The need to use special tools

To connect one socket or switch in an apartment, it is not necessary to buy professional equipment. You can strip a piece of wire with a regular kitchen knife. However, if there is a large-scale repair with a complete update of the electrical wiring system, then it is impossible to do without specialized devices.

The number of contacts that must be cleaned when repairing a house with an area of 100 square meters. m can reach thousands. Carrying out such work without specialized devices is an unreasonable waste of time and effort.

A modern room requires the installation of many sockets, switches, panels, junction boxes and lighting fixtures.

In addition, stripping insulation without professional wire stripping tools is fraught with negative consequences:

- there is a high risk of cable damage, which reduces the safety of electrical wiring;

- cutting the conductor leads to a decrease in the cross-section of the wire, resulting in a break or burning at the junction;

- if cut carelessly, the damaged wire may break when bent.

In high-frequency systems with alternating current, the situation is complicated by the appearance of the skin effect - the current is distributed unevenly, but mainly in the surface layer of the conductor. In such wires, any minor defect in the core can damage the equipment.

You can carefully scrape off the insulation with a knife, but the work will take a lot of time. And if you need to prepare a lot of cables, then mistakes are inevitable - it will not be possible to quickly make a large number of high-precision cuts

When it comes to significant volumes of work, it is better not to take risks and use special devices. Damage to the conductor can cause a fire, cause equipment failure, or cause electric shock.

Types of electrical installation devices

The variety of instruments can be classified according to the following criteria:

- method of removing insulation;

- volumes of work performed;

- process automation.

The insulating shell can be removed in two ways: thermal and mechanical.

The first option is only valid for thin, low-power conductors used in communication devices, audio equipment and electronics operating at a voltage of about 5 volts.

Thermal exposure is suitable for one-time stripping of a small batch of conductors. To heat the insulating shell use: a lighter, a soldering iron, a heated chrome thread

Professional methods are exclusively mechanical stripping. The operation of the tools is based on one of the principles of removing the protective coating:

- Cutting. The tip cuts through the insulating layer in a circle, leaving the current-carrying conductors without damage. Afterwards, part of the cut covering is removed from the wire.

- Break. The insulation is clamped and, with force, literally torn off the conductor.

Based on the expected volume of work performed, all tools can be divided into two groups:

- household;

- professional.

Some people include an electrician's knife in the first category. However, such a tool is invariably present in the arsenal of a professional. The knife is often used in everyday life due to its affordability and ease of use.

Professional equipment: pliers, forceps, pullers and strippers. For small jobs, pliers and side cutters are suitable.

The most popular among electrical installers are strippers. Professional tools for quick cable stripping come in three types: manual, semi-automatic and automatic.

In addition to the general classification, devices may differ in purpose. If universal tools or devices used exclusively for Internet wires or electrical cables. The diameter of the stripped wire may also differ; the range of values is about 4-40 mm.

Homemade strippers

Home craftsmen offer a great variety of handmade devices. Let's take a closer look at some of them and look at how to make them at home.

Homemade clothespin

For production you will need:

- wooden clothespin;

- pencil sharpener knife;

- screw for fastening the knife for the sharpener.

Unscrew the screw and remove the knife from the sharpener. We attach it to one of the halves of the clothespin so that the blade greatly overlaps the hole for the clothesline and screw it to the clothespin with the original screw.

The puller is ready. Let's look at how to use it. The core is passed through the hole for the rope and lies on the knife blade. The clothespin is “closed” and the insulation is cut and pulled together in a circular motion. Sorry and amazing.

Three screws

Two screws are screwed into a thin board. The main condition is to screw them into the board not completely and at an angle towards each other so that the caps overlap one another. Ideally, between them there should be a passage for the wire, with a height and width slightly larger than its diameter. From below, another screw is screwed into the same board so that its sharp end comes out between the first two screws. The insulated core is pulled through this device, cutting the sheath in the longitudinal direction. In this way, craftsmen extract non-ferrous scrap for sale.

Nippers or pliers: nuances of use

A proven tool that works to break. The working principle of the cutters is simple. Using a screw, select the desired diameter of the wire, then grab the cable, twist it a little in a circle and tighten the insulating coating.

When setting up the pliers, choose a grip width slightly larger than the cable cross-section. This will protect the conductor from scratches while removing the protective layer.

Expensive models of tongs are made with insulated handles made of high-quality steel. Some pliers strip even the thinnest wires without breaking.

Additional advantages of wire cutters include:

- reliability;

- durability;

- ability to work in hard-to-reach areas;

- stripping live wires.

Disadvantages of wire cutters: the inability to choose the length of removal of the insulating layer, the need to constantly reconfigure the screw when stripping wires of different diameters.

Why do you need to remove insulation?

The insulating layer is usually removed from wires for the purpose of replacing or updating the connection. There can be quite a lot of cases for this. It is especially common to expose the ends of wires when replacing switches and sockets. Connecting some electrical devices also requires a direct connection to the network backbone. And this leads to the need to strip the wires.

Wires without insulation

Sometimes you have to replace the old protective layer. Then the old base is removed and replaced with a new one. Oxidation of the wire may remove the damaged area, which requires reconnection. Need to increase cable length. In each of the presented cases, the presence of bare ends is required, which will later be connected to the same parts of another conductor.

You may be interested in this. Features of the multimeter

Electrician's knife - a traditional tool

A knife with a curved blade simplifies the work and speeds up the stripping process. There are several types of such devices.

Features of using the device

An electrician's knife is more suitable for stripping flat cables. Experienced craftsmen will easily remove the insulation from round wires, but the ease of use will be less.

Removing the protective shell using a knife must be done with gloves to avoid injury. This is especially true when stripping cables manufactured in accordance with GOST. The insulation thickness of such a conductor is much greater than that of a wire according to specifications, and it fits more tightly to the cores, which complicates the work.

When performing stripping, the tool must be held at an acute angle relative to the cable. If this rule is neglected, there is a high risk of damage to the soft metal conductor.

The braid is removed with light movements, cutting the insulation away from you.

The main advantages of using knives:

- affordable price;

- availability of models with an insulated handle;

- practicality - the knife is suitable for wires of different diameters.

The main disadvantage is the duration of work. Stripping large cross-section cables is quite labor-intensive. In addition, with little experience there is a risk of damage to the cores.

Variety of electrician knives

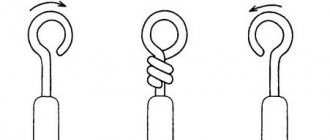

There are three options for electrician knives. They differ from each other in the shape of the blade and the type of tip.

Knife with heel. A device with a short wedge concave inward. A “heel” is soldered perpendicular to the blade, limiting the depth of the cut.

This knife is perfect for preparing double-insulated wires, when the top protective layer needs to be removed, but the bottom one needs to be left intact.

It is better to use a plow tool for wires with hard conductors; a knife removes the soft encircling sheath worse.

Knife with beak. A tool with a rounded blade. This knife has a very smooth bend, unlike the “heel”. The specific shape of the wedge complicates the work; the device is more often used by experienced craftsmen.

The beak-shaped point is suitable for making a circular cut in the shell. Longitudinal cuts must be made with extreme caution, since there is no cut depth limiter

Knife with hook. This tool is capable of transverse cutting and longitudinal cutting of cables. The wire is fixed at the top with a bracket, and a sharp fang cuts through the insulation.

You can set the cutting depth of the protective sheath on the knife - an adjustment wheel is provided for this.

This model is universal and suitable for processing most types of cables. The device is popular among professional electricians.

Evaluation of instrument quality parameters

When choosing a knife for stripping the insulating layer, you must follow a number of rules.

Primary requirements:

- It is better to use a knife with a small blade. The tool will be convenient to use in a limited space (cabinet, panel).

- The blade should be made of durable steel - such metal retains its sharpness longer.

- It is better to choose a straight edge - this will simplify the cutting of double-insulated wires.

You need to pay attention to the sharpening of the blade. It should not be too sharp, otherwise it is easy to get hurt when working.

In addition, a sharpened tip can accidentally damage the cores of the cable being processed or adjacent wires.

Some tools have an insulated handle. The maximum voltage that the knife can withstand is indicated on the device itself.

Stripper - ease of use

The best and most popular wire stripper that makes your work process as easy as possible. The instruments are presented in a wide range of models.

How different models work

The mechanism of action is based on processing the cable with two movable knives having a semicircular shape. The cut gauge is adjusted to the wire cross-section, ensuring the accuracy of the notch and the absence of damage to the metal core.

Depending on the automation of the process, there are three types of strippers:

- mechanical;

- semi-automatic;

- auto.

Manual stripper. The insulation stripper has a simple design and is used for stripping individual wires.

Externally, a mechanical stripper is similar to pliers. On the inner surface of the clamps there are several holes with blades designed for cutting the sheaths of wires of different sizes

Working with a manual stripper is not difficult. General scheme for removing insulation:

- Determine the diameter of the wire.

- Select the appropriate hole on the lips of the device.

- Bite the cable by pressing the handles.

- Remove the braid from the wire by moving the stripper in a circle.

If you choose a socket with a smaller diameter than the wire cross-section, there is a risk of damaging the wire. If a larger hole is used, the braid will not be removed.

Pros of a manual stripper:

- compact size and light weight;

- possibility of crimping the tip;

- the presence of several gaps for wires - usually up to seven with a range of values 0.25-2.5 mm.

Semi-automatic stripper. This option is more convenient for large volumes of work. The semi-automatic unit is equipped with a mechanism that does not require turning the stripper around the wire.

It is enough to select a cell to match the diameter of the wire, adjust the length of stripping of insulation and bite the cable. The stripper will cut the sheath and pull it off without damaging the conductor

Auto. The tool simplifies the work as much as possible. The user does not need to select the diameter of the wire cross-section. The device has one socket, the size of which automatically adjusts to the installed cable.

The stripper is suitable for stripping wire insulation with a cross section of 0.2-6 mm.

Some models are equipped with an adjusting screw to adjust the size of the grip for smaller diameter wires

Most automatic strippers have advanced functionality. In addition to the direct task, they are able to perform:

- crimping of tips;

- cutting the ends of the wire;

- twisting of multi-core cables.

The automatic stripper is capable of stripping wires with single and double insulation. In one pass, the tool will remove only the top shell. To remove the lower braid, the manipulations must be repeated.

Stripper selection options

It is necessary to purchase a tool based on the specifics of the activity. Before going to the store, you must compare the following criteria:

- scope of application – professional or household;

- volumes of work – regular or periodic use;

- tool skills;

- purchase budget.

For professional electromechanics, it is definitely better to choose semi-automatic or automatic devices designed for stripping a large number of cables. The high price of the devices is justified by the speed and convenience of work.

A special stripper is provided for cleaning television and Internet cables. It differs from the usual one in the presence of additional knives for subsequent installation of the F-connector

A home craftsman can “enrich” his arsenal of tools with a hand stripper. If you do not have the skills to work with electrical wiring, then it is better to choose a semi-automatic device - the risk of cutting the cores is minimized.

Preference should be given to trusted manufacturers who guarantee the safety of materials and the durability of the tool. It is better to avoid cheap models made of low-quality alloys and with a plastic body.

You can read more about how to choose a stripper in this material.

Recommendations for choosing a tool

Manufacturers usually do not write in the technical specifications whether the model is mechanical or automatic. However, they indicate whether the basic parameters are adjusted, as well as what cross-section or diameter the tool is designed for.

Let's consider the main criteria that you need to rely on when choosing a manual stripper.

Criterion #1 – maximum/minimum cable diameter

In order not to buy a tool “for all occasions,” you need to determine in advance what type of wires you most often have to deal with. Perhaps this is a power cable, with which there is still a lot of work to be done in connection with the renovation or redevelopment of the apartment, or an 8-core twisted pair cable for the Internet. Accordingly, we also take into account the diameter of the wire.

A sample of a stripper designed for stripping wires of various diameters. Removing insulation begins with selecting the desired socket - the parameters are indicated directly on the working part

The diameter scale indicated by the manufacturer for selection may vary, for example, from 0.13 mm to 90 mm. If you only work with home electrical wiring, then it is reasonable to choose a stripper designed for a diameter of 1.5-2.5 mm. A professional tool usually has a wider range.

Criterion #2 – availability of replaceable knives

Typically, a tool with monolithic sharpened “lips” is not able to replace the cutting equipment, since the working part is the main mechanism. But more complex devices consist of a large number of parts that can be replaced if necessary.

If you constantly work with cables that are insulated with a rigid polymer braid, it makes sense to purchase pliers with replaceable blades that dull and chip over time.

Replacement knives look different: it can be a pair of blades with a fastening screw or a full-fledged cutting head that connects to the handles with a hinge mechanism.

You should know that for domestic use you do not need to purchase expensive equipment with replaceable knives (which cost on average 600-1000 rubles), it is easier to immediately buy new pliers.

Criterion #3 – adjusting the diameter and depth of cut

The ability to adjust is very important, since the quality of the cut and the integrity of the exposed wires depend on it. Many electricians refuse automatic tools in favor of mechanical ones, because they do not trust the devices and are accustomed to independently installing or selecting the necessary parameters.

Sample of universal pliers. To strip the wires, no special sockets are needed - the tool automatically adjusts to the desired diameter, and can strip 2 or more wires at the same time

To adjust the depth, some types of strippers have a limiter installed - a small plastic or metal part that fixes the cores in a certain position. The wire simply cannot be inserted beyond the limiter, so the cut is carried out strictly according to the specified depth, for example, 10 mm.

Let's look at how to work with an adjustable tool. As a sample - the simplest wire cutters.

Image gallery

Photo from

Stripping pliers

Plastic braid cutting process

Removing insulation from a wire

Screw cutters in everyday life

If maximum accuracy is required, purchase an automatic machine or give preference to a stripper for stripping insulation with a set of holes for different diameters.

Criterion #4 – additional features

Some strippers are multifunctional, that is, removing polymer insulation is one of the purposes, perhaps the main one. For example, many pliers, even automatic ones, often have a small blade. It is used to cut the wire to the required length before stripping it.

Universal twisted pair pliers have two working sockets, marked 8P and 6P - they are designed not only for stripping, but also for crimping network and telephone connectors

Some manufacturers have gone further and equipped the tool with voluminous handles, from which, if desired, you can take out any devices - from scissors to a corkscrew. Of course, a simple installer does not need such technical delights; experienced craftsmen love a simple but reliable tool.

And multifunctional devices, as you know, break down much faster, and most of the built-in devices are most often not needed.

Criterion #5 – best producer

Wire stripping pliers are produced by both well-known manufacturers and numerous Chinese companies that do not particularly care about product quality. Of course, branded products are stronger, more reliable and more accurate, and the point here is not in the promotion of the brand, but in the quality of production.

It is known that German-made instruments undergo rigorous testing. To make the same pliers, strong hardened alloys are used, and the insulation is checked in special voltage baths.

The KNIPEX KN stripper, designed for stripping insulation from coaxial cables, is equipped with adjustable cutting depth and diameter. Removes outer braid, screen and inner shell in one step. Cost – 1550 rubles

Safety when working with conductive conductors comes first, so it is better to purchase an expensive tool with a manufacturer’s warranty than to rely on the reliability of an inexpensive stripper “without family or tribe.”

Popular and proven brands: FIT, HAUPA, JTC, KING TONY, Knipex, SHTOK, TOPEX.

Among the domestic products, KVT strippers are known to almost all electrical installers, as they are universal, convenient, affordable and rarely fail in work.

The cost of equipment for stripping insulation depends on the brand and specifics. The average price of a good household tool is 600-1500 rubles. Please note that cheap models are attractive only by their price; good cutting quality or reliability of the knives is out of the question.

We also recommend reading our other article, where we examined in detail various methods of stripping wires of insulation. For more details, follow the link.

Alternatives: side cutters and pliers

By using some tools for purposes other than their intended purpose, it is quite possible to remove the insulating wrapping. Popular alternatives to professional tools: side cutters and pliers.

Side cutters. The device is designed for cutting small-diameter wires, as well as for trimming plastic and metal elements when performing installation and repair work.

When using side cutters to clean insulation, you must control the pressing force so as not to damage the core.

The cutting edges should be directed in the opposite direction to the movement of the tool. The sheath is carefully removed with a tube without damaging the conductor

For processing wires, pliers with precision holes of various diameters are suitable. A universal tool is in demand when installing wiring.

These pliers allow you to:

- grab and bend wire;

- cut medium hard wire;

- carry out crimping of contact sleeves;

- remove insulation.

The number of holes determines the functionality of the tool; usually pliers are designed for processing wires of 3-6 standard sizes.

The permissible parameters of the wire cross-section are indicated on the handle, the standard range of values is 0.5-3 sq. mm

You must work with pliers carefully. If you do not calculate the clamping force, you can easily damage the core.

Choosing a stripping method for different wires

The complexity of removing insulation is largely determined by the type of wire. When choosing a tool, you should consider the cable features:

- Coaxial wire. When removing double insulation, work is carried out in two stages. The top layer can be removed thermally, and the bottom layer can be removed using a stripper. The cores of such a cable are very fragile and thin, so they are easily damaged.

- Cable with fluoroplastic coating. Heat-resistant insulation that can only be removed mechanically. An electrician's knife or stripper will do.

- Enameled wire. If the cross-section is less than 0.2 sq. mm, then you need to resort to the thermochemical method using a soldering iron and vinyl chloride tape. The wire is placed on the tape and passed along the cable with a soldering iron - the released chlorine promotes the “removal” of the enamel sheath from the wire.

When choosing a tool, you need to take into account the diameter of the wire the device is designed for, as well as the material used to make the handle.

The cable cutter is universal in terms of size. But pliers, pincers, manual and semi-automatic strippers are limited by their gripping range

If it is necessary to process electrical cables, it is necessary to select strippers with a handle made of dielectric material.

The coating protects against voltages up to 1000 W.

Types of strippers and their prices

All strippers can be divided into several conditional groups, the first of which is a hand tool.

This is a universal insulation stripper, reminiscent of side cutters, but on the inside of the jaws there are marked socket holes with blades for specific wire sections.

To remove insulation with such a stripper, it is necessary to perform a number of mechanical actions, namely, determine the required socket by cross-section, install a core into it, close the handles, thereby biting the wire, and then remove the insulation with a special circular motion.

Another design option is a similar lever mechanism, but with jaws, at the end of which there are cutouts for removing insulation.

Closer to the hinge joint there is a stop screw on the jaws, which allows you to adjust the tool to the required cross-section.

Below are specific types of this tool with their brief descriptions.

Mini stripper (clothespin stripper)

A universal tool that resembles a clothespin with spring-loaded jaws.

There are holes for round and flat wires, several blades for different tasks and an output regulator for the main blade to adjust for a wire of a certain cross-section.

The attachment (rack) version deserves special attention, which is a cylindrical multifunctional tool with knives for circular and longitudinal cuts of the insulating shell, marked holes with blades for specific sections, as well as a retractable knife for cutting the insulation “the old fashioned way.”

The average cost of manual versions is about 400 – 1000 rubles.

In addition to manual mechanical models, there are two more types of strippers:

Semi-automatic

This tool is used when performing extensive electrical installation work; it is equipped with a mechanism that eliminates the need to twist the core to remove the insulation.

Before stripping the cable, you need to set the length of removal of the insulating coating.

According to the principle of operation, such a stripper is similar to the manual version, since the wire is also inserted into a suitable socket, but after squeezing the handles, the master does not need to do any further actions.

The shell is removed evenly.

The average cost is about 1 – 2.5 thousand rubles.

Auto

A professional tool that can independently determine the size of the wire cross-section.

This self-adjusting version is usually designed for wiring 0.2 - 6 sq. mm, and in micro ranges up to 0.2 sq. mm a micro-adjustment screw is used.

Some models are suitable for stripping insulation from both single-core and stranded wires of various cross-sections, as well as for stripping flat cables.

During operation, the tool does not require any settings; it is usually produced in a multifunctional version, that is, with various built-in auxiliary tools, such as a cutter and crimping dies.

Automatic strippers also include models equipped with an electric drive, where stripping is performed completely automatically.

The average price is 2 – 5 thousand rubles.

Pocket stripper

A miniature tool that fits easily into your pocket.

The body is made of special plastic, into which knives are built in on both sides, with recesses for wires of different sections.

There are strippers designed to work with a specific type of cable:

For twisted pair

It looks like a clip with a blade and is designed for precise cutting of outer insulation from wires.

This tool is also called a twisted pair knife.

In addition, such a stripper is suitable for preparing a coaxial cable for screwing on an F-connector.

This simple option costs about 100 rubles.

For coaxial cable

Reminiscent of the previous option, but has an adapter for switching the tool to work with a cable of a certain brand.

This is a rotating stripper, which includes a hexagon designed to adjust the depth of insulation penetration.

The blades simultaneously cut the outer and hidden insulating layers.

For fiber optic cable

A precision tool used to remove the varnish layer from a fiber optic wire.

High precision of work, strict adherence to tolerances, preventing the glass fiber itself from breaking, make this tool expensive.

The cost of professional copies is within 7 thousand rubles, simple options can be found at a price of 2 thousand rubles.

For external insulation

It is a handle with a clamp and an adjustable blade in the center, adjusted to the desired thickness by a regulator located on the opposite side of the handle.

Cuts insulation both lengthwise and crosswise.

Cleans the conductors both at the end of the cable and in the area remote from it.

For power cable

The tool is designed to work with cross-linked polyethylene cables with a diameter of up to 150 mm, removing insulation and semiconducting screen.

The device has two types of knives: conical and straight.

Has smooth adjustment of cutting depth.

Special mention should be made of automatic machines capable of not only stripping insulation from cables, but also crimping and twisting wires.