- 1 Purpose

- 2 Pros and cons

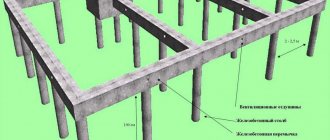

- 3 How to make a concrete pillow?

- 4 Tools and materials for work

- 5 Preparatory work

- 6 Installation of formwork

- 7 Reinforcement

- 8 Pouring and compaction

- 9 Conclusion

Concrete products have high strength and longevity, and this also applies to concrete foundations. In order for foundations to last for decades without reducing their strength properties, it is important to properly prepare the mortar and lay it in compliance with the sequence of the technological process. At the base of the foundation there is a cushion that provides the structure with a flat and durable surface. Foundation pillows are the main component of all foundations and future buildings. To build large houses, you do not need to skimp on the solid construction of its foundation, because its reliability, service life and other important quality characteristics will depend on a well-made foundation.

Purpose

The concrete pad is used in problem areas of the foundation of buildings and structures and is capable of increasing the area of the foundation. An additional base is necessary to evenly distribute the loads on the insulating layer, and also equalizes the pressure from uneven shrinkage of the soil with low bearing capacity. The purpose of concrete pads is to prevent deformation of prefabricated foundations.

Return to contents

Advantages and disadvantages

When working with a foundation on soils where the use of sand cushions is not recommended, choose a cushion at the base, which contains concrete. A concrete pad for the foundation has the following advantages:

- an additional base on concrete allows you to install reinforcement on a surface with increased rigidity and strength;

- when working with concrete in winter, the process of installing formwork and pouring mortar is simplified, which means it does not create problems when installing a concrete pad under the foundation;

- the use of an additional layer of concrete strengthens the foundation of buildings and reduces the cost of purchasing high-quality concrete;

- when working with a concrete pad, there will be no large costs for purchasing raw materials;

- due to the fire-resistant property of concrete, the structure has a corresponding indicator of resistance to fire;

- the material has a long service life, which means that the longevity of the concrete pad is guaranteed;

- The concrete structure is dense and durable.

The disadvantages of the material include low tensile strength, which leads to the formation of cracks under the influence of various force loads. There is also an environmental deficiency in the mixture of sand, crushed stone and Portland cement, which negatively affects natural resources, water quality and air quality.

Return to contents

Advantages and process of arranging a cushion of sand and crushed stone

Sand and crushed stone are considered the most affordable materials, and therefore are popular among private developers. Despite the low cost of materials, they are ideal for creating the basis for a strip foundation.

In addition, such a foundation provides the following advantages:

- The work falls into the category of simple activities, so it is possible to carry out the entire process independently.

- The materials have reduced thermal conductivity, which avoids significant heat loss.

- A base of this type turns out to be quite dense and reliable, therefore, the entire structure receives similar properties.

- A foundation cushion made of sand and crushed stone evenly distributes loads of any type.

- Thanks to the arrangement of the foundation cushion, the rise of moisture from the soil at the capillary level is prevented.

Basics for strip foundation

Creating a cushion of sand and crushed stone for the foundation is carried out according to the following scheme:

- The bottom of the prepared trench is well leveled and compacted.

- Lay geological textiles, leaving edges on both sides that will cover the finished pillow on top.

- Then pour a layer of coarse river sand, level it, moisten it and compact it.

- Next, crushed stone of the middle fraction is laid, its layer can be about 20 cm. The material is evenly distributed over the entire surface and compacted using a vibrating plate.

- A layer of sand 0.2 meters high is again poured on top of the crushed stone and watered with water. During this process, sand particles penetrate between the crushed stone, making its layer even more dense.

- The free edges of the cushion made of sand and crushed stone are covered with geological textiles. To prevent the material from being damaged during the creation of the main structure, you can pour an additional layer of sand on top of it.

How to make a concrete pillow?

The height of the upper part of the formwork structure must correspond to the zero level of the foundation.

In order to make a high-quality concrete pad for the base of buildings and structures, which will strengthen the structure, you should adhere to the sequence of installation work. First of all, prepare a base based on sand or crushed stone one centimeter thick. When laying the material, it is compacted into leveled soil. Next, the formwork is installed and the waterproofing layer is laid. At the next stage, the reinforcing mesh is installed and the solution is poured. The poured structure is left to harden until the mixture completely sets. It is important to remember that drying of the solution should be carried out naturally at optimal air temperature and humidity. Concrete reaches its maximum strength characteristics after 3-4 weeks.

Return to contents

General requirements

Sand is the most inexpensive and accessible material for a pillow.

When designing a structure, you need to decide on several parameters that the pillow for this foundation will correspond to:

- Material (concrete, gravel, sand). Availability, cost, and the ability to do the work yourself are taken into account immediately;

- Thickness. Building codes establish a recommended pad depth of 3 times the width of the foundation. In practice, 0.25-0.8 m is chosen depending on the massiveness of the building;

- Width. Reduced pressure on the base and stability of the support are achieved by increasing the size of the embankment in relation to the width of the stacked blocks by 0.1-0.15 m in each direction;

The trench (pit) has a depth equal to the design height of the tape + the thickness of the embankment. When calculating the foundation elevation, a norm is laid down: the bottom of the cushion for any foundation is made no closer than 1 m to the groundwater level. Possible rises due to snow melting, flooding, and heavy rain are taken into account.

The blind area on the ground surface should be wider (overlap) the perimeter backfill strips.

In conditions where the foundation cushion is operated with high humidity of the adjacent layers, the complex includes drainage and waterproofing with film material.

Tools and materials for work

The following tools and materials will be required:

- vibrating plate;

- reinforcing mesh;

- deep vibrator;

- wooden boards;

- waterproofing material;

- components for preparing concrete (sand, water, crushed stone) or ready-made concrete;

- concrete mixer;

- buckets;

- shovel;

- hammer;

- anchors or fasteners;

- wire;

- building level;

- concrete mixer;

- container if you need to prepare a solution.

Return to contents

Preparatory work

Laying a concrete pad begins with preparatory work, which includes the following steps:

- They dig a trench and carefully level the bottom and compact the soil.

- Backfill with sand, if required by the soil, one hundred millimeters thick. Next, the sand is watered with water, which will ensure shrinkage of the material.

- A waterproofing layer using polyethylene is laid on top of the sand. Spread the material overlapping by ten centimeters.

- A concrete solution one centimeter thick is laid on the waterproofing layer.

Return to contents

Types of pillows for the foundation

The main parameter by which backfills differ from each other is the material used.

Sand cushion for the foundation

The easiest to implement and inexpensive option. Most often, such a pillow is used under a strip foundation, on which it is planned to erect a one-story or two-story building. Its walls are made of the following materials: foam concrete, wood, frame.

How is it done?

Sand is poured into the trench in an even layer. It is compacted with a vibrating plate or other available means. It is moderately spilled with water and compacted again. The layer usually ranges from 15-25 cm. The easiest way to find out if it is compacted enough is to walk on it. With proper density, the weight of an adult should not leave marks on the surface. If groundwater lies close to the surface, it is necessary to equip a drainage system.

Advantages

- the cheapest type of foundation fill;

- least labor-intensive arrangement, can be done quickly enough even alone;

- the ability to carry out work without the use of technology.

Flaws

- It is not recommended to install this type of embankment in periodically flooded areas.

Crushed stone cushion for the foundation

This type of bedding can withstand heavy loads, so the foundation and walls of the building can be made of almost any material.

How is it done?

The bottom of the trench or pit is lined with a layer of coarse sand 10-15 cm thick. It is compacted with water and leveled. This substrate is necessary to adjust the level of the construction site before backfilling with crushed stone. Next, the crushed stone is distributed. Depending on the soil and type of structure, the height of the crushed stone cushion can reach 50 cm, but experts recommend stopping at 25-30 cm. The gravel is compacted and leveled with a vibrating plate.

Advantages

- the gravel bed is not washed away by groundwater;

- arrangement is cheaper than pouring a concrete base.

Flaws

- the need to use technical means, at least a vibrating plate.

Concrete pad for foundation

The most expensive, but also the most reliable type of foundation. Serves to reduce the protective layer of concrete and as a base for the reinforcement cage of the foundation itself.

How is it done?

The bottom of the pit is leveled with crushed stone or sand and gravel backfill up to 15 cm thick (compacted with a vibrating plate). Formwork and reinforcement are being installed. The latter can be either a connected reinforcement frame or rubble. Concrete is poured. The finished slab is processed with a deep vibrator to evenly distribute the solution and eliminate voids. The surface is leveled. During the hardening process, depending on weather conditions, the pillow is spilled with water and/or covered with film to prevent cracking.

Advantages

- unpretentiousness to the underlying soil.

Flaws

- high price;

- a long waiting period before the start of the next stage of work: from several weeks to several months, depending on the weather and the type of concrete.

Installation of formwork

The process of pouring a concrete pad for the foundation of a house.

After checking the evenness of the base, installation of the formwork begins. Wooden boards are fixed with brackets, with the help of which the structure does not move from its place. Install the formwork exactly in the middle of the laid cushion. During the installation of formwork, it is important to maintain a right angle at the junction of the extreme corners of the base. The resulting spaces between the boards are covered with boards of smaller diameter and hammered with nails. After the formwork is erected, soil is poured into the weak points of the structure, which will not allow the solution to seep under the structure.

Return to contents

Application of a concrete layer for the base

The use of a concrete pad under the foundation makes the structure more durable and reliable.

Work must be carried out in the following sequence:

- At the first stage, the soil surface is prepared. It is carefully leveled;

- Crushed stone is being laid. Its height should not be more than 10 cm;

- Crushed stone must be thoroughly compacted using a vibrating plate;

- Wooden formwork is installed around the perimeter of the base. Its height should correspond to the thickness of the concrete layer. The upper level must coincide with the zero level of the main foundation;

- To make the concrete layer more durable, reinforcement is carried out;

- The resulting structure is filled with concrete and compacted. You can use a construction vibrator for this.

Pouring and compaction

When the process of installing the formwork and reinforcing bars is completed, they begin pouring the concrete solution. After laying, the mixture is compacted. Compaction will remove air and excess water from the solution. The mixture is compacted with a special electric vibrator, with the help of which the concrete becomes fluid and the crushed stone is compacted, raising air bubbles upward.

After compaction, the concrete solution takes on a dense and durable structure. Manual compaction of mortar is carried out with a long pin, a thin tube or a piece of reinforcement. After compacting the concrete mixture, the poured structure is left to dry under optimal conditions. To prevent the solution from drying out, it is necessary to maintain its constant wet state; for this, the surface is periodically irrigated with water.

Return to contents

Preparing the gravel bed

The use of this basis for the foundation structure is more durable and reliable:

- Before starting work, a layer of coarse river sand is poured into the pit. Its height should not exceed 15 cm;

- After preparing the sand layer, gravel is laid on it. Its height must be at least 25 cm;

- At the next stage, the surface is leveled and compacted. The process is carried out using a vibrating plate;

- It is necessary to check that the level of the top layer coincides with the zero level of the foundation base;

- The length of each side of the gravel layer should exceed the dimensions of the foundation by 20 cm.

Conclusion

Today, the use of concrete for foundation pads is considered the most reliable and durable material. A concrete pad can withstand any load from the structure being built. It is used for the construction of buildings of any number of storeys, and with any weight of the structure.

However, it is worth remembering that installing a pillow is an important stage in the construction of buildings, which requires painstakingness and compliance with all rules. High-quality construction of a concrete pad guarantees the strength and reliability of structures for many years.

Concrete pad under the foundation (intermediate covering between the base and the ground)

The foundation of the house is the most significant part of the building structure.

The lifespan of the structure will depend on how correctly it is installed.

An important role in solving this issue belongs to the foundation cushion.

It creates a stable and level platform to ensure less settlement of the building structure.

What types of such products exist? When is a concrete pad used for a foundation?

The answers to these questions will help you more accurately understand how best to build your foundation.