- 1 Definition

- 2 Where are they used?

- 3 Advantages and disadvantages

- 4 Types

- 5 Production technology

- 6 Installation, repair and disposal of sleepers

- 7 Conclusion

During the existence of railways, supports for sleepers were made from various materials. There were stone ones, but stone is difficult to process, quickly cracks and becomes unusable. Durable wooden sleepers are tarred to protect against the negative effects of weather conditions. But after a while they also demanded either replacement or repair of the railway tracks. Today, reinforced concrete structures are rightfully considered the material of the future for the manufacture of supports for sleepers and foundations for buildings and structures. A foundation made of reinforced concrete sleepers is used for buildings of all possible complexity and number of storeys on any type of soil. However, it is worth considering that this product weighs a lot.

Definition

Reinforced concrete sleepers have the form of a rail support, the manufacture of which will require beams with varying sizes and cross-sectional shapes. Concrete rail supports are reinforced with steel wire, the diameter of which depends on the modification. When working with reinforced concrete sleepers, the following requirements are imposed on their production technology:

- preparing concrete mortar requires a uniform consistency;

- for the necessary transmission of stress, the material must have appropriate strength;

- When manufacturing products, they adhere to the exact dimensions and shapes that are important for reinforced concrete sleepers at the junction with the rails.

Return to contents

Where are they used?

Nowadays, everyone wants to save money - used sleepers provide this opportunity when building your own home.

Reinforced concrete sleepers are used in the construction of foundations and railway tracks. Due to different natural operating conditions and varied mechanical loads on products, increased requirements are adhered to in the manufacture of reinforced concrete supports. This will increase the service life, which under favorable conditions of use will reach sixty years. Posts made using prestressed concrete outshine common wood posts everywhere due to their strength, durability and speed of installation.

Return to contents

A little history

In the photo - wooden sleepers after long-term use

In addition, despite their apparent strength, these slabs were not the most durable solution, since due to prolonged mechanical exposure they cracked and became partially or completely unusable.

Kawabanga! Requirements for arranging a country toilet

Despite the fact that wooden products are still used on secondary branches, it is reinforced concrete structures that are rightfully considered the most modern and promising solution.

Advantages and disadvantages

Reinforced concrete sleepers have the following advantages:

- long service life;

- sufficient resistance to the negative effects of environmental factors;

- no possibility of rotting during operation;

- resistance to various mechanical loads;

- low price category;

- installation and installation do not require large physical costs;

- do not require large maintenance costs during operation;

- Due to the fact that the width and length of the product are perfectly even, convenient transportation and unloading is ensured.

Reinforced concrete sleepers have the following disadvantages:

- The need for periodic inspection of railway tracks due to fatigue failure of a structure made of concrete.

- The sleeper weighs 0.27 tons, which means that manual installation of the products is impossible. Thus, due to the heavy weight, there is a need for specialized equipment. Concrete structures, unlike wood products, which weigh less, are mounted with special mechanisms - sleeper layers.

- The need to use elastic pads that reduce the rigidity of the product.

- Reinforced concrete sleepers have high electrical conductivity, which requires the use of insulation.

Return to contents

Wooden sleepers

Wooden sleepers predominate on the world's railways, since from a technical point of view they best meet the requirements for an under-rail base.

The main advantages of wooden sleepers are good elasticity, ease of manufacture and operation (transportation, tamping, changing), and high electrical resistance.

The disadvantages of wooden sleepers are their short service life with high load loads, and the great need for industrial wood, which is necessary for the diverse needs of the national economy.

Since January 1, 1966, wooden sleepers (Fig. 1) of two types have been laid on Russian roads:

- edged (A), in which all four sides are sawn;

- unedged (B), in which two opposite sides are sawn - beds.

Wooden sleepers are divided into three types:

- I – for main paths;

- II – for station and access roads (non-public railway tracks);

- III – for inactive paths of non-public use of industrial enterprises.

Rice. 1 – Types of wooden sleepers (cross sections)

Sleepers are made from pine, spruce, fir, cedar, beech and birch. The length of the sleepers is 2.75 m. For particularly heavy-duty sections, sleepers with a length of 2.8 m are supplied, and for sections with combined tracks of different gauges - 3.0 m.

where A is the total number of sleepers lying along the way;

m1, m2 – the number of unusable sleepers along the way according to field inspection data, respectively, at the beginning and at the end of the period (year, five-year plan);

n – number of sleepers laid on the track during the period tн;

tn – duration of observation.

The values of A, m1, m2 and n are taken from the technical passport of the track and technical reports.

Rice. 2 – Change in service life of wooden sleepers depending on the tonnage passed: 1 – crutch fastening; 2 – separate rigid; 3 – separate with spring terminal

Kawabanga! Drainage trays: 10 tips for selection and installation

Types

Reinforced concrete sleepers are divided into the following types, which depend on resistance to possible cracks, quality and the exact width, length and other dimensions of the product:

- First class support.

- Second grade support. It is characterized by a low degree of resistance to cracks, geometric dimensions do not require high requirements.

Depending on the type of rail fastening, there are the following types:

- Ш-1, with a separate type clamp-bolt connection, which is fixed to the support using a gasket and a bolt.

- Sh-2 of an inseparable type of fastening.

- Sh-3 are similar to Sh-2 supports, but differ in the method of fastening.

Reinforced concrete sleepers vary in class, the presence of electrical insulation and the type of reinforcement used. Reinforced concrete sleepers have differences in electrical insulation parameters:

- isolated;

- non-insulated, without insulating liners.

Return to contents

Production technology

Regardless of the area of use, reinforced concrete supports are made with the same strength and performance properties. There are four types of support manufacturing technology:

- Carousel type followed by mold removal. It consists of preparing the mixture and pouring it into molds, where it is further compacted. Remove the supports from the container after the solution has completely hardened and reached its maximum strength. For manufacturing, cassette structures are used, which accommodate six supports. To achieve the required adhesion and provide prestress, reinforcement is used, with the help of which the stress is transferred to the surface of the concrete. Upon completion of the product, the mold is removed and started for the next production.

- Linear. This type of manufacturing a reinforced concrete support involves a linear technology, which requires a conveyor on which the forms are placed in a certain sequence. The length of the installed forms reaches one hundred meters. The sides of the container are covered with specially designed devices, which are also capable of transmitting voltage to the reinforcement. As the mortar sets, stress is transferred to the surface of the concrete.

- Dismantling of forms with further stress. This type of manufacturing of reinforced concrete supports requires the installation of templates, with the help of which the location of steel reinforcement is determined. The containers are filled with concrete mortar and compacted. While the solution is setting, the pins are immersed in it. After some time, the mold and template are removed.

- Dismantling forms with prestressing is the same technology as when dismantling forms with further tension, only instead of pins, frames are used that provide a tension force in the product.

Return to contents

Installation, repair and disposal of sleepers

The installation of railway tracks has the following features:

- Reinforced concrete supports and rails are installed on a pre-prepared surface, which consists of soil, sand and crushed stone. To preserve the sleepers during operation and the passage of trains over them, it is important to preserve the top layer of earth by installing sand strips.

- A reinforced concrete support weighs a lot, and an ordinary worker cannot lift such a weight of the structure; installation is carried out using mechanized equipment. This approach reduces the use of physical force and reduces the cost of installing products. The mechanized complex also reduces the time for laying the railway.

- To use reinforced concrete sleepers for fifty years, it is important to diagnose the tracks, which will identify deformations and breakdowns. The fastening elements are checked to ensure that there is no breakage, as this could lead to disruption of the fixation of the lining, which makes sounds as the train passes along the tracks.

- Failure to timely detect the failure of fasteners leads to the appearance of cracks and partial or complete breakage of the sleeper.

- When the service life of the product has expired or the reinforced concrete support has become unusable due to possible destruction, the sleeper is disposed of. Disposal occurs with a jaw crusher, with the help of which the product is crushed to the size of crushed stone of a small fraction or medium fraction. The recycled products are subsequently used to fill holes.

Repairing reinforced concrete sleepers involves identifying and eliminating defects and damage. Seal chips, potholes, sinkholes and cracks. When a breakdown is repaired, train traffic does not stop; the workplace is fenced off with a special signal sign. Major repairs are carried out between repairs, where sleepers do not need to be changed, repairs are carried out using track machine stations according to prepared individual projects and calculations. Repair of reinforced concrete supports is divided into:

- capital;

- average;

- lifting;

- reconstruction.

By type of top installation: laying on new crushed stone or on old crushed stone. To enhance the power and durability of tracks, in the process of repairing damaged parts, under-rail bases of various designs are used.

Return to contents

Making a foundation from reinforced concrete sleepers

A foundation made of reinforced concrete sleepers is considered a more expensive option than its counterpart made of wood material. However, its range of applications is wider. You can even build a foundation for a frame house from reinforced concrete sleepers, if the number of floors in it does not exceed two levels.

Transportation of structures is more labor-intensive than transportation of wooden sleepers, and this is explained by the difference in the weight of the elements.

When designing a foundation made of reinforced concrete sleepers, it is recommended to take into account the costs of transporting the material to the construction site.

To lay a strip foundation made of railway sleepers, a foundation trench is first prepared, the depth of which is determined taking into account the weather conditions of the region. If the soil composition is prone to crumbling, then a formwork structure made of wooden panels is placed at the height of the foundation and the plinth.

Due to the solid soil composition, it is allowed to install formwork only for the base, the height of which is approximately one and a half meters from the surface of the earth. At the bottom of the trench, a sand cushion is placed in a layer of fifteen to twenty centimeters.

The sleepers are laid in a layer of mortar mass, which performs the functions of rubble material.

The sleepers are laid in rows, and the staggered order of their placement should be observed, without joining the rows of structures with the previous ones. With this installation option, the base has a high reliability indicator and resists movements of the soil composition. It is recommended to pour a layer of mortar fifty centimeters deep after each row. The distance between adjacent elements of the same row should be within seventy centimeters, and the foundation will serve you for a long time.

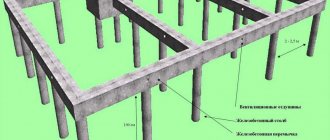

A column foundation made of reinforced concrete sleepers is considered a more economical option, since its construction requires less building materials.

Unfortunately, the installation work on its construction is characterized by certain difficulties, since vertical installation of heavy reinforced concrete sleepers by hand is impossible. We will have to involve a working team and install special lifting devices.

Construction work begins with marking. After this, a hole is dug under each sleeper, observing the installation step determined by the calculated data.

A mandatory requirement for successful construction of the foundation is the installation of supporting elements in the corner sections of the structure.

The depth of the pit should be one and a half to two meters, its width is determined by the cross-section of the structure, taking into account the need for a space around the sleeper to be filled with cement mortar.

Before installing the support, sand and crushed stone are poured into layers at the bottom of the pit, everything is thoroughly compacted. As soon as the place for installing the sleeper is prepared, a reinforced concrete product supported by a winch is lowered into the hole. The pillars are adjusted vertically, after which all free space is concreted. While the solution dries, the post should be securely fixed in the desired position. After all the sleepers are installed and the concrete has gained the required strength, a strapping is performed that connects all the pillars into a single structure.