How is it deciphered?

The transcript of this wire reads:

- K - means control cable;

- B - the insulation inside is made of PVC;

- B - external one is also made of PVC materials;

- G - indicates that the product is flexible.

What KVVG looks like in cross-section

The control cable generally has several cores and is never single. KVVG wire is manufactured with a different number of cores from 5 to 60. If the name contains the letter “E”, this indicates that the product has a shielding sheath. It protects lines from interference from other lines that are at close range.

If the name contains the symbols NG and NG-ls, this means that the wire has low flammability and does not spread further fire. This must be remembered when laying wires in places of high temperatures.

Product design

The name KVVG indicates that the cable is made of copper, and AKVVG is made of aluminum.

Note! The entire description of the product can be found from the name and labeling itself.

To decrypt any cable, you can use the specification.

Explanation of the designation

The marking of a wire of this type consists of two blocks: alphabetic (consisting of 4-8 letters) and digital (two numbers separated by the multiplication sign “×”).

The designation (abbreviation) of the simplest wire KVVG 4×1 is deciphered as follows:

- “K” – the cable is a control cable;

- “B” - a material such as polyvinyl chloride plastic compound (PVC plastic compound) is used as insulation for the internal cores of the conductor;

- “B” – the outer insulation of the entire conductor (sheath) is made of PVC plastic;

- “G” – the cable does not have a special protective outer coating (can also be interpreted as “bare”).

The number block indicates the number of cores and the nominal cross-section of each of them. In this case, the wire contains 4 cores, each of which has a cross-section of 1.0 mm.

In addition to the basic symbols indicated above, the marking may also contain the following additional letters:

- “E” - the cable has a screen (a layer of aluminum foil and copper mesh located between the external insulation and the internal current-carrying conductors), which provides protection against the occurrence of induced voltage (noise) in it from nearby high-voltage power lines;

- “NG” - the material used for internal and external insulation has reduced flammability;

- “NG-LS” - the internal and external insulation of the wire, when melted, releases a small amount of harmful gases and smoke;

- “(A)” – the insulating material does not propagate fire;

- “C” - the internal current-carrying conductors of the control wire are color-coded.

On a note. If in the marking of this control wire there is a letter “A” before the mandatory letter block “КВВГ”, this means that the internal current-carrying conductors are made of aluminum. If there is no such letter in the marking, then the conductive elements of the cable are made of copper.

Technical specifications

Main characteristics of this type of cable:

- normal operating temperature range from -50 to +70 degrees;

- the maximum permitted operating temperature is 75 degrees, at 80 or more the KVVG fails;

- permitted maximum voltage 630 V;

- air humidity should not be higher than 92%;

- permitted temperature when laying cables from 0 to 15 degrees;

- insulation resistance from 5 to 9 MOhm per kilometer. The thicker the wire, the lower the resistance;

- construction length 145 m;

- allowed bend radius 4 own diameters;

- product weight starts from 70 kg/kilometer.

Cable KVVG technical characteristics of the cross-section

The flexible control cable always has a protective sheath made of PVC. But it can be easily damaged by a sharp stone or tool. On average, the warranty for such a cable is up to three years. The period may be longer or shorter, it all depends on the laying area and method. The service life with proper use is 20-25 years. In places with aggressive weather conditions, the period will be no more than 15 years.

You might be interested in this: How to do wiring

Purpose and application

In modern industry, KVVG is used in the following works:

- for supplying electricity to stationary equipment, in distribution installations at an alternating current voltage within 660 V and a frequency of up to 100 Hz, for direct current - up to 1 kV;

- for single installation of cable power lines inside structures and industrial buildings. The use of cables for group installation is intended only for external power lines or indoors, where the constant presence of maintenance and repair personnel is not expected.

If the cable is used for group installation, a mandatory requirement is the implementation of passive preventive measures for fire protection.

Also read: Technical characteristics of the cable - AVBbShv

Scope of use

Such products can be used not only in industrial facilities, but also in everyday life, in construction and agricultural enterprises, in the forestry area, in processing plants, etc.

Almost any human activity makes underground and overhead installations of power cables popular. Sufficiently high characteristics and quality ensure long-term operation of the KVVG.

Multicore cable

The most basic quality of a cable for use in fairly narrow areas will be its resistance to hazardous environments. Therefore, KVVG can be used with high efficiency in the chemical industry, in areas with high humidity or nuclear power plants.

Every year the scope of application of the KVVG power cable becomes more extensive. Therefore, many factories take on great responsibility, because products must not only be safe for humans and nature, but also comply with all GOSTs. To do this, you need to register the product and conduct a lot of testing. It must be emphasized that there must be a certificate of state registration of products for each product.

Underground laying process

How to choose

The first step is to select the appropriate wire cross-section. There are special tables that indicate what cross-section of aluminum/copper conductor is required for a particular load. Masters use the usual formula:

- For example, a load of 8 kW is taken. A copper wire cross-section of 1 mm2 passes through 10A or 2.2 kW;

- therefore, a load of 8 kW in amperes will be equal to 36 A (load = 8 kW / 220V), therefore a cable with a cross-section of 4 mm2 can be used.

This formula is most suitable for wires whose cross-section does not exceed 6 mm2. For thicker cables, you need to use the table of “permitted current loads”.

With the same load, the cross-section of the copper wire should be approximately 30% smaller than that of aluminum.

Aluminum conductors

Which wire is better to choose, aluminum or copper?

Most electricians always prefer copper. Because it is much cheaper than aluminum and deteriorates much more slowly. Therefore, there is no point in overpaying.

If two types of cables are used, they must be combined so that they do not touch each other.

Because after a short period of time at the point of contact of two metals, the resistance will increase. This may cause the product to overheat, break, or cause a short circuit, which may result in a risk of fire. Also, wires can quickly oxidize and become unusable.

You may be interested in this Features of cable lugs

Important! When choosing a cable, you need to look at what the cores are made of. They can be copper and aluminum, sometimes steel. If you are not sure what the core consists of, then it is better to use a terminal strip.

Terminal block for combining

KVVG cables can be rigid or flexible. The greater the number of veins inside, the harder the product will be.

What are the problems when using

Due to its fairly large weight, it can sag when laid by the ground method. To do this, before work it is necessary to prepare special supports on which to lay the cable.

A common problem is incorrect handling of the cable, as a result of which the outer layer of the sheath is damaged and the functions of the product are significantly deteriorated. To do this, you need to observe the temperature regime during operation, and keep the cable away from sharp objects.

Warehouse storage

Storage and transportation rules

When storing any cables, you must strictly follow certain rules; this is the only way to ensure the safety of all parameters and properties of the product.

Storage conditions depend on the raw materials from which the cable is made. According to the rules, all conductor and power cables must be stored in specially designated areas:

- in a ventilated area;

- under a canopy;

- in skeins in warehouse.

How cables are transported

GOST 18690-82 specifies all the rules for the proper storage and transportation of cable products. These instructions are followed by industrial facilities in the Russian Federation and CIS countries that produce cables, wires and other things.

This GOST also applies to wholesale and retail stores engaged in the purchase and sale of cable products. This GOST provides clear instructions for storage conditions, type of packaging, shelf life, temperature conditions, and so on.

Note! If these rules are not followed, the service life of the cable will be significantly reduced.

If the cable packaging is not intact or there are defects, then it is better to discard such products. It may have gotten wet.

If the cable is stored indoors, it should be as bright as possible. Products should be stored away from hot substances and mixtures. It is necessary to provide ventilation in the room, as well as place boxes with sand (in case of fire). Outdoor storage should not total more than a year.

The product cannot be stored at temperatures above 23 degrees Celsius. It is also not recommended to leave cable drums in the open sun, as ultraviolet radiation can damage the sheath of the product.

You might be interested in Cable laying

It is strictly forbidden to twist the wire tightly, bend it or fit it into a tight box. Because of this, the wires may be damaged and a short circuit may occur during installation.

Cable drum

Specifications

The KVVG cable can be used in installations of 660 Volt and 100 Hz alternating voltage frequency. The maximum voltage of DC installations is 1000 V. The conductor is tested at 2500 V. KVVG can be put into operation at ambient temperatures from -50 to +50 degrees Celsius. The maximum permissible temperature is –70 degrees Celsius.

Important! The brand of cable in question cannot be subjected to mechanical stress and stress; when laying, it is necessary to take into account in advance all factors that can lead to sagging, vibrations, longitudinal stretching, etc. Subject to these conditions, the service life of a KVVG laid in a tunnel, corrugation or channel is 25 years, and in the open air and in rooms with high humidity and other harmful factors - 15 years.

Characteristics of the KVVG cable that you should know about:

- The normal cable insulation resistance if it is polyethylene is 300 MOhm, PVC is 6 MOhm.

- The insulation thickness is from 0.6 to 0.8 mm, depending on the cross-sectional area of the cores (the more, the thicker).

- The construction length of KVVG is 150 meters, but it is also found in bays with a different amount of cable.

- Size range from 0.75 mm2 of each core to 10 mm2, from 4 to 61 cores.

Cables with a cross-sectional area of conductors up to 1.5 mm2 can contain a maximum number of cores - 61. Well, in the case of sections 4-6 mm2 - from 4 to 10. Individual manufacturers can produce KVVG with two cores of 0.5 mm2 each and others .

The weight of the line depends both on the diameter of the conductors and on their number. Below is a table where in the first column is the number of cores and their cross-section, in the second the dimensions according to the outer diameter of the KVVG, in the third - the weight (kg per km).

KVVG cable manufacturers

Currently, there are not many honest and respectable manufacturers.

Very often you can end up with a fake. You can always ask the seller for a sales license; if he refuses, then the buyer may be faced with a fake. Below are the most popular manufacturers of KVVG.

Marposadcable

There is a huge number of installation, power, and automotive cables available. More than 1000 macro sizes of wires. The factory was founded in the Moscow region more than 30 years ago. Has an excellent reputation and reviews. Compared to other enterprises, this factory has very affordable prices.

Kubankabel

They make products to order, and in a fairly short time. Each product is issued a certificate of conformity and a guarantee. Delivery to other regions by rail company is possible. The company employs truly professionals in their field with an individual approach to each client. The first in Russia to produce wires with protection against rodents.

Kirskabel

The plant was founded back in 1729. There are many models with low smoke emission in the range. Currently, new types of cable products with halogen-free compositions and a high degree of fire resistance are being developed. Several years ago, a new workshop for the production of FRLS control products was opened. The plant has many thanks and certificates.

How to measure a cross section

Control cable brands KVVG, KVVGng

Control cables with copper or aluminum conductors with PVC insulation in a PVC sheath (ng - flame retardant).

Galla-Cable M LLC sells KVVG cable and other electrical products. For you – high quality, confirmed by certificates of conformity, a wide range and an affordable price. You can find out how much the KVVG cable costs on our website. The price list shows the current cost. You will also find information about the availability of KVVG in stock. If you have any questions, please contact our managers. They will tell you which KVVG cable makes sense to purchase and help with delivery. We also select products in accordance with the customer’s wishes and carry out fast shipment.

Decoding KVVG:

K – control

B – PVC insulation

B – shell made of polyvinyl chloride plastic compound

D – lack of protective cover

(A) – fire safety class category A

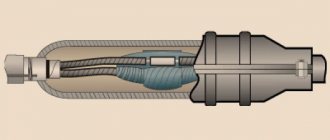

KVVG design:

1. Conductor - copper or aluminum, single-wire, class 1 according to GOST 22483. 2. Insulation - made of polyvinyl chloride (PVC). 3. Twisting - the insulated cable cores are twisted. Each layer has a counting pair, the insulated wires of which differ in color from each other and from the rest of the wires. 4. Sheath - made of PVC plastic compound, for cable brand KVVGng made of PVC plastic compound of low flammability.

Application of KVVG:

Designed for fixed connection to electrical devices, devices, terminal assemblies of electrical distribution devices with a rated alternating voltage of up to 660 V with a frequency of up to 100 Hz or direct voltage of up to 1000 V, for installation in rooms, channels, tunnels, in aggressive environments, in the absence of mechanical influences on the cable. It is permissible to lay cables in the ground (trenches) provided that the cables are protected where they come to the surface.

KVVGng brand cable is used for installation in cable structures and premises to ensure fire safety of cable circuits when laid in bundles.

All brands of cables can be laid outdoors.

Technical characteristics of KVVG:

— Operating ambient temperature: from -50°С to +50°С — Relative air humidity at a temperature of +35°С: 98% — Nominal insulation thickness for conductors with a cross-section: 0.75 — 2.5 mm2 — 0.6 mm 4 — 6 mm2 — 0.7 mm 10 mm2 - 0.9 mm - Electrical insulation resistance of cores at a temperature of 20°C cross-section: 0.75 - 1.5 mm2 - not less than 10 MOhm*km 2.5 - 4.0 mm2 - not less than 9 MOhm*km 6 mm2 - not less than 6 MOhm*km - Long-term permissible heating temperature of the cores during operation: +70°C - The cables are resistant to installation bends. — The bending radius of unarmored cables with copper conductors when laid at an ambient temperature of at least 0°C is: for cables with an outer diameter of up to 10 mm inclusive: at least 3 cable diameters for cables with an outer diameter of 10 - 25 mm inclusive: not less than 4 cable diameters - Bending radius of unarmored cables when laying and installing without preheating at an ambient temperature not lower than -15°C: not less than 6 cable diameters - Construction length of cables: not less than 150 m - Service life: at laying in the ground (trenches) and on overpasses, at least: 15 years; when laid in rooms, channels, tunnels, no less than: 25 years - Warranty period: 3 years from the date of putting the cables into operation

| Number of lives | D, mm | Specific |

| cross section, mm² | weight, kg/km | |

| 4×1,0 | 8 | 99 |

| 4×1,5 | 9,2 | 130 |

| 4×2,5 | 10,2 | 180 |

| 5×1,0 | 9,3 | 120 |

| 5×1,5 | 10 | 160 |

| 5×2,5 | 11,1 | 220 |

| 7×1,0 | 10 | 160 |

| 7×1,5 | 10,7 | 200 |

| 7×2,5 | 11,9 | 280 |

| 10×1,0 | 12,3 | 230 |

| 10×1,5 | 13,3 | 290 |

| 10×2,5 | 15,6 | 410 |

| 14×1,0 | 14,2 | 280 |

| 14×1,5 | 14,4 | 370 |

| 14×2,5 | 16,9 | 530 |

| 19×1,0 | 15,7 | 360 |

| 19×1,5 | 16,9 | 670 |

| 19×2,5 | 19,2 | 680 |