Basic concepts and definitions

The most critical operation in the process of building a fiber-optic line, which determines the quality and range of communication, is the installation of optical fibers. Such connection of fibers and installation of cables is carried out both during the production process and during the construction and operation of cable lines.

Installation is divided into permanent (fiber splicing) and temporary (detachable connectors). Optical fiber connectors, as a rule, are fittings designed to align and fix the fibers being connected, as well as to mechanically protect the splice.

The main requirements for connectors are:

- simplicity of design;

- low transition losses;

- resistance to external mechanical and climatic influences;

- reliability;

- In addition, detachable connectors are required to ensure that their parameters remain unchanged when re-joined.

The losses introduced by the connection of optical fibers into the cable transmission path are divided into external and internal .

External

are called losses associated with the peculiarities of the connection method, including the preparation of the ends of the optical fibers, and including the transverse displacement of the core, the separation of the ends, the inclination of the axes, the angle of inclination of the fiber end, and Fresnel reflections.

Internal

are losses associated with the properties of the optical fiber itself and due, for example, to variations in core diameter, numerical aperture, refractive index profile, non-circularity of the core, non-concentricity of the core and cladding.

Optical cable connection methods

The methods of laying optical cables offer little new information to the traditional ones; the joining method is different. The main requirement here is the absence of mechanical damage. If the fiber is scratched, some of the energy will be lost. The quality of the connection is characterized by the amount of loss in dB. A joint that reaches 0.4 dB is considered a defect. A good welded connection will provide a reading of 0.01 dB. To withstand stringent requirements, special equipment is produced for the work. Today, the following methods of connecting optical cables and installing connectors have become widespread.

Welding

This is the simplest method, any type of optical cable can be used. The parameters of which are stored in the device’s software module. By visiting the menu, the technician selects the desired type. The procedure is similar.

Cable welding

First, let's find a sleeve (KDZS) for a fiber-optic cable of the appropriate thickness. The insulation is stripped a couple of centimeters. The Kevlar braid is removable (if present). Afterwards, the core is fired using a welding machine with a special grip. It is necessary to finally get rid of isolation. The end is cut off (broken off) with a cutter (structurally included in the welding machine). Helps the section become perfectly smooth. Both ends are processed alternately; we put a heat-shrink sleeve on one.

The welding process takes a matter of seconds; for quality control, the device can broadcast video (if you don’t like it, change it). The display shows the connection loss value in dB. Hundredths.

Mechanical connections

They have the advantage of being disassembled n number of times. To carry out the work, a special coupling is purchased; it is difficult to do without a tool: you will have to strip the insulation to the specified distance (tens of mm). Afterwards, the ends are cut evenly using a device resembling a glass cutter. The ends are inserted into the coupling and clamped. Installation is considered complete. We use one coupling for fiber-optic cores of different diameters, using special adapter inserts. The preparation process changes a little in small ways.

Connectors

At the entrance of distribution boxes, when connecting user equipment, connectors are often used. Special connectors exhibit high losses, allowing for countless re-wiring changes. Each company has its own technologies. Giganet has developed instructions that come with specialized tools.

- Cable stripping is an art. The outer insulation and braiding are removed to the specified length, and the inner layer is stripped (down to the core).

In the latter case, you need to act carefully, freeing the glass from excess material by centimeters. It is important not to break the core or break it off. The slightest scratch increases losses through the walls. Glass fragments easily sting the skin.

- The stripping is finished, it’s time to put on the insulators and connector housing. The central core is obviously pulled through with a large margin.

- Fill the connector with the compound included in the kit until a small drop appears through the central hole. It is important not to overdo it, not to combine the outer and inner circles of the coax.

- The supporting glass fiber is lubricated with a hardener. Docking is done quickly so that the mixture does not have time to set.

- After using a glass cutter (sold by Giganet), the core is cut and broken off with a small margin.

- The sanding process begins with fine sandpaper. A microscope will be used for quality control. If a chip is found below the contact surface of the connector, the work remains to start over. Grinding is carried out until the surface becomes perfectly smooth.

- Then finishing procedures follow, the product can be used.

Internal losses

Internal loss results from the connection of two dissimilar optical fibers, which have essentially different diameters and numerical apertures.

When light propagates forward (from left to right), losses at the junction are zero; when light propagates in the opposite direction, some of the peripheral rays pass into the cladding of an optical fiber with a smaller diameter and are lost.

In single-mode optical fibers, internal losses do not depend on the transmission direction and are determined only by the discrepancy between the mode field diameters of the mating optical fibers.

A possible source of loss is also

the non-concentric placement of the core inside the reflective shell.

That is, the core of the optical fiber is offset from the center point of the optical fiber. Also, additional losses in the optical fiber can be introduced by the non-ideal shape of the cross-section of the optical fiber in the cable. Also, internal losses can be caused by inequality in the diameters of the optical fiber cladding. What can affect the mechanical connection of optical fibers.

Internal losses due to: a - non-concentricity; b - elliptical shape of the cores.

Internal losses due to inequality of shell diameters

Optical cable installation

The efficiency of any modern office depends on well-established telephone communications. For this purpose, mini PBXs are installed in offices or high-speed Internet is connected.

To do this, you need to lay a fiber optic cable, which is used to connect the local network and the high-speed Internet.

FOCL is a method of transmitting information via dielectric optical fibers, which can be distinguished by area of use and purpose.

The optical cable can be used for internal, external and universal installation. It is also used to produce optical patch cords, which are a piece of cable terminated on both sides with connectors. They are indispensable when constructing SCS. Among the popular segments, the fc patch cord occupies a special place.

Installing a fiber-optic link is one of the most important stages in creating a network based on optics. Optical cable installation

can be done in two ways:

- by welding;

- mechanical splicing of fibers inside the splice plate.

To choose one method or another, it is necessary to take into account absolutely all the factors and conditions in which it is planned to lay the cable. In the first case, a fiber-optic welding machine is used.

Important! The speed of the fiber optic cable, as well as the efficiency of the network as a whole, will depend on how well the installation of the optical cable is done. It is for this reason that all installation work must be carried out by highly qualified specialists who have extensive experience in installing fiber-optic communication lines.

Features of laying fiber optic cable

Data transmission to the fiber-optic line is carried out using video light pulses. The transmission medium is an optical cable. Different products are usually intended for installation in environments that differ from each other. The choice of a specific brand of optical cable is influenced by the conditions in which the fiber-optic line is laid.

The success of the work is influenced by the competent choice of technical solution, as well as the installation method in each specific case. Installers with extensive experience and modern equipment will help you find the right solution in any situation that may arise during the work process. This is especially true in cases where work is carried out in urban environments. Since here you have to lay an optical cable, bypassing a huge number of man-made objects and all kinds of restrictions put forward in order to ensure safety.

Classic installation methods

Today there are several known ways to lay an optical cable:

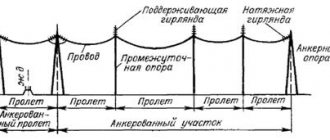

- supportive;

- tension;

- combined.

The first method is carried out using support clamps, which are designed for areas where the optical cable runs strictly in a straight line. The permissible angle of rotation when using such clamps is 10-20 degrees. Today you can find a huge number of different clamps of domestic and foreign production. They are intended for supporting installation of self-supporting and figure-of-eight cables in a vandal-proof wall cabinet .

The second way to install the cable is to use tension clamps, used for more rigid fastening. They can be used on turns, branches and ends. In addition, they can be used throughout the entire route. This is what distinguishes them from support clamps.

Installation of an optical cable in a combined way is most often carried out using PPO and SC30\34 clamps. The essence of this method is to alternate the first two clamps, anchor and support. This significantly increases the reliability of the line and helps reduce construction and further operation costs. The ideal ratio is four support clamps to one anchor clamp.

External losses

External losses are caused by four main reasons:

- radial displacement of optical fibers;

- angular displacement;

- axial displacement;

- quality of ends.

The optical fiber in the connector must be placed along its central axis. If the central axis of one fiber does not coincide with that of the other, then losses due to radial displacement . Also, if the connection of two optical fibers is separated by a small gap (axial displacement), then the optical fiber becomes susceptible to an additional type of loss. Which is due to the effect of Fresnel reflection, which is associated with the difference in refractive indices of the fibers and the medium in the gap (usually air).

Fresnel reflection: a - in the absence of an air gap; b - in the presence of an air gap.

Reflection at the interface between two media is characterized by the parameter R, which is the ratio of the power of the reflected wave to the power of the input wave.

Also, the chips of processed optical fibers must be perpendicular to the axes of the fibers and parallel to each other when connected. The losses associated with the angular mismatch in the orientation of the optical fibers relative to each other ( angular displacement ) are shown in the figure. The level of losses in this case is also determined by the value of the numerical aperture NA.

Angular displacement loss

Laying an optical cable in the ground

When installing and operating a fiber-optic cable in the ground, it experiences a number of impacts that must be minimized to avoid damage to the product. They can be divided into 2 groups:

1. Mounting

— affect the fiber-optic cable once when laying the product in the ground. Installation impacts include:

- dragging on an abrasive surface and abrasion;

- tensile loads (for example, you cannot unwind the cable from the drum by tension) and crushing loads (as a rule, after eliminating the compressive factor, the violation of attenuation indicators is restored);

- torsion and dynamic bending, incl. at low temperatures;

- shock and vibration loads;

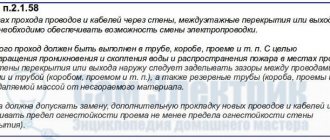

Table of rules for using optical communication cables

2. Operational

— valid for the entire service life of the cable (25-30 years). Their influence should be neutralized by the design features of the cables (the minimum requirements are established by order of the Ministry of Communications of the Russian Federation No. 47 dated April 19, 200):

- tensile and crushing effects can occur when an optical cable operates in loose and mountainous soils, seismically active areas, permafrost (critical temperature - 0 C) or under surfaces with high road traffic;

- high and low temperatures, their differences;

- moisture penetrating into the optical cable in the longitudinal and radial plane;

- electromagnetic influences that occur during a short circuit (+excessive heating) and from induced electric currents located nearby equipment on the metal components of cable products.

More detailed information can be found in the video:

The choice of method for laying fiber optic lines into the ground depends on the results of the research, soil types, assessment of interference and risks, and other factors. As a rule, for complex and long cable routes several installation methods are used:

- trench - the fiber optic cable is laid in a dug and prepared trench;

- mechanized - cable laying machine or HDD, devices for horizontal directional drilling. This method provides high laying speed;

- blasting operations are carried out in rocky areas.

The depth of laying the optical cable depends on the type of soil and is usually about 1.2 m. Bypassing communications encountered along the route, for example, railway and road crossings, water barriers, pipelines, power lines and others, is carried out using HDD using special polymer pipes.