Description OKL

Fire-resistant cable lines OKL

is a range of products used for sealing cable trays and cable ducts, as well as plastic pipes and individual wires through walls, ceilings or fire barriers.

Amendments made to Law N 123-FZ of July 22, 2008 established new additional requirements for fire safety; according to these amendments, many systems must maintain the functionality of the entire line for 15 minutes - the time necessary for the evacuation of people and the work of fire brigades.

“...In places where cable channels, ducts, cables and wires pass through building structures with a regulated fire resistance limit, cable penetrations with a fire resistance limit not lower than the fire resistance limit of these structures must be provided.”

Federal Law of July 22, 2008 N 123-FZ, Technical Regulations on Fire Safety Requirements. Article 82, paragraph 7.

OKLs are used to increase the operating time of the following systems in an emergency:

- Emergency internal and external lighting.

- Emergency lights that indicate the direction of evacuation.

- Sound warning system in case of fire.

- Smoke removal and fire extinguishing systems.

- Elevators for fire brigades.

- Electrical panels with the ability to connect fire equipment.

- Security alarm system.

- Shields in operating rooms and hospital intensive care units.

To summarize, systems with routes based on metal trays used during emergency situations must comply with the requirements of GOST R 53316-2009. Fire-resistant cable penetrations are designed to ensure the power supply of these systems for the required time, respectively, their operation in fire conditions.

Fire protection of cable routes is required for:

- reduction:

- fire hazard of lines;

- fire spread zones;

- toxic emissions and smoke formation;

- fire resistance of cable structure;

- operating time of the cable line after the start of the fire;

- corrosive activity.

What standards and requirements exist?

In the regulatory documents of the PUE Chapter 2.1. Clause 2.1.58 and SNiP 3.05.06-85 describe the requirements for cable passages:

According to the requirements listed above, it turns out that the cable entry in the building must be able to retain water, not support combustion and prevent the spread of fire. With all this, it is possible to re-replace the cable or wire, if necessary.

Design

In essence, OKL cable penetrations are a specific set of products or a prefabricated structure for installation that meets the requirements of the regulations: fire-resistant cable and fire-resistant sealing materials, also metal trays, cable ducts, prefabricated elements, junction boxes, ties, anchors, etc. The question often arises: is a perforated tray acceptable in OKL? The tray can be of any type: perforated, ladder, etc. The cable is directly protected by a coating with special fire-fighting properties.

The composition of a fire-resistant cable line may include:

- metal cable trays and accessories OSTEK (correspond to GOST R 53316-2009);

- fire-resistant mounting boxes;

- mineral wool plate;

- fire-resistant coating and sealant for cables and walls (Silotherm EP-6K Cable, Silotherm EP-120, Silotherm EP-71 sealant).

The design of the cable penetration complies with the requirements of GOST R 53310-2009 and assumes a fire resistance limit of at least EIT 120. Fire-resistant cable penetration in the event of a fire is certified according to the following parameters:

- (R) - loss of carrying capacity;

- (E) (Integrity) - loss of integrity of the refractory penetration material due to the formation of through cracks or holes in the refractory structure through which combustion products and flame penetrate to the surface.

- (I) (Insulation) - loss of thermal insulation ability due to a critical increase in temperature on the surface of the structure.

- (T) (Temperature) - critical temperature reached during heating of cable insulation in an unheated area of the structure.

- (W) - reaching the limit of heat flux density at a certain distance from the unheated surface.

- (S)—smoke-gas tightness limit.

Compliance with regulations and standards:

| GOST R 53310—2009 | 2009 “Cable penetrations, sealed entries and busbar penetrations. Fire safety requirements. Test methods for fire resistance." |

| GOST 30247.0-94 | “Building structures. Test methods for fire resistance. General requirements." |

| GOST 30247.1-94 | “Building structures. Test methods for fire resistance. Load-bearing and enclosing structures." |

| SNiP 21-01-97 | "Fire safety of buildings and structures" |

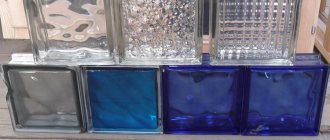

Types of fireproof penetrations for cables

Cable penetration is a part (prefabricated or solid) for sealing the locations of wires in a building, fire barriers, preventing the spread of flame to adjacent (adjacent) rooms for a specified time.

Penetrations with fire protection:

- mortgages:

- boxes;

frames (fire-resistant glands);

- trays;

- pipes;

- blocks;

- sealing agents:

- seals;

simple or heat-expanding fire retardant mastic;

- foam;

- windings, corrugation;

- prefabricated structural parts:

- fire-resistant pillows;

cuffs; partitions;

- panels.

Types:

| Option | Description |

| Monolithic, mortar universal | Special fire-resistant mastic, foam in finished form or in powder. |

| Mineral wool (basalt) in the form of windings or blocks |

|

| Trays, boxes, sleeves for passage through walls sealed with non-combustible materials | Box with plugs and partitions inside. The gaps are sealed with a special compound. |

| Pipe | For wiring with power loads. Includes bandage tape, fire retardant mixture, mastic. |

| Metal corrugation | In cable tunnels for systems with low fire hazard. |

Operating principle

The task of fire-resistant penetration is to create a reliable barrier to the spread of fire. The voids between the cable and the tray are carefully sealed by sealing with a fire-retardant vulcanizing compound. The peculiarity of the composition is that it swells when exposed to temperature by fire.

Metal trays are not subject to combustion, but the insulation of the wires can melt and release combustion products. Fire-retardant non-flammable mastic forms a vulcanite crust during a fire, thereby preventing the burning of wire insulation. After exposure to high temperatures, a hermetically sealed seal is created, ensuring the operation of the cable line for the required time.

OSTEK products intended for fire-resistant cable lines have competitive designs and differ from conventional OKL; all cables for OKL are manufactured to order by partner companies with whom joint development and testing have been carried out. High-temperature sealants presented on the Ostecmarket website are non-toxic and do not emit potentially harmful substances during the curing and heating process.

Instructions for installing cable lines of fire protection systems

Stages of work performed:

- Cable preparation: cleaning with a brush from dust, degreasing with a solvent at a distance of 200 mm from the surfaces on each side;

- Preparation of cable trays: cleaning with a brush from dust, degreasing with a solvent at a distance of 200 mm from the surfaces on each side;

- Applying 2 layers of fire-resistant paint EP-6K to cleaned surfaces with intermediate drying for 24 hours. The thickness of the applied layer is 2 mm;

- Measuring the internal size of the penetration, cutting and fitting a mineral wool board according to the internal size of the penetration;

- Fitting blocks, gluing with non-flammable glue “EP-71 kNS” and installing ready-made mineral wool slabs into the opening of the cable route;

- Hermetic sealing of seams with “EP-71” sealant from a mounting gun;

- Filling the remaining voids with silicone sealant “EP-120”;

- Painting the outer surface of the penetration with fire-retardant paint “EP-6”;

- Final drying: the penetration time until the final polymerization of the sealant is 168 hours.

Rules for the design and installation of OKL:

- Taking into account the characteristics of the object, determine the required operating time of the fire-resistant cable penetration, focusing on GOST standards that prescribe the speed of evacuation of people from buildings.

- When choosing the type of cable, cable support and installation system, take into account their dimensions and design in accordance with GOST 31565–2012.

- When performing installation, strictly follow the instructions.

- It is prohibited to attach fireproof cable penetrations to flammable materials and surfaces whose fire resistance is lower than the fire resistance of OKL!

- It is prohibited to install non-fire-resistant cables in fire-resistant cable lines!

- The use of fire-resistant mounting boxes is mandatory.

- OKL lines are fixed to building surfaces and ceilings so that the distance from the trays to the floor is more than 2 m.

- Installation to concrete floors should be carried out with a maximum pullout load of at least 1.8 kN.

- Work on the installation of OKL should be carried out by experienced specialists trained in the rules for installing fire-resistant cable lines in accordance with the instructions and rules.

- Before proceeding with the installation of the penetration, you should check the cable for damage and check for a break.

- The permissible installation temperature should be adhered to (from -10 to +50°C).

- You should also monitor the maximum permissible bend of the cable during installation.

Mixtures that expand when heated

Fire protection of cable penetrations by applying thermally expanding rubber compounds is popular. The shelf life of materials reaches 30 years.

Installation can be carried out with processing of the ends with a permanent wiring layout or without it with a temporary layout.

A good effect is achieved by using expanding rubber in combination with insulation with mineral wool sheets treated with fire-resistant mastic.

The use of fire-resistant materials made from raw materials that increase in volume (foam or expand) to protect cable penetrations requires special attention . The reaction of converting the starting products into the finished sealant occurs under strictly defined conditions: temperature, humidity.

All instructions for preparing products for filling cable penetrations are available in the accompanying documents. If the conditions for preparation for installation and the installation itself are violated, fire protection at the proper level cannot be ensured.