Before purchasing a wire, be sure to measure its cross-section. Moreover, if you change the wiring or add a new point to the old one, then in this situation you will need to measure the cross-section of the wire. Since all wires are of different diameters, their cross-section is different. Nowadays, there is often deception on the part of the manufacturer. For example, the specified wire diameter for sale is not entirely reliable. Therefore, rather than be deceived, it is better to determine the size of the conductor yourself. We will teach you how to determine the cross-section of a wire by diameter.

Wire diameter

Wire diameter and what materials the wires can be made of

A conductor transmits a certain amount of energy. This amount depends on many factors, the main one of which is the material from which the conductive conductors are made. The following non-ferrous metals can be used as the core material of wires and cables:

Aluminum. Their main advantage is that aluminum conductors are cheap and lightweight. Among the negative qualities, the following can be noted: tendency to mechanical damage, low electrical conductivity, high transient electrical resistance of oxidized surfaces.

Copper . This metal is the most popular in comparison with other competitive options. They are distinguished by the following main properties: low electrical and transition resistance at the contacts, fairly high elasticity and strength, as well as ease of soldering and welding.

Aluminum copper. A peculiar synthesis of two metals. These are cable products with aluminum cores coated with copper. They are characterized by slightly lower electrical conductivity than their copper counterparts. They are also lightweight and have average resistance while being relatively cheap.

Materials from which wires are made

Conductor materials

The amount of energy that a conductor transmits depends on a number of factors, the main one of which is the material of the current-carrying conductors. The following non-ferrous metals can be used as the core material of wires and cables:

- Aluminum. Cheap and lightweight conductors, which is their advantage. They are characterized by such negative qualities as low electrical conductivity, a tendency to mechanical damage, high transient electrical resistance of oxidized surfaces;

- Copper. The most popular conductors, which have a high cost compared to other options. However, they are characterized by low electrical and transition resistance at the contacts, fairly high elasticity and strength, and ease of soldering and welding;

- Aluminum copper. Cable products with aluminum cores coated with copper. They are characterized by slightly lower electrical conductivity than their copper counterparts. They are also characterized by lightness, average resistance and relative cheapness.

Some methods for determining the cross-section of cables and wires will depend specifically on the material of their conductor component, which directly affects the throughput power and current strength (method of determining the cross-section of conductors by power and current).

Wire diameter and methods for determining wire cross-section by diameter

The diameter of any conductor must match the parameters specified in the documentation that comes with it. However, such a complete coincidence, unfortunately, does not always occur. For example, if the marking says that the cable is 3 X 2.5 , then its cross-section should be at least 2.5 mm2 . But when you check it yourself at home, the result may well not be what the manufacturers promised. It will not be surprising if it turns out that the wire is 20-30% less than the stated figure. Therefore, it is better to check and determine the wire cross-section by diameter additionally.

To determine the diameter of the wire, you need to measure it. In this case, the measuring instruments can be a caliper or a micrometer . They use mechanical and electronic (with digital screen). The first option is more common and is measured more often, but in some cases electronic devices are preferred.

Basically, they measure wires and cables using a caliper, since this device can be found in almost every household. It can also measure the diameter of wires in a working network, for example, a socket or panel device.

In fact, there are several ways to determine the diameter of a wire. Each is based on determining the diameter a of the core with subsequent calculations of the final results.

Method one. Using instruments that help measure the diameter of a wire or wire strand. And also using the formula.

Wire Diameter - Measurement

This option is primarily suitable for professional electricians who are constantly installing electrical wiring. That is, the person conducting the measurements must have experience in this area. Of the two measuring instruments, the most accurate results can be obtained using a caliper. The advantage of this device is that it allows you to measure the diameter of a wire even on a section of a working line, for example, in a socket.

Appearance of a mechanical micrometer

We talk here about what types of switches there are.

Determining the wire cross-section using the formula

After you have measured the diameter of the wire , you need to make calculations using the following formula:

Determining the wire cross-section using the formula

The above formula is suitable for all measurements.

It must be remembered that the number "Pi" is 3.14, so if we divide the number "Pi" by 4, then we can simplify the formula and reduce the calculation to multiplying 0.785 by the diameter squared.

Also, to determine the cross-section, the formula for finding the area of a circle by diameter is also suitable. It looks different: S = π/4 X D2 . This formula is more labor-intensive, but, in any case, by substituting the numbers and solving the example, we get the same result. In cross-section, any cable core has the shape of a circle. It doesn't matter whether it's wire or wire. What is the wire cross-section? This is nothing more than the cut circumference area of the wire. And the area of any circle, knowing its diameter and radius, can be easily calculated using a simple formula familiar to everyone from school: S = πR2 . “π” is a constant number and is always equal to 3.14, “R2” is the radius squared.

We substitute the values into the formula, first dividing the diameter by two to find out the radius, because in this formula the area is found out precisely with its help. It turns out: S = 3.14 X 0.342 . All you have to do is solve this simple example, the result is 0.36. What does it mean - the cross-section of the wire being tested is 0.36 mm2. But it is better not to use such a “weak” wire in the power network.

Method two.

Measuring wire cross-section using a ruler. If you do not have one of the special measuring devices and you decide not to spend money on purchasing one, then you can use an available proven method for measuring. Take a simple pencil, ruler and wire. Strip the core of insulation. To do this, wind it tightly onto a pencil, and then use a ruler to measure the total length of the winding.

Measuring wire cross-section using a ruler

Then divide the length of the wound wire by the number of cores. The resulting value will be the diameter of the wire cross-section.

So you need

1. Clean the insulating layer of the core;

2. Wind the turns around the pencil tightly to each other (there should be at least 15-17 pieces);

3. Measure the winding length;

4. Divide the resulting value by the number of turns.

Rules to consider when performing this work:

- the more cores you wind on a pencil, the more accurate the result will be; the number of turns should be at least 15;

- try to press the turns tightly against each other so that there is no free space between them, this will significantly reduce the error;

- The measurements must be repeated several times (while changing the side of the measurement and the direction of the ruler). By getting multiple results, you have a better chance of avoiding large errors.

Disadvantages that you should pay attention to with this measurement method:

- You can only measure the cross-section of thin wires, since it will be difficult for you to wind a thick wire around a pencil.

- You will need to purchase a small piece of the product first before making the main purchase.

Method three. Measuring the cross-section by wire diameter using a table. Using this particular method, you do not have to carry out calculations using the formula. In a specially selected table for your convenience, the diameter of the wire (in millimeters) and the cross-section of the conductor (in square millimeters) are already indicated.

Read here about what to do if a person is electrocuted. Everyone should know this!

Methods for determining wire cross-section step by step

There are several ways to measure the cross-section by core diameter. If the wire is single-core, then measurements will be made immediately on it, but one conductor must be untangled from the cable coil. After this, it is cleared of insulation so that only metal remains.

To calculate the area of a circle through the radius, use the formula: S = π × R2, where:

- π – constant equal to 3.14;

- R is the radius of the circle.

But, due to the fact that from a practical point of view it is much easier to calculate a diameter equal to two radii, the calculation formula will take the following form: S = π × (D/2)2. Depending on the methods for measuring the diameter, such methods for calculating the cross section are distinguished.

By diameter using a caliper or micrometer

The most relevant option to measure the diameter are instruments such as calipers and micrometers. These devices allow you to measure the diameter as accurately as possible. To do this you will need a wire and a micrometer.

To do this, latch B is moved to the open position. The micrometer handle is unscrewed to such a distance that the wire easily fits in the space between probes A. Then, using handle G, the device is twisted until the ratchet operates. After this, readings are recorded on all three scales at point B.

In this example, the diameter is 1.4 mm, therefore, to calculate the cross-section, you need S = 3.14 × 1.4 × 1.4 / 4 = 1.53 mm². The same procedure for determining the cross section can be performed using a caliper. The advantage of this method is the ability to measure any round conductor, even if it is already installed and used to power any electrical device. The main disadvantage of the method is the high cost of the devices; naturally, purchasing them for a couple of measurements is completely impractical.

By diameter using a pencil or pen

This method of determining the cross-section is based on the fact that the wire has the same diameter along its entire length. Take a regular pencil, pen or felt-tip pen and wrap the wire around it in a spiral. To eliminate the thickness of the insulation, it must be cut along its entire length. The rings should be placed as tightly as possible; the larger the space between the rings, the lower the accuracy.

Since all wires have the same thickness, to determine the diameter of the copper wires, measure the length of the entire winding and divide by the number of turns. In this example, D = 15 mm / 15 turns = 1 mm, respectively, using the same calculation formula, we obtain a section S = 3.14 × 1 × 1 / 4 = 0.78 mm². Note that the more turns you make, the more accurately you determine the cross-section.

It is worth noting that the advantage of this method is that only available means can be used to determine the cross-section. The disadvantage is low accuracy and the ability to wind only thin conductors. In the example, a relatively thin wire was used, but the distance between the turns is already visible. Because of which the accuracy leaves much to be desired, it goes without saying that aluminum wire cannot be bent in this way.

By diameter using a ruler

Let’s immediately make a reservation that for measuring with a ruler you can only take a relatively thick wire; the smaller the thickness, the lower the accuracy. The diameter of the vein can be determined by thread or paper; the second option is the most preferable, as it gives greater accuracy.

Tear off a small strip and fold it over on one side. Thinner paper is preferable, so there is no need to fold the sheet several times. Then the paper is applied to the wire and wrapped around the circumference until the strip touches. At the point of contact, it is bent a second time and applied to the ruler for measurement.

Using the resulting circumference L, the vein diameter D = L / 2 π is found, and the cross section is calculated as shown earlier. This method of determining the cross-section is well suited for large aluminum conductors. But the accuracy in this method is the lowest.

By diameter using ready-made tables

This method is suitable for standard gauge wires. For example, you have already determined the diameter using one of the above methods. Then you use the table to determine the section.

Wire diameter and diameter correspondence table with definition of cross-section

This table will save you from the need to make unnecessary calculations. Despite the fact that each cable coil has a tag that indicates its marking and all its parameters, you should not trust what is written. It would be better to play it safe and measure the diameter of the conductor, and then use the table to estimate approximately what its cross-section is.

| Diameter of conductor element, mm | Cross-sectional area of the conductor element, mm2 |

| 0,8 | 0,5 |

| 0,9 | 0,63 |

| 1 | 0,75 |

| 1,1 | 0,95 |

| 1,2 | 1,13 |

| 1,3 | 1,33 |

| 1,4 | 1,53 |

| 1,5 | 1,77 |

| 1,6 | 2 |

| 1,8 | 2,54 |

Diameter correspondence table with definition of cross-section

Cable products with a cross-section of up to 10 mm2 are almost always produced in a round shape. To meet the domestic needs of houses and apartments, such conductors are quite sufficient. However, with a larger cross-section of the cable, the input cores from the external electrical network can be made in segment (sector) form, and it will be quite difficult to determine the cross-section of the wire by diameter.

It is best to use a micrometer or caliper to measure the thickness (diameter) of the wire. Micrometers are a priority, it doesn’t matter - mechanical or electronic, they will show the most accurate result. However, the results given by a caliper will also work quite well. To make a measurement, you need to clean the wire from the plastic insulation, but not every seller will allow such actions with the end of the wire on a coil put up for sale. Therefore, it is best to buy a meter of cable in advance and then take measurements. Once data on the diameter of the core has been obtained, you can begin to calculate the cross-section.

Marking of wires by diameter

In particular, the following will be written on the tag: “VVNG 2x4.” This encoding means the following: in the cable - the number of cores is 2, each of which has a cross-section of 4 mm2. To confirm or refute the stated parameters, we measure the diameter of the cable core without insulation using one of the methods. We carry out calculations.

Wire marking

Calculation of cable cross-section by diameter. Option #1

Fig.1

It is possible to determine the cable cross-section by the diameter of the core. In practice, the diameter of the core without insulation is most often measured with a caliper or micrometer. To remember how to work with a caliper when measuring the diameter of a core, see Fig. 1

Knowing the core diameter, it is quite easy to determine the cable cross-section. To do this, you need to use the cable cross-section formula, which coincides with the usual school formula for calculating the area of a circle (Fig. 2)

Rice. 2 Formula for calculating cable cross-section

Example of section calculation:

A 3-core VVGng cable without markings with a core diameter of 5.6 mm was received at the warehouse. Let's determine the cross-section of the VVGNg cable by diameter: Skr=3.14*5.6^2/4=24.6 mm2

The nearest standard section is 25mm2. Thus, the VVGng 3x25 cable was delivered to the warehouse.

What to do if the actual cross-section does not match that indicated on the marking? Cable manufacturers also have their own tolerances regarding the cross-section of cable cores. These tolerances are regulated by GOST 22483-77, according to which the cross-section of the core must correspond to the electrical resistance specified in GOST.

For example, for a VVG cable (core flexibility class 1), the range of core diameters corresponding to GOST is calculated and shown in the table below:

| Nominal cross-section, mm2 | Max. core diameter, mm | Min. core diameter based on max resistance according to GOST 22483-77, mm |

| 0,5 | 0,80 | 0,78 |

| 0,75 | 0,98 | 0,95 |

| 1 | 1,13 | 1,10 |

| 1,5 | 1,38 | 1,35 |

| 2,5 | 1,78 | 1,72 |

| 3 | 1,95 | 1,90 |

| 4 | 2,26 | 2,18 |

| 5 | 2,52 | 2,45 |

| 6 | 2,76 | 2,67 |

| 8 | 3,19 | 3,12 |

| 10 | 3,57 | 3,46 |

| 25 | 5,64 | 5,49 |

| 35 | 6,68 | 6,47 |

| 50 | 7,98 | 7,52 |

| 70 | 9,44 | 9,04 |

| 95 | 11,00 | 10,65 |

| 120 | 12,36 | 11,97 |

| 150 | 13,82 | 13,29 |

| 185 | 15,35 | 14,87 |

| 240 | 17,49 | 17,05 |

Read more about this in our article - Undersized cable cross-section. Acceptable norms for underestimation of cross-section

Conductor markings (wire diameter)

If the cross-section coincides with that indicated on the tag, great, you can safely take it. But when the resulting result is much less, you should opt for a more powerful cable that has the next best parameters. Otherwise, you can look for wires in other stores. Unfortunately, high-quality goods that meet GOST standards are not so easy to come by these days. Remember that a high-quality cable will not be cheap. The conclusion follows from this: if you want to get a quality product, look for trusted stores with markings that comply with GOST.

Before making a final decision - to take or not to take the wire, it is necessary to inspect the insulation very carefully. The plastic shell of the core must be continuous, have an impressive thickness, which will be the same along the entire length. If, in addition to discrepancies in diameter, negative nuances with the braid are also revealed, then of course you need to look for another store where the cable would be purchased elsewhere and from a completely different manufacturer. It's better not to take risks with electricity.

Therefore, it is better to overpay, perhaps spend more time searching, but buy a high-quality conductor made according to GOST, and not made according to specifications. In this case, you can guarantee that the cable will serve the time stated in the documents without any problems, and, most likely, much longer. The choice of wires is a very serious matter, and it certainly cannot be handled carelessly. You should not risk the building just to reduce the search time or save extra pennies.

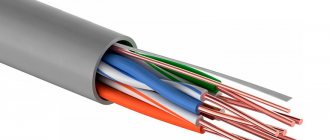

Determining the cross-section of a stranded wire

Stranded wires contain many thin wires inside them. How to determine the wire cross-section in this case? Some “craftsmen” twist all the wires into one tight twist, measure it with a caliper and calculate the cross-section using the found diameter.

Diameter of stranded wires

But this is completely the wrong approach. Only a micrometer is suitable for this option. To measure the cross-section of a stranded conductor, you need to measure the diameter of one small wire. Having received the result of the cross-section of one wire, you should count the number of others, then multiply the cross-section of one wire by the total number of wires. Only in this sequence of actions will the cross-section of the stranded wire have the correct parameters.

Calculation for stranded wire

Stranded wire (stranded) consists of single-core wires twisted together. Anyone who is even a little familiar with mathematics understands perfectly well that it is necessary to count the number of these wires in a stranded wire. After this, the cross-section of one thin wire is measured and multiplied by their total number. Let's consider the following options.

Calculation using a caliper

The measurement is carried out with a caliper with a conventional scale (or micrometer). Experienced craftsmen always have this tool at hand, but not everyone is a professional electrician.

To do this, using the VVGng cable as an example, cut the thick sheath with a knife and spread the wires in different directions.

Then select one core and strip it with a knife or scissors. Next, measure this core. The size should be 1.8 mm. Please refer to the calculations to prove the measurement is correct.

The resulting figure of 2.54 mm² is the actual cross-section of the core.

Measuring with a pen or pencil

If you don’t have a caliper at hand, you can use improvised methods using a pencil and ruler. First, take the wire to be measured, strip it and wind it around a pencil or pen so that the turns lie close to each other. The more turns, the better. Now let's count the number of wound turns and measure their total length.

For example, we got 10 turns with a total winding length of 18 mm. It is easy to calculate the diameter of one turn; to do this, divide the total length by the number of turns.

As a result of all the calculations made using the formula, you will obtain the required diameter of the core. In this case it is 1.8 mm. Since the diameter of one core is known, it is not difficult to calculate the cross-section of the entire VVGng wire using the already known formula. You can see that the results were equal.

Using tables

How can you find out and measure the cable cross-section if you don’t have a caliper, a ruler, or a micrometer at hand? Instead of racking your brains over complex mathematical formulas, just remember that there are ready-made tables of values for measuring cable cross-section. There are, of course, very complex tables with many parameters, but, in principle, to begin with it is enough to use the simplest of the two columns. The diameter of the conductor is entered in the first column, and the ready-made values of the wire cross-section are given in the second column.

Wiring cross-section table for closed wiring

There is another “approximate” method that does not require measuring the thickness of individual wires. You can simply measure the cross-section (diameter) of the entire thick scroll. This method is usually used by experienced electricians. They can find out the cable cross-section both “by eye” and with the help of tools.

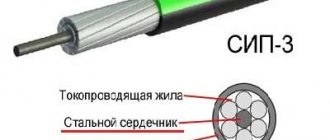

Aluminum cable with sector conductors

Cable type : Segment cross-sectional area, mm2 : S35 50 70 95 120 150 185 240

Four-core segment cable type - cross-sectional area h - 7 8.2 9.6 10.8 12 13.2, as well as w - 10 12 14.1 16 18 18

Three-core segment stranded 6(10) - h 6 7 9 10 11 12 13.2 15.2, as well as w 10 12 14 16 18 20 22 25

Three-core segment single-wire , 6(10) - h 5.5 6.4 7.6 9 10.1 11.3 12.5 14.4, as well as w 9.2 10.5 12.5 15 16.6 18.4 20.7 23.8

These are indications where the name of the cable type is on the left, and on the right opposite it is the cross-sectional area of the segment. Where the size (height, width) of the cable takes on the corresponding cross-sectional area. Initially, it is necessary to measure the height and width of the required segment with a ruler, after which the required parameter can be calculated by correlating the obtained data.

Aluminum cable with sector conductors

When choosing a cable, you must be guided by several criteria:

- the strength of the electric current that the cable will pass;

- power consumed by energy sources;

- current load exerted on the cable.

Description and technical documentation

The dimensions of the cable largely depend on the number and type of cores that it contains. The minimum diameter of the core gives 1.5 mm 2 in its cross-sectional area. The maximum cross-sectional area of the core is 240 mm 2 in a single-core cable, 95 mm 2 in a two- or four-core cable and up to 50 mm 2 in a five-core cable. The cross-sections of neutral conductors (in the case of a smaller cross-section than the main ones) and grounding conductors, depending on the cross-section of the main conductors up to 50 mm 2, are given below.

| Main veins | 1,5 | 2,5 | 4 | 6 | 10 | 16 | 25 | 35 | 50 |

| Zero core | 1,5 | 1,5 | 2,5 | 4 | 6 | 10 | 16 | 16 | 25 |

| Grounding conductor | 1,0 | 1,5 | 2,5 | 2,5 | 4 | 6 | 10 | 16 | 16 |

Larger options are much less common. The most common among VVG cables with conductors of unequal cross-sections are cables with three main and one neutral conductor (the so-called “three plus”).

The outer diameter of the electrical wire is directly proportional to the number of cores and the nominal cross-section. With an area of 1.5 mm2, the cable diameter starts from a size of 5 mm and can reach up to 53.5 mm in four-core versions. In the same way, the weight of one kilogram of cable increases, starting from 39 kg/km and reaching several tons, so the weight of the wire must be taken into account when designing its installation.

The nominal and minimum values of the radial insulation thickness for VVG cables with a cross-section of up to 50 mm 2 for an operating voltage of 0.66 kV and 1 kV are given in the table.

| Cable voltage, kV | Nominal cross-section of cores, mm | Nominal insulation thickness, mm | Minimum insulation thickness, mm |

| 0,66 | 1 — 2,5 | 0,6 | 0,44 |

| 4 and 6 | 0,7 | 0,53 | |

| 10 and 16 | 0,9 | 0,71 | |

| 25 and 35 | 1,1 | 0,89 | |

| 50 | 1,07 | ||

| 1-2,5 | 0,8 | 0,62 | 1,3 |

| 4-16 | 1,0 | 0,8 | |

| 25 and 35 | 1,2 | 0,98 | |

| 50 | 1,4 | 1,16 |

The thickness of the protective sheath of the VVG electrical wire depends on the twisting diameter of the insulated conductors under the sheath. The nominal and minimum values of the shell thickness are given in the table.

Power (wire diameter)

The most important parameter during electrical installation work (in particular, cable laying) is throughput. The maximum power of electricity transmitted through a conductor depends on the cross-section of that conductor itself. Therefore, it is extremely important to know the total power of the energy consumption sources that will be connected to the wire. Often, household appliances and other electrical appliances indicate the maximum and average power consumption on the label and in the accompanying documentation.

If, for example, a washing machine in the process of washing clothes can consume electricity in the range from tens of W/h during rinsing mode to 2.7 kW/h when heating water. This is a lot of power and naturally, a wire with a cross-section that is sufficient to transmit electricity of maximum power must be connected to it. In the case when two or more consumers are connected to the cable, the total power is determined by adding the limit values of each of them. The average power of all electrical appliances and lighting devices in an apartment rarely exceeds 7500 W for a single-phase network. Accordingly, the cable cross-sections in the electrical wiring must be selected to this value.

For example, for a total power value of 7.5 kW, it is necessary to use a copper cable with a core cross-section of 4 mm2, which is capable of transmitting about 8.3 kW. The cross-section of the conductor with an aluminum core in this case must be at least 6 mm2, passing a current power of 7.9 kW.

In some special residential buildings, a three-phase power supply system of 380 V is often used. But the fact is that most equipment is not designed for such electrical voltage. A voltage of 220 V is created by connecting them to the network through a neutral cable with an even distribution of the current load across all phases.

Electric current (wire diameter)

Quite often you can encounter a situation where the power of electrical equipment and equipment is not known to the owner due to the absence of this characteristic in the documentation or the loss of the necessary documents and labels. There is always a way out. For this situation, it is as follows: make the calculation using the formula yourself. Power is determined by the formula:

P = U*I,

Where:

- P – power, measured in watts (W);

- I – electric current strength, measured in amperes (A);

- U is the applied electrical voltage, measured in volts (V).

When the strength of the electric current is unknown, it can be measured with control and measuring instruments: an ammeter, a multimeter, and a clamp meter.

After determining the power consumption and electric current, you can use the table below to find out the required cable cross-section.

Measuring with pliers

| Wire cross-section. | Electrical voltage 220 V | Electrical voltage 380 V |

| Current strength A; Power, kWt | Current strength A; Power, kWt | |

| 2,5 | 27 5,9 | 25 16,5 |

| 4 | 38 8,3 | 30 19,8 |

| 6 | 50 11 | 40 26,4 |

| 10 | 70 15,4 | 50 33 |

| 16 | 90 19,8 | 75 49,5 |

| 25 | 115 25,3 | 90 59,4 |

| 35 | 140 30,8 | 115 75,9 |

| 50 | 175 38,5 | 145 95,7 |

| 70 | 215 47,3 | 180 118,8 |

| 95 | 260 57,2 | 220 145,2 |

| 120 | 300 66 | 260 171,6 |

Load (wire diameter)

Calculation of the cross-section of cable products based on current load must be carried out to further protect them from overheating. If too much electric current passes through the conductors for their cross-section, destruction and melting of the insulating layer may occur. The maximum permissible long-term current load is the quantitative value of the electric current that can pass the cable for a long time without overheating. It's important to know this. To determine this indicator, it is initially necessary to sum up the powers of all energy consumers. After this, calculate the load using the formulas:

I = P∑*Ki/U (single-phase network),

I = P∑*Kи/(√3*U) (three-phase network),

Where:

- P∑ – total power of energy consumers;

- Ki – coefficient equal to 0.75;

- U – electrical voltage in the network.