Specifications

When choosing concrete for construction, specialists primarily focus on its technical parameters. They are regulated by the above-mentioned GOST 26633-2012.

According to the new standard, concrete M250 corresponds to class B20, so it is marked with the double designation M250 B20. At the same time, the brand indicates the maximum possible load on a mature stone, and the class indicates the average load with a margin.

Technical characteristics of concrete m250:

| Index | Units | Meaning |

| Maximum strength | kg/cm2 | 260 |

| Density (density of concrete) | kg/m3 | 2300-2400 |

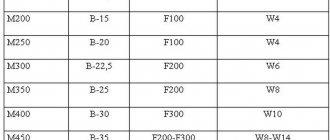

| Frost resistance | Cycles, F | 200 |

| Waterproof | W | 6 (waterproof) |

| Solution mobility | P | P2-P3 |

The density of concrete depends on the type, fraction and brand of crushed stone, sand, and the amount of water. Sometimes the weight of concrete is taken into account the type of coarse filler (granite or limestone, their mass differs significantly).

The parameters of strength, water resistance and frost resistance can be adjusted with complex or narrow action plasticizers. This can be superplasticizer C3, liquid glass and other chemical or mineral additives.

Standardized indicators

The strength of the constructed object depends on the correctly selected concrete mixture. When making a decision, they are guided by the characteristics of a particular brand of monolith. For solutions and frozen products M250, the indicators are as follows:

- The compressive strength class is B20, which indicates an average value of 262 kg/cm² 28 days after laying the mixture.

- Frost resistance - the number of cycles of freezing and thawing of products is indicated by the letter F and has the values F100, F150, F200.

- Water resistance W is the ability of concrete to withstand the static pressure of water: not to absorb or pass it through the body of the structure. M250 has indicators W2, W4, W6, W8, where the numbers indicate the amount of hydraulic load in kg/cm². Greater values are achieved by using granite crushed stone in the solution.

- The mobility of a concrete mixture is the degree of its thickness and fluidity: the lower the indicator, the harder the solution. The limits of change are in the range from P1 to P5, for M250 - P2, P3, P4. A high index allows you to use a concrete pump to pour the mixture into the formwork of a structure.

READ Technology for manufacturing reinforced concrete curb stones

The specific gravity of concrete depends on many factors and is an indicator regulated by combining aggregates with different properties, water-cement ratio and methods of mortar compaction. Improvement of individual indicators is achieved by introducing special additives into the mixture.

Compound

The composition of concrete m 250 includes a standard set of components:

- Portland cement M400 or M500 - the higher the grade, the less binder is required;

- Sand of the first or second grade, cleared of impurities and dust. It is optimal to use river sand with a particle size of no more than 2.5 mm;

- Crushed stone is granite or gravel, or slag. To make concrete beds or blind areas, crushed limestone can be used;

- Water with a standardized mineralogical composition. It is optimal to use a central city water supply or a well as a source;

- Plasticizers increase the density of concrete, its frost resistance, and the mobility of the solution to create an optimal consistency for stable placement and distribution. Using an additive will reduce water consumption without losing the strength of the finished concrete stone.

All components must comply with the requirements of GOST 26633-2012 “Heavy and fine-grained concrete”.

Mixing equipment and concrete preparation

To obtain a concrete mixture, all components in given proportions are thoroughly mixed to a homogeneous mass with an even distribution of large and small aggregates in the cement mortar. The main unit of mixing machines is a drum or bowl. The entire cycle consists of three operations: loading raw materials, mixing with the addition of water, and emptying the finished concrete mixture. Based on the method of moving ingredients inside the drum, machines are divided into 2 types:

- Gravitational - when particles fall freely at circular rotations of the bowl at a speed of 20 rpm.

- Forced mixing by means of a paddle shaft or rotor rotating inside a stationary drum.

READ Fine-grained concrete class M200: formulation and properties

Both devices are manufactured in mobile or stationary versions. The table shows their defining characteristics for domestically produced samples .

| Mixing method | Cyclic machines, bowl volume in liters | Continuous process, output in m³/h |

| Gravitational | 65―3000 | 120 |

| Compulsory action | 165―1000 | 15―60 |

Private developers use a 65 liter concrete mixer. Loading of materials is carried out manually, the rotation speed of the drum is 23 rpm using a 0.6 kW electric motor.

Proportions and preparation

Concrete M250 does not differ in composition from other grades of material, the difference lies in the proportion of components. To prepare the solution yourself, you must try to maintain the amount of binder, crushed stone, sand and water to obtain a building material with the expected characteristics.

The proportions of concrete grade 250 and composition are given in the table:

| Cement | Sand | Crushed stone | Water-cement ratio w/c | Plasticizer |

| For cement M400 | ||||

| 1 | 2,1 | 3,9 | 0,55 | No more than 5% |

| For cement M500 | ||||

| 1 | 2,6 | 4,5 | 0,62 | No more than 5% |

As you can see, the higher the grade, the less cement you need.

The water-cement ratio is the amount of water relative to the mass of the binder. The table shows conditional values that can be adjusted by using a plasticizer.

It is inconvenient to use scales on a construction site, but a bucket (10 liters) is always at hand. The proportions for preparing concrete 20 m250 will be as follows:

- Cement M400 – 1 bag 25 kg;

- Sand – 5 buckets;

- Crushed stone - 12 buckets;

- Water – 3.5 buckets.

Proportions in buckets (10 l) for preparing M250 concrete:

- Cement M400 – 10 liters;

- Sand – 1.9-2;

- Crushed stone – 3.4-3.5;

- Water – 1.7-2.

Concrete M250 from M500 cement:

- Cement – 10 liters (1 bucket);

- Sand – 2.4;

- Crushed stone – 3.9;

- Water – 4.

In general, water should be no more than 30-40% by weight of the binder. But such a mixture is not plastic, semi-dry and practically unusable. Excess liquid leads to a decrease in the strength of the stone. Plasticizers similarly bind components and maintain design strength, so their use is very reasonable.

How to make concrete with your own hands:

- Pre-mix sand and crushed stone with a shovel.

- Add some water into the concrete mixer.

- Then introduce the mixture into the concrete mixer and add cement in portions;

- Next, water is added. The plasticizer must first be diluted in it. Water must be added in portions and mixed thoroughly.

In order not to calculate proportions, you can order a ready-made solution from manufacturers. The cost of 1 m3 is approximately 2500 rubles. A cube of concrete weighs on average 2300-2400 kg.

Composition and proportions of mixture components

The composition of the popular M150 concrete includes standard components - Portland cement, sand, crushed stone, water. Due to its simple composition and ease of manufacture, it is produced not only in industrial conditions, but also independently, directly in private construction. The main condition that must be observed when preparing M150 concrete is thorough mixing, in compliance with all proportions in accordance with the approved GOST standards. In this case, the properties of the solution can change within certain limits due to the difference in the properties of the fillers.

To produce concrete grade M150, you can use Portland cement grades M400 and M500. The mass proportions of the components are determined according to the following table:

| Brand of Portland cement | Mass proportions cement: sand: crushed stone |

| M400 | 1:3,5:5,7 |

| M500 | 1:4,5:6,6 |

From here we can draw the obvious conclusion that the higher the , the less it will be required for the concrete mixture, but it must be taken into account that cement of a higher grade will be more expensive.

In private construction, mixing the mortar is often done manually, and the volume of components is measured in buckets. Considering that the volume of a standard bucket is 10 liters, this amount of M400 Portland cement will require 32 liters of sand and 50 liters of crushed stone, resulting in 64 liters of solution after thorough mixing. For 10 liters of Portland cement M500, 40 liters of sand and 58 liters of crushed stone will be required, and the output will be 73 liters of the mixture. For better placement, plasticizers can be added to the solution.

In the industrial production of concrete, the composition is calculated per 1 m³ of the finished solution, taking into account the strength and workability class of the mixture, water resistance and frost resistance, which are indicated by the corresponding indices. The ratios of components per cube of concrete can be seen in the corresponding table:

| Mixture parameters | Proportions of components per 1 m3 of concrete, kg | ||||

| Cement | Sand | Crushed stone/gravel | Water | Additive | |

| V10 P3-P4 | 210 – 230 | 780 – 850 | 1170 – 1190 | 150 – 180 | plasticizer |

| B10 P3-P4 W2 F50 | 230 – 240 | 750 – 850 | 1170 – 1190 | 150 – 170 | plasticizer |

| V12.5 P3-P4 W2-4 F50 | 240 – 260 | 700 – 800 | 1150 – 1190 | 150 – 170 | plasticizer |

Portland cement can be marked I 32.5N or I 42.5N, in this case the proportions for making M150 concrete mortar and the number of components for making 1 m³ of material can be found in the table:

| Cement brand | Proportions, kg C:P:SH:V | Cement, kg | Sand, kg | Crushed stone, kg | Water, l |

| I 32.5N | 1:3,4:5,4:0,9 | 215 | 735 | 1140 | 190 |

| I 42.5N | 1:4:6:1 | 190 | 755 | 1140 | 190 |

When preparing the solution, it is recommended to wet the mixer in advance to avoid excessive spraying of cement. After that, the ingredients of the solution are loaded and thoroughly mixed for at least 5 minutes; the less mobility of the mixture, the longer the solution needs to be mixed. If necessary, a dissolved plasticizer is added.

To obtain a high-quality solution, it is necessary to ensure that the fillers meet certain requirements. Sand can only be river or washed without the inclusion of foreign components, fraction 1.5-2 mm. It is recommended to use gravel or crushed limestone with a fraction of 5-20 mm as a coarse filler. The water used in the preparation of the solution should not contain mineral or organic impurities.

Concrete grade M150 is one of the most common materials in construction. It does not have increased strength characteristics, has high water permeability and average frost resistance, which are considered to be its disadvantages. At the same time, it is one of the cheapest materials, so it can be used in maximum quantities. Upon completion of hydration, the concrete structure acquires the declared technical characteristics, which are maintained for many years. In cases where significant volumes are required for pouring a cushion under the foundation or other work, it is more profitable to order the mixture from specialized factories. They purchase materials in large quantities at wholesale prices, which has a positive effect on the final cost of the product. In this case, you need to require a quality certificate for the provided material, its compliance with GOST.

Application

Concrete strength grade B20 is used in private and low-rise construction:

- Construction of foundations for lightweight houses, garages, bathhouses, outbuildings;

- Manufacturing of prefabricated reinforced concrete structures;

- Monolithic construction of private one-story and attic cottages, country houses;

- Pouring private areas for cars;

- Construction of landings, stairs and porches;

- Improved hydraulic concrete is suitable for making supports for pipelines.

M250 concrete can compete with higher grades and help save money on the construction of a private house. It can be safely used on any type of soil under walls made of timber, frames, as well as any lightweight outbuildings. The use of additives will provide an additional margin of safety.