Types of concrete grades

Concrete for the foundation of a fence includes water, sand, cement, gravel or crushed stone, and the strength and other characteristics of the material depend on their percentage, according to which it is divided into the following grades:

- M100-150

is the most affordable option, containing a large amount of coarse fraction. It is suitable for constructing a lightweight fence made of metal profiles on light soil with relatively flat terrain. - M200-250

are brands that optimally combine affordable cost and high quality. Foundations made from such concrete are suitable for creating medium-weight fences on sloping areas and difficult soils. - M300

- used for making bases for heavy stone fences in soils prone to freezing.

There are also higher grades of concrete, but their cost significantly exceeds the listed options, so their use for organizing the foundation of a fence is considered unprofitable.

Which brand of cement should I choose?

In practice, several methods of installing fence posts are used. The technology, which involves concreting fence posts, allows you to build a reliable foundation on any soil.

It’s not that difficult to make a mixture for fence posts yourself—you just need to know the recipe and choose a brand of cement.

Expert opinion

Vladimir Ulyanov

I have been involved in fences for over 10 years, answering questions and helping people cope with the installation task on their own.

Ask a question to an expert

To prepare the mixture, as a rule, the M-400 brand is more often used. The choice of brand is recommended based on the operating conditions of the fence.

Since the fence is subject to such loads - the weight of the fence, wind pressure, the binder must be of high quality. When choosing a brand of binder, you need to take into account the purposes for which it will be used.

When constructing a fence, concrete is used for the following purposes:

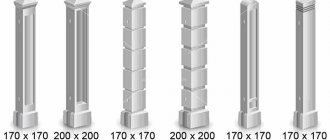

- production of solid fence posts;

- construction of a foundation for a fence;

- performing brick laying.

The marking of the binder includes two parameters required to obtain concrete

- ability to withstand a given load;

- composition of the material.

The ability of the mixture to withstand a given load is designated by beech M. M400 is capable of withstanding a load that lies within 400 kg/cm. The presence of the letter D indicates that this substance contains additives, that is, the D20 marking tells the user that the binder contains up to 20% of the volume of additives. These substances are responsible for the plasticity and strength of the mixture.

Useful Which poles are best to install for a chain-link fence and after how many meters

Some people believe that the numbers on the label indicate how much sand needs to be added to the composition. But this is far from true. These figures are the result of numerous studies and tests carried out in factory laboratories.

To conduct research in the laboratory, a cube measuring 100*100*100 mm is made. The cube is destroyed using power machines. If it collapses under a pressure of 400 kg/cm, then the M400 grade is assigned to this product.

The brand, volume of additives and other technical parameters are indicated on the label of the cement bag. As a rule, such data is placed on the front of the bag. For work, cement grades M400/D20 and M500/D20 are most often used.

- The first brand is resistant to frost and moisture. And suitable for constructing foundations for fence posts.

- For brickwork, a second grade of cement is used. In addition to the fact that this cement resists frost and moisture, M500/D20 cement resists rusting.

Key selection criteria

In order to select the correct grade of concrete for the strip foundation of a fence, it is necessary to take into account the type of base. When installing lightweight fences, the choice is most often made on a pile foundation, for which inexpensive concrete M100 or M150 is suitable. If a heavier structure is being erected, it is recommended to make a strip foundation using M200 compounds. Massive brick structures require a columnar monolithic foundation. In this case, concrete M250 or M300 can provide maximum strength.

To find out what brand of concrete is needed for the foundation of a fence, in addition to the type of structure, it is necessary to take into account additional criteria, which include:

- Water resistance

- this criterion must be paid attention to if the foundation will lie in an area located in a lowland or with a high risk of flooding with groundwater. This parameter is designated by the letter W and varies from 2 to 12. The higher the number, the greater the resistance to moisture. - Frost resistance of concrete

is designated by the letter F and determines the ability to maintain the performance characteristics of the composition for a certain number of freezing and defrosting cycles. Their number is indicated next to F. - Mobility

- this characteristic determines the plasticity of the solution, on which the ease of working with it, uniform distribution over the formwork and the ability to fill geometrically complex structures with many hard-to-reach places depend. But, it should be borne in mind that mobility is achieved mainly by increasing the volume of water, so the frozen base turns out to be less reliable and durable.

In order to correctly select the grade of concrete for a strip foundation for a fence, it is recommended to pay attention to the wind loads inherent in a particular area. With their high performance, it is recommended to use grade 250 and higher, since solid enclosing structures are characterized by high windage.

What concrete to make the foundation from?

Most often, the foundation for the fence is made of M100-250 concrete. For tape construction use M150-250. It is easier to concrete the pipes of a pile foundation or erect a columnar foundation for a fence using M100-150 concrete.

The type of soil is important when laying the foundation. Inexpensive and not particularly reliable, M100 can only be used as a foundation base, which is poured into a hole in front of the formwork, concreting pipes, installing pillars or building light fences in light soils. In places with difficult terrain and heavy soil, you need to choose concrete for the fence of a grade of at least M200.

How to make the right brand of concrete yourself?

To properly prepare concrete, it is necessary to strictly observe the proportions of the main components of the composition: cement, sand, crushed stone. Each grade of concrete for a fence foundation has a certain ratio, each of which is indicated in the table:

| Concrete grade | Volume of concrete from 10 liters of cement | Component ratio C:P:W (kg) |

| M100 | 78 | 1:4,6:7 |

| M150 | 64 | 1:3,5:5,7 |

| M200 | 54 | 1:2,8:4,8 |

| M250 | 43 | 1:2,1:3,9 |

| M300 | 41 | 1:1,9:3,7 |

To obtain the required grade of concrete, add cement and sand to a special container or concrete mixer, which must be mixed well until a homogeneous mixture is obtained. Then it is introduced into crushed stone and also mixed. During the kneading process, water is added in portions until the required density of the composition is obtained. When mixing concrete mortar, it is not recommended to change the proportions, as the strength of the base can be greatly reduced.

Composition of the mixture and its characteristics

The concrete mixture consists of several components. Four of them are mandatory:

- Water.

- Cement.

- Coarse aggregate - crushed stone.

- Fine aggregate - sand.

As necessary, special additives are introduced into concrete - antifreeze, plasticizing, gas-forming, inhibiting, catalyzing, waterproofing, pigment, increasing strength characteristics.

Binders and fillers

Cement is the most used type of binder in construction. This powder, produced by firing limestone and clay together, binds water to form solid compounds. Cement is not used in its pure form - it cracks when it sets. But in combination with fillers, it shows its qualities.

Cement is characterized by brand and class. The grade is the average tensile strength of a sample from the standard composition of a mixture prepared on the basis of cement, and the class is the guaranteed strength of such a sample.

The filler most often is crushed limestone, although in some cases granite is used. Sand serves as a fine aggregate. There are certain requirements for their quality. Thus, they should not contain clay particles, organic contaminants, or chemical impurities. Before mixing, all this must be removed by washing the aggregate.

Parameters of ready-made formulations

The mixing of concrete is calculated in advance, because the characteristics of the finished structure will depend on the proportions of the components. These include the following parameters:

- concrete grade;

- frost resistance;

- water permeability;

- workability;

- hardening time.

But it is possible and even necessary to plan for appropriate strength. If you plan to concrete a structure using a concrete pump, you should consider ensuring that the concrete has a good cone settlement, that is, it is mobile. Otherwise, the pump will either not work or become clogged.

Compliance with technology

When mixing concrete yourself, you should follow the rules for preparing the mixture and laying it. You also need to remember about creating conditions for hardening, especially if this is done in hot, dry or, on the contrary, frosty weather. The sequence of actions during kneading will be as follows:

- Measure out the required amount of ingredients.

- Pour water into the concrete mixer.

- Add all the cement there.

- If it is planned to introduce an additive, then it is added to the water-cement mixture.

- Pour sand and crushed stone into the mixture.

- Mix thoroughly until smooth.

The concrete is placed into the formwork immediately. You shouldn’t take long breaks, so it’s better to fill large structures with ready-mixed concrete from a mixer. During installation, the poured mixture must be vibrated. There are special tools for this - vibrators. Small volumes can be compacted with a shovel or knocked on the formwork with a hammer. Failure to comply with this rule will reduce the quality of the concrete - air bubbles will form in it, which will negatively affect the strength and other characteristics of the hardened concrete.

The procedure for pouring the foundation

If you have already decided what brand of concrete is needed for the foundation of the fence, you should start arranging it. In order to obtain a high-quality, solid foundation, it must be poured and the following steps must be observed:

- Clearing the site for installing the fence and installing markings.

- Digging a trench for a foundation or holes for pillars. The depth will depend on the height of the fence, but usually varies from 0.5 to 1 m. The width of the trench is made within 30-40 cm.

- Installation of formwork from boards or other wood material. The height of the formwork must be at least 15 cm.

- Organization of a gravel-sand cushion about 25 cm high with backfilling of materials and their compaction.

- Laying a reinforcing frame made of rods, 6-8 mm thick.

- Filling the trench with concrete and carefully spreading it using hand tools or special vibrating equipment. This will remove air from the mixture, avoid separation and provide the necessary strength.

The formwork is removed no earlier than after 8-10 days, after which the installation of the fence begins.

Author of the article

Composition of mortar mixture for fence posts

The mortar for fence posts consists not only of cement, sand and water are also added to it. In some cases, for example, to prepare a mortar that is used to build brick fence posts, any brand of detergent is also added to it. According to experts, this increases the elasticity of the finished solution.

READ ALSO: How to Attach Corrugated Sheet to a Wicket Safely from Cutting from the Edge

Sand without clay impurities is used for the solution. The fact is that clay greatly reduces the quality of the finished solution, since it is gradually washed out under the influence of precipitation. Such fence posts will not last long.

The water should also be free of impurities: do not take it from nearby bodies of water, use water from the tap. In reservoirs, it may also contain sand, clay, small stones and other impurities that reduce the quality of the solution. If there is no other option than water from a lake or river, then at least filter it.

There are no special requirements for the detergent - it can be anything: for dishes, regular shampoo or washing powder, etc. The only condition: the detergent must dissolve completely in water

If you want to make pillars from concrete that is not the standard gray color, you can add dyes to the solution. The material will turn out to be a darker, contrasting shade. Color the solution with soot or graphite. But keep in mind that these additives will affect the quality of the finished mixture: the concrete will be brittle after hardening.

The second way to make the solution dark is to use more cement, and there are also special dark grades of material.