Application of plastic boxes

Most often, plastic channels are used in everyday life. They have the following positive qualities:

- Low cost. It is associated with the low price of the manufacturing material itself - plastic, and the simplicity of the production process.

- Mass production of plastic products due to the development of modern technologies.

- Resistance to the negative effects of moisture, fire, acids, fungi, mold.

- Resistant to mechanical stress.

- Non-conductivity of electric current.

- Possibility of use in conditions of high humidity.

- Easy to connect and pull wires.

- No special tool required.

- A wide range of colors, thanks to which the box can organically fit into the color design of the room.

Despite the large selection of colors, you should understand that the plastic box will still be noticeable on the wall. For this reason, you also need to think in advance about how to lay plastic boxes for electrical wiring so that they do not spoil the appearance of the room.

Materials used for the manufacture of cable ducts, their advantages and disadvantages

Various materials are used to make cable ducts for electrical wiring. This determines not only the appearance of manufactured products, but also their technical characteristics. Do not think that wire boxes perform a purely decorative function. Their main purpose is to protect people inside the building from the consequences of an emergency, for example, a short circuit. Considering the load on the electrical network, plastic products are most often installed inside residential premises, and in industrial enterprises. Each type has its own distinctive features, which you should definitely familiarize yourself with before purchasing.

The choice should be approached individuallyMetal boxes for laying cables: types and installation features

The appearance of metal boxes for electrical wiring can hardly be called attractive. However, from a safety point of view, they are significantly superior to their plastic counterparts. Can be open or closed.

Metal products are highly durable

When laying a power supply system at an industrial enterprise, open steel products are often used, mounted on the walls or fixed directly under the ceiling. This metal wiring box is wide enough to accommodate thick cable bundles inside it.

Open models are popular in industrial plants

The use of closed products is abandoned due to the inevitable heating of the cable due to the meeting of the magnetic fields of adjacent wires. This can cause the electrical wiring to catch fire and turn off the automation. In open systems, natural ventilation ensures timely heat removal.

Metal is a good conductor. To ensure the safety of nearby people when installing electrical steel boxes, grounding must be provided.

Related article:

Grounding is mandatory

Another type of metal cable ducts are products made of anodized aluminum. They are used primarily in the installation of power supply systems in industrial enterprises. Sometimes they are used in home interiors decorated in Hi-Tech style. They consist of a box with a lid, a column, polycarbonate fastenings and wiring.

The advantages of such products include:

- Possibility of protection against electromagnetic influence;

- High impact strength;

- UV resistance;

- Fire resistance;

- Ability to withstand significant temperature fluctuations without loss of geometric shape.

The disadvantages include the complexity of installation work. Dowels are used to secure the box and lid, which significantly complicates installation and requires special tools.

Anodized aluminum box

Types and features of plastic cable boxes

Plastic boxes for electrical wiring cost much less than their metal counterparts. Can be open or closed. Considering that plastic is not an electrically conductive material, grounding is not provided when installing plastic systems.

Plastic products are presented in a wide range

Self-extinguishing PVC is used for their manufacture, which eliminates the possibility of flame spreading in the event of an emergency. In closed products, the lid fits tightly to the channel. This also helps to increase the level of safety, since proper combustion becomes impossible due to limited access of oxygen.

A plastic plinth will hide the wires

Despite the fact that PVC cable duct can be purchased at a relatively low price, their use in industrial enterprises is limited. Due to their low strength characteristics, such products have a limited service life. Open models are purchased when laying a small number of cables.

Closed plastic cable ducts are widely used in the installation of household wiring. Manufacturers offer products of various colors, shapes and sizes, and therefore choosing the right option for a specific room will not be difficult.

A wide selection of standard sizes will allow you to choose the right option

How to choose the right plastic box

The determining factor that goes into making the right choice is the size of the box. In fact, a lot will depend on the number of wires that will fit into it. Plus a small amount of space. Therefore, the main boxes (from distribution boxes to branches) should be larger, and those going to sockets or switches should be smaller.

Next, you need to decide on the number of plastic elements. Here everything will depend on the length of the electrical wiring, taking into account that the box itself has a standard length of 2 m. By the way, in stores it is sold without trimming. In order not to make a mistake with the quantity, it is necessary to add 20% to the estimated length of the wiring.

Main dimensions of cable channels

The cable channel is also used as a decorative element that should fit into the interior design of the room. Let's just say that this material is mainly produced in white, so there is a fairly wide range here. With wood-effect models, the assortment is minimal. Although it is the “wood look” that is distinguished by its presentable appearance, which can fit into almost any interior.

Some manufacturers of plastic boxes for electrical wiring offer, as an addition, some decorative elements: plugs, corner adapters, tees, corners (internal and external). Therefore, the advice is to purchase cable channels with decorative fittings that enhance it. Wood-look fittings are also available.

When purchasing, you need to pay attention to the quality of the product. And if uneven ends are a small problem that can be hidden with plugs, then the poor quality of the locking connection between the panel and the lid is the number one problem that occurs quite often. That is, during operation the cover always falls off or, conversely, it is very difficult to install it on the lower mounting panel.

Decorative plastic box to look like wood.

A good quality product should be closed by hand without tapping. But the most interesting thing is the moment when the back of the box is installed, the cables are laid, and the lid does not close or falls out after installation. The most important thing here is not to overdo it. Many installers start hitting the lid with their hands or a mallet, after which not only it, but also the box itself cracks and falls apart before our eyes. So my advice is to purchase boxes for connecting wires from well-known manufacturers.

Installing plastic boxes is not only the correct choice, it is the correct choice of junction boxes, both in size and color. Everything should be in harmony. Pay special attention to the holes in the junction boxes where the wiring boxes will be inserted.

Plinth boxes for laying cables.

Specifications

The minimum length of a product section is 2 m. Of the many standard sizes, the most popular are:

- mini-channels. Available in minimum sizes from 10x10mm to 60x80mm. Designed for very thin signal wires;

- products that are placed on the floor. It has the following dimensions: 160x65 mm, 50x12 mm, 92x20 mm and 75x17 mm;

- main plastic boxes. Can be from 20×10 mm to 60×100 mm. There are intermediate sizes.

Note! Skirting elements have a curved shape, so you need to be careful with the area. The lid can serve as a guide, namely its width and the depth of the internal groove. Electrical wiring can be laid under and above the box.

You might be interested in Weight about wire VVGng A LS

Triangular corner systems have a small area compared to rectangular ones with the same walls. The most popular sizes will be 40x40 mm, which will accommodate up to three cables.

Skirting boxes

Cross-sectional dimensions of the most popular cable channels: 10×10mm; 10×12 mm; 12x12 mm; 12×16 mm; 16×16 mm; 16×20 mm; 20×20 mm; 20×25 mm; 25×25 mm; 25×40 mm; 40×40 mm; 40×60 mm; 60x80 mm.

Floor dimensions: 160×65 mm; 50×12 mm; 92×20 mm; 75×17 mm.

Trunk made of plastic for power wires: 20×10 mm; 30×10 mm; 40×25 mm; 25×25 mm; 40×40 mm; 40×16 mm; 80×60 mm; 100×60 mm.

Dimensions of plastic wiring box

Plastic boxes for electrical wiring vary in length, width and thickness. According to section 8 “Dimensions” of GOST R IEC 61084-1-2007 “Cable and special cable duct systems for electrical installations”, it is recommended to produce straight sections of cable channels with a length that is selected from the size range in increments of 0.5 m. Minimum section length should be 2 m.

This section also indicates that the manufacturer must indicate the value of the cross-sectional area (in mm²) inside the box, that is, the usable area that can be used when installing the cable. The width of the box depends on the number of wires that can be placed inside, as well as on the purpose of the product itself.

Dimensions of electrical installation cable channels in cross section

Mini-channels are produced by industry with the following typical cross-sectional dimensions:

- 10x10mm;

- 10x12mm;

- 12x12mm;

- 12x16mm;

- 16x16mm;

- 16x20mm;

- 20x20mm;

- 20x25mm;

- 25x25mm;

- 25x40mm;

- 40x40mm;

- 40x60mm;

- 60x80mm.

Trays of this type are designed to accommodate one or two wires.

Floor boxes are produced with the following cross-section:

- 160x65mm;

- 50x12mm;

- 92x20mm;

- 75x17mm.

Trunk plastic boxes for electrical wiring have the following typical cross-sectional dimensions:

- 20x10mm;

- 30x10mm;

- 40x25mm;

- 25x25mm;

- 40x40mm;

- 40x16mm;

- 80x60mm;

- 100x60mm.

For the plinth type, the size is determined by the width of the cover (diagonal wall) and is usually made 50 or 70 mm. You can also find the sizes of skirting boards with cable channels, which are given according to the height and width of the base. In this case, the most popular are 50x50 mm skirting boards. They allow you to place several wires in one product. Trays measuring 100x100 are designed to accommodate three-wire wires.

Dimensions for corner structures depend on the dimensions of the internal part of the product. The most popular size is 40x40 mm. Depending on the purpose, flexible corrugated models are available in the following diameters: 16mm; 20mm; 25mm and 50mm.

- 16mm pipes are used for laying lighting and telephone cables;

- to create outlets for sockets or switches, use 20mm corrugated channels;

- Corrugated cable ducts with a pipe diameter of 25 mm are used between electrical panels or distribution boxes.

Metal boxes - types and sizes

Since metal trays and boxes are designed for heavy loads, the need to use them in domestic conditions arises quite rarely. The types and sizes of metal cable ducts are mainly suitable for external and internal laying of cables in industrial premises where there are highways consisting of a large number of wires. To prevent the material of the boxes from rusting, galvanized steel is used in their production. Like plastic ones, the cross-section of metal cable channels is U-shaped - with or without a cover.

Depending on the conditions of use, perforated, smooth and ladder trays are manufactured. The former are easier to install and secure cables inside, while the latter are heavier and are installed on special supports.

Cable tray sizes:

| Dimensions (width × height × length), mm | Metal thickness, mm | Useful cross-sectional area, cm2 |

| 50×50×2500 | 0,55 | 24,22 |

| 100×50×2500 | 0,55 | 48,44 |

| 200×50×2500 | 0,7 | 98,44 |

| 300×50×2500 | 0,7 | 147,44 |

| 400×50×2500 | 1,0 | 198,44 |

Due to their heavy weight, gluing metal boxes is not practiced - they are attached to the surface with anchors, dowels, or “mounted” on a bolted connection. To install smooth trays, shelves or brackets pre-fixed to the surface are used.

Most often, metal boxes are used to form electrical lines in raised floors or suspended ceilings. For their installation, additional blocks are used - rotating, lifting (for transferring wires between planes), branching, etc.

+ Pros of metal cable channels

- Withstands the weight of a large number of power cables.

- They allow you to easily trace the route of any cable, provide ease of installation and easy access for inspection or replacement.

- An additional plus for fire safety.

— Disadvantages of metal cable channels

- Greater weight requires more serious installation work.

- It is more difficult to process during installation (if cutting is required).

- These types of cable channels for electrical wiring necessarily require additional components for the installation of turns and transitions.

Calculation of the size of a plastic box for electrical wiring

Before you purchase cable channels for installing electrical wiring, you must first draw a layout diagram of the structure in the room, indicating the type of cable channels and the length of each section. After this, determine the required size of each type of tray. To calculate the size of the box, you need to know the cross-section of the wires and their number.

It is recommended to take a cable channel with a small margin in length (10%) and width.

The length reserve takes into account the additional costs that arise during installation in places with corners, as well as in the event of material damage. It is also advisable to have free space inside the box, which may be needed when laying additional electrical cables.

There is no need to purchase a wide tray if you initially plan to lay only one cable, since its price also depends on the width of the product. Usually the calculation is carried out taking into account an increase in the number of wires by 2-3 pieces.

Also, taking into account the “Rules for Electrical Installations”, in the case of multi-layer filling of plastic cable channels, the sum of the cross-sections of all conductors located in them should not exceed 40% of the cross-section of the product itself in the case of using a box with a lid or 30% in the case of a blind box.

Table for calculating the minimum dimensions of cable channels

| single-section | two-section | three-section | |||||||||

| 10x22 | 10x30 | 10x22 | 10x30 | 15x54 | 10x40 | ||||||

| number of wires in one section | |||||||||||

| 1,5 | 10 | 12 | 3 | 3 | 5 | 5 | 19 | 13 | 5 | 4 | 5 |

| 2,5 | 7 | 10 | 2 | 2 | 3 | 3 | 13 | 13 | 3 | 3 | 3 |

| 4 | 4 | 8 | 1 | 1 | 2 | 2 | 10 | 13 | 2 | 2 | 2 |

| 6 | 2 | 3 | 1 | 1 | 1 | 1 | 5 | 5 | 1 | 1 | 1 |

Cable channels are delivered to hardware stores in packages. Depending on the size of the trays, the packaging differs in the number of products and, accordingly, in the total footage. To calculate the total length of cable channels in a package, the number of products is multiplied by the standard length of one tray (2 m).

A table of parameters for one package, depending on the size of one box, is shown in the figure. Parameters of one package of electrical boxes, depending on their size

When purchasing boxes, it is advisable to purchase fittings for them (plugs, corners, branches, etc.).

Also, for household purposes, it is better to purchase single-lock products, as they will last longer than double-lock ones. This is due to the fact that the wall thickness of single-lock structures is greater, and, consequently, the products themselves are more durable.

Correctly sized cable channels will allow you to quickly install the system, and the additional space inside the box will make it possible to easily add wires to the system without the use of additional trays.

No. 5. Cable channel size for electrical wiring

The length of straight sections of the cable channel is, as a rule, 2 m; products of other sizes are less common. Width and height are more variable parameters. The choice depends only on how many wires will be hidden inside and what their cross-section is. It is recommended to leave enough free space inside the cable channel so that the wires do not overheat. Paragraph 2.1.61 of the PUE states that in boxes with openable lids, wires should fill no more than 40% of the internal space ; for boxes with blind lids this figure is lower - 35%. It turns out that in order to choose the right cable channel for electrical wiring, you need to calculate the sum of the cross-sections of all the wires, and then start from this when choosing the dimensions of the box itself.

In practice, things are a little easier than they seem. Many manufacturers indicate how many and what kind of wires can be placed in a particular cable channel. Cable channels of the following sizes in mm are considered popular: 12*12, 10*20, 10*30, 16*16, 16*20, 16*25, 16*40, 16*60, 25*25, 40*40, 60*60, 60*80, 100*150 are less common. Mini cable channels have dimensions of 10*10 and 10*15 mm. Products in other sizes are also available for sale. When choosing, it is important to pay attention to the fittings of the appropriate size, which will allow you to build a neat system.

What color solutions are there for cable channels?

The choice of cable channels depends on the overall interior design. There is a large assortment of white products, but colored wire boxes are also often used. Fittings must be used in suitable colors. Different types of tees, adapters and plugs must match the color palette of the cable channels. Products painted to resemble wood are especially popular. Such designs are used in the arrangement of wooden houses and baths.

The color palette includes more than 10 items. Colors such as beech, pine and oak are often found.

Depending on the interior of the room and the color scheme used, the color of the wiring boxes is selected. The use of a colored cable channel allows you to select the material taking into account the basic design of the room. The most popular products are white or wood-look, as they are used to decorate office premises. An unusual version of the cable channel in black.

The beige color palette is in demand, especially the wood texture.

Installation process

Depending on the load, the gaps between the attachment points are determined. The load is calculated from the number of wires inside the box.

Installation steps:

1. The bottom of the cable channel is drilled in the places where the fasteners will be located. They must coincide with the mounting points on the wall. 2. The channel is attached to the wall. To do this, use long screws or dowels. 3. The cable is placed in a box. 4. Make sure that the wires do not rest against the cover, otherwise it will not latch. 5. The decorative cover is covered after laying the cable.

Construction adhesive must be used for fastening. This will be the fastest way. It is often used when laying cables on tiles or metal bases. Although the adhesive composition is more often used to strengthen the main fasteners.

Floor and baseboard cable channels

Floor and baseboard cable ducts are a separate category. All floor and plinth cable channels also have their own additional elements that simplify the laying of highways.

Plinth cable channels are hollow inside and can accommodate many wires. This is an excellent option for laying antenna or computer cables.

Pros of cable channels

- There is no need to groove walls to lay wires.

- The laid cable is always open for inspection - you can always lay an additional line nearby.

- Despite its apparent softness, the cable channel additionally protects the wires laid in it from mechanical damage.

- The installation of the main line is carried out as quickly as possible.

- Various forms of cable channels allow you to fit the external electrical wiring line into most interior solutions.

Cons of cable channels

- Sometimes cable channels do not look at all in the interior of the room.

- The box “takes away” several centimeters of space from the wall.

- It is easy to accidentally snag the cable channel - knock it off the fastening or break it.

- High-quality installation is only possible with the use of a large number of additional accessories - turns, branches, etc.

Methods of using cable channels for laying open electrical wiring

A wide range of components for electrical wiring allows you to implement the most complex projects. Installation of the wall box is carried out taking into account the height of the sockets, junction boxes and switches. For open spaces, designs of wall and floor cable ducts made of metal are used. This provides protection from the effects of electromagnetic vibrations. Such options are relevant when installing information wiring.

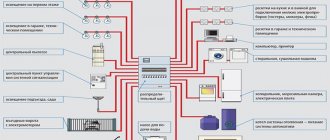

Before proceeding with installation, it is worth understanding the basic elements of the electrical circuit.

Angled cable channel

Used for mounting LED strip lighting. Most often, such products are made of aluminum, and the lid is made of heat-resistant plastic.

The corner cable channel is used to fill the junction of the main line in the corners.

For the home, a flexible cable channel for wires is often used. Lightweight metal models are also used. There must be enough space inside the case for a certain number of cables. It is important to check the availability of the necessary accessories for the cable products.

Flexible designs allow you to disguise a large number of wires. When choosing products, you need to count all the locks, mounting fasteners and plugs on the spot.

Electrical wiring can be organized according to an open circuit using the following types of electrical boxes:

Wall box for wires with double-sided and one-sided lock.

Wall Channel Installation

- floor plinth with separate sections for low-current wires;

- ceiling material;

- designs of cable ducts on the floor with protection from mechanical impact;

- corrugated pipes and trays used in utility rooms or for external facades.

Outdoor cable channels are used for the local area.

Flexible structures can be used for the street.

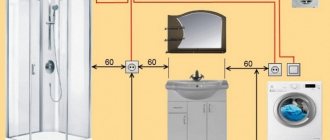

Installation of wall boxes is carried out using self-tapping screws. They should be installed at certain intervals. The load is determined by the number of wires inside. To fix it on a wooden surface or on drywall, it is necessary to screw it in every 40-50 cm. If the walls are uneven, then the distance may be less to hide flaws.

To work with a brick or concrete wall, installation is carried out using dowels. To work, you will need a hammer drill with a nozzle with a diameter of 6 mm. The simplest fastening option is liquid nails, which are construction adhesive.

Wall mounting option

Floor channels will allow you to disguise any wiring so as not to spoil the interior. In this case, the structure is combined with the baseboard. Before installation, markings should be made on the walls and floor. Interestingly, plastic cable channels are mounted not to the floor, but to the wall. Installation is carried out using screws, liquid nails and dowels.

Installation of a floor skirting box

Installation of wiring in the channels is carried out after completion of finishing work. Markings for the cable mesh are marked on the walls. Laying is done from the distribution panel. First of all, main lines are installed, and then branches from them. If the channels do not have holes, you can make them yourself.

Installation of a wall channel with wires. The channel section is fixed to the wall. In this case, the line should be positioned in the center of the holes. After this, fastening with dowels is carried out. After installing the connecting parts, the box is cut to the required length.

The features of installing a cable in a box are shown in the video:

Types of wire boxes

Boxes for wires exist in different variations. Each has its own characteristics:

- mini-channels are designed for laying electrical wires to the end user, and this is a computer, TV, etc.;

- floor, oval-shaped and do not interfere with the movement of people and furniture in the room;

- parapets are used in residential buildings, offices and other administrative buildings;

- perforated. The weight of the channels is reduced due to perforation of the walls;

- baseboards. As the name suggests, channels of this type are installed under the baseboard to eliminate aesthetic disturbances inside the living space;

- Flexible ones can be rubber or plastic. Perforation helps solve architectural and design decisions;

- corner ones are installed mainly in the ceiling;

- transparent ones allow you to place an LED strip inside. This type of cable channel is decorative.

Table of sizes of electrical plastic boxes

Depending on the material

As mentioned above, cable channels are made of metal, plastic, and wood. The most popular are plastic, then come metal, and in last place are wooden. The latter are rarely made of natural wood; they are mainly skirting boards with internal cut-out channels for laying wires.

Note! If wood is mentioned, most often it means plastic that matches the color or texture of the wood.

Metal ones are used in places where protection from precipitation is needed, in production, in places where wires may be subject to mechanical stress. Galvanized steel is used when installing communications for video surveillance and warning, since these systems are subject to mechanical, magnetic, and other influences with an electrical attachment. Galvanized steel protects wiring well from fire. The same can be said about anodized aluminum.

Metal cable channels

Plastic products are the most popular. There are even fireproof plastic ones. Their cross-section and purpose are varied. The advantages of plastic include:

- light weight;

- anti-corrosion resistance;

- ease of fastening;

- installation without using any tools;

- PVC cable channel has low cost;

- choosing the required length;

- decorative properties;

- ease of care;

- no deformation occurs due to temperature fluctuations.

You may be interested in Description of wire PV-1

By location and purpose

The communication box can be placed anywhere, as long as it does not interfere. There are many options for laying:

- floor-mounted, as the name suggests, are installed indoors on the floor, providing protection for communications from mechanical damage. The profile can be round, and the channel can be in the form of a corrugated or perforated hose. If the floor material allows, that is, the aesthetics will not be affected, you can cut a recess in the floor for the channel, lay it in it, covering the cable with decor. Most often, floor ducts are made of metal, they allow you to easily service the wiring by opening the cover. The boxes are heat-resistant and can withstand temperatures up to 600 ⁰C. Scope of application: office, medical, administrative institutions;

- corner products are in addition to baseboards. They are located in the corners of the room. They have a triangular or semicircular cross-section. The box is easy to install. The color palette is white or white with a cream tint;

- skirting channels are used in offices and residential buildings. Used in areas where ceilings and walls meet, ensuring easy installation. The box includes a place for laying wires. Often it replaces the baseboard and, with a well-chosen palette, fits perfectly into the interior of the room;

- wall-mounted ones have a rectangular cross-section with a removable lid. Some designs provide separate recesses for separate cable routing. Thanks to this internal arrangement, the wires do not sag and are firmly fixed. A decorative wall box for wires is used to visually complement the interior;

- ceiling ones are, in fact, the same skirting boards. They are laid at the junction of the wall and ceiling with a branch from the wall channel to a chandelier or any other electrical appliance on the ceiling. They can be really wooden depending on the interior;

- flexible boxes, or perforated ones, have the form of a corrugated hose or the same rectangular cross-section. They are produced in 20 m lengths. They are easily mounted and connected using glue. They are used in industrial buildings and offices.

The profile with LED strip is a decorative element. Its use is possible in production to illuminate the workplace, but this rarely happens.

Types of cable channels

Note! This is a channel with an open outer part into which an LED strip is inserted, covered with a transparent plastic cover. Suspended around the perimeter of the room. Used for illuminating shop windows and advertising banners.

You may be interested in this Features of the PNSV wire

Aluminum threshold-channel

Wall mounting methods

Liquid nails can be used as a temporary fastening method. Correct fixation also affects the life of the product. There are several ways to attach a cable channel to the wall:

- Self-tapping screws. The laying step is calculated in advance, which depends on the load on the box, the number of wires, and the cross-sectional dimensions. The average step is 50 centimeters. If the wall has an uneven surface, the step should be reduced to visually hide the gaps and defects of the wall. There is no need to take long screws; a product 40 mm long is enough. Application: wooden and plasterboard walls.

- Dowel-nails. Typically used for installation on concrete and brick surfaces. On the base of the cable duct, holes should be made every 50 cm with a diameter of 6 mm. The channel should be attached to the wall and, using a pencil, place the places where the fastening will be made. In these places you need to drill holes, then attach the box and drive in dowel-nails.

- Bedbugs. These are special mounting clamps that are used for fastening to metal up to 2 mm thick or to aluminum profiles.

- Liquid Nails. They are used when the methods described above cannot be used. Example - tiles in the bathroom, smooth metal surface. It has poor reliability, so it is used as a temporary method of fastening.

The best method depends on the wall material.

Installation features

When installing, cable channels are located horizontally or vertically. Sloping areas are only allowed on stairs or attic floors. At the branch points, junction boxes are placed in which all connections occur.

Only vertical and horizontal

Fixation methods

There are two ways to install cable channels: with dowels/screws and with glue/adhesive double-sided tape. The first method is universal. Suitable for all types of bases. Only the types of dowels need to be selected (plasterboard and foam blocks have their own fasteners). When choosing fasteners, look for dowels or self-tapping screws with large diameter heads so as not to tear the plastic. If you don't find any, you can use washers.

The amount of fasteners for a 2-meter-long tray (standard length) depends on how smooth the wall is. If it is perfectly aligned, 3 fastenings are enough - at the beginning, at the end and in the middle. If the wall is curved, more fasteners are needed so that the tray fits tightly to the wall and does not “bulge.” If there are a lot of cables or very curved walls, installation every 20 cm may be necessary.

To prevent cable ducts from bursting when installing cable ducts on screws or dowels, first drill holes in them with a diameter slightly smaller than the diameter of the fastener. Then the tray is applied to the wall, and the holes are marked with a marker/pencil/felt-tip pen. Remove the cable channel, drill holes, and install plastic plugs. Then apply the tray and secure it with dowel nails).

When tightening fasteners, be careful not to damage the plastic

In some cases, you don’t want to drill into the surface. Then you can use glue or adhesive tape. The glue must be used with quick initial fixation. The tray does not weigh very much, but if the fixation force is insufficient, it will “crawl” down. To prevent this from happening, you can install spacers in the opposite wall (if distances allow) or secure the box with pieces of adhesive tape.

Floor adhesive tape requires a smooth, dust-free base. It is better to take it on a foam basis. In this case, the requirements for the “smoothness” of the wall are reduced. Due to the foam base, small pits/protrusions are smoothed out.

How and what to cut

If you need to cut a piece of cable channel of a certain length, first put on the cover and align the edges. Then, using a felt-tip pen, a mark is made on the tray and on the lid. After this, you can cut the cable channel separately: the tray and the cover. In this case, their length will be the same.

To achieve an exact match in the places of cuts, you can use a carpenter's miter box. Even better is to find a special saw for plastic. In this case, the cut will be neat and, after a little sanding of the edge, everything will match perfectly.

How to cut plastic straight

It is better to cut cable trays with a fine-tooth metal saw. The edge turns out smooth. If necessary, it can be sanded with fine-grain sandpaper. You can also use metal scissors, but then there is a high probability that the edges will wrinkle and/or lose their ideal geometry.

Sequence of work for installing an electrical box

Installation of the mounting box occurs in several stages.

- Preparatory work.

- Box fastening.

- Laying cables.

- Cover fastening.

The lion's share of the preparatory work for installing a box for electrical wiring lies in reasonable planning of the location of the cable network.

Following safety rules, it is recommended to avoid laying the route in places of water supply and gas equipment, near heating devices. Do not also forget that in the event of an emergency, smoke spreads through the cable duct system, which can cause harm to human health. All this must be taken into account when developing an energy supply project.

Directly on the ground, the installation area of the boxes must be pre-marked. At the same time, the vertical and horizontal sections of the route are observed. It is preferable to make turns and additional layers at right angles, over the shortest distance.

Installation of the cable route is carried out in the following sequence:

- Disassemble it by removing the top cover.

- Attach the box to the wall. The distance between fasteners is accepted to be at least 0.5 m. Many products have holes for fastening, they can be used, but it is always worth making allowances for the specific situation. It is best to fasten the box every 50 cm

- For fastening, you can use screws, dowel-nails, anchors or clamps. Thin and light plastic boxes can be secured with glue or double-sided tape. But at the same time you need to ensure that contact with the wall surface is reliable. The surface of the wall must be cleaned and degreased so that contact with the plane of the box is as tight as possible

- Laying wires. The wires can be laid one at a time or in a bundle tied in several places. It is advisable to label each cable or install special tags to make the work easier for those who will deal with the wiring diagram in the future. Wire markings must contain clear symbols and be protected from abrasion over time.

- Installing the cover. It is recommended to lubricate the locking grooves or latches with a special sealant. This will enhance the protective properties of the lid and prevent the entry of dust and moisture. The edges of the mounting box can be coated with sealant before closing.

Cabling

It seems like a simple process, but even here there are some nuances. We recommend choosing cable boxes that have longitudinal partitions in their design. You can easily lay cables in them, so to speak, floor by floor, so that they do not interfere with each other. If the cable channel is a box without partitions, then pay attention to the quality of the cover fastening. It is important here that it is not squeezed out under the pressure of the weight of all the laid wires.

Covers cannot be joined at the joints of the rear panels; installation must be done offset.

What is a cable channel?

To install exposed wiring, it is not at all necessary to nail the wires to the wall. To give open wiring a beautiful and neat look, special fittings called a cable channel are used. A cable channel is a box that covers wires and plays not only a decorative role, but also a protective one. The protective cable box protects small children and pets from electric shock.

Advantages of an electrical box

The main advantages of placing wiring in a cable channel are as follows:

- ease of installation work;

- mobility;

- availability of communications for modernization or repair;

- Possibility of installation in well-finished rooms. The electrical network, packaged in a box, has a completely acceptable aesthetic appearance;

- scalability. If you correctly calculate the size of the box, there is always the possibility of laying additional cables and wires if the need arises in the future.

Due to the flexibility of the installation process, the technology of using electrical boxes has become widespread in both the industrial and residential sectors. If any problems occur, the suspicious section of the cable network can be easily opened to eliminate the problem.

Among other things, plastic boxes have a low cost and significantly reduce the risk of mechanical damage to wiring. They reliably protect power lines from open contact with a person for whom electric current poses a danger.

Where to buy cable channels for electrical wiring: types, manufacturers and prices

You need to understand the manufacturers of such products if you want to buy cable channels for your home. Many companies offer high quality boxes. In such a situation, it is important to distinguish a fake. You need to ask the consultant for the necessary documents for the products.

Let's take a look at some branded manufacturers:

- Hager. The German manufacturer specializes in office products, but due to the high quality of the boxes, they are also used in residential areas. The products are made in a modern design and are suitable for many interiors. The tehalit.BRP series is used for laying main lines. Universal models are boxes of the tehalit.LFF series, which are characterized by simple installation;

- Legrand. The company offers profiles in different sizes and widths up to 220 mm. There can be up to three sections inside the case. The cable channel is equipped with two types of partitions. Some are mounted in a special groove, while others are flexible and glued to the wall.

- DKS. This domestic manufacturer produces 4 types of channels. Wall-mounted ones have a flat lid and are compact in size. Floor boxes are equipped with turns. They are easily connected to each other. The mini channels come in dark brown and white;

- Schneider Electric. The manufacturer offers the Ultra series with two types of channels. Switches and sockets are mounted in modular frames. Mini channels have a U-shaped cover. For quick installation, you can choose products with self-adhesive tape.

We suggest looking at some types, sizes and prices of cable channels in our table.

Table 1. Average cost of cable channels.

| Elekor 2m IEK white | Suitable for low-current, information and power communications in offices and residential premises. | 36 |

| Ruvinil PKK 16×16×0.8 m | The texture of the material is wood, the color is oak. The material used is self-extinguishing polyvinyl chloride. | 76 |

| Cable channel 25-25 mm. Mutlusan (pack of 100 m) | The material is made to look like light wood. | 2007 (per package) |

| Cable channel 20×10 mm (160 meters per package) T.Plast | Product material is white plastic. | 1390 (per package) |

| Hager LFF channel 60×110 | The structure is made of white plastic. | 422 |

| Legrand DLP with flexible cover 105×50 | Material white PVC. | 695 |

| Perforated DKC 25x40, 2 meters. | The design has a corrugated structure. Made of high quality plastic. | 456 |

Elekor 2m IEK whiteCable channel 25-25 mm Mutlusan packaging 100 mCable channel 20×10 mm T.PlastLegrand DLP with flexible cover 105×50Perforated DKC 25×40

When choosing a cable box, you need to take into account the size, appearance, manufacturer and cost of the product. Properly selected cable channels will disguise unsightly wires and become a great addition to a modern interior. We hope that our article is useful to you. If you want to add something, write in the comments.

Form

At first, manufacturers produced U -shaped profiles in gray and white, as well as rectangular ones. Now there are boxes of different colors and shapes.

Profiles are made in the form of a hemisphere or triangle. It all depends on the room in which they are laid. The type of finishing materials plays an important role.

Cable channels are made of non-flammable PVC or polyethylene.

The standard length of the segment is 2 meters.

But you can find a longer piece.

are products with a cross-section in the shape of the letter P. They are made with perforated or blind sides.