Caps for brick fence posts, fastening methods

Sometimes beginners do not know how to make or attach caps to brick fence posts. And without caps, the pillars will quickly collapse.

Brick support pillars must be protected from precipitation in the form of snow and rain. Moisture penetrating into the brick destroys it.

- 1 Caps on posts for brick fences 1.0.1 Reasons for installing caps on posts:

- 1.1.1 Design elements:

- 1.4.1 Installation of lighting fixtures

- 1.8.1 Caps for posts for brick fences, video

Making a cap at home

All home craftsmen should know how to make caps for fence posts. Moreover, almost any material is suitable for their manufacture - plastic, plywood, wood, various metals. The types and shapes of products for brick pillars depend on the availability of blanks, tools and the practical experience of the craftsman.

Scheme with the dimensions of the top for a brick pillar

As an example, the following presents the main stages of manufacturing a cone-shaped protective cover from roofing iron:

Stub diagram with main parameters

If there are no factory rivets, they can be “cut” from soft wire. Aluminum blanks are the best option for these purposes. With their help, the structure will be securely fastened.

Types of caps for brick racks

Caps for fence posts are produced by many domestic and foreign companies. Products are distinguished by shape, purpose and material of manufacture. Primary information will help determine the need to purchase and the feasibility of installing a protective cover made of a particular material.

The photo shows the tops for the pillars.

A variety of caps for brick supports

Concrete caps

Concrete caps for posts for fences made of bricks are presented in a wide range on the construction market. They are attached to the supports using a concrete mixture. The price of the products is affordable for the majority of the population. However, they weigh close to 20 kg. They are mainly installed on concrete structures; they also look good in tandem with brick and stone structures.

Variety of types of concrete protective devices

Stone caps for posts for brick fences

They are made by cutting from solid pieces of granite or marble. They have an exceptionally “cost-effective” appearance. Even the standard form looks advantageous. They have significant weight. They have a long service life. The cost of such a product for fences is in a high price category.

The photo below shows a fence made of brick and metal.

Option for installing a stone cap on a brick support

Ceramic

Ceramic caps for brick fences have an attractive appearance; their shape is usually simple. But the mosaic texture of the ceramics makes them attractive, and if they are topped with a lantern, then an exceptional appearance is guaranteed. The price is higher than the market average.

Scheme of a ceramic product with dimensions

Polymer-sand caps

They are made using the latest technology. Visually appealing. The strength and service life are close to those of stone products, but their cost is an order of magnitude lower. Thanks to this, polymer-sand mounting is increasingly recommended for use in individual construction of fences, especially since they are easy to install.

The photo shows a fence with brick pillars at the dacha.

Such models go well with brick and corrugated sheets

Metal caps

Metal clinkers are widely used today. They are made of stainless and galvanized steel, tin, copper alloys. The weight is insignificant, the price is affordable, you can buy it at any hardware store. As an option, forged caps for posts increase artistic value if they are installed on metal fences with similar inclusions or on stone structures. Their price may be higher than that of stone products.

The photo shows a beautiful fence support.

Metal plug on the fence

Wooden fence caps

Wooden caps are in the most affordable price category. You can easily make them yourself. But it is impossible to make rounded or round contours without the use of special machines. Their service life is short. Repeated impregnation with an antiseptic and application of paint and varnish are required.

The photo shows the fence of a private house.

Wood products for fences require periodic processing

Plastic fence finials

PVC products are light in weight, they are beautiful, and the price is low. When purchasing them, you should remember that plastic caps are susceptible to the negative effects of ultraviolet rays.

Plastic elements benefit from price and variety of shades

Fiberglass

Products made from this material are dielectric. A pole lamp made of this material will be completely safe. They produce fiberglass caps with lighting elements installed in them.

General information

The main reasons to put covers on fence posts are:

Protection is especially required for fence columns made of stone. This is a porous material, which is why it is much more susceptible to negative environmental factors.

The photo shows a fence of a private house with brick pillars.

Types of protective covers for poles

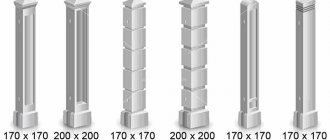

Even the simplest tops for support posts have a number of parameters that must be taken into account when choosing them. They can be made in different shapes:

In addition, there are protective fence covers that imitate metal tiles or wood.

Popular product sizes for brick fence posts: 38x38, 40x40, 40x60, 50x50, 60x60, 60x80, 70x70, 80x80 cm.

For greater protection of the supports and to give an original look, you can install a special parapet on top along the entire perimeter of the fence.

Depending on the material, caps for brick fence posts come in the following types:

Moreover, a large number of colors will please any consumer. The most popular colors are brown (RAL 8017), to match the brick or tile, and green, to match the shrubs planted near the fence.

The surfaces of protective fence covers are matte and glossy. It should be taken into account that any cap on a brick pillar must correspond to the overall composition of the installed fence.

To make it easier to mount metal caps on a brick support, they are made hollow inside. This reduces their cost and also allows them to be used in any weather conditions. Emptiness does not degrade the quality of the product and does not make the caps fragile and unreliable.

The cost of a metal cover for brick fence posts includes the cost of work to produce the product and the direct price of the material. Therefore, brick fence caps made of stainless steel are inexpensive. In addition, they are easy to transport by simply placing them in the trunk of a car.

Lights can be installed in protective caps on the fence. This will help organize street lighting and decorate the fence.

When choosing a cap for a fence post, attention should be paid not only to aesthetic indicators, but also to the parameters of the future cap. Before you buy a product, you need to determine the dimensions and material of manufacture.

If there is no suitable model among the large selection of popular ones, then you can make caps and a canopy for a brick fence to order according to your own drawing.

The photo shows a beautiful cap for a brick support.

Features of choice

The design of protective covers for fence posts is very simple. On each there are only two main elements that fulfill their intended purpose:

To choose the right protective cover for brick fence supports, you can use a few simple rules. They will allow you to check the main structural parts and fasteners, as well as determine the quality of the product:

Compliance with the described points will allow you to select and purchase pole caps of the model that suits your own wishes.

The photo shows a fence with brick pillars at the dacha.

Fence caps: what material to use, how to secure, installation process

Each brick fence requires protective caps, which are installed on the top of the support posts. These caps are made with a certain angle of inclination so that when it rains, water flows down without falling on the fence. Such protective structures will help extend the life of any fence, at the same time, to complement the interior, they come in different shapes, colors, caps in which you can illuminate the entire fence.

- Material of manufacture

- Appearance

- Attaching plugs to poles

- Installation of the cap with glue

Material of manufacture

- concrete;

- plastic;

- metal is tin, copper, steel, galvanized and stainless steel, brass;

- tree;

- stone;

- clinker is a durable brick that is not afraid of fire and water;

- ceramics;

- sand-polymer.

Of these materials, plastic is the most budget option, but has an average appearance; wood plugs do not provide protective functions, but look aesthetically pleasing. Ceramics has good protective properties and an attractive appearance, but during operation and transportation it is quickly damaged, since it is a very fragile material.

Clinker caps are considered the most reliable; they are not afraid of water, snow, fire, frost and retain their original appearance for many years. Concrete caps are easy to install, last a long time, their disadvantage is that they are fragile and quickly lose their attractive appearance.

Metal caps look very original and stylish, they have various beautiful curved lines, serve for many years, their minus is corrosion, it appears even when protective coatings are applied; when it rains, such caps make a characteristic sound.

Products made from metal profiles have the same features as metal caps; their big advantage is that you can make them yourself. The most stable and suitable for any climate are polymer-sand caps; they are not afraid of temperature changes, water, snow, rain and frost, and last for many years.

Appearance

Plugs can be used not only on support pillars, but also on spans; the material used is different, the color, shape and size are selected to order. On sale, post covers come in the shape of a pyramid, cone, round and square, so you can choose the right product that will suit the appearance of the fence, building facade and yard.

Attaching plugs to poles

Depending on the material of manufacture, the methods of fastening for caps are completely different, these are glue, cement mortar, self-tapping screws.

Features of fastening the caps:

- All metal products are fastened with dowels, first holes are made on the upper part, 3-5 cm in size. The same holes need to be drilled to strengthen the lower part, then the cap is put on and secured with dowels.

- Ceramic and concrete plugs are installed with glue; the adhesive composition must be applied to the entire size of the cap and below its level; this method will save you from washing out the composition.

- The main rule is that all side seams must be sealed.

Installation of the cap with glue

- The upper part of the post must be thoroughly cleaned and a primer applied.

- Then a solution or glue is applied and the entire surface is leveled.

- The cap is installed using a building level.

- All seams need to be sanded.

- If there are no lower overhangs, to drain rainwater, you need to treat the side seams with a water-repellent compound.

After the base of the plug is secured and the solution has hardened, decorative decorations can be installed. The main task of the caps is to extend the service life of each fence.

Decor and protective cap

In addition to the “security” function, caps decorate fences. They are a great decorative item. Moreover, you can often see unusually shaped caps on pillars.

Diagram of the structure and names of the elements of the fence

It is not very difficult to make them yourself.

Any unusual design, decorated with a decorative cap, becomes unique. To create a creative design, you can install a decorative lantern at the top of the product. The fence will look original and very stylish.

Return to contents

Purchased options

The market is saturated with manufacturers of finished parts and fence structures. Let's look at the 3 most popular ones.

Tetto

A well-known brand specializing in the production of polymer sand products.

The advantages of Tetto hoods are as follows:

- the presence of a drip on the overhang;

- the material from which the caps are made is not afraid of constant exposure to ultraviolet radiation;

- size for mounting on a pole is 390*390 mm, when other companies have 385*385 mm;

- ease of installation of the cap on the pole.

The price range allows customers with different financial capabilities to make a purchase. Average price – from 770 rubles/pcs.

Reference

The Russian production association "Etalon" produces and sells rolled metal products, roofing materials, fences, and related products.

The range includes caps made of galvanized steel and polyester. The price for the first type is from 1000 rubles/piece, the second – from 1100 rubles/piece.

VladMetalProfile

located in the city of Vladimir. Specializes in production:

- profiled sheet;

- metal tiles;

- profiles for drywall;

- roofing elements (ridges, eaves and wind strips);

- chimneys;

- caps for poles;

- insulation materials;

- drainage systems, etc.

Manufactures greenhouses, gazebos, canopies, gates.

Making a tin cap video

02/28/2017 at 01:46

Hello, thanks to the authors for the article, there are a lot of interesting things, but I think that in this situation it is better to rely on professionals and purchase a finished product, for example, the manufacturer of polymer sand products TK Titan, under the Tetto brand, produces beautiful and durable caps for poles that will serve for a long time and delight with its appearance.

Add a comment Cancel reply

Fences, gates, pillars.

Professional installation! Free consultation!

Our phone: +7

E-mail: Opening hours: daily from 10:00 to 21:00 Our address: Moscow, st. Prospekt Mira, 97

How to make your own protective “hat”

If you want to save money or just like to make things yourself, you can create both the cap and the post with your own hands. A brick support is a metal pipe lined with bricks. Every man knows that this is not at all difficult, but to create a cap you can use two options:

- Concrete

- Tin coating

To pour a cement tip from concrete, you must first create a tin mold that will match the dimensions of the support. The shape must have a pyramidal appearance and neat, even edges.

Pre-cut pieces of material (tin) are fastened using improvised means, after which they are placed on a flat surface and fixed with spacers. After this, concrete is poured into the mold. To give the product an original appearance, you can add dyes to the solution or create a certain texture. It is very important in such a sensitive matter to give the item time to dry. This takes about three weeks. If the cement does not dry sufficiently, it may become damaged during installation.

To create a metal cover for a support, you will need not only galvanized or tin metal, but also a correctly selected drawing. It is this that is the first and most basic stage in this so-called art. Initially, you should take all measurements, then decide on the angle of inclination and height of the product. The upper part of the “roof” most often consists of four triangles. All the necessary parts must be carefully cut out according to the drawing, after which the fold lines must be marked and assembled into a single whole.

More about iron structures

If your fence is a galaxy of metal pipes, then you will have to act, in principle, according to a similar scheme. It is important to take into account the specifics of the pipes. And you need to make the lid first.

List of required materials:

- metal plate;

- zinc treated sheet;

- aluminum or tin.

First, work is done on the workpiece in accordance with the drawing. Then you need to roll the workpiece by hand, and overlap the edges of the pattern, approximately 1.5 cm.

Overlaid sheets must be secured. Copper rivets will help you here.

Installing a cap on such a pole will be successful if metal strips (2-4 pieces) are connected to the surface of the cap itself. The width of each strip is 1.5 cm and the thickness is 2 mm.

The caps described above for brick pillars are also attached to metal fences using traditional screws. A drill or hammer drill will help here. This is what a classic cap on a brick fence will look like, photo:

Assembling an umbrella, canopy or head

After preparing the skirt, we assemble the umbrella with rivets, and attach the skirt in exactly the same way, through the rivets.

Read: Cosmetic renovation of a cottage or house, what is included in the crew’s work estimate

In conclusion, for the first time it is better to make blanks from paper in small sizes, this is so as not to spoil the metal, if everything turns out well, then make it in your own sizes from metal 0.5 mm thick

Tell your friends or leave a note on your page:

Pros and cons of lids made of different materials

Metal protection products for poles

Caps for protecting bricks from moisture are divided into several types, depending on the material from which they are made. They can be brick, concrete, plastic, metal or stone. The most common ones are tin lids. They provide reliable protection for the brick.

To install them yourself, without the help of professionals, you will need the skills of a tinsmith. In addition, without special tools, the process of making such a cap will be very problematic. Their wide distribution is due to the fact that they are most often installed by hired workers involved in the construction of the entire fence.

Less common on brick pillars are covers made of tiles. This look is easiest to create yourself. This does not require specialized equipment. Only the most common construction tools will be needed. Considering that such elements are almost never found ready-made in stores, we can say with confidence: they will add uniqueness to any suburban area.

Covers can also be made from tiles (paving or facing). They are easy to install. All that is needed for fastening is ordinary glue or cement-sand mortar. The tiles for production can be taken of any color and any texture. The design will depend entirely on the imagination of the manufacturer. The disadvantage is that it is impossible to make a beautiful pyramid-shaped cap. It will turn out flat.

There are also concrete covers. Their advantages include ease of installation, low price, unique appearance, provision of reliable protection for the pole, durability, and low maintenance requirements. But their disadvantage is fragility. In addition, their appearance quickly loses its attractiveness.

Plastic and fiberglass covers are also made to protect brick fence posts. And today, fiberglass caps are becoming increasingly popular. They are lightweight, have good strength, durability, and resistance to precipitation.

Self-production

Making protective covers for a fence post is not difficult. To do this, you can choose any material - plastic, plywood, wood, corrugated sheet. The type and shape will depend on the available workpieces, the availability of tools and work skills.

For example, we can describe step-by-step instructions for making protection in the form of a cone made of roofing metal:

After correct installation of the side edges, you need to secure the elements with rivets. If they are missing, the rivets can be chopped. Aluminum wire is best suited for this. This way the structure will be securely fixed to the fence posts.

The photo shows caps on brick fence posts.