Characteristics of sleeper foundations

Railway sleepers are an affordable and inexpensive solution.

They are quite easy to find, and transporting such material will not be a problem. Many have a negative attitude towards the idea of using sleepers for the foundation of a house, as they believe that they have served as a railway covering for a long time and have lost their strength. But in reality this is not the case; sleepers are specially treated with creosote and have an unlimited service life, which allows them to become a strong foundation for any building. The advantages of a base made of reinforced concrete sleepers include:

- High elasticity of the material;

- long service life thanks to creosote impregnation;

- resistance to temperature changes;

- low price;

- high level of adhesion to ballast;

- insects or rodents will not be able to harm this type of foundation.

This solution also has disadvantages. These include the large weight of the material, which can vary from 45 to 80 kg, as well as the limited size of the sleeper - up to 2.75 m.

DIY foundation made of reinforced concrete sleepers

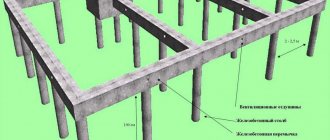

Columnar foundation made of wooden sleepers: 1 - Sleeper; 2 - Waterproofing, which should already be present on the sleeper; 3 - Concrete shoe (option 1), brackets (option 2); 4 - sand cushion (option 1), wooden support (option 2); 5 - sand cushion.

The construction of the foundation of a private house must be approached with special responsibility. This is due to the fact that today the market for construction-related services is rapidly developing, while some contractors do not quite correctly prioritize the construction of private houses, ignoring basic safety rules. An unscrupulous attitude towards laying the foundation in the future can easily turn into a disaster for all residents of the house.

In the process of selecting railway sleepers for the manufacture of a foundation, it is quite important to control the purchase of material and carefully analyze the road surface that will be used for the construction of the foundation of a private house.

If the sleepers are too worn out, they may result in a poor-quality foundation that will need to be restored over time, spending quite a lot of money. The savings that were achieved at the beginning may come to naught in the event of such a sad ending. It is necessary to carefully monitor the activities of an organization that plans to build a foundation from sleepers.

Sleepers must be additionally impregnated with moisture-repellent agents before laying.

Some people mistakenly begin organizing all construction processes by designing the foundation of the future building. However, you should know that this is not the most rational approach, because first of all it is recommended to determine the territory of the site. Once a suitable choice has been made, you can save some money for further construction.

If you carefully approach the design and laying of the foundation of a future building, you can achieve maximum reliability and a long period of operation of a residential structure.

It is preferable to lay such a foundation on soils with a high degree of hardness, otherwise it will not be possible to avoid settlement under the pressure of the total weight of the building. Foundations that can be constructed using sleepers come in different types:

- columnar;

- tape;

- pile;

- slab;

- foundation on sand cushions.

The sleepers can be laid on a gravel bed; moisture will not linger on it, and the sleepers will not rot.

Of all these types of load-bearing structures, strip and column bases are best suited for using sleepers.

During the construction of the strip foundation, logs will be joined along the entire perimeter. If sleepers are planned to be laid horizontally, the markings should be carried out according to plan, after which you will need to make 2-3 rows under the base. These rows should be connected to each other.

A layer of sand and crushed stone, well compacted and moistened, should be placed under the foundation from below. Next, sleepers are laid on top, which are placed with overlapping joints, as in brickwork. Metal staples should be used to secure the end joints. Metal pins should be used to tighten the bottom and top layers.

If you plan to lay a columnar foundation, the logs will need to be placed vertically at a certain distance from each other. During the preparatory work, sleepers must be treated with a special compound with antiseptic properties and coated with bitumen. This type of foundation has a long service life, which can be up to 50 years.

Creating a foundation using railway products allows you to save a lot of money.

Sometimes during the construction of a building a situation arises in which it is not possible to use standard materials to lay the foundation.

In this case, you have to make non-standard decisions and use alternative materials. These include railway sleepers. A sleeper foundation actually has a number of advantages.

This article will discuss the characteristics of this type of basis and the procedure for its creation.

Railway sleepers are an affordable and inexpensive solution. They are quite easy to find, and transporting such material will not be a problem.

Many have a negative attitude towards the idea of using sleepers for the foundation of a house, as they believe that they have served as a railway covering for a long time and have lost their strength.

But in reality this is not the case; sleepers are specially treated with creosote and have an unlimited service life, which allows them to become a strong foundation for any building.

The advantages of a base made of reinforced concrete sleepers include:

- High elasticity of the material;

- long service life thanks to creosote impregnation;

- resistance to temperature changes;

- low price;

- high level of adhesion to ballast;

- insects or rodents will not be able to harm this type of foundation.

This solution also has disadvantages. These include the large weight of the material, which can vary from 45 to 80 kg, as well as the limited size of the sleeper - up to 2.75 m.

Before work, you need to carefully check all materials for quality.

We invite you to familiarize yourself with Knitting reinforcement: methods, patterns, norms and rules of knitting for beginners

Many newcomers to the construction trade consider the use of sleepers to create a foundation unsafe, citing the impregnation of this material - creosote.

The fact is that this substance has a rather pungent odor and contains components that can harm human health.

But all these fears are not justified, since only recently made sleepers cannot be used for the construction of houses, and products that are exposed to the open air for a long time are quite suitable. Precipitation and sunlight have removed the harmful substance from the surface of the material, and now it is safe for humans.

It is recommended to use sleeper foundations for the construction of frame houses. Such a building will be much lighter than its counterparts built using standard materials.

Before you begin, you will need to prepare the following tools and materials:

- reinforced concrete products;

- cement;

- crushed stone and sand of fine or medium fraction;

- equipment for lifting sleepers;

- metal staples and pins;

- bitumen;

- antiseptic solution.

Sleepers can also be used to construct garages or sheds.

The construction of the base must be treated with great responsibility. It is necessary to carefully analyze the condition of the products that will be used for such work. If they are damaged, the created foundation may turn out to be of poor quality and after a certain time it will be necessary to carry out restoration procedures.

Before laying sleepers, they must be thoroughly treated with special water-repellent solutions.

It is best to create such foundations on soil with high hardness to prevent the possibility of settlement under the load of the house. The foundation made of reinforced concrete sleepers can be of different types:

- Columnar;

- tape;

- pile;

- slab.

The optimal solution for using such material are tape and columnar varieties. For a strip base, logs must be laid around the entire perimeter. A layer of sand and crushed stone is preliminarily laid under the foundation, which will need to be thoroughly compacted and moistened. Then sleepers are placed on top, which are placed with overlapping joints. For fastening you need to use metal staples and pins.

If it was decided to use a columnar base, the logs should be placed vertically with a certain interval from each other. During preparation, it is necessary to treat the sleepers with a special antiseptic and bitumen.

This type of foundation has a fairly long service life, which can last up to 50 years. The sleepers are laid on a concrete base and gradually covered.

They are then connected to other sleepers installed in a similar pattern.

The following video will help you learn in more detail about the procedure for creating a foundation from sleepers with your own hands.

For two-story wooden houses, it is best to create a strip base. In this case, concrete sleepers are laid in a special formwork made of wood, which allows you to save a lot on pouring cement. The whole procedure consists of the following steps:

- First, a trench is dug. Its depth must exceed the soil freezing level.

- The formwork is being created. Often boards are used for manufacturing. It must be securely fastened from the bottom of the pit to the top of the basement.

- A layer of sand is added to a height of up to 20 cm. This will help prevent damage to the foundation.

- A cement mixture or concrete is prepared.

- Concrete is poured along the entire perimeter of the pit to the required height, after which the sleepers are installed. They will be used as buta. Then a new layer of concrete is poured and the sleepers are laid again. They need to be installed not on top of each other, but in a checkerboard pattern. According to this scheme, the base is poured to the top of the formwork. This will prevent the tape from cracking. The height interval between sleepers should be about 50 cm. The distance between the edges can vary from 50 to 70 cm.

To install such material you will need to use special equipment.

This type of basis is the most economical. It can be used for frame or wooden buildings, as well as buildings made of foam concrete blocks.

A foundation made of reinforced concrete sleepers allows you to save a lot of money, but you need to take into account that such material has a fairly large mass. Not every master will be able to place it in the formwork or pit with his own hands. For these purposes, you will need to use special equipment, which will greatly simplify the work. Creating a columnar foundation consists of the following steps:

- The first step is to dig a hole for each post. The interval of their installation depends on the design of the building. The depth of the hole can vary from 1.5 to 2 m. The width should allow you to install the material and pour cement mortar around it.

- At the bottom of each pit you will need to create a cushion based on sand and fine crushed stone.

- After which the installation of reinforced concrete products is carried out.

- Each hole is filled with cement mortar.

In what cases is it advisable to build a foundation from sleepers?

The time has come to directly consider the sequence of actions for constructing a bathhouse from sleepers.

It is worth following a number of suggested recommendations:

- First of all, we purchase the material. To build a bathhouse, you will need to purchase about a hundred high-quality, that is, strong, sleepers.

- After laying the foundation and its subsequent hardening, we lay a waterproofing layer. To do this, the surface of the concrete is lubricated with liquid bitumen mastic, and two layers of roofing material are laid on top.

- Now the starting ring of sleepers is being laid. The first row should be laid on slats, thanks to which the sleepers will not touch the foundation.

- Each subsequent row of sleepers is fastened to the previous one by means of a tenon joint. The gap between the first row and the foundation is filled with construction (installation) foam.

- Insulation is laid on top of the first crown, which can be tow, moss, jute, and other materials that are usually used as caulking for a log house.

- The subsequent crown is laid on the insulation. Fastening is used using the “groove-tenon” method, but experts advise resorting to an additional dowel connection. This is done by cutting holes in the sleepers at opposite ends for attaching dowels.

Finally

Formation of walls

The technology for assembling the walls is similar to laying conventional timber; here, steel brackets are driven in every 3-4 rows to connect the crowns. The joints are laid with dried moss, flax, and jute. Corners are cut using the “half-tree” method, alternating opposite directions.

In the case of a compact bath, the ceiling beams are placed simultaneously with the last 2 crowns. The overlap is formed from the cleanest sleepers divided in two. The pairs are spliced into a long piece that will cross the ceiling.

The rafters for the roof are formed and connected on the ground, then raised in pairs to the upper segment of the walls and cut into the last crown. At the same time, the sheathing is filled and covered with roofing felt. The structure must overwinter in this form for complete shrinkage to occur.

The covering of the ceiling is done from the inside of the dressing room and steam room; at the same stage, hydro- and thermal insulation is laid.

Before deciding to use this material in the construction of the foundation, you need to take into account some nuances that can play an important role in the construction of the foundation:

- the opportunity to inexpensively buy sleepers that have already served their useful life at an inexpensive price;

- transportation and delivery of material to the site, if the sleepers are located far from the construction site, then transportation and transport costs can reduce your savings to zero;

- the structure installed on a foundation made of wooden sleepers must be small and light;

- the foundation will be arranged independently, without the involvement of third-party labor.

From sleepers you can create classic types of foundation with your own hands, and it will be reliable and durable, provided that construction technologies are followed. Also, each developer has the choice to build a foundation from reinforced concrete sleepers or choose wooden ones, it all depends on the construction budget.

The process of installing a foundation made of reinforced concrete sleepers

This is what used reinforced concrete sleepers look like

In addition, you can build a foundation with your own hands, since the material does not require special processing and is quite easy to use. It is enough to have one assistant who will drag the sleepers with you from place to place and help in laying the material in the foundation trench.

Construction of a columnar foundation

A sleeper foundation is an excellent solution for laying a foundation in cases where it is necessary to do without the use of standard materials.

It will be durable and the construction will be inexpensive (if there is somewhere to buy them). Foundations constructed using reinforced concrete elements are ideal for technical buildings. It will be durable and stable.

The use of this material to create a foundation for summer kitchens, baths, and living quarters is highly not recommended.

Its availability may be attractive, but it has a fairly strong unpleasant odor and cannot boast of high environmental friendliness.

Simply put, its use is harmful to the body during the construction of a house.

BUT. The above applies only to elements of the construction of railway tracks that have been manufactured recently and are impregnated with creosote.

Old ones (that have served their time), which do not emit a specific smell, are quite suitable for building the foundation of a house, but it is still better not to do this.

Creosote is a poisonous impregnation agent.

Another reason for refusing this material is the high cost of delivery, almost equal to the transportation of reinforced concrete blocks.

It is possible to use wooden sleepers to build a foundation, but such a structure will have insufficient strength and there is no point in taking such a step when building a house.

Fastening wooden foundation sleepers

A sleeper foundation allows for simple and quick foundation creation (there is no need to carry out a large number of construction processes).

As already mentioned, it is better not to use it for the home, but it is quite applicable for greenhouses and technical extensions.

Reinforced concrete material can be used to create with your own hands both a foundation with a grillage and a strip foundation.

Foundation made of wooden sleepers on pillars

It is worth noting that the use of railway elements is optimal as a grillage - horizontal elements of the foundation (piping). The process for creating a base is as follows:

- A trench or pit is being dug. Their depth should be about 0.4 m.

- Wells are drilled around the perimeter. The distance between them should be 1.35 and 2.7 meters. To carry out this process with your own hands, you can use a drill with a diameter of 0.3-0.4 cm. The depth of the holes is selected depending on the weight of the future structure, but cannot be less than 1 m.

- Roofing felt and a frame with reinforcement are placed in the well. The first should be rolled up in the form of a roll, and the second should look like 4 vertical pins connected by elements (strapping) in increments of 0.3-0.4 cm.

- Wells are filled with concrete.

- After arranging the supports, the turn comes to the grillage. It is important that the supports gain maximum strength. If the distance between the supporting elements was chosen at 1.35, then the sleeper will rest on 3 supports, and if at 2.7 - on 2. The first method is ideal for a garage or barn, and the second - for small structures with low mass.

Using railway elements as a grillage

It is also worth noting that the process of constructing a base from wooden sleepers with your own hands is absolutely similar.

Strip base for garage on sleepers

Work algorithm:

- A regular trench is dug (like for a house), necessary for the construction of a strip foundation. Its width should not exceed the width of 2 sleepers stacked side by side.

- Creating a pillow: 10 cm of gravel and about 30 cm of sand. After doing this work with your own hands, the depth of the trench should be 40-50 cm. This height will be enough to lay sleepers in 2 or 3 layers.

- The walls and bottom are waterproofed using a film, onto which the railway elements are laid directly. Laying method: on top of each other, creating a dressing (the upper element is placed on 2 lower ones, installed adjacent to each other).

- After installing the sleepers with your own hands, the empty space is filled with concrete.

The construction of such a foundation involves the use of sleepers as a core - this reduces the consumption of concrete and reinforcement, which allows for great savings.

This technology involves the use of only reinforced concrete elements. It is worth finding another use for wooden ones.

For example, installing a basement or building walls.

Key points when using reinforced concrete sleepers for the foundation

Sleeper table: dimensions

Sleepers, thanks to treatment with creosote, are able to have high strength indicators for quite a long time.

True, when choosing reinforced concrete sleepers for the foundation of a house or other structure with a large mass, you need to pay special attention to their wear. If it is too large, the strength of the foundation will not be sufficient to support the house.

Foundation made of wheels and sleepers

Sometimes when arranging a greenhouse, it becomes necessary to build a foundation for it.

The fastest and most economical way to accomplish this task is to use railroad ties.

First, we need to list a number of situations when a greenhouse really needs to build a foundation:

- The soil level is low.

- The structure is buried in the ground to a level below its freezing point.

- It has a wooden frame (the base will extend the service life of such a greenhouse).

- Mounted on a slope or in close proximity (adjacent) to buildings.

- Designed for year-round use.

- Its dimensions exceed the standard several times.

- It is located far from housing (there is no constant supervision over it and it could be destroyed).

At the same time, for the base of the greenhouse, you can use elements from any material: wood or reinforced concrete.

Greenhouse on a sleeper base

It is worth noting that wood sleepers are treated with creosote, a substance quite dangerous to humans.

Therefore, it is better to use railway elements that have faithfully served their service life and are no longer in use.

In this case, there is a high probability that the poison has evaporated and the level of danger has become much lower.

Of course, the sun, wind and air are not able to make the material environmentally friendly, but they can affect the disappearance of unpleasant odors.

True, creosote is responsible for the strength of products, so the best option for use in the construction of a foundation is sleepers that have been in use for a long time, without a characteristic odor, but whose condition is above average.

Whether to use sleepers to lay the foundation of a house or not is a rather difficult choice. On the one hand, one is attracted by the profitability of purchasing such material and the degree of savings when using it.

On the other hand, when using such a foundation element, there is a fairly high risk of harm to health: creosote is a toxic substance for humans.

We suggest you familiarize yourself with How to make protective grounding in a private home

Therefore, the choice is up to everyone, but it’s better not to take risks.

Strip foundation made of sleepers for permanent buildings.

Most of the opponents of the use of sleepers as a material for the manufacture of foundations accuse the impregnation that is used in the production of railway tracks - creosote.

It is known that this substance, which has a characteristic odor that is quite difficult to tolerate, contains components that are toxic to humans. Some people express concern when it is recommended that they build a foundation for a private home using sleepers that are impregnated with creosote.

You should know that this is actually true. New sleepers that have just been manufactured are not recommended for construction. However, this does not apply to sleepers, the operational period of which as a railway track has come to an end.

Such sleepers spent quite a long time in the open air, therefore, the sun's rays and numerous precipitation managed to remove most of the harmful impregnation from their surface. Therefore, a foundation made of sleepers with a long service life is absolutely safe to use as the basis for the construction of private houses, which are made using frame technology. Such houses are much lighter than their analogues, which are built from materials such as blocks or bricks.

To work you will need the following elements:

- reinforced concrete sleepers;

- cement;

- crushed stone;

- sand;

- special equipment for lifting reinforced concrete sleepers;

- metal staples;

- metal pins;

- bitumen;

- composition with antiseptic properties.

For a two-story frame, wooden house or a one-story structure made of brick or concrete blocks, in most cases a strip foundation is made. Concrete sleepers are laid in wooden formwork, which can significantly reduce the cost of cement for pouring.

- First of all, it is necessary to dig a trench to a depth that exceeds the depth of soil freezing (each area has its own characteristics).

- Next, the formwork is made. In most cases it is made from boards. It must be securely fixed from the bottom of the trench to the top of the base (up to 1.5 m above the ground surface). In the case of hard soils that do not crumble, it is allowed to perform formwork only for the base.

- Next, backfill is performed - a compensation layer of sand 15-20 cm high. This layer can protect the finished foundation from the influence of heaving forces that occur when the soil thaws and freezes.

- Cement mortar or concrete is prepared.

- Concrete is poured along the entire perimeter of the trench to a small height, after which sleepers are laid in it as rubble. After this, pour the next layer of concrete and lay the sleepers again. They must be laid not on top of each other, but with overlap in relation to the previous row, that is, in a checkerboard pattern. In this way, the foundation can be poured to the top of the formwork. This will make it possible to prevent cracking of the finished tape.

It is important to note that it is not recommended to lay sleepers directly on top of each other. The height distance between them should be about 50 cm. In this case, the distance between the edges is 50-70 cm.

A foundation made of reinforced concrete sleepers, which is made in this way, can be quite strong and last a long time.

Drawing of a reinforced concrete sleeper.

This type of foundation for buildings is the most economical. It may be suitable for frame, wooden buildings, houses made of foam concrete blocks on damp soils, especially if they are subject to heaving.

Installation of a columnar base

Preparation for laying a columnar base includes the involvement of a drilling rig, the search for rope, twine, and an increased supply of roofing material that will replace the formwork.

They use a rope to mark the construction site and drill vertical trenches for sleepers. The pillars will be placed at a depth of about 1.5 m, leaving a distance of at least 2 m between them.

The bottom of the pit is covered with sand and crushed stone, making dense cushions, waterproofing material is laid, and sleepers are inserted into a permanent place.

A supply of reinforcing bars remains on top of the pillar, to which the reinforcing center of the grillage is attached, roofing material is tightly wound around the sleeper as a form, and the cement mixture is poured.

How to make a columnar foundation from reinforced concrete structures

For a columnar foundation you will need the following tools and materials:

Scheme of a columnar foundation made of sleepers.

- rope or twine;

- shovel;

- fittings;

- concrete mortar (cement, sand, crushed stone);

- concrete mixer, bucket, trowels;

- permanent formwork - roofing felt;

- drilling rig;

- piles - pillars.

First, you should install a cast-off piece of twine and mark the places where the pillars will be dug. Dig a trench in accordance with the dimensions of the future structure; reinforced concrete sleepers should be placed in the ditch. Then you need to drill holes with a diameter that will coincide with the diameter of the pillars. Do not forget about the depth of soil freezing (about 1.5 m). The distance between the dug pillars is 2 m. At the bottom of the hole you need to make an air cushion, install the formwork, put in waterproofing material and only then lay the sleepers in the ditch. After this, make a concrete solution and fill the hole with it.

A foundation made of reinforced concrete elements can be called the reinforcing heart of the future structure; in addition to a durable and rigid structure, significant savings can be achieved.

How to make a foundation from sleepers with your own hands - installing a grillage

In the foundation structure, sleepers are most often used as horizontal beams (grillage).

Well, the construction of the foundation itself, in this case, is carried out according to the following scheme:

- A pit or trench is dug under the base, the depth of which is 40 centimeters.

- At the bottom of an open trench, holes are drilled for vertical supports in increments of 1.35 or 2.7 meters. To construct such wells, you can use a hand drill, the diameter of which is 30-40 centimeters. The drilling depth, in this case, is determined individually, but cannot be less than 1-1.25 meters.

- Rolled roofing material and a reinforcement frame (four vertical pins with horizontal bandaging, mounted in increments of 30-40 centimeters) are inserted into the pits. After that, concrete or a sand-cement mixture is poured into the pit.

- Having arranged the supports, you can start grilling. To do this, you need to wait for the supports to completely harden and lay the ends of the sleepers on them. If the supports were installed in increments of 2.7 meters, then the sleeper will rest on two supports. And if the step was 1.35 meters, then there will be three supports under the sleeper. The latter option is used in the construction of block garages or sheds. The first option is used as a base for small architectural forms or frame structures.

It should be noted that the foundation of wooden sleepers is built according to the same scheme. That is, the grillage can be assembled not only from reinforced concrete, but also from wooden beams.

Use of sleepers in the construction of strip foundations

In addition, using sleepers for the foundation of a block or brick structure, you can use not only the technology of assembling a beam grillage on poured supports, but also a slightly different arrangement option, which involves the construction of a full-fledged strip foundation.

And the process looks like this:

- A standard trench is dug at the site for a strip foundation. The width of the trench should not exceed twice the width of the sleeper.

- After completion of the excavation work, a 10-centimeter cushion of gravel and a 25-40-centimeter cushion of sand are added to the bottom of the trench. After which the depth of the trench should be 40-50 centimeters - this will be enough for arranging two or three layers of sleeper masonry.

- The walls and bottom of the trench are covered with a waterproofing film, on top of which sleepers are placed, stacking them on top of each other. In this case, you need to take care of the dressing by placing the element from the top layer on two lower sleepers located next to each other (it should cover the vertical joining seam).

- After laying the sleepers is completed, sand-cement mortar is poured into the free space.

The basement part of the foundation, in this case, is laid out of brick or concrete blocks. And, of course, this technology involves the use of only reinforced concrete sleepers. Wood products, in this case, can be used for the construction of walls or installation of a basement floor.

About the site

zalman

Sleeper base for home: harmful or not

Scheme of a foundation made of sleepers with deepening.

There are several important reasons when it is necessary to make a foundation. One of the best options is a greenhouse base made from sleepers. you can make it yourself. First of all, you need to figure out in what cases a foundation for a greenhouse is needed, and only after that figure out how to make the foundation yourself. A foundation for a greenhouse is needed if the structure:

- adjacent to residential premises and used throughout the year;

- installed in an unguarded place (then the foundation will not allow vandals to demolish it or steal it);

- buried in the ground below the freezing level;

- made of wood (the foundation will extend its service life);

- installed on ground with low soil standing;

- installed on a slope of the site;

- has dimensions several times larger than standard ones.

The foundation for a house made from sleepers is an excellent alternative to traditional types of foundations. Such a foundation will be quite durable and reliable.

At the same time, the developer has a choice: to prefer a foundation made of wooden sleepers or to make a structure from reinforced concrete products.

The main disadvantage of wooden sleepers is the creosote impregnation. Firstly, it is toxic. Secondly, it has an unpleasant odor. However, this impregnation extends the service life of the material and resists the negative effects of various biological factors and moisture.

In the case of using sleepers that have served for a certain time for their intended purpose, you can ignore this drawback. Water, sun and air, acting on the material, caused the smell to disappear. Provided that the sleepers have retained their strength and integrity, they are perfect for building a foundation for a greenhouse or a lightweight country house.

Prepare a site of suitable size, level it, and remove vegetation. Make markings in accordance with the known dimensions of the greenhouse. Dig a trench about 20-30 cm deep. Level the horizon.

Install logs (sleepers) of the required length around the perimeter. Excessively long ones need to be sawed off. Double-check the level relative to the horizon of the laid logs (sleepers). Fasten them together using construction staples.

Measures for waterproofing the structure are carried out in the same way as when constructing other foundations. A foundation made of wooden or concrete sleepers must be coated with bitumen and a layer of waterproofing applied, which can be polyethylene film, roofing felt and other similar materials. If possible, the sleeper base can be insulated. The design requires the implementation of exactly the same protective measures as a foundation made of any other building materials.

If all the work on laying the foundation for a house, greenhouse or any other outbuilding made from sleepers was carried out in accordance with established norms and rules, and the protective waterproofing and other treatments were carried out with high quality, then even wooden sleepers will last a very long time. Experience shows that such a foundation can last up to half a century without loss of quality and reliability.

It is necessary to mention that a pile foundation made of sleepers is a semblance of an ordinary pile foundation. Provided that a reliable reinforced concrete grillage is installed, even a fairly heavy building can be erected on such a foundation.

Sleepers thoroughly impregnated with creosote have an almost unlimited service life. So even products that have already served their purpose can be used in the construction of a foundation for a house, greenhouse and other buildings and structures.

We suggest you familiarize yourself with what brand of concrete to pour under the foundation

Most opponents of the use of sleepers for the construction of foundations most often argue their position precisely by the fact that creosote is used in the manufacture of railway tracks.

It is really better not to use new sleepers that have just come from production for the construction of residential buildings. As already mentioned, such impregnation not only has an unpleasant odor, it is also poisonous to humans. However, this does not apply to those sleepers whose service life as a railway track has already expired, and they can be safely used in the construction of a foundation for a house, greenhouse, etc.

The construction of a foundation for a residential building, greenhouse and any other outbuilding must be approached with the utmost responsibility. Due to the fact that the construction services market is currently developing rapidly, most contractors incorrectly prioritize the construction of residential buildings, ignoring the simplest safety rules.

Diagram of a sleeper foundation with gearing.

This subsequently results in an unscrupulous attitude towards the construction of the foundation, which as a result can turn into a real disaster for all residents of the house. When choosing sleepers for building a foundation, it is necessary to carefully analyze the road surface and control the process of purchasing material that will be used in the construction of the foundation of the house.

If the sleepers are too worn out, they will create a foundation of very poor quality, which will have to be repaired after some time. And this is a very expensive pleasure. All the savings that were achieved at the beginning of construction will simply come to naught with such a sad ending.

Many developers mistakenly start work by designing a future house, greenhouse or other building. However, this is not the most optimal approach, because first it would be nice to determine the territory of the construction site. The right choice will save a significant amount of money that will be spent on the construction process.

It is best to lay the foundation on soil with a high degree of strength. Otherwise, settlement will occur under the pressure of the total weight of the building. Foundations can be of different types: strip, slab, columnar, pile, base on sand cushions.

Of these types of load-bearing structures, columnar and strip foundations are best suited for using sleepers.

A layer of crushed stone and sand, carefully compacted and well moistened, is placed underneath the base. After this, sleepers are laid on top, which are arranged with overlapping joints, like brickwork. Metal staples can be used to secure the end joints, and metal pins can be used to tighten the bottom and top layers.

In the process of laying a columnar foundation, the logs must be positioned vertically at a certain distance from each other. When performing preparatory work, sleepers must be treated with a special antiseptic solution and coated with bitumen. This type of foundation is characterized by a long service life (up to 50 years).

Sleepers for the foundation are installed on a concrete base, gradually sprinkled, and then sewn together with other sleepers already installed according to the same principle.

BUT. The above applies only to elements of the construction of railway tracks that have been manufactured recently and are impregnated with creosote. Old ones (that have served their time), which do not emit a specific smell, are quite suitable for building the foundation of a house, but it is still better not to do this.

Creosote is a poisonous impregnation agent.

Another reason for refusing this material is the high cost of delivery, almost equal to the transportation of reinforced concrete blocks.

It is possible to use wooden sleepers to build a foundation, but such a structure will have insufficient strength and there is no point in taking such a step when building a house.

Work algorithm:

- A regular trench is dug (like for a house), necessary for the construction of a strip foundation. Its width should not exceed the width of 2 sleepers stacked side by side.

- Creating a pillow: 10 cm of gravel and about 30 cm of sand. After doing this work with your own hands, the depth of the trench should be 40-50 cm. This height will be enough to lay sleepers in 2 or 3 layers.

- The walls and bottom are waterproofed using a film, onto which the railway elements are laid directly. Laying method: on top of each other, creating a dressing (the upper element is placed on 2 lower ones, installed adjacent to each other).

- After installing the sleepers with your own hands, the empty space is filled with concrete.

The construction of such a foundation involves the use of sleepers as a core - this reduces the consumption of concrete and reinforcement, which allows for great savings. This technology involves the use of only reinforced concrete elements. It is worth finding another use for wooden ones. For example, installing a basement or building walls.

Key points when using reinforced concrete sleepers for the foundation

Sleeper table: dimensions

Sleepers, thanks to treatment with creosote, are able to have high strength indicators for quite a long time. Even railway track elements that have been used and replaced with new ones can be used to construct the foundation of a house and other buildings, and there is no need to worry about the life of the foundation.

True, when choosing reinforced concrete sleepers for the foundation of a house or other structure with a large mass, you need to pay special attention to their wear. If it is too large, the strength of the foundation will not be sufficient to support the house.

Foundation made of wheels and sleepers

- The soil level is low.

- The structure is buried in the ground to a level below its freezing point.

- It has a wooden frame (the base will extend the service life of such a greenhouse).

- Mounted on a slope or in close proximity (adjacent) to buildings.

- Designed for year-round use.

- Its dimensions exceed the standard several times.

- It is located far from housing (there is no constant supervision over it and it could be destroyed).

Assembling the strip structure

To lay the foundation from sleepers0, you will need to prepare the necessary things in advance and hire special equipment.

The materials you will need are: reinforced concrete products, concrete mortar, sand, crushed stone, clean water. Consumables - metal pins, staples, bitumen-based mastic, antiseptics, fittings, boards for formwork, nails.

You need few tools, just take a building level, a shovel, a hammer, a crowbar, a construction mixer, and an electric drill with an attachment.

The markings are applied with a tape measure, pegs, and rope.

A trench is dug along the perimeter of the future foundation, 80 cm deep and 30 cm wide.

The bottom is first covered with crushed stone, compacted, covered with sand in layers, periodically irrigated with water to increase density. The total size of the pillow is 30 cm minimum.

They move on to laying waterproofing made of dense polyethylene, roofing felt, and laying beams.

The length of the piles should correspond to the length of the ditch. The parts are fastened with metal staples.

The formwork is installed, tied, a reinforcing belt is inserted, and concrete is poured.

Material selection

Capital buildings, built, as they say, to last, are built of stone or brick. Cinder blocks or foam concrete blocks are also often used. It is reliable, durable, but expensive, and when creating such a structure you cannot do without the skills of a builder, otherwise it will simply fall apart. In most cases, wood or a material based on it is chosen for a shed in a country house.

Boards and slabs

If you need to build a wooden shed with your own hands, but have financial difficulties, you can choose a budget option - a frame structure with cladding made of boards or wood-based slabs. Despite all its apparent simplicity and flimsiness, such a shed will last for decades, and if made well, it will fit perfectly into any backyard.

In this case, timber will serve as the material for the frame. It is easy to work with, and the resulting structure will have sufficient strength and reliability. This solution is perfect for wetlands, where it is impractical to build a permanent building on a foundation.

From all of the above we can conclude: wood is the best material for a shed. This is true. A wooden shed benefits from a number of characteristics:

- ease of manufacture;

- short work deadlines;

- availability of material;

- environmental cleanliness;

- the ability to build a cold and warm barn.

It is also worth noting the fact that the final finishing of a barn, like any other wooden structure, is characterized by extreme simplicity and an abundance of options. Any method is suitable here: from budget painting to original clapboard paneling.

Log

Since ancient times, logs have been used as a building material. This is an excellent choice for building a wooden shed, especially in wooded areas where this material is not in short supply. A log barn has an excellent appearance; it can be built in an ensemble, for example, with a bathhouse; it will be a good addition to a wooden house. The only significant drawback is that the work will require specific skills.

An excellent building material for the construction of any building. The characteristics of the timber are comparable to those of a log, but thanks to its rectangular profile it is much easier to work with. A barn made of timber will fit perfectly into a wooden courtyard; few people would dare to disparagingly call a masterfully built structure a barn.

Sleepers

A shed made of sleepers is an excellent budget solution, especially for villages located near the railway. Wooden sleepers are gradually being phased out, but they are a very reliable and durable material. A sleeper, even if it has served for decades, can be an excellent choice for the walls of a small shed.

The advantages of this material are obvious: the sleeper is cheap, due to its shape, even a beginner can build a wall from it, and thanks to its impregnation, the sleeper will last for many more decades. True, it is in the impregnation that the main drawback of this material lies - a characteristic odor plus an unsightly appearance.

Watch this video on YouTube

How to make a foundation from used reinforced concrete sleepers

Nowadays, when almost all building materials are rising in price, every person strives to save as much as possible on the construction of their own home or auxiliary building.

Construction of a foundation made of used reinforced concrete sleepers

In this article I would like to briefly present one of the many ways to save money on the construction of a shallow foundation using used (hereinafter abbreviated as used) reinforced concrete sleepers, photo 1.

Reinforced concrete sleepers can be used in foundation construction as:

- coarse aggregate (like rubble), in order to save concrete for the foundation;

- foundation for light buildings.

Photo 1. Used reinforced concrete sleepers

Used reinforced concrete sleepers can be used to construct a strip foundation for construction:

- wooden one- and two-story frame houses;

- one-story brick houses;

- light one-story cottages, sheds and greenhouses.

Construction of a strip foundation using used reinforced concrete sleepers

Here is a brief sequence of the main work on installing a strip foundation from used reinforced concrete sleepers:

- First, as usual, a trench of the required depth and width is dug.

- Then the formwork is installed and a sand cushion 10...15 cm thick is laid (we wrote more about this here).

- Used reinforced concrete sleepers are installed according to the following rules:

- First, it is recommended to lay a layer of concrete mixture 10...20 cm thick at the bottom of the trench, and then install the sleepers;

- sleepers should be laid in a similar way to brickwork, i.e. with dressing (in a checkerboard pattern);

- to ensure the strength of the entire foundation, sleepers should be laid at a distance of 50...70 cm from each other horizontally and vertically (in height) - 40...50 cm;

- To ensure the strength and solidity of the foundation, together with used reinforced concrete sleepers, a spatial reinforcement frame is used, photo 2.

- A concrete mixture is prepared (or delivered to the construction site), which is placed in the formwork, photo 3.

Photo 2. Construction of the foundation using used reinforced concrete sleepers and reinforcement cage

Photo 3. Ready-made strip foundation using used reinforced concrete sleepers

For light structures of one-story wooden frame houses, a columnar foundation can be made using used reinforced concrete sleepers.

The essence of a columnar foundation is the construction of vertical pillars made of sleepers. To do this, you need to dig holes 1.5...2 m deep in increments of 1.3...2 m, into which a layer of sand or concrete 10...20 cm thick is poured, and then sleepers are installed and filled with concrete mortar. After the concrete has hardened, work is carried out to install a grillage, after which the construction of the building itself can begin.

The main advantages of using used reinforced concrete sleepers

- Very low cost of used reinforced concrete sleepers.

- Long service life of reinforced concrete sleepers.

- High strength sleepers.

- Significant savings on building materials when constructing the foundation.

Disadvantages of used reinforced concrete sleepers

- Large dead weight of sleepers (more than 200 kg).

- When purchasing reinforced concrete sleepers, you should carefully look at their condition and refuse sleepers with deep longitudinal or through transverse cracks, because in the body of the foundation such a sleeper will weaken it.

The author of the article is an expert from GIDproekt

Konev Alexander Anatolievich

Disadvantages of foundations on sleepers

Now let's talk about the bad. Why you shouldn’t use such a foundation for residential buildings. I impregnate the sleepers with a special poison - creosote, so that various bugs do not eat them. Creosote is considered a potential carcinogen, a substance that can cause the formation of malignant tumors in humans and animals. And in hot weather there will be a specific smell.

Therefore, I don’t understand people who, in addition to the foundation, build the walls of their house from sleepers.

Railway sleepers are often used in the construction of various structures. They are an inexpensive building material with good technical characteristics. Since when laying and repairing railway tracks, high demands are placed on them, sleepers that have served their intended purpose are quite suitable for further use.

You can buy them inexpensively, especially if you compare their cost with the prices of new building materials. One of the popular types of construction structures using elements of the railway track is a sleeper foundation for a house.

Railway structures are divided into two types:

- wooden;

- reinforced concrete.

Both can be used in construction, but when choosing a material, several important points should be taken into account. Each type has its own advantages that make them an excellent material for certain work, and disadvantages that limit their use.

Wooden sleepers are impregnated with a special composition - creosote, which protects them from the harmful effects of moisture and various organisms living in the ground. Thanks to chemical treatment, wood material retains its mechanical properties for a long time.

Wooden sleepers

We invite you to familiarize yourself with the DIY bored foundation step-by-step instructions

But the use of such material in construction has a number of limitations. Wooden sleepers impregnated with a caustic substance have a strong odor, so good insulation is needed to build walls.

In more detail: how to build a house from sleepers.

In addition, creosote gradually evaporates, making the environment around it potentially harmful to health. Due to such features, the use of processed beams is usually limited to the construction of outbuildings or bathhouses, and the most appropriate is the use of these railway structures in the manufacture of foundations rather than walls.

The harmful effects of toxic substances released by railway sleepers weaken over time, as does the unpleasant odor emanating from them. Therefore, for safe use, it is better to select material that has already been in use for several years.

A thorough external inspection of used sleepers is also necessary to identify defects on them, the presence of which can lead to weakening of the building structure. The foundation is the basis of the future structure, and the material used for its manufacture should not have critical flaws.

You can make a foundation from wooden sleepers in different ways. If you plan to build a structure on poles, then the sleepers are placed vertically, followed by strapping. This method is suitable for small rooms whose walls are light in weight.

The foundation for a greenhouse from sleepers is assembled by installing them directly on the ground. This base is easily adjustable in height, and its installation does not take much time.

In a similar way, you can make a base for the walls of small garages and country houses.

A foundation made of sleepers for a shed laid directly on the ground will also be reliable, and the structure installed on it will last for decades.

For heavy walls, sleepers are laid horizontally in a pre-prepared trench, at the bottom of which a cushion of sand or, which is the preferred option, crushed stone is placed.

Waterproofing is laid between the wall of the building and the foundation, which, by the way, also serves as a means of getting rid of the smell of creosote. The depth of sleepers is determined based on the characteristics of the soil on which construction is carried out.

Reinforced concrete sleepers are a more expensive building material compared to wooden sleepers, but they have a wider range of applications in the manufacture of foundations. They can be used in the construction of residential premises, mainly frame wooden one- and two-story houses.

Reinforced concrete sleeper

Transportation of structures of this type is more labor-intensive than wooden analogues due to their heavy weight. Therefore, when designing foundations from this building material, the costs of delivering the material to the work site should be taken into account.

When making from reinforced concrete sleepers, a trench is first dug, the depth of which is selected based on local climatic conditions. If the soil on which construction is being carried out is prone to crumbling, then formwork from wooden boards is made for the entire height and base along the entire length of the trench.

On hard soils, it is allowed to erect formwork only to the height of the base, the height of which should be approximately one and a half meters above ground level. A sand cushion is poured into the bottom of the trench. Its height should be approximately 15-20 cm.

Reinforced concrete sleepers are laid in a poured layer of cement mortar, performing the role of rubble in this manufacturing method.

Rows of sleepers should be laid in a checkerboard pattern, and in no case along the joints of the structures of the previous row. This method of installation will make the base reliable and not affected by soil movement. It is advisable to pour a layer of solution up to half a meter deep between the rows. It is best to leave a distance of about 70 cm between adjacent sleepers of the same row. Such a foundation will last a long time.

Reinforced concrete structures are more economical than strip structures, as they require much less building materials during production.

However, its installation is more labor-intensive, because it is almost impossible to install heavy railway structures vertically without special devices. Therefore, for the practical implementation of a foundation of this type, it is necessary to attract additional labor to the construction and erect additional lifting structures.

The construction of a base of pillars begins with markings. Then a hole is dug for each sleeper, so that the distance between the posts is 1.5 - 2 meters. A prerequisite for the successful construction of a building is the installation of supports in the corners of the foundation. The depth of the pits for sleepers is 1.5-2 meters, the width is selected based on the transverse dimensions of the structure and taking into account how much space is needed for pouring cement mortar around it.

A cushion of sand and crushed stone is installed at the bottom of the pit. After preparing the installation sites, the poles are lowered into them; it is convenient to use a winch to carry out this operation. After installation, the free space around the pillar is filled with mortar, and it is advisable to ensure that the support remains stationary while the concrete hardens. The piping of the pillar foundation is carried out after the final hardening of the solution.

A pillar foundation made of reinforced concrete sleepers does not have such high strength characteristics as a strip foundation. If you plan to make a foundation from sleepers for a bathhouse, then this method of construction will be the most pragmatic and reliable. Also on this basis you can build small residential buildings from wooden beams or logs.

Not only a specialist builder can make a foundation from sleepers with his own hands. The simplest ones can be done by any developer, which is why this building material is in great demand.

How to build a bathhouse from black sleepers

First of all, the material purchased for the construction of a bathhouse must be sorted and the cleanest and most even sleepers selected. They will be used to lay the walls on the facade. Part of the sleeper beams will be dismantled into facing material - a homemade tongue-and-groove board, ordinary beams will be used for laying the walls, the most impregnated with phenol will be used for arranging the foundation and base of the bathhouse.

If in the area allocated for the construction of a bathhouse, the soil is too saturated with water, or the area is periodically flooded with melt or rainwater, it is best to place the room on a pile foundation. One of these options is shown in the photo.

The main difference is the use of sleepers to make piles. The frame of a sleeper bath weighs at least 8000 kg, this is much heavier than in the case of a frame or panel construction, so the pile support is made from one or two sleepers, sawn in half.

A pit is dug under the future support, into which a layer of crushed stone and sand is poured. The halves tied together with wire are re-treated with resin or bitumen, placed in a hole and covered with the same mixture of sand and screenings.

The technology for assembling bathhouse walls from sleepers is practically no different from laying timber, the only difference being that the crowns are tied together every 3-4 rows with steel brackets made of thick reinforcement. In the process of laying the next crown, the surfaces are laid with jute, flax, but more often with dried moss.

The corners of the bathhouse are cut from two sleepers with a lock “in half a tree”, while the direction of the cut changes to the opposite with each subsequent crown.

For a small bathhouse, the last two crowns are laid simultaneously with the ceiling beams. The material used is the best sleepers split in two from the available remainder. The resulting pairs are spliced into a long beam, which covers the ceiling. At the same time, the ceiling is hammered with a board.

The rafters for the roof of the bathhouse are cut and joined on the ground, then raised in pairs to the ceiling and cut into the last crown of the walls. The sheathing is immediately filled and covered with roofing felt. In this condition, the bathhouse should overwinter, the walls will gain weight, and the structure will shrink.

At the stage of finishing work, the crowns are packed and embossed with jute tow, the floors are cut out and laid inside the paired dressing room and rest room. All that remains is to cut out the window and door opening, install the frames, hang the doors and move on to finishing work inside the room.

The ceiling is hemmed from the inside of the steam room and dressing room, a waterproofing film is laid and filled with expanded clay backfill. All elements inside the bathhouse are assembled to their final dimensions, without any gaps for shrinkage or sagging.

Therefore, the outer surface of the walls is thoroughly cleaned, treated and dried before the sheathing and lining are installed.

Foundation construction procedure

The construction of the base must be treated with great responsibility. It is necessary to carefully analyze the condition of the products that will be used for such work. If they are damaged, the created foundation may turn out to be of poor quality and after a certain time it will be necessary to carry out restoration procedures.

It is best to create such foundations on soil with high hardness to prevent the possibility of settlement under the load of the house. The foundation made of reinforced concrete sleepers can be of different types:

- Columnar;

- tape;

- pile;

- slab.

The optimal solution for using such material are tape and columnar varieties. For a strip base, logs must be laid around the entire perimeter. A layer of sand and crushed stone is preliminarily laid under the foundation, which will need to be thoroughly compacted and moistened. Then sleepers are placed on top, which are placed with overlapping joints. For fastening you need to use metal staples and pins.

If it was decided to use a columnar base, the logs should be placed vertically with a certain interval from each other. During preparation, it is necessary to treat the sleepers with a special antiseptic and bitumen. This type of foundation has a fairly long service life, which can last up to 50 years. The sleepers are laid on a concrete base and gradually covered. They are then connected to other sleepers installed in a similar pattern.

The following video will help you learn in more detail about the procedure for creating a foundation from sleepers with your own hands.

https://youtube.com/watch?v=JIuWi_cECt4

Tape base made from sleepers

For two-story wooden houses, it is best to create a strip base. In this case, concrete sleepers are laid in a special formwork made of wood, which allows you to save a lot on pouring cement. The whole procedure consists of the following steps:

- First, a trench is dug. Its depth must exceed the soil freezing level.

- The formwork is being created. Often boards are used for manufacturing. It must be securely fastened from the bottom of the pit to the top of the basement.

- A layer of sand is added to a height of up to 20 cm. This will help prevent damage to the foundation.

- A cement mixture or concrete is prepared.

- Concrete is poured along the entire perimeter of the pit to the required height, after which the sleepers are installed. They will be used as buta. Then a new layer of concrete is poured and the sleepers are laid again. They need to be installed not on top of each other, but in a checkerboard pattern. According to this scheme, the base is poured to the top of the formwork. This will prevent the tape from cracking. The height interval between sleepers should be about 50 cm. The distance between the edges can vary from 50 to 70 cm.

Columnar base made of sleepers

To install such material you will need to use special equipment.

This type of basis is the most economical. It can be used for frame or wooden buildings, as well as buildings made of foam concrete blocks.

A foundation made of reinforced concrete sleepers allows you to save a lot of money, but you need to take into account that such material has a fairly large mass. Not every master will be able to place it in the formwork or pit with his own hands. For these purposes, you will need to use special equipment, which will greatly simplify the work. Creating a columnar foundation consists of the following steps:

- The first step is to dig a hole for each post. The interval of their installation depends on the design of the building. The depth of the hole can vary from 1.5 to 2 m. The width should allow you to install the material and pour cement mortar around it.

- At the bottom of each pit you will need to create a cushion based on sand and fine crushed stone.

- After which the installation of reinforced concrete products is carried out.

- Each hole is filled with cement mortar.

Creating a columnar base from non-standard materials is not so difficult, the main thing is to carefully follow the work technology.

Using sleepers for bases is a good solution. Thanks to this material, you can save a lot on building a house. The main thing is to carefully select products to ensure a long service life.

DIY sleeper base: step-by-step instructions

The construction of the base must be treated with great responsibility.

It is necessary to carefully analyze the condition of the products that will be used for such work. If they are damaged, the created foundation may turn out to be of poor quality and after a certain time it will be necessary to carry out restoration procedures. It is best to create such foundations on soil with high hardness to prevent the possibility of settlement under the load of the house. The foundation made of reinforced concrete sleepers can be of different types:

- Columnar;

- tape;

- pile;

- slab.

The optimal solution for using such material are tape and columnar varieties. For a strip base, logs must be laid around the entire perimeter. A layer of sand and crushed stone is preliminarily laid under the foundation, which will need to be thoroughly compacted and moistened. Then sleepers are placed on top, which are placed with overlapping joints. For fastening you need to use metal staples and pins.

If it was decided to use a columnar base, the logs should be placed vertically with a certain interval from each other. During preparation, it is necessary to treat the sleepers with a special antiseptic and bitumen. This type of foundation has a fairly long service life, which can last up to 50 years. The sleepers are laid on a concrete base and gradually covered. They are then connected to other sleepers installed in a similar pattern.

The following video will help you learn in more detail about the procedure for creating a foundation from sleepers with your own hands.

For two-story wooden houses, it is best to create a strip base. In this case, concrete sleepers are laid in a special formwork made of wood, which allows you to save a lot on pouring cement. The whole procedure consists of the following steps:

- First, a trench is dug. Its depth must exceed the soil freezing level.

- The formwork is being created. Often boards are used for manufacturing. It must be securely fastened from the bottom of the pit to the top of the basement.

- A layer of sand is added to a height of up to 20 cm. This will help prevent damage to the foundation.

- A cement mixture or concrete is prepared.

- Concrete is poured along the entire perimeter of the pit to the required height, after which the sleepers are installed. They will be used as buta. Then a new layer of concrete is poured and the sleepers are laid again. They need to be installed not on top of each other, but in a checkerboard pattern. According to this scheme, the base is poured to the top of the formwork. This will prevent the tape from cracking. The height interval between sleepers should be about 50 cm. The distance between the edges can vary from 50 to 70 cm.

To install such material you will need to use special equipment.

This type of basis is the most economical. It can be used for frame or wooden buildings, as well as buildings made of foam concrete blocks.

A foundation made of reinforced concrete sleepers allows you to save a lot of money, but you need to take into account that such material has a fairly large mass. Not every master will be able to place it in the formwork or pit with his own hands. For these purposes, you will need to use special equipment, which will greatly simplify the work. Creating a columnar foundation consists of the following steps:

- The first step is to dig a hole for each post. The interval of their installation depends on the design of the building. The depth of the hole can vary from 1.5 to 2 m. The width should allow you to install the material and pour cement mortar around it.

- At the bottom of each pit you will need to create a cushion based on sand and fine crushed stone.

- After which the installation of reinforced concrete products is carried out.

- Each hole is filled with cement mortar.

Creating a columnar base from non-standard materials is not so difficult, the main thing is to carefully follow the work technology.

Using sleepers for bases is a good solution. Thanks to this material, you can save a lot on building a house. The main thing is to carefully select products to ensure a long service life.

Let's take a closer look at the construction of a strip foundation made of sleepers. There are two options: to arrange a shallow or non-buried foundation and a deep foundation. The first method is ideal for any outbuildings, such as a barn, greenhouse, or garage. The second is for more capital ones, for example for a bathhouse.

Before laying sleepers you need to make preparations. To do this, remove the vegetable ball of soil and fill the trench with gravel 10-15 cm thick and compact it. We lay the sleepers. They need to be fastened both to each other and to the ground. They are fastened together with a strapping beam, and into the ground with the help of crutches. The support beam is laid on the strapping beam and then the wall is erected.

A deep foundation is laid in the same way as any other prefabricated foundation. That is, a trench is dug, preparations are made and piles are laid, tied and fastened together. The drawing above shows a detailed assembly of the foundation.

1 - Sleeper; 2 - Waterproofing, which should already be present on the sleeper; 3 - Concrete shoe (option 1), brackets (option 2); 4 - sand cushion (option 1), wooden support (option 2); 5 - sand cushion.

When sleepers are positioned vertically, their laying depth should be below the freezing depth. At the top, the pillars should be tied with a grillage (this can be a wooden beam).

Strip foundation made of sleepers for permanent buildings.

Most of the opponents of the use of sleepers as a material for the manufacture of foundations accuse the impregnation that is used in the production of railway tracks - creosote.

It is known that this substance, which has a characteristic odor that is quite difficult to tolerate, contains components that are toxic to humans. Some people express concern when it is recommended that they build a foundation for a private home using sleepers that are impregnated with creosote.

You should know that this is actually true. New sleepers that have just been manufactured are not recommended for construction. However, this does not apply to sleepers, the operational period of which as a railway track has come to an end.

Such sleepers spent quite a long time in the open air, therefore, the sun's rays and numerous precipitation managed to remove most of the harmful impregnation from their surface. Therefore, a foundation made of sleepers with a long service life is absolutely safe to use as the basis for the construction of private houses, which are made using frame technology. Such houses are much lighter than their analogues, which are built from materials such as blocks or bricks.

To work you will need the following elements:

- reinforced concrete sleepers;

- cement;

- crushed stone;

- sand;

- special equipment for lifting reinforced concrete sleepers;

- metal staples;

- metal pins;

- bitumen;

- composition with antiseptic properties.

For a two-story frame, wooden house or a one-story structure made of brick or concrete blocks, in most cases a strip foundation is made. Concrete sleepers are laid in wooden formwork, which can significantly reduce the cost of cement for pouring.

- First of all, it is necessary to dig a trench to a depth that exceeds the depth of soil freezing (each area has its own characteristics).

- Next, the formwork is made. In most cases it is made from boards. It must be securely fixed from the bottom of the trench to the top of the base (up to 1.5 m above the ground surface). In the case of hard soils that do not crumble, it is allowed to perform formwork only for the base.

- Next, backfill is performed - a compensation layer of sand 15-20 cm high. This layer can protect the finished foundation from the influence of heaving forces that occur when the soil thaws and freezes.

- Cement mortar or concrete is prepared.

- Concrete is poured along the entire perimeter of the trench to a small height, after which sleepers are laid in it as rubble. After this, pour the next layer of concrete and lay the sleepers again. They must be laid not on top of each other, but with overlap in relation to the previous row, that is, in a checkerboard pattern. In this way, the foundation can be poured to the top of the formwork. This will make it possible to prevent cracking of the finished tape.

We suggest you familiarize yourself with How to build a foundation for a bathhouse

Sometimes, during the construction of a house and other buildings, it turns out at the stage that for some reason it is impossible to use standard materials that are usually used for pouring the foundation, such as crushed stone, cement and sand. What can replace standard materials for laying a foundation? One of the excellent solutions is a foundation made of sleepers, a very accessible and inexpensive material.

The foundation on sleepers is mainly used for light structures, such as small country houses, garages, gazebos, outbuildings, and so on.

The good thing about such a foundation for a house, greenhouse or other outbuilding is that the material for its construction is very easy to obtain. The second important advantage is the low cost, and if sleepers are delivered directly to your home, then you simply cannot find a better alternative option for a greenhouse or other outbuilding.

Many experts speak out against the use of sleepers, because such material probably already has a long service life as a railway track. But not everything is so simple. For example, while such a foundation may not be suitable for building a reliable and solid house, it is perfect for constructing greenhouses.

Overlapping sleeper connection diagram.

A sleeper base is a very effective and simple option for installing a greenhouse base. It is necessary to provide recesses that can be made from pipes in those places where the pins are structurally placed to bury them in the ground.

When building any type of foundation, you will need approximately the same set of tools. In each specific case, you can determine for yourself which of the following tools you will or will not need:

- shovel and bayonet;

- hand drill;

- plumb line;

- building level;

- hacksaw;

- boards for formwork;

- tape measure 10-20 meters;

- staples;

- nails;

- hammer;

- axe;

- broken brick;

- Stone;

- Sand and gravel;

- logs;

- sleepers;

- tar or other moisture-proofing material;

- roofing felt;

- cement;

- brick;

- container for stirring the solution;

- reinforcing wire;

- reinforcing bar;

- device for cutting reinforcement.

- shovel and bayonet;

- hand drill;

- plumb line;

- building level;

- hacksaw;

- boards for formwork;

- tape measure 10-20 meters;

- staples;

- nails;

- hammer;

- scrap;

- axe;

- broken brick;

- Stone;

- Sand and gravel;

- logs;

- sleepers;

- tar or other moisture-proofing material;

- roofing felt;

- cement;

- brick;

- container for stirring the solution;

- reinforcing wire;

- reinforcing bar;

- device for cutting reinforcement.

Fastening the wooden sleepers of the foundation

For the strip foundation, a ditch is dug out of the sleepers, up to 80 cm deep.

DIY wooden shed

A do-it-yourself shed using frame technology is a simple and economical construction option. Initially, you need to decide on the location on the site where the future shed will stand. Then we decide on the choice of foundation. All actions can be divided into several stages.

Here are the main stages of building a barn with your own hands:

- Preparing the area when building a barn with your own hands. This stage includes clearing the area of bushes, trees, stumps and large rocks;

- Preparatory work before building the foundation when building a barn with your own hands. If piles or support beams are selected, no additional ground manipulation is required. When pouring a block, strip foundation or foundation slab, it is necessary to dig a pit, the depth of which is at least half a meter;

- The bottom trim, floor joists, subfloor, bottom beam must be coated with a composition that prevents wood from rotting, keeps it dry and prevents the penetration of insects;