Fastening drywall to plywood

When choosing a material for finishing the premises, you can choose different types, for example, use plasterboard or plywood as the main surface for the walls. The first option is the most common due to its qualities and cost, the second is used less frequently, but is more durable.

Drywall or plywood. materials have their advantages and disadvantages

Another principle of use is to mount drywall on plywood, and in this case it will be possible to significantly strengthen the walls. It is especially important to carry out such cladding of walls and ceilings in dachas, where veneer sheets are often used as cladding for rooms. So, how to install according to the “plasterboard on plywood” scheme, and is it possible to use the latter as room decoration?

Full contents of the material

Laying plywood on the floor

Laying plywood on the floor is a quick and economical way to level the surface. This material is usually used as a base for laying finishing, decorative coverings, such as parquet, linoleum or carpet. Although, if you simply varnish the plywood floor, you will get a rather attractive surface. This finishing method is often used when renovating premises in country houses.

The good thing about plywood is that it is very easy to work with. Its strength allows you to make a fairly strong floor in your home. In this article we will look at not only all the advantages and disadvantages of this finishing material, but also how to lay plywood with your own hands.

Advantages of plywood floors

- Environmental friendliness: a plywood floor will be an environmentally friendly coating. It can be installed in any residential premises (children's rooms, bedrooms, living rooms).

- Strength: this material is highly durable and is excellent for flooring.

- Heat and sound insulation: such a coating can be used not only as an internal leveling layer. This material can be used to increase sound absorption and thermal insulation in a room. If you lay a parquet board, laminate or carpet on top of plywood, you will get a very beautiful warm floor.

- Moisture resistance: plywood has a high resistance to water, so it can be used in finishing rooms such as a bathroom, toilet or kitchen.

- Cost: this floor leveling option is one of the most economical.

- Labor intensity and speed of installation: plywood is laid quite simply and quickly. In addition, it can be laid even on an old coating, the main thing is that it is smooth and durable.

Disadvantages of plywood floors

- Fire resistance: Plywood consists almost entirely of wood, so this surface will not be resistant to fire.

- Material price: this finishing material is slightly more expensive than its “analogues”, for example, fiberboard or chipboard. However, the final cost of a plywood floor will be very reasonable.

- Labor intensity: due to the structure of the material itself (one layer is perpendicular to the other), some difficulty may arise when processing the edges of plywood. But all this is feasible, and later in the article we will consider the technology for performing all stages of work.

Plywood floor installation technology

Preparatory work

First, you should remove the old floor covering, carefully inspect the base and, if defects are found on it, eliminate them. For example, areas with fungus and mold can be cleaned with an antiseptic solution. Rust on the surface is removed with copper sulfate, and various contaminants (grease, soot, etc.) are removed with special cleaning agents.

The undoubted advantage of plywood is that it can be laid directly on an old wooden plank floor, if, of course, it is in more or less normal condition. If necessary, old logs can be repaired, and all existing bars and boards can be coated with an antiseptic to protect against insects and microorganisms.

If this is your case, then you should immediately proceed to paragraph 3.1. of this article. Otherwise, you will need to completely dismantle the old floor to the base, repair large cracks and potholes on it (for example, with cement mortar or dry backfill), and only then proceed to the next stage.

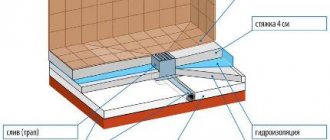

Marking the floor and installing joists. Surface insulation

There are several ways to install plywood on the floor. It can be laid either on logs or laid directly on the base base of the room.

The first option is more labor-intensive. To do this, you will need to mark the surface, determine the level of the new floor, level all the bars and install them correctly. You can learn about the technology for performing this work in the article “Laying logs indoors.”

But despite the labor-intensive nature of this method of installing plywood, it remains a very popular option because it allows you to give your floor greater functionality. Thus, various communications can be placed between the joists, as well as thermal insulation boards can be laid (link). In addition, this option allows you to level any surface, even with the largest level differences.

The second installation method is easier to implement. It does not involve performing all of the above operations, so finishing the floor with plywood is done very quickly. And how to do all this correctly, we will look further.

Laying plywood sheets

Whatever method of laying plywood sheets you choose, the material must be left in the room for acclimatization for 3-4 days. During this time, the wood will completely “get used” to the temperature and humidity conditions of the room.

Also, regardless of the chosen option for installing plywood, you should remember two rules. Firstly, in the places where the floor covering adjoins the walls, it is necessary to leave a gap of about 7-10 mm (the so-called “temperature joint”), and secondly, when laying and securing the sheets, they should be adjusted to each other as best as possible in order to form very smooth surface. Subsequently, you can safely lay parquet or any other decorative covering on the plywood floor.

To determine the quantity of all materials and components, we recommend that you use a plywood calculator. He will also help you choose the most optimal installation option, sheet laying scheme and calculate the cost of all finishing work.

3.1. Method 1: installation on logs

It is best to start installing plywood from the threshold. It is necessary to ensure that the longitudinal edges of the sheets fall in the middle of the logs, and their ends form one straight line. The plywood is attached to the beams using self-tapping screws. The installation step is 20-30 cm. To ensure greater structural strength, each joist can be additionally coated with glue.

When laying plywood, be aware of offset seams between rows of materials. They should be at a distance of 20-30 cm from each other. In addition, when forming a two-layer coating, it is also necessary to observe the offset location of the seams between the sheets of the two layers. It (the displacement) should be at least 30-40 cm.

If plywood is mounted on an old plank floor or any other strong and reliable base, then one layer will be enough. In case of installing plywood directly on the joists, it is recommended to form a two-layer structure with a thickness of about 20-25 mm. The second layer is glued to the first and secured to it with self-tapping screws. The installation step is 35-40 cm. In this case, the screws should be recessed into the sheet by 3-4 mm.

3.2. Method 2: plywood sticker

To begin with, the base of the room must be carefully primed. This is required to ensure reliable fastening of the plywood to the floor. Next, you need to apply glue to the surface of the base and level it with a notched trowel. For these purposes, it is recommended to use water-based glue. It is environmentally friendly, but it dries for quite a long time - about 7 days, so before this period has expired, the floor cannot be loaded with heavy objects.

As an alternative, you can choose solvent-based adhesive. It dries faster - 3-5 days, but has the disadvantage of a sharp, specific odor when used.

Next, plywood sheets are laid on the surface and attached to the base, ensuring that the seams are offset 20-30 cm from each other. In this case, the thickness of the material should be at least 12-16 mm. This is enough to create a single-layer structure of sufficient strength and reliability. The thickness of plywood is selected as follows: it must be at least 3/4 of the thickness of the finishing coating (for example, a cork board floor).

After gluing the plywood to the floor, it is recommended to secure it with dowel nails, screws or self-tapping screws 30-40 mm long. They are screwed into sheets every 20-25 cm. In this case, the heads should be recessed into the surface by 3-4 mm

Finishing

If there are gaps in the joints on the surface of the plywood floor, they should be treated with wood putty. After this, you need to check the evenness of the installation. This can be done using a building level. If changes, unevenness, etc. are detected on the floor. defects, they will need to be eliminated by surface grinding. For these purposes, grinding machines with medium and fine sandpaper are used.

After this, it is recommended to vacuum the floor and then cover it with a primer to improve adhesion, followed by a finishing coat. In addition, those areas of plywood where resin has appeared should be treated with an acetone solution in a ratio of 200 g of acetone to 700 g of distilled water. To carry out this operation, it is advisable to use a brush with natural bristles.

As a result, we will get a surface on which we can apply almost any floor covering: parquet, tiles, linoleum, or assemble a floor from laminate, boards and other finishing materials. But if you decide to do without an external decorative layer, then we recommend painting or varnishing the plywood floor. This will not only increase the wear resistance of the coating, but also give it an excellent appearance. For these purposes, you can use special tinted varnishes or a solution of stain (3 g of stain per 100 g of water). It should be noted that during such work, the windows and doors in the room must be closed. This will prevent dust from entering the floor surface and will also protect the varnish coating from the formation of sagging.

Video

You can install a plywood floor yourself. After watching this video, you will once again learn about installation technology, all stages and sequence of performing this type of work.

Types and grades of plywood

Most common brands

There are a huge number of brands of plywood, but the following brands are widely available:

- FC (not very resistant to water, adheres to formaldehyde resin);

- FSF (extremely resistant to water, contains phenol-formaldehyde);

- FOF (used in furniture production, covered with laminated plastic and has an attractive appearance);

- FB (resistant to moisture, including salt water due to impregnation with bakelite solution).

Before buying material, it is worth calculating the required amount based on the measurements of the room. In addition, you need to decide what thickness of plywood is ideal for your needs.

Most often, when decorating walls in a wooden house, the following types of plywood are used:

- FSF;

- construction plywood on a glued base;

- laminated plywood (coated with phenol film, which provides high water resistance and allows it to be used for finishing baths, country cottages, private wooden houses);

- FC.

The fewer leaf defects, the higher the grade

Screw mounting

Screw fastening is used for assembling wooden cabinet furniture. The advantage of fixing with screws is the ability to disassemble the finished product into parts at any time and reassemble it without losing the quality of fixation.

Screw installation involves creating holes in the plywood where the fasteners enter. The exception is when the fasteners will not be subjected to serious loads, which allows the use of self-tapping screws.

For an inexperienced person, the process of drilling plywood can cause difficulties, although in fact there is nothing complicated about it: just remember the simple rules:

- To prevent the formation of chips and unevenness, a small wooden block should be placed under the plywood at the drilling site;

- The drill should enter the sheet from the front side;

- It is important to pay attention to the matching thread sizes of the screw and drill. If the hole is thicker than necessary, the fixation will not be strong, and if you try to fix the screw in a hole that is too narrow, the plywood may become cracked;

- Damage to the integrity of the material can also occur if excessive force is applied when tightening the screw.

Superficial damage to plywood not only spoils its appearance, but can also reduce its strength characteristics. To prevent cracking of the veneer, it is better to choose screws with a wide head or use washers.

Work order

How to properly lay plywood on a wooden floor? It is important to follow the installation plan exactly and strictly follow the installation sequence.

If there is a difference exceeding 1 cm, a frame is installed around the entire perimeter of the room and joists made of multi-layer plywood are fastened. Their width is 30 cm, and the distance between them should not exceed the specified figure. The covering sheets are laid in such a way that the joints between them fall exactly in the middle of each joist, between which thin insulation can be placed.

The absence of differences or their value not reaching 1 cm allows plywood to be laid on the substrate. In this case, it is important to remember the need for gaps between the walls and the sheets, and also strictly follow the laying sequence, paying attention to the numbering of the sheets.

The substrate is spread close to the walls. Fixing the flooring material is not required, but if desired, you can secure it in several places with the staples of a construction stapler.

Plywood is laid directly on top of the substrate, doing this offset and in accordance with the plan.

Self-tapping screws are screwed in along the edges and diagonals. The fastening step is 20 cm.

During the installation process, you need to ensure that all screw heads are screwed in. This will make further work easier and safer. After installation is completed, the surface is sanded and treated with antiseptic compounds.

General information

Nowadays, there are many building materials that can be used for wall decoration, while many prefer to use wood from plywood on the wall, since this material has the following qualities:

- environmental friendliness - does not emit harmful substances even when heated;

- looks attractive;

- strength and mechanical stability;

- good thermal insulation properties;

- moisture resistance (not applicable to all brands);

- due to its light weight, it is not difficult to carry out finishing work with your own hands;

- can be used as a finishing coating, for example, covered with varnish or stain, or as a rough coat under wallpaper or other finishing materials.

As for the disadvantages, they only include a higher price compared to other wall coverings.

Advice! Home craftsmen are often interested in what is better: drywall or plywood for walls? The choice depends on individual preferences. For example, if you want to decorate the walls with paintings or even hang furniture on them, then, of course, you should give preference to plywood.

FK grade plywood sheets

Laying plywood on a wooden floor

If you don’t know how to attach plywood to a wooden floor, here is a list of necessary tools and consumables:

- building level;

- fasteners;

- roulette;

- screwdriver;

- jigsaw

Installation of plywood sheets on a wooden base should begin from the center of the room, after which fragments are attached in difficult places near ledges, columns and passages. To begin with, the sheets must be laid without the use of fasteners.

After you have placed the cut pieces in place and checked the flooring diagram, you need to check the damping joints. After this, the plywood sheets should be secured using fasteners and a screwdriver. It is better to make holes for fasteners in advance, and recess the heads of the screws deeply into the building material. Sometimes it is allowed to use glue, which should cover most of the area of the plywood fragments.

Plywood must be fixed over the entire area

After completing this operation, it is necessary to check the correctness of installation using a building level, and it would also be a good idea to check the expansion joints again.

The material must be laid strictly horizontally, the maximum permissible deviation is 2 millimeters. After this, you need to tap all the coatings with a wooden mallet or a simple piece of wood. This is done to determine the presence of delaminations. If the sound of the blows is dull, then this part is damaged and will have to be replaced with a new one.

How to properly upholster interior walls with sheet plywood

How to properly upholster interior walls with sheet plywood

Using sheet plywood for interior decoration allows you not only to speed up the construction process and improve quality, but also to correct mistakes. Using this technology, it is possible to level out fairly large uneven areas and provide additional insulation. We will tell you how to make lathing under plywood; the quality of the sheathing largely depends on it.

Preparatory work

First of all, you need to measure the total area of the walls and buy materials. To install the sheathing, you will need wooden slats measuring ≈ 25x40 mm; the number of slats depends on the number and size of plywood sheets. When making calculations, keep in mind that the plywood should be nailed at a distance of approximately 30 centimeters; the pitch of nails or screws depends on the thickness of the plywood and ranges from 20 to 30 centimeters. In addition, slats must be installed at all sheet joints; this is a prerequisite. At the same time, calculate the amount of plywood, do not forget to add at least 10% to the results obtained for unproductive waste.

For sheathing you need plywood with a thickness of 4–5 mm; too thin it is difficult to level, and too thick it will be quite expensive. If you plan to cover the plywood with finishing coatings in the future, buy cheap grades of plywood. If you plan to leave it this way, purchase high-quality sanded plywood; in the future, you can additionally varnish it with transparent varnishes.

Prepare the tools: a hand-held circular saw, an electric jigsaw, hardware for fastening and other small items for marking and fastening. You can fasten plywood with nails and self-tapping screws. We suggest using self-tapping screws - if necessary, sheets of plywood can be dismantled without damaging its quality. In the case of fastening with nails, you will not be able to “painlessly” remove incorrectly installed sheets.

Why do you need plywood?

When laying finishing material on the floor, it is necessary to first level the base. If this is not done, then not only the appearance of the finish may suffer, but also its integrity. For example, a laminate with a locking joint can crack, linoleum can wear out in places where it bulges, etc.

The best option for leveling a wooden floor is to lay plywood.

Plywood is a multi-layer veneer that is joined together using a special glue. The material is divided into three main types: peeled, planed and sawn. Based on texture, there is a distinction between homogeneous and combined plywood. Depending on the surface treatment, the material is divided into sanded, unpolished and laminated types. Based on the degree of moisture resistance, plywood is divided into limited moisture resistance (FB), average moisture resistance (FC, FS, FBA) and moisture resistant (FSF).

For leveling, it is better to use FK plywood with a thickness of 10 or 12 mm with a surface sanded on one side. These sheets are characterized by sufficient strength and reliability. If a fairly heavy finish with a significant thickness will be laid on top (for example, parquet 22 mm thick), then the sheets, accordingly, need to be taken in larger sizes. You can also use a moisture-resistant type of material. However, it will cost more, which must be taken into account when purchasing.

How to attach plywood to a wooden floor? For work you need to stock up on a drill, a screwdriver, a hammer, an electric jigsaw, a tape measure and a building level.

Plywood for interior decoration. Choosing plywood for interior wall decoration

Level or insulate walls and ceilings, restore and update renovations, give the room a pleasant woody style and create a warm, cozy atmosphere - plywood can do all this. Let's discuss what kind of plywood you need to choose for interior decoration. Main criteria: Brand The choice of plywood brand is largely based on environmental friendliness and water resistance. Different brands of plywood have their own, depending on the type of adhesive joint. FC waterproof plywood is made on the basis of urea glue, which is not harmful to humans. Therefore, FC plywood takes an honorable first place in interior decoration. FSF plywood has increased moisture resistance due to phenol-formaldehyde glue. The most significant disadvantage is its release, so this plywood is not recommended for indoor use, with the exception of non-residential industrial and well-ventilated areas. Laminated plywood (FOF) is practically not used for wall decoration. Its areas of application are construction and vehicle manufacturing. Bakelite plywood is used indoors only in bathhouses or in rooms where the walls are constantly in contact with water. This type of plywood has a veneer impregnated with bakelite varnish, which gives it absolute water resistance and high cost. It is mainly used in shipbuilding, aircraft and automobile manufacturing, and construction (reusable formwork). Safety It is possible to determine whether a material for interior decoration is safe by the emission class specified in the certificate. Of the existing several emission classes, class E1 is acceptable for internal use. Grade From the list of grades for finishing work, everyone chooses an acceptable option for themselves. Grade E has ideal characteristics, the absence of any defects. You won’t find this variety on the Russian market, because for the most part it is exported. And for finishing it is uneconomical and will cost a tidy sum. Grade 1 (designation 1/1) also has an almost perfect appearance; only a few healthy pinhead knots or a healthy discoloration of the shirt are allowed per square meter. It is used for the front cladding of walls without further processing or coating with anything. For rough sheathing and under the covering, plywood of lower grades is used, since the first grade is not economically feasible. Grade 2 (designation 1/2, 2/2) allows wood inserts from first grade veneer, as well as live knots the size of a pinhead, on the shirt fabric. It is more in demand in wall decoration as it has a lower cost and a pleasant wood structure. Grade 3 (designation 2/3,3/3) is used as a non-face wall finish, except in cases where a pronounced wood pattern is needed, since grade 3 allows live ingrown knots. Grade 4 (designation 2/4,3⁄4,4/4) is used only for rough finishing of walls and as a layer in insulation. This grade tolerates dead fallen knots, edge defects and surface defects. Thickness Experts recommend thicknesses of 4 mm or more, depending on what you want to achieve decoration, insulation or leveling of walls. Type of wood On the Russian market, the list of types of wood consists of two main types: birch and coniferous. Birch is usually used if you need a more uniform, lighter pattern and dense structure. Pine needles are used if you need a pronounced wood pattern and on a limited budget, since pine plywood is cheaper than birch plywood.

Features of installing wooden coverings

You can put plywood on the floor in cases where the floor boards dry out and become unusable, and replacing failed elements is impossible or unprofitable.

To achieve a positive result, it is important to strictly follow the requirements and rules of the technological process:

- Plywood is laid on a wooden floor only if there is no deflection along the joists and complete dismantling of the floor is not required.

- There should be no high humidity in the room where the work is planned to be performed.

- Laying is carried out dry. According to the plan, 3 seams should converge at one point.

- There should be gaps of at least 1 cm between individual sheets and between plywood and walls.

- Laying is carried out in strict accordance with the plan and markings, and for this purpose all sheets are numbered before installation.

- When fixing sheets with self-tapping screws, all fasteners are placed at a certain distance from each other. The step size is 20 cm, the distance from the edge of the sheet is 2 cm. The screw caps should be recessed by 1–2 mm.

- Self-tapping screws are chosen so that their length exceeds the thickness of the plywood by 3 times.

Before proceeding with installation, you need to conduct a humidity test. To do this, you will have to lay a plastic film on the floor and only after 3 days, having made sure that there is no condensation on its back side, make a positive decision about carrying out the work.

Important! Before laying plywood on an old wooden floor, the base must be sanded and impregnated with a primer containing antiseptic additives.

This treatment will provide complete protection of the structure from rotting, mildew and mold.

Fastening plywood with nails and slats

One of the most common methods is the nail and batten method. So, regardless of whether you need to attach this finishing material to the wall or the ceiling will be the mounting location, you will also need slats and nails. As for nails, it is advisable to select them with barely noticeable heads, which, when hammered, will go slightly into the plywood sheet and become invisible. If special slats are used, then you can try to find decorative nails. There is no need to hide the heads of such nails, since they are made in the style of real decoration.

The use of special slats helps to create a number of visual effects in the apartment. This is achieved in the following way: the slats can be positioned both vertically and horizontally. When the slats are positioned vertically, you will get the imaginary effect of increasing the height of the room. If you glue the slats horizontally, then your room will become a little longer. It is also worth emphasizing that both options not only enlarge or expand the room, but also have the opposite effect: vertical slats will increase the height, but thereby reduce the depth of the room.

Video on finishing the attic of a residential building with high-grade plywood

An important issue is the choice of spacing between adjacent nails. You can retreat 15–30 mm from the edge. Next, install the lath and hammer nails into it. Approximately the distance between them should be from 50 to 70 cm. If slats are not used, you can buy wire nails. Acid-resistant nails are ideal for cladding the exterior of a home.

To increase the strength of the structure, you can use special glue for the joints between the sheets. Remember that you can try to glue all the finishing material onto the glue without using nails, but then the plywood must be unveneered! Wood glue does an excellent job of gluing unveneered plywood. Inside the house you can use PVA - a colorless adhesive composition that does not violate the structure of plywood and has increased adhesive strength. If you will be gluing finishing material outside the house, then we recommend buying epoxy glue or phenol. Remember that epoxy adhesive is the best choice when cladding metal wall elements is required.

Sometimes special glue is used to strengthen the plywood structure.

Important! If plywood sheets are laminated, then no glue will be suitable for them. Then the gluing area on the sheet will need to be first cleaned with sandpaper to remove the top layer of film, and only then apply the same epoxy glue to it.

How to glue plywood

Most modern flooring is laid on a subfloor rather than directly on concrete. One of the most popular types of substrate is plywood.

It is attractive due to its ease of installation and affordable price; we should also not forget about the important fact that it is a natural material. Its popularity is evidenced by the fact that manufacturers have begun producing a moisture-resistant type for use in bathrooms

Also, the sanded variety on one side is gaining great popularity, which facilitates installation under the final floor covering.

Choosing the right substrate is not enough, the main thing is to choose a good glue for gluing plywood to concrete. It depends on it how firmly the sheets will stick to the floor, how quickly everything will dry and you can move from preliminary work to final work.

Types of glue

The huge assortment presented on the shelves of construction stores can be divided into several main types:

- water based;

- polyurethane;

- epoxy.

These types of glue for plywood on concrete floors differ in price, composition, consumption and drying time.

PVA glue for plywood

But besides its advantages, it also has its disadvantages:

- takes a long time to dry (up to 7 days for large volumes);

- suitable only for interior work in heated rooms (there is an option marked D with frost-resistant additives, but its price is much higher);

- the fastening of the base to the flooring is not very strong, so the sheets must be screwed with self-tapping screws until they dry completely;

- When using this type of glue, the floor must be fairly level, the difference cannot be more than 2 mm.

Polyurethane adhesive has high strength, viscosity and ductility. It can be either two-component or one-piece.

Two-component adhesive for plywood on concrete floors has a high viscosity (applied with a comb trowel). This is both an advantage and a disadvantage. On the one hand, it sets in literally half an hour, but on the other, it cannot be prepared in large portions “in reserve,” as it quickly dries out and becomes unusable.

The solid version takes much longer to dry, so it does not harden during installation. Complete drying takes 36 - 48 hours, and the strength of the resulting layer exceeds concrete and can withstand changes up to +55 ° C.

Installation of plywood with glue

The disadvantages include:

- high toxicity, but harmful substances are released only during installation, after hardening it becomes safe;

- two-component mixtures harden too quickly, which creates inconvenience during the work process.

Epoxy adhesive for plywood on concrete floors also consists of two components that must be mixed before installation. Complete drying occurs after 4-5 days, but you can walk on the plywood covering within a day.

Read the topic: how to properly lay plywood on a concrete floor.

When laying, harmful substances are also released into the air (due to the alcohol base, the smell is rich and pungent), so you need to work in compliance with safety precautions. Safety glasses, gloves and a respirator must be present, no matter what glue you used to glue the plywood to the concrete floor.

But there are a few general rules:

- The concrete must first be cleaned of construction debris and other contaminants (vacuum or wet clean if necessary).

- It is advisable to prime it before work - this will reduce the consumption of raw materials and improve adhesion to the surface. For these purposes, both a primer (regular or water-repellent, for damp rooms) and the glue itself are suitable. It must be diluted and applied in a thin layer to the prepared surface.

- Although only PVA and its water-based analogues require additional fastening, when working with the rest, for better adhesion, it is also advisable to press the sheets with something to the floor (put them under pressure) until completely dry.

- It is best to cut the sheets into 0.5x0.5 squares, so they will fit better without creating cavities in uneven areas. Such squares are laid in a checkerboard pattern, or simply offset.

- It is necessary to leave a technological gap of 2 - 5 mm between the sheets.

- Depending on the condition of the surface (cracks, unevenness, contamination) and the selected type of glue, the consumption will be 0.5 - 1.5 kilograms per square meter.

Laying plywood on a concrete floor

The PVA label often says “consumption from 0.25 kilograms per square meter,” but don’t get your hopes up. This type of glue must be coated not only on the concrete base, but also applied to the sheet. Therefore, when calculating consumption, the numbers indicated on the label should be multiplied by two.

Installation on a wooden base

Plywood is suitable for leveling a rough wooden floor.

We need moisture-resistant brands FSF or FC. Depending on the finishing coating, you must choose sanded or unsanded plywood. A sheet thickness of 15 mm is enough to provide good strength to the coating.

The following installation rules give real results:

- Before installation, the base must be prepared: cleaned of debris and well strengthened;

- the seams of the sheets should not be joined at one point, so they must be laid offset;

- Be sure to leave a compensation gap of about 10 mm near the wall. In any case, it will be covered with a plinth;

- for easy installation, the sheets are cut into equal squares;

- plywood must be fastened with damper gaps of about 1 mm;

- Fastening is carried out using nails or self-tapping screws. Nails with a large head and a certain length give high strength to the coating. The length of the nail must be chosen equal to approximately twice the thickness of the sheet;

- the distance between fasteners should be about 300 mm, and from the edge of the sheet about 150 mm;

- The quality of fastening sheets will increase significantly if you use glue.

Subtleties of installing plywood on a wooden floor

Now let's talk about how to lay plywood on a wood floor. If the flooring was installed on joists, then before installation work you should find out whether the boards will bend. If this is the case, then the floors will have to be dismantled, and then the base of the floor covering will have to be repaired.

Attaching plywood to a wooden floor is not possible in every room. For example, in rooms with aggressive conditions, building materials will very quickly lose their properties. Such conditions for plywood sheets are unstable temperature conditions, as well as high humidity. Therefore, it is not recommended to use plywood for arranging floor surfaces in bathrooms, kitchens or rooms in which heating is not provided, for example, on plinths.

You can measure the level of moisture in the air in a room using a simple experiment. To do this, you need to take a small piece of polyethylene and attach it to the floor with tape. After three days, you will need to remove the polyethylene and check whether there is condensation on the back side. If it is missing, you can think about covering the floor with plywood.

The installation of the first sheets of building material should be carried out with a slight offset. This is done so that more than three seams do not intersect in one place.

The distance between individual plywood elements should be about 10 millimeters. It is called a damper seam. This seam prevents the material from deteriorating during expansion due to temperature or humidity.

The distance between the plywood sheets on the floor and the walls should be about 20 millimeters. These seams also perform protective functions. By the way, they will in no way be able to influence the design of the entire floor surface, since then the seam will be covered with a plinth.

Laying plywood and forming expansion joints

Before starting all installation work, it is better to prepare fragments of building material of the required dimensions. It would also be a good idea to number each fragment so that there is no confusion during installation. Numbers should be applied to the plywood sheets and indicated on the coating diagram.

Most experts say that it is best to use square plywood elements with dimensions of 0.6 X 0.6 meters. These dimensions allow you to assemble a mosaic with the ideal number of seams.

Before laying plywood on a wooden floor, it must be thoroughly cleaned of dirt and dust. Then you need to cover the base with a primer.

Fragments of building material are attached to the base using glue or fasteners. Fasteners must be screwed in not only around the perimeter of the plywood fragment, but also diagonally. The distance from the edges should be no more than two centimeters.

The distance between fasteners is no more than 20 centimeters. The screws must be screwed in very tightly so that the caps are completely buried in the material.

During installation work, fasteners should be used, the length of which should exceed the thickness of the plywood fragment three times.

Technology of laying plywood on an old wooden floor using glue

Methods of fastening plywood

Plywood is a type of wood building material. It consists of several (three or more) sheets of sawn, planed or peeled veneer of various wood species with a special, mutually perpendicular orientation of structural fibers in adjacent layers. This structure provides stability of shape and increased strength, which is undoubtedly an advantage. The veneer layers are glued together using various types of glue, which can also give the sheets water-resistant properties.