproofing material.

Decoration

Solving the question of how to make a round porch from concrete is not difficult. However, the owners end up with an unremarkable gray cement “blank”. It has to be covered. Clinker tiles are recognized as the best material for this purpose.

Unlike brick or ceramics, it has the ease of processing and the strength of steel. A special feature will be giving the elements rounded depressions in order to combine them with the bases of the steps. How to do it:

- First, you should “try on” the material on a dry porch and mark the points for cutting.

- Next, the tiles are soaked in water. This will allow you to cut what you need in the future accurately and without chipping.

- Cut the tiles according to the lines. It is worth knowing that due to the thickness of the cement mortar, the actual dimensions should be less than the width of the joint.

- Only the elements adjacent to the base of the rings will require precise cutting. The rest can be of various shapes. Even broken tiles will do - by laying the fragments in disarray, you can achieve an unusual effect.

Laying tiles:

- Start from a concrete platform and then down. It is worth using special plastic crosses to maintain the accuracy of the lines or laying the tiles in a chaotic manner, which will look unusual and imaginative.

- After installing all the elements, the almost finished porch is left to set the decorative surface, and then grout is applied to the seams. It can be in contrasting colors or in harmony with the main background.

The concrete porch with decorative coating is ready. As a rule, maintenance of the structure is minimal - it is enough to keep it clean and not allow the fresh area to get too wet.

The rest of the time, such a porch will not require any manipulation from the owners. In winter, the formation of ice can damage the surface of the decorative coating or cause injury to residents.

Therefore, the owner should think about installing a canopy, canopy or other protection from external manifestations.

Achieving the best results in home construction is achieved through accurate calculations. Therefore, before you build a round porch with your own hands, you should carefully read and understand each point of the instructions for self-assembly.

The durability of concrete and the structure as a whole depends on this. If the processes are inaccessible to ordinary owners or there is simply no time for construction, you can always invite professionals to do the work - the price justifies the result.

Alexander Skorokhodov

Author of publications on 1Drevo.ru with topics: Options for dormer windows | Mansard roof | Townhouse | Rounding against chopped logs | Staircase design | Construction timeframe | Construction method | Log house for a cottage | Log house | Facade painting | Roundwood house | Caulk of log houses | Insulation | Glued laminated timber technology | Foundation Repair | Pile foundation and others.

Collections of publications on topics:

Laying porcelain tiles

Was this publication useful to you?

Bookmark it on social networks!

Total score: 0Votes: 0

How to pour a semicircular concrete porch at the entrance to a house

How to align poles for a canopy: pole installation technology

We recommend! — Encyclopedia Wooden Houses — NEW

You can find out detailed and expanded information on the topic of the article from the book “Wooden Houses,” which reflects all stages of building a house, from laying the foundation to installing the roof. Book price = 77 rubles.

You may also be interested in other BOOKS on building houses from wood with your own hands.

We recommend other posts on this topic:

How to make a wooden staircase for a country house

Staircases to the attic floor - what are the options

Which staircase design to choose for a rounded house

Building a staircase in a wooden house with your own hands

Manufacturing and installation of wooden interfloor stairs

Installation of an attic hatch with a ladder in a wooden house

How to make a semicircular porch from concrete

Let's start our master class with the fact that all concrete porches must be designed and cast together with the foundation of the house. Only this approach to the matter guarantees the absence of cracks between the threshold and the base of the mother building. But this is in theory. In practice, when building a house, the canopy over the front door is the last thing people think about, and the base for the semicircular steps has to be poured separately.

For example, consider this situation.

There is a flat façade with a plinth height of 500 mm and a clean area in front of it with non-heaving sandy soil.

Since our soil is not very susceptible to frost and does not accumulate moisture, we propose to build a porch on a floating slab foundation, but before that we will calculate the area of the building site.

- So, the optimal rise of the steps is 15 cm, so with a base height of 50 cm you will need 3 of them. One of which will also be the porch deck, and the other two will add 300 mm each to its dimensions. This time.

- The width of the door leaf of the entrance door is 0.9 m, which means the platform, at a minimum, cannot be narrower than this value. That's two.

- Someone must open the front door, and at the same time somehow miss it, and therefore you need to add at least another 30 cm to the original 0.9 m. That's three.

As a result, we have a building spot in the form of a semicircle with a radius of 1700 mm. 900 mm for door opening + 300 mm for maneuver space + 600 mm for two steps.

Porch design

When creating a drawing of the future porch, you should pay attention to several important parameters:

- The width of the semicircular porch (staircase) should be at least 80-85 cm. It is believed that this is the optimal parameter for the free movement of 1 person. Or you can navigate by the door. In this case, the width of the upper part of the semicircular staircase should be 50 cm wider. Also, the width of the stairs must fully correspond to its diameter.

- The ladder must be mounted at an angle of 45 degrees (less possible). The angle of inclination of each step should be no more than 5 degrees, the height should be 12-20 cm. In this case, one step can hang over the other by no more than 30 mm.

Healthy! The inclination of the steps is a must. Maintaining strict horizontality is very difficult. If you do not follow this rule, then a reverse slope is likely to form. As a result, after the rain you will see how water begins to accumulate on the steps. Sooner or later it will penetrate into microcracks in the grout and will collect under the tiles. In winter, water expands, which means it can destroy the finish and the concrete base itself. In addition, it is dangerous to walk on frozen water on the steps.

- There must be an odd number of steps. You can clarify their number if you divide the height of the staircase itself (the distance from the ground to the top point) by the height of one step.

- The difference between the front door and the upper platform of the porch can be no more than 50 mm. In this case, the platform must be calculated so that a person can freely open the door.

It turns out that if the door width is 70 cm, then the diameter of the porch platform will be at least 120 cm. It is recommended to make the upper step wider by about 25-30 cm on each side (compared to the diameter of the platform). If our platform turns out to be 130 cm, then the diameter of the upper step (regardless of their number) should be 190 cm. If we take into account the angles of inclination and other parameters, then the lower step should already have a diameter of 250 cm.

Healthy! To speed up the work, you need to find a central point (usually the center of the doorway) and, using a compass installed in it, draw a semicircle from one wall to the other. Using a similar technique, you can draw each staircase, adding 26-30 cm to the original radius.