What it is

If you plan to connect electrical equipment with voltages up to 660 volts to the network, you will have to take into account a number of important points. Experts prohibit the use of a regular power cable for such purposes, so manufacturers are developing special models. Among them we can highlight the RKGM wire.

Heat resistant conductor

The cable marking is deciphered as follows:

If the letter "A" is missing, the conductor core is made of copper. If present, the core is made of aluminum.

- "P" - designation of material for insulation. It is made of rubber.

- “K” - rubber insulation made on the basis of organosilicon compounds.

- “G” - this designation characterizes the flexibility of the product.

- “M” - The outer braid is made on the basis of glass fibers, which are impregnated with heat-resistant varnish, as well as on the basis of organosilicon compounds with special enamel.

Technical indicator of the product

Checking the wire after installation

The 2 most basic elements of the cable are tested:

- Core control. Using a measuring device (micrometer, caliper) check the exact diameter of the conductive element. With a reduced diameter, the core will pass less current.

- Insulation check. A visual examination is carried out, and then light mechanical loads are applied (unbend - bend). The cable itself must be marked.

At the final stage, the core material is checked; for this purpose, the insulation is removed and the color determines whether the core is made of aluminum or copper.

Technical characteristics of the RKGM cable

- The nominal AC voltage is 660 volts.

- The conductor is multi-wire, its cross-sectional area is 0.75-120 mm². Belongs to the fourth class in terms of flexibility, taking into account GOST 22483-77.

- When laying the product, pay attention to the bending radius. It should not be less than two diameters.

- The operational indicator of air humidity at a temperature is no more than +33°C - 100%.

- Operating temperature: 60 +180°C.

- The installation temperature should not be lower than −14°C.

- Service life up to 8 years.

Purpose

Cable marking

Wire SIP 3

For rkgm, the decoding explains the design features:

- since the letter “A” (aluminum) is absent in the name of the cable, it means that the conductor is made of electrical copper;

- P – material of the first shell, rubber;

- K is an abbreviation for the characteristics of this layer - organosilicon; in some reference books they mention “silicon rubber” without changing the letter in the abbreviation of the standard name;

- G - this letter emphasizes the main feature of the product - flexibility (shells and stranded cores), the parameter corresponds to the definition according to the GOST 22483-77 classification;

- M – the presence of an additional outer layer (fiberglass braid);

- “25” or another number after the letter abbreviation indicates the cross-sectional area of the single conductor in the cable (sq. mm).

Where is it used?

The RKGM wire can be freely operated with a voltage of 660 V. It is a heat-resistant cable that can be laid in rooms with high humidity.

Numerous enterprises and chemical manufacturing industries have been using rubber insulation for a long time. This type of conductor provides ideal protection against the aggressive effects of chemical reagents.

You might be interested in this Features of the AVVG cable

With the help of KRGM, windings are usually made in electrical systems with increased power, for example, in an AC motor.

Important! To conduct electrical wiring in a sauna or bathhouse, you need to use rubber insulation. This is the only way to ensure 100% protection against short circuits.

When laying electrical wiring in rooms with high humidity, you need to take into account the cross-sectional area of the conductor wires intended for the outlet. It is recommended to use a product with 2.5 mm². When connecting lighting devices, you can take from 1.5 mm². Products are produced in two colors: white, brown.

Conductor selection

Application of RKGM wire

In industry, RKGM wire and cable are used for the manufacture of output ends of electric motors, windings of electrical machines of temperature class “H” and devices, if operating conditions are not associated with the influence of aggressive environments, ingress of vapors or drops of oils, etc. After obtaining the appropriate license, it can be installed at nuclear industry facilities.

RKGM wire and cable, due to the functions of heat resistance and heat resistance, is used for installation with fixation in the production of lighting fixtures, industrial and household electric heating devices, as well as electric stoves, ovens, thermal cabinets and other devices, wherever the wiring is exposed to temperature, electric motors, inside, including in tropical conditions. In construction, RKGM is actively used in electrical wiring of dryers, baths and saunas.

How to choose the right one

To lay the wire for the operation of ovens, stoves or other devices operating at high temperatures, you need to use a product of the RKGM type.

Note! When purchasing a new cable, you should take into account such a parameter as the thickness of the core. The quality of insulation plays an equally important role. Therefore, before purchasing a conductor, you need to require a quality certificate.

To check the core material, you need to take a sharp object and then peel off the top layer. If the wire is made of copper, it will be red. If the core is made of aluminum, it will be white. Experts do not recommend buying such a product.

In addition, the wire must be checked for bending. A quality conductor must be flexible. If the cable is rigid, it is better not to take it. Most often these models are made in China.

Device structure

Marking: decoding of symbols

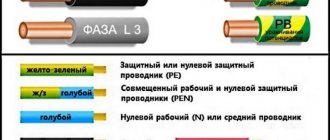

- The first marking letter is A. It means that the conductive element is made of aluminum. The absence of this symbol means that the current-carrying conductor is made of copper. Copper, unlike aluminum, has better electrical conductivity and mechanical properties.

- The second character is R. Shows the type of insulation. R – rubber rim.

- The third one is K. Characteristics of rubber protection, K – organosilicon (silicone). This point is one of the most important when choosing a cable type.

- Symbol G. _ Cable flexibility indicator. Flexibility classes are indicated in the regulatory documents for this type of wire.

Images of cross-sections of RKGM cables, according to their 6 main classes

- The last letter character is M. This symbol indicates additional braiding. The letter M is a fiberglass rim.

- After the letter designations, numerical symbols are written. The number at the end of the marking is the cross-section of the electrical wire. (example: RKGM 25 - a conductive unit with a cross section of 25 square millimeters).

Wire structure

In accordance with TU16.K80-09-90, such a cable is called single-core. A core made of copper must be at least class 4 according to the GOST 22483-77 classification.

Core insulation

The upper part of the copper core is made of silicone rubber. The material has another name - silicone rubber (SiR). A distinctive feature of this insulation is increased flexibility.

Note! In the manufacture of the RKGM product, a composition is used that does not lose its unique properties over time when heated to 200 degrees Celsius. Fireproof products, which are in high demand, can withstand temperatures up to 950 degrees.

Application

Features and current standards

These cable products were previously produced in accordance with GOST 16036-79 standards. References to the outdated standard are still found in technical and reference documentation. It is recommended to note this feature in order to eliminate errors when implementing power supply projects.

Currently, the RKGM cable is created according to the technical specifications TU 16 k80 09 90. Using this document, you can study the nuances of current production standards and control testing methods.

Main features of the product:

- maintaining integrity under high temperature and mechanical influences;

- resistance of the conductor to repeated bending.

How to use the cable

Using the RKGM cable, it is possible to produce the lead ends of electric motors and the windings of electrical machines of temperature class “H”, but the operating conditions must be observed. It is necessary to exclude the influence of aggressive environments, the ingress of vapors or drops of oils. Having received the appropriate license, this product can be installed even at nuclear industry facilities.

You might be interested in this All about the KVVG cable

RKGM wire and cable has excellent heat resistance. Using such products, lighting fixtures are usually installed. Using RKGM you can connect industrial and household electric heating devices. For example, electric stoves, ovens, thermal cabinets and other devices.

Important! In construction, RKGM is actively used for laying electrical wiring for dryers, baths and saunas.

What causes problems when using the product?

Manufacturers of wire RKGM

Coil of wire RKGM

Many factories of electromechanical products are engaged in the production of RKGM cable. The following enterprises produce the highest quality products in accordance with GOST:

- Uralcable.

- Kamkabel.

- Rybinskcable.

Manufacturers are required to produce cables in accordance with technical specifications TU16.K80-09-90.

Transportation and storage of RKGM cable

Transportation and storage must comply with the requirements of GOST 18690-82 “Cables, wires, cords and cable fittings. Labeling, packaging, transportation and storage." The conditions for transporting wires in terms of exposure to climatic factors must comply with storage conditions 3 according to GOST 15150-69 “Machines, instruments and other technical products. Versions for different climatic regions. Categories, operating, storage and transportation conditions regarding the impact of environmental climatic factors.”

The storage conditions for wires must comply with group 3 according to GOST 15150-69.

The best companies producing cable products

RKGM wire structure

To increase resistance to repeated bending and possibly reduce the radius of turns during installation, the conductor is made of twisted copper wires. The main protective (insulating) functions are provided by a rubber layer. The braid made of fiberglass threads is not damaged by high temperatures and fairly strong mechanical stress.

Cable design

Core insulation

Wire VVGNG frls

Rubber is used to create the main shell. In addition to good insulating parameters, the material has damping properties. This feature explains the resistance to shock loads and the preservation of the integrity of the layer under strong external pressure. Precise dosing of silicon additives increases strength without compromising the flexibility of the product. At the same time, reliable insulation is maintained at a significant increase in temperature. Some common types of rubber begin to conduct current at + 125°C.

Shell

The external protection is made of fiberglass threads. The dense braid is impregnated with a special varnish that is resistant to high temperatures. The heat-resistant wire rkgm is capable of maintaining functionality at +850°C or more. During operation, it is recommended not to exceed the range established by the manufacturer in the accompanying documentation. However, it should be noted that some modifications of products in this category are successfully tested for compliance with this parameter of the classification of special-purpose products - OKP 35 5115 0100.

For your information. Intermediate layers are not installed between the shells. Additional reinforcement with armor plates or other technical specifications is not provided.

Weight and diameter

For transportation, storage and solving other practical problems, information about the weight and dimensions of the product will be useful. As a rule, products are offered in coils. In individual stores you can purchase a certain amount of wire in linear meters.

Weight and dimensions parameters

| Characteristics | Values | ||||

| Conductor cross-section, mm sq. | 0,75 | 1 | 2,5 | 6 | 10 |

| External diameter, mm | 3,5 | 3,6 | 4,6 | 6,4 | 7,5 |

| Product weight, kg per kilometer | 18,5 | 21 | 41,8 | 86 | 128 |

Manufacturers

We are considering enterprises that present high-quality heat-resistant wire RKGM on the domestic market:

- "Kamkabel";

- "Uralkabel";

- "Rybinskkabel";

- "Novomoskovsky" cable plant.

RKGM wires are manufactured taking into account all international parameters required by technical specifications for cable products. If there is a need to replace the product, this brand of product can be replaced with another wire that meets the technical parameters.

Enterprise "Kamkabel"

"Kamkabel"

The company produces wires that are intended for the output ends of windings of temperature class “H” (+180°C) of electrical machines and devices for alternating voltage up to 660 V, frequency up to 400 Hz, in the absence of exposure to aggressive media and oils.

Heat-resistant wire is intended for use in all macroclimatic regions on land, except for regions with very cold climates. The wires can withstand at least 10 bending cycles around a cylinder equal to twice the diameter of the wire. The wires are resistant to low atmospheric pressure up to 1.3×102 Pa (1 mm Hg) and high atmospheric pressure up to 29.4×104 Pa (3 kgf/cm2). The wires are resistant to vibration and mechanical shocks, mold fungi. Product service life is at least 8 years.

You may be interested in this Permissible insulation resistance

JSC "Uralkabel"

"Uralkabel"

Owning modern technological equipment, Uralkabel CJSC produces cable products for various sectors of the national economy. The main consumers of the products are enterprises of the metallurgical, oil and gas production, energy complexes, automotive, aviation, construction industries, the Ministry of Defense, the Federal Atomic Energy Agency, and structural divisions of JSC Russian Railways.

"Rybinskkabel" - features of the enterprise

"Rybinskkabel"

The plant was founded in 1949 to meet the needs of the automotive and tractor industry. Located in the center of the industrial zone, the Rybinsk Cable Plant quickly turned into a large enterprise, the main focus of which was the production of cables and wires for civil and defense products. In 1989, an analogue of the joint Russian-Austrian enterprise Volmag, which produces enamel wire, was created at the industrial site of the plant. Today, Rybinsk Cable Plant produces more than 16,000 standard sizes of cable and wire.

Novomoskovsky Cable LLC is based on the former pilot plant of the All-Union Scientific Research Design Institute of Cable Industry (VNIIKP) in Yerevan, where heat-resistant wires based on organosilicon silicones were first introduced into production in the early 70s. Since then, the company has accumulated experience in the production of highly reliable wires with multilayer insulation based on organosilicon and fluorosilicon rubbers of heat resistance class F and H, which has also become the main priority direction of development.

In conclusion, it should be noted that today there are many fakes on the cable market, especially those made in China. Therefore, you should not chase a cheap cable, since it will not be able to provide high-quality insulation; its conductors may look like copper on the outside, but in practice it may turn out that these conductors are aluminum with copper plating. Such products have significantly greater resistance.

Structure of the RKGM wire

In full agreement with TU16.K80-09-90, the wire is single-core. Its conductive copper core of increased flexibility must be no less than class 4 according to the GOST 22483-77 classification. This document established the correspondence of the nominal cross-section of the core with the diameter (number) of thin conductors of which it consists. For example, for a core with a cross-section of 1 mm2, the greatest thickness of the components is 0.31 mm, i.e. it must consist of at least three wires.

The nominal area values are presented in Table 1.

Core insulation

On top of the copper core there is an extruded layer of silicone rubber insulation. Currently, this material has a more modern name - silicone rubber (SiR). Silicone organic insulation is characterized by increased flexibility, heat resistance, and higher elongation to break. The production of RKGM wire uses a composition that retains its properties when heated to 200°C; in general, silicone rubber is used to produce insulation for special fire protection wires that can withstand temperatures up to 950°C. The insulation thickness, depending on the nominal cross-section of the core, can be estimated according to Table 1. — RKGM wire technical characteristics.

Shell

The sheath provides high strength and fire resistance of RKGM wire and cable. Structurally, it is a braid of fiberglass threads impregnated with heat-resistant varnish type KO-921. The varnishes in this series are a mixture of modified silicone resins and glyphthalic varnish. This impregnation is capable of withstanding temperatures up to 250°C; in general, the entire RKGM wire insulation system complies with class H according to GOST 8865-93, and can withstand heating up to 180°C.

Technical characteristics of wire RKGM 2.5

Type of climatic modification of heat-resistant wire RKGM 2.5: O 2 according to GOST 15150-69 Heat resistance class of heat-resistant wire: N. The maximum operating temperature of RKGM 2.5 is 180 degrees Celsius. The minimum operating temperature is 60 degrees. The minimum bending radius of the RKGM 2.5 wire is 9.2 millimeters. Installation is carried out at a temperature not lower than -15 degrees. Relative air humidity during operation should not exceed 100%. RKGM 2.5 wire is resistant to mold fungi. The wire is resistant to low atmospheric pressure up to 1.3x102 Pa (1 mm Hg) and high atmospheric pressure up to 29.4x104 Pa (3 kgf/sq.cm). RKGM 2.5 is resistant to shock, vibration, and up to 10 bending cycles. The calculated mass of the heat-resistant wire RKGM 2.5 is 0.0417 kilograms per meter. Service life of at least 8 years. The outer diameter of the RKGM 2.5 wire is 4.6 millimeters.