Eurofence is a set of building structures (decorative reinforced concrete slabs and reinforced concrete pillars) and is the cheapest and most quickly erected fence for any territory.

Quickly navigate through sections

- Prices for fencing

- Eurofences are one-sided

- Special orders

- Fence posts

- Installation of fences

- Application of Eurofences

- Advantages of Eurofences

- Additional Information

Prices for fencing

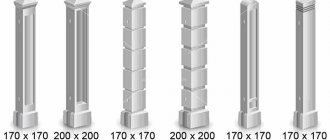

| Name | Price/piece rub | Wholesale price, rub | Weight, kg | Quantity, pcs. in the car 20t. | Dimensions, mm |

| Decorative panel | 500 | 350 | 60 | 300 | 2000x500x40 |

| Pillar 1 panel | 600 | 450 | 60 | 335 | 900x105x100 |

| Pillar 2 panels | 850 | 700 | 75 | 265 | 1600x105x100 |

| Pillar 3 panels | 1100 | 900 | 85 | 235 | 2200x105x100 |

| Pillar 4 panels | 1600 | 1350 | 95 | 210 | 2700x105x100 |

| Pillar 5 panels | 2100 | 1800 | 120 | 165 | 3200x105x100 |

| Textured narrow pillar 4 panels | 2100 | 1800 | 115 | 175 | 3000x110x100 |

| Textured wide pillar 4 panels | 2600 | 2250 | 140 | 150 | 3400x180x110 |

| Pillar block | 450 | 300 | 18 | 720 | 260x255x255 |

| Pole covers 270 | 200 | 150 | 10 | 800 | 270x270x55 |

Special orders

Directly after production, concrete fences are gray in color. But if you want to add artistic decoration in color, then our craftsmen will paint the panels with high-quality and durable paints. Below are some of our works with additional artwork.

Eurofence No. 7 art. zb-10-10-9 + coloring

panels x-51-52

Eurofence No. 25 art. zb-57-58-86 + coloring

panels 150-150's

Installation of fences

Decorative fencing is an integral part of your garden plot. An important advantage of our prefabricated concrete fencing system is its quick installation. This type of fence does not require a strip foundation, and the reinforced concrete pillars we produce require a simpler foundation than brick ones.

To install a concrete fence yourself, you must have certain construction skills. If you have purchased a fence for a dacha or a fence for a cottage, then with the help of a team of two or three people, it is quite possible to install a decorative fence on your own. The average weight of a panel is 75 kg, a column is 90 kg, so the use of special equipment is not necessary.

Work begins with determining the level of the concrete fence, marking the installation locations of the pillars, and, if necessary, gates and gates. Pegs are fixed in the places where the pillars are installed, then the cord is pulled. The pegs must be strictly “in a line” and spaced one marking step apart from each other. The problem of slopes is solved by using pillars of different lengths or installing steps. To install slabs in such pillars, it is necessary to increase the length of the pillar groove or trim part of the slab. In this case, the height difference between adjacent spans should not exceed 1/10 of the length of the decorative fence panel. To rotate the fence, you need to use two posts.

Holes in the ground for the posts can be made with a drill using appropriate knives or manually using a crowbar and a shovel. The recommended depth is 70-90 cm; for heaving soils, the drilling depth is at least 120 cm. After the pillar is erected, it is crushed - gravel, broken bricks, and stones are placed in the base. The rubble is compacted and covered with coarse sand, which is thoroughly watered to compact it. The upper part of the rubble is secured with a concrete screed. When installing posts, it is recommended to provide a gap of 30-40 mm between the ground and the lower panel slab of the fence.

Method 1 Using the technology described above, all pillars are mounted and concreted. Then the slabs are installed by inserting the slabs into the grooves of the pillars through the top. The disadvantage of this method is that the slabs rise to the entire height of the fence - it is physically difficult. Also, this method does not tolerate markup errors.

step 1

step 2

step 3

Method 2 Using the technology described above, the first pillar is mounted, the second pillar is not fixed. The required number of slabs is installed in the groove of the first column. The second pillar is, as it were, stretched onto the slabs and only then fixed. The section is aligned in the vertical and horizontal planes, and the installation continues. After installing all sections of the concrete fence, the pillars are filled with concrete mortar.

step 1

step 2

step 3

The filling between the pillars can be anything - metal, wood or our reinforced concrete textured panels. The fence panels are installed using mortar.

Important to know: The destruction of the supporting part of the fence is a consequence of improper installation of the pillars during its construction. The most typical damage to the supporting part is a violation of the depth of the initial installation of the posts - some of the fence posts are higher than the level of their installation, and some “fall through”. Often this picture is accompanied by an arbitrary tilt of the fence posts, both to the outside and to the inside. Incorrect installation of posts, as a rule, appears already in the next summer season - after the fence has been overwintered.

If you want to entrust the installation of your garden fence or cottage fence to professionals and receive a 2-year guarantee on its installation, contact US!!!

Fence installation

The fence made of concrete slabs is assembled in stages, work begins with preparatory operations. At this stage, the territory is marked with the subsequent formation of a solid foundation. If heavy structures are used, then a monolithic strip foundation made of concrete and a small depth is required. The foundation should be slightly wider than the fence being installed. If the site has a large slope, then the base is stepped, the pillars are installed in places where there are drops, and construction takes place according to the following plan: marking the area, digging a trench, installing formwork, pouring ready-made concrete and then installing slabs.

Concrete for the foundation of the fence is poured into pre-prepared formwork with reinforcement Source klademkirpich.ru

The process of arranging the foundation goes like this:

- the ground is leveled around the perimeter, stones, roots, and stumps are removed;

- marking is carried out using pegs (approximately 60 cm high) and construction cord in accordance with the calculations made, marking starts from the gate;

- a trench is dug, which should be 20 cm below the soil freezing level;

- support pillars are mounted, the depth of the holes under them should be 10 cm below the depth of the trench, the holes are made using a hand drill;

- crushed stone is poured into a 15 cm layer at the bottom of the trench and compacted thoroughly;

- the first pillar must be measured vertically and horizontally using levels, the pillar is fixed with crushed stone and then filled with concrete;

- reinforcement with a diameter of at least 8 mm is laid in the trench on crushed stone;

- Concrete is poured onto the formwork, each layer is compacted;

- After the concrete has dried, waterproofing is carried out on top in the form of a cement screed with a sealant.

Installation of fence elements is carried out after the foundation has completely dried. Source beautycontraception.ru

Installation of fence elements begins only after the foundation has completely dried. It may take 3-4 days to complete the installation of the fence. A sectional concrete fence is assembled according to the principle of a designer. The slabs are installed one on top of the other in special grooves in the pillars. To equip an area with such a fence, you need to make simple calculations - you need to know the length of the future fence. Then choose the type of panels based on decorative elements and color. After the panels are delivered to the site and the foundation is prepared, the construction of the fence can begin.

Advantages of Eurofences

★ Durability and reliability Euro fences are made of high-quality concrete with metal reinforcement and will serve you for many years.

★ Cost-effective Eurofences are a less expensive solution in the long term. The fact is that wood or corrugated board will require timely replacement after some time, not to mention the high maintenance needs to maintain the appearance, for example, of a bush fence. Taking into account any maintenance, the cost of the fence increases from the original cost. So prices for reinforced concrete fences will be higher at the time of purchase, but cheaper in the long term.

★ Easy to install Eurofences, unlike brick and stone fences, are installed on any soil and do not require laying a foundation. They can also be installed on surfaces that have a significant horizontal slope.

★ Speed of installation Installation of prefabricated decorative concrete fences is much faster than the construction of any other permanent fence.

★ Diversity of design The modular principle of Euro fences allows the customer to combine type-setting slabs to their liking, set the height and shape of the fence, select the texture and color of concrete slabs, and include elements from other materials into the design: natural stone, brick, metal and wood.

★ Aesthetic properties Decorative concrete fences are very beautiful, a large selection of models of stacked slabs with different surface textures and a wide range of colors allows you to create a unique individual type of fencing that can satisfy the most demanding customer.

By ordering the construction of decorative concrete fencing in, you will receive a reliable and aesthetically attractive new generation fencing at affordable prices and in a short time.

Forms of decorative concrete fences

The popularity of concrete fencing models is due not only to the large number of advantages of the source material, but also to the opportunity to make a fence with decorative characteristics with your own hands.

For the manufacture of sections, specialized casting molds are used, giving the product a special texture or openwork outline.

Basic materials for the matrix:

- polyvinyl chloride or PVC forms, characterized by elasticity, making it easy to obtain high-quality panels with an increased level of fire resistance. Such matrices can withstand about 120-150 production cycles and are distinguished by an affordable price, which varies depending on the texture and complexity of the pattern;

- molds made of ABS plastic , characterized by strength, rigidity and high chemical resistance, which allows you to cast geometrically correct fence sections with the clearest pattern or design. Plastic matrices can withstand about 300-400 pouring cycles and are easy to use, compact, and also have low adhesion to cement, so the use of lubricants can be neglected;

- polyurethane forms are designed to reproduce the most complex textures on concrete sections, imitating slate, natural stone and wood with the clearest possible depiction. Such matrices are usually used for the production of double-sided decorative fencing panels.

The highest productivity and fastest demoulding are characterized by modern fiberglass forms with a full metal frame and comfortable handles.

The disadvantage of high mold productivity is the impossibility of producing high-quality painted sections, since the use of pigments that reduce the strength of the board can result in finished products with defects and various damages.