Selection of copper bars

The copper electrical busbar is a conductor with low resistance. Copper electrical busbars are made with a rectangular cross-section. Visually, a copper electrical busbar is similar to a sheet, but thicker. UMMC-OTsM produces copper electrical busbars in a wide range of sizes: thickness 1.2 - 80 mm and width 8 - 250 mm. Tires are produced in pressed and drawn condition, in coils and sections.

Cracks, cavities, blisters, transverse tears and dirty technological lubricants are not allowed on the surface of copper busbars. Deviations in cross-sectional shape, mechanical properties, crescent shape do not exceed the values established by regulatory documentation. It is possible to produce non-standard tire shapes. In this case, the shape is specified in the specification and a drawing of the future product must be attached.

The choice of copper busbar depends on the conditions of use. When choosing the current cross-section of copper busbars, take into account the maximum current that will flow through the busbar. Section - the ratio of width and thickness. Based on the value of the maximum current, the busbar cross-section is selected according to PUE and GOST 434-78.

Section of copper bars

The copper busbar is a semi-finished product. Electrical copper busbar is used in the assembly of low-voltage and high-voltage equipment, in the installation of electrical panels, compensation jumpers, electrical power supply and distribution units.

The advantages of a copper bus are ease of installation, durability, reliability, and corrosion resistance. Compared to a cable, an electrical bus requires less installation and maintenance time. Copper withstands temperature changes, it is ductile, easy to cut and drill. It is well known that copper electrical busbars are highly thermally and electrically conductive. Therefore, copper tires, despite their apparent high cost, are economically viable.

Types of cross-sections of copper busbars

Tires are produced in different grades of alloys, lengths and different sections.

Types of copper busbars depending on the cross-section:

- Rectangular;

- Box tires;

- Tubular tires.

Rectangular section is the most common type. Such a tire looks like a rectangular strip of metal and is called flat. An electrical busbar of rectangular cross-section is made from copper rod, billets, pressed ingots from copper grade M1 (GOST 859-2001).

The ratio of the width and thickness of the product varies. The choice of cross-section of copper busbars depends on the permissible current. With a size of 40 * 4 mm in a single-phase conductor, a current of 625 A is allowed. In a two-phase conductor (2 plates), the value of the permissible maximum current will increase to 1090 A. All standard sizes and values of the permissible current are in the tables of permissible current loads.

When choosing the cross-section of copper busbars, normal operating conditions, post-emergency conditions, uneven current distribution between busbar sections and operation during repairs are taken into account.

UMMC-OTsM offers rectangular copper busbars with a width of 8 - 250 mm, a thickness of 1.2 - 8 mm. Alloy grades: M1, M2, M3, M1E, Cu-ETP, C11000.

Box busbars are used for high operating currents. They provide the best cooling conditions with low additional losses from the surface effect. Box busbars are installed in open conductors to connect turbogenerator units.

Tubular copper busbar is considered the most effective: the optimal combination of strength characteristics and heat dissipation. A uniform electric field is formed around such busbars, which prevents corona formation.

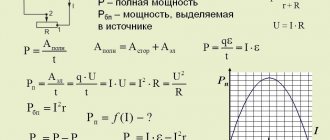

Calculation of the cross-section of copper busbars

The cross-section of copper busbars is calculated using formulas. It is necessary to know the parameters of the buses: resistance, internal inductance, heat transfer coefficient, frequency of sinusoidal current, etc. The operating conditions of the bus (ambient temperature) are taken into account; a single-layer bus will be a multi-layer bus.

Due to the properties of copper, under the same conditions, a smaller copper busbar is chosen than an aluminum or steel-aluminum one.

Order a copper busbar

UMMC-OTsM offers copper busbars of its own production. It is not inferior in its characteristics to foreign products. The tire is manufactured in accordance with GOST 434-78 and complies with the international quality standard EN 13601. The price is determined without additional costs (import, duties, etc.). We offer copper bus bars of alloys M1, M2, Cu-ETP, M3, C11000 in pressed and drawn states. Delivery to sections and bays. Minimum order – 500 kg. Fill out an application on the website or contact us by phone.

www.ocm.ru

Features of choosing a copper bus for current

The shown examples of long-term permissible current indicators for copper busbars are given based on the permissible heating temperature of up to 70o C. The ambient temperature should not exceed 25o C. Reliability of operation of copper electrical busbars is ensured when heated no higher than 85o C. But when choosing the cross-section of a copper busbar, the maximum possible permissible temperature of the components with which the product interacts. And the probability that the ambient temperature will exceed 25o C.

To facilitate the selection, technical specialists have calculated correction factors. The maximum current parameters have been recalculated for several temperature conditions. These tables are publicly available. They will help you make the right choice.

If there are no strict criteria, the choice is made in favor of flexible tires. They are more durable and have better characteristics.

Selection of busbars based on continuous current capacity

The choice of busbars based on long-term permissible current (for heating) takes into account not only normal, but also post-emergency modes, as well as modes during repairs and possible uneven distribution of currents between bus sections [L2, p. 220].

1.1 Determine the normal mode current when the transformer is loaded at 60%:

Where:

- Sn.tr-ra = 16000 kVA – rated power of the TDN-16000/110-U1 transformer;

- Un.=10.5 kV – rated network voltage;

1.2. We determine the maximum operating current when one of the transformers is overloaded by 1.4 times the rated power (heavy duty):

Using table 1.3.31 (PUE 7th edition) we determine the permissible current for single-strip aluminum busbars of rectangular cross-section 80x8 mm with permissible current Iadd.o = 1320 A.

1.3. We determine the long-term permissible current for rectangular busbars with a cross-section of 80x8 mm, taking into account correction factors according to formula 9.11 [L1, p. 170]:

Where:

Iadd.o = 1320 A – long-term permissible current of the strip at bus temperature θsh = 70 °C, ambient temperature θо.с = 25 °C and busbars are located vertically (on edge), determined according to table 1.3.31 (PUE 7th edition );

k1 - correction factor when tires are positioned horizontally (flat), according to PUE 7th edition clause 1.3.23, should be reduced by 5% for tires with a stripe width of up to 60 mm and by 8% for tires with a stripe width of more than 60 mm. We take k1 = 0.92 (since the tires will be placed flat).

k2 – correction factor for tires at ambient (air) temperature θо.с different from 25 °С, determined according to PUE 7th edition, table 1.3.3. We accept k3 = 0.94, taking into account that the average monthly temperature of the hottest month is +30 °C.

We accept a busbar cross-section of 80x10 mm, with a permissible current Iadd.o = 1480 A.

1.4. We determine the long-term permissible current for rectangular busbars with a cross-section of 80x10 mm, taking into account correction factors according to formula 9.11 [L1, p. 170]:

We accept AD31T1 brand tires with a cross section of 80x10 mm.

Permissible continuous current for rectangular busbars

| Dimensions, mm | Copper bars | Aluminum tires | Steel tires | |||||||

| Current*, A, with the number of stripes per pole or phase | Dimensions, mm | Current*, A | ||||||||

| 1 | 2 | 3 | 4 | 1 | 2 | 3 | 4 | |||

| 15 x 3 | 210 | 165 | _ | 16×2,5 | 55/70 | |||||

| 20 x 3 | 275 | — | — | — | 215 | — | — | — | 20×2,5 | 60/90 |

| 25 x 3 | 340 | — | — | — | 265 | — | — | — | 25 x 2.5 | 75/110 |

| 30 x 4 | 475 | — | — | — | 365/370 | — | — | — | 20 x 3 | 65/100 |

| 40 x 4 | 625 | -/1090 | — | — | 480 | -/855 | — | — | 25 x 3 | 80/120 |

| 40x 5 | 700/705 | -/1250 | — | — | 540/545 | -/965 | — | — | 30x 3 | 95/140 |

| 50x 5 | 860/870 | -/1525 | -/1895 | — | 665/670 | -/1180 | -/1470 | — | 40×3 | 125/190 |

| 50×6 | 955/960 | -/1700 | -/2145 | — | 740/745 | -/1315 | -/1655 | — | 50×3 | 155/230″ |

| 60×6 | 1125/1145 | 1740/1990 | 2240/2495 | — | 870/880 | 1350/1555 | 1720/1940 | — | 60 x 3 | 185/280 |

| 80×6 | 1480/1510 | 2110/2630 | 2720/3220 | — | 1150/1170 | 1630/2055 | 2100/2460 | — | 70 x 3 | 215/320 |

| 100×6 | 1810/1875 | 2470/3245 | 3170/3940 | — | 1425/1455 | 1935/2515 | 2500/3040 | — | 75 x 3 | 230/345 |

| 60 x 8 | 1320/1345 | 2160/2485 | 2790/3020 | — | 1025/1040 | 1680/1840 | 2180/2330 | — | 80 x 3 | 245/365 |

| 80 x 8 | 1690/1755 | 2620/3095 | 3370/3850 | — | 1320/1355 | 2040/2400 | 2620/2975 | — | 90×3 | 275/410 |

| 100×8 | 2080/2180 | 3060/3810 | 3930/4690 | — | 1625/1690 | 2390/2945 | 3050/3620 | — | 100×3 | 305/460 |

| 120×8 | 2400/2600 | 3400/4400- | 4340/5600 | — | 1900/2040 | 2650/3350 | 3380/4250 | — | 20×4 | 70/115 |

| 60 x 10 | 1475/1525 | 2560/2725 | 3300/3530 | — | 1155/1180 | 2010/2110 | 2650/2720 | — | 22 x 4 | 75/125 |

| 80 x 10 | 1900/1990 | 3100/3510 | 3990/4450 | — | 1480/1540 | 2410/2735 | 3100/3440 | — | 25 x 4 | 85/140 |

| 100 x 10 | 2310/2470 | 3610/4325 | 4650/5385 | 5300/6060 | 1820/1910 | 2860/3350 | 3650/4160 | 4150/4400 | 30×4 | 100/165 |

| 120 x 10 | 2650/2950 | 4100/5000 | 5200/6250 | 5900/6800 | 2070/2300 | 3200/3900 | 4100/4860 | 4650/5200 | 40×4 | 130/220 |

| 50×4 | 165/270 | |||||||||

| 60×4 | 195/325 | |||||||||

| 70×4 | 225/375 | |||||||||

| 80×4 | 260/430 | |||||||||

| 90x 4 | 290/480 | |||||||||

| 100×4 | 325/535 | |||||||||

*The numerator shows the values of alternating current, the denominator shows the values of direct current.

Advantages of copper busbars

Copper electrical busbars are more expensive than their aluminum counterparts, but have superior technical characteristics. Purchasing copper busbars is beneficial for the following reasons:

- due to high thermal conductivity, the copper busbar will withstand a significantly higher current load compared to aluminum analogues;

- when transmitting energy, losses on the copper busbar are minimized;

- elasticity, resistance to stretching and other mechanical loads without loss of technical characteristics is an important advantage of the product;

- Due to its resistance to changes in temperature and humidity, and the ability to withstand high voltages, a copper busbar is a more economical purchase than its aluminum counterpart.

The objective advantages of the product make it possible to assemble distribution installations with compact dimensions based on copper electrical busbars. The use of such products is becoming increasingly popular and relevant.

Advantages of copper busbars

Along with copper busbars, aluminum busbars are used in electrical engineering. Aluminum tires are valued for their affordable price and lightness of the metal. However, in the long term, copper bars will be a cost-effective solution.

Copper has high thermal conductivity. With the same cross-section, a copper busbar will withstand a percentage greater load than an aluminum busbar of the same size. The copper busbar minimizes energy loss during transmission. They are highly elastic and resistant to stretching. The copper bus bends easily without losing its technical properties. This allows smaller distribution and power units to be assembled. It is resistant to high and low temperatures and can withstand higher voltages. When choosing between an aluminum busbar and a copper one, preference is given to the latter.

Current carrying capacity of copper bus

Copper bus current across the PEU section section 1.3.24

Calculation of the cross-section of a copper bus for long-term permissible currents must be carried out in accordance with Chapter 1.3 of the “Rules for Electrical Installations” issued by the USSR Ministry of Energy in 1987.

That is, the same PUE 1.3.24, familiar to all electricians." When choosing large-section busbars, it is necessary to choose the most economical design solutions in terms of throughput, providing the least additional losses from the surface effect and the proximity effect and the best cooling conditions (reducing the number of strips in the package, rational design of the package, use of profile tires, etc.). Based on them, permissible long-term currents for uninsulated wires and buses are selected. In addition, you can often hear in electrical engineering that this is the current carrying capacity of the copper strip. The maximum permissible continuous currents for rectangular copper busbars PUE 1.3.31 for direct and alternating current when connecting 1 strip per phase are collected in the following table of copper busbar currents: In addition to the table of copper busbar currents, you can also study the materials

Permissible current loads on copper busbars

When choosing a busbar, the buyer does not need to calculate the product parameters. It is enough to know the maximum permissible current in the system, direct or alternating. Using the table below, you can select the appropriate cross-section of the electrical busbar and buy products in the required volume.

| Busbar cross-section | Direct current, A | Alternating current, A |

| Copper electrical busbar 15×3 | 210 | 210 |

| Copper electrical busbar 20×3 | 275 | 275 |

| Copper electrical busbar 25×3 | 340 | 340 |

| Copper electrical busbar 30×4 | 475 | 475 |

| Copper electrical busbar 40×4 | 625 | 625 |

| Copper electrical busbar 40×5 | 705 | 700 |

| Copper electrical busbar 50×5 | 870 | 860 |

| Copper electrical busbar 50×6 | 960 | 955 |

| Copper electrical busbar 60×6 | 1145 | 1125 |

| Copper electrical busbar 60×8 | 1345 | 1320 |

| Copper electrical busbar 60×10 | 1525 | 1475 |

| Copper electrical busbar 80×6 | 1510 | 1480 |

| Copper electrical busbar 80×8 | 1755 | 1690 |

| Copper electrical busbar 80×10 | 1990 | 1900 |

| Copper electrical busbar 100×6 | 1875 | 1810 |

| Copper electrical busbar 100×8 | 2180 | 2080 |

| Copper electrical busbar 100×10 | 2470 | 2310 |

| Copper electrical busbar 120×8 | 2600 | 2400 |

| Copper electrical busbar 120×10 | 2950 | 2650 |

The NTCM company offers to buy electrical copper busbars in a large assortment. The company's warehouse offers products in various standard sizes. Excellent technical characteristics, competitive prices, short delivery times for products to any region of the country are the main advantages of ordering electrical busbars from NTCM.

Source

Copper Bus Bandwidth

| Tire section, mm | Direct current, A | Alternating current, A |

| Permissible current copper bus 15×3 | 210 | 210 |

| Permissible current copper bus 20×3 | 275 | 275 |

| Permissible current copper bus 25×3 | 340 | 340 |

| Permissible current copper bus 30×4 | 475 | 475 |

| Permissible current copper bus 40×4 | 625 | 625 |

| Permissible current copper bus 40×5 | 705 | 700 |

| Permissible current copper bus 50×5 | 870 | 860 |

| Permissible current copper bus 50×6 | 960 | 955 |

| Permissible current copper bus 60×6 | 1145 | 1125 |

| Permissible current copper bus 60×8 | 1345 | 1320 |

| Permissible current copper bus 60×10 | 1525 | 1475 |

| Permissible current copper bus 80×6 | 1510 | 1480 |

| Permissible current copper bus 80×8 | 1755 | 1690 |

| Permissible current copper bus 80×10 | 1990 | 1900 |

| Permissible current copper bus 100×6 | 1875 | 1810 |

| Permissible current copper bus 100×8 | 2180 | 2080 |

| Permissible current copper bus 100×10 | 2470 | 2310 |

| Permissible current copper bus 120×8 | 2600 | 2400 |

| Permissible current copper bus 120×10 | 2950 | 2650 |

You can buy electrical copper and aluminum busbars from our company from the warehouse and on order:

Calculation of the theoretical weight of electrical busbars:

At Nevskaya Aluminum Company you can buy aluminum from a warehouse in St. Petersburg or order delivery throughout Russia.

The warehouse of the Nevskaya Aluminum Company is located at 266 Ligovsky Prospect, not far from the Moskovskie Vorota metro station, next to the freight highway - Vitebsky Prospekt, exits to the WHSD and the Ring Road. Loading documents are issued on site.

Source