Some types of asphalt concrete do not require maintaining a high temperature when paving - laying cold asphalt can be done without preheating the mixture, which leads to the main advantages of this material.

Cold asphalt is a type of asphalt concrete (AC) that does not require heating before laying. The composition of cold AB includes certain solvents that dilute bitumen resins, due to which heating of the mixture is not required. Due to the simplification of asphalt paving technology, the cost of laying asphalt using the cold method will be lower than in the case of hot mixes.

Characteristics and properties

The composition of cold asphalt is quite simple, because when supplied from the factory, it includes aggregate and small crushed stone. Having delivered the bag to the site, it will be in a solid state, but has a loose structure.

To bring it into working condition, it is recommended to thoroughly mix the composition using special mixers. The presence of fine crushed stone allows you to fill up road potholes to an ideal condition, comparing the surface with the main coating.

The composition of cold asphalt includes kerosene, organic acids, bitumen, as well as various additives. Viscosity retention is the main characteristic of this material, since viscosity is maintained at any time, which does not limit builders in their work.

The package containing cold asphalt is always marked with the minimum temperature permissible for performing the work. Therefore, by choosing the right material, you can carry out road repairs even at critically low temperatures.

The composition loses its properties if the rules of installation and operation are not followed. For example, manufacturers of many brands indicate that the layer size should not exceed 6 centimeters in thickness. If the hole is deeper, then two or more layers are laid.

In this case, each layer must be pressed down with a tamper. Like other materials, cold asphalt shrinks. During installation, it is necessary that it rises to a height of 1-2 cm above the primary coating, since after shrinkage, the surfaces will become level.

In order to improve the operating parameters and properties of cold asphalt, a depression in the road or a full-fledged hole must first be treated with bitumen. This will allow the material to better adhere to the base.

conclusions

The technology for laying cold AB is a little simpler than laying hot mixtures, but it also requires maximum adherence to the technological process. Cold asphalt itself is an indispensable material for urgent road repairs, since it does not require heating before laying, due to which it can be used in cold seasons, and traffic is allowed almost immediately.

The performance characteristics of cold mixtures are lower than those of hot ones, therefore, during the construction of public roads, laying cold asphalt is not allowed. However, the material is quite suitable for pedestrian areas and pothole repairs.

Main types

Asphalt can be divided into types:

- Type A. This composition includes mixtures containing at least half crushed stone.

- Type B. This includes all mixtures that contain from 40 to 50% crushed stone.

- Type D. This is a cheap option because it uses stone chips, screenings, sand and other components. This is the most inexpensive type of asphalt, since due to its fragility it is not recommended for use on road surfaces with intense surface loads. Therefore, class “D” is mainly used for repairing paths in the territory of private houses, in parking lots, as well as in other low-traffic areas.

Advantages of cold asphalt

The cold method of paving has gained immense popularity due to its simplicity. With the advent of cold asphalt, any homeowner can carry out repairs or make a small asphalt area without special skills or the use of expensive equipment.

Cold asphalt pavement is highly durable, durable and can be used immediately after completion of repair work. As vehicles drive along the repaired area, the asphalt becomes compacted and acquires the necessary hardness.

Composite additives included in the material improve the adhesion of the mixture to the surface, which facilitates the masonry process and guarantees high quality of work performed.

The advantage of this method over hot styling is that the work can be carried out at temperatures down to minus 20 degrees. In this case, preliminary preparation of the surface to be repaired is completely unnecessary. All you need to do with the hole is sweep the dust out of it.

Transportation of the material can be carried out in any weather conditions, in a vehicle of appropriate carrying capacity. Well-packed cold asphalt in bags can be stored almost forever. The opened mixture can be used for a year, which is very convenient.

Production methods

Cold asphalt technology is similar, regardless of the manufacturer. For example, a method without heating is applicable in production. That is, the output asphalt is delivered in containers in its original state.

For better adhesion to it, bitumen additives are recommended. All this is mixed at the laying stage and the holes are sealed. At the end we get a high-strength composition that provides ideal adhesion to the surface. A patch placed on the road will not be afraid of rain, freezing, or exposure to sunlight.

Technologies that involve heating are somewhat similar to the production of hot asphalt. Here they choose fine-grained gravel, heating it to a temperature of 110-120 degrees. After adding bitumen here, the material is thoroughly mixed, and for some time it is exposed to a temperature of 100-105 degrees.

Then, it is sent to the cooling stage, where it is cooled to 25 degrees and packaged in containers, after which it is sent for sale on store shelves. Depending on the quantity and quality of additives used, such formulations can be stored from 2 weeks to six months.

Therefore, when buying bags on the shelves of your stores, pay attention to the production methods. It’s not at all scary if the trading floor is located in the open air, outside the premises. This is quite acceptable according to the recommendations of the factories.

The “secret” of cold asphalt production

The material is an asphalt concrete mixture that is ready for use. During its production, the usual bitumen is replaced with special analogues in the form of elastic bitumen with thinning additives or bitumen emulsions. They are characterized by a special “behavior” when temperatures drop: they add additional viscosity to the material. Among other advantages of the component are:

- Increasing the service life of the coating.

- Special “grainy” structure.

- Additional resistance to aggressive operating conditions.

Read on topic: Gasoline consumption on Hyundai Solaris has increased: what to do

The production of cold asphalt is quite simple and involves several stages. Preheated crushed stone, gravel, sand and elastic bitumen or bitumen emulsion are poured into a special mixer. All components of the mixture are thoroughly mixed. Then, in some industries, a diluent additive is additionally introduced into the same mixer. The additive is introduced into the mixture through a separate sleeve. All components are thoroughly mixed again and cooled naturally. After mixing the components, the asphalt is ready for use and can be packaged.

Tip: Some industries use technology that does not require heating the components. Heat treatment is compensated by a special composition of plasticizers. The unique type of bitumen used in cold asphalt is considered an expensive innovative development, and it is this fact that determines the high cost of the material itself.

Area of operation and application features

As we have already indicated, laying cold asphalt is possible not only to fix potholes, but is also used by private individuals to restore sidewalk paths, driveways, parking lots and other places.

At the same time, even major road construction still affects the use of cold compounds. They are used where access for large equipment is difficult. For example, they are used for arranging storm drains and hatches. Station platforms, viaducts, waterproofing drainage channels, repairs and installation of flexible roofing are industries where cold bagged asphalt .

As for use by private individuals, the compositions are used for arranging floors on verandas and gazebos, and will be used in landscape designs. The latter is possible due to the fact that there are compositions with dyes on sale. Methods of working with cold-type asphalt can be divided into the following stages:

- It is important to determine how much repairs will be required. It is worth knowing that approximately 1 cubic meter of the mixture will weigh about 1.1 tons. The latter will help you calculate what transport will be needed for delivery.

- After delivery, they immediately begin to work. First, determine the depth of filling the hole, taking into account that the thickness of 1 layer should be no more than 6 cm. Next, the edges of the hole must be cut down to 5 cm around the perimeter to improve coverability. After the pit has been treated, it is necessary to remove all foreign dust, dirt and other inclusions that will interfere with the adhesion of the asphalt.

- Bitumen should be used. It must either be poured into the pit, heated to the recommended temperature, or treated on top with a brush. Having completed the preparation, you can begin to work. We remember that the thickness of 1 layer should be no more than 6 centimeters. Therefore, if your financial capabilities allow, you can lay out several layers. But to make the job cheaper, you should fill the bottom of this hole with small crushed stone. After compacting it, you can lay asphalt, first filling the crushed stone with bitumen.

- You can't save money. The poured part should extend beyond the road surface by 2 cm. It is after compacting it, using vibrating plates, that you can achieve a flat and smooth surface of the road surface. When tamping the surface with a vibrating plate, you need to start from the edge and move towards the middle. This will allow you to achieve better results.

- The final stage of work is filling the surface with sand or cement. The latter will protect the wheels of cars and the shoes of passers-by from sticking. In about a day, the asphalt will completely set and you can walk on it without hindrance.

Laying cold asphalt for pothole repairs

Laying cold asphalt is widely used for pothole repair of roads for another reason that the repaired area can be put into operation faster than in the case of using hot mixes. Cold asphalt concrete does not require time to cool, so transport can be started almost immediately after compaction.

Technology for laying cold asphalt concrete for pothole repair

- 1. The damaged area and its edges are cleaned of foreign elements, debris, dirt, dust and moisture.

- 2. The damaged area is given the correct geometric shape - the edges of the hole are aligned.

- 3. The bottom and walls of the prepared area are impregnated with liquid bitumen emulsions at the rate of 0.5 liters per 1 sq.m. to ensure adhesion of the layers.

- 4. If the depth of the damage is more than 20 centimeters, a layer of crushed stone is laid on the bottom (the thickness depends on the depth of the hole). After laying, the crushed stone layer must be compacted and covered with liquid bitumen

in the proportion described above. - 5. The final stage is laying cold asphalt

on the prepared base followed by

compaction

. The laying height should be 2 centimeters higher than the required level to compensate for compression during compaction.

If compaction is carried out not with a road roller, but with manual equipment, we recommend compacting from the edges to the center (in a spiral). When no traces of compaction remain on the asphalt, the procedure can be considered complete.

Packaging and prices

There are many manufacturers, so the packaging is different. The same applies to the price. The most popular sizes are bags weighing 25 and 50 kg, respectively. There are also 30 kg bags on sale. There are containers of greater mass, but it is not practical to buy them in comparison with smaller volumes.

This is due to the large weight of 1 bag. As for the price, you can find bags on sale that cost 250 rubles. for 25 kg, 500 rubles for 50 kg, respectively. The price can vary between 10-15%, which depends on the manufacturer and the quality of the material, where the quality depends on the type of product. Type “A” is considered the most expensive, type “B” occupies the middle segment, type “D” is considered the cheapest.

When purchasing, you should consider the consumption of cold asphalt . For example, work statistics show that about 25 kg will be used per square meter for a layer 1 cm thick. It may seem that such a coating is expensive due to the high consumption.

But its performance properties are much higher than other materials, which justifies the investment. Therefore, if you have a very small depression in the road or partial repairs are needed, you will need 25 kg cold asphalt .

Cold asphalt weighs a lot at 50 kg, so additional labor is needed to carry it. This bag is larger in volume, therefore, relative to the smaller packaging, it is profitable to buy it. The use of bags is important for working with large volumes.

What is cold asphalt?

Cold asphalt is called an innovative material for road repair, the use of which opens up new opportunities for public utilities and owners of private territories. This species came to us from abroad quite recently, but has already proven itself well on the Russian market. The unique qualities of the coating allow it to be used in the most extreme conditions, when laying hot asphalt is completely impossible. Many people are interested in the question, what does cold asphalt consist of? What it is?

The product is produced in the form of a ready-made asphalt concrete mixture with the addition of bitumen, polymers and plasticizers. During the production process, all the main components of the material are thoroughly mixed, fine-grained crushed stone and elastic additives are added. The resulting mixture undergoes heat treatment and is sent for packaging.

Cold asphalt is sold in 50 kg bags, 15 kg plastic buckets or in large packages up to a ton.

Advantages of cold asphalt

We invite you to familiarize yourself with the advantages that put this material first in comparison with other options:

- Ease of transportation. It all depends on the volume. For small values, you can bring the material by car. In the case of large volumes, either trucks or manipulators are suitable. A dump truck is not needed for operation.

- Long shelf life. Everything depends on technology. If it does not involve heating, then the material in bags can be stored for up to 2 years. If heating was used, it depends on the manufacturer and the additives used, since for many the bags are stored for no more than 2 weeks, for others up to six months.

- All-season use. Now you don’t need to wait for the onset of summer, dry time. The composition is delivered ready-made, or only bitumen needs to be added to it to achieve better viscosity. The manufacturer allows repairs to be carried out even at temperatures down to -20 degrees Celsius.

- Work intensity. Almost everything is done by hand and does not require machinery. It is enough to have a vibrating plate and a good tamper. The latter is convenient for working for personal purposes.

- Safety. If you can get burned from hot asphalt if you are not careful, then there can be no damage here. The material is non-toxic, so you can work with it without a respirator. A wheelbarrow should be used for local transportation. Asphalt will not stick to its surface and the tool will not have to be washed after finishing work.

- Long life and use. The hardened composition is not afraid of freezing, getting wet and ultraviolet radiation. With professional installation, it will last for more than one summer under intense loads, and in ordinary conditions it will last without a statute of limitations. In case of partial destruction, you can simply finish your work rather than remove the entire patch.

Technology of working with cold asphalt

For use in small quantities, it is necessary to determine how much of the mixture needs to be purchased, for this you should know that 1 cubic meter of the mixture weighs from 1,100 kilograms to one and a half tons, dismantled old asphalt weighs 1,400 kilograms per cubic meter. The technological process for repairing road surfaces using cold asphalt consists of the following stages:

- The damaged area is marked so as to cover an area at a distance of 5 centimeters from the boundaries of the damage, seams are cut and materials from the damaged area of the coating are removed with a milling cutter or jackhammer.

- The dismantled area is cleaned of coating residues and dust.

- The edges and bottom of the area prepared for repair are treated with bitumen.

- The asphalt layer should not exceed 5 centimeters in thickness; if the depth of the repaired area is greater, it is necessary to add a layer of crushed stone. It is necessary to pour a layer of asphalt so that it protrudes 2 centimeters above the level of the road surface, this is the so-called compaction reserve.

- Compaction is carried out manually or with a vibrating plate, starting from the edges to the middle.

- Upon completion of compaction, the repaired area should be sprinkled with cement or sand to prevent the mixture from sticking to car wheels.

Disadvantages of cold asphalt

Cold mixture is irrelevant in matters of capital construction of roadways with high traffic. This means the use of cold asphalt to replace the asphalt by 100%. It is not recommended to be used for major repairs due to destruction under high loads.

But, as a rule, this is not done, since another disadvantage is the high cost of the material. According to experts, 1 square meter of coating will cost up to 3 times more than using hot-melt asphalt.

Compacting cold asphalt

The savings come down to the fact that this asphalt is used in small batches. In turn, no one will bring you cheap asphalt produced using hot technology for filling holes and cracks, or they will bring it, but for a lot of money. Therefore, when you buy such a composition in bags, you deliver it by personal vehicle and carry out the repairs yourself. This way you will save money.

For reference, the approximate price for 1t of hot asphalt is 3,000 rubles. For a similar volume of cold asphalt you will have to pay up to 10 thousand rubles. You can save on labor costs, no need to use special equipment and other nuances of work.

Laying cold asphalt during paving

Laying cold asphalt is similar to hot mix asphalt paving technology. The only exception will be that there is no need to warm up the asphalt concrete before laying, which also eliminates the need to use special equipment.

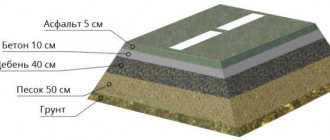

Technology for laying cold asphalt concrete during paving:

- 1. Clearing the work area of large foreign elements and vegetation.

- 2. Removal of the top layer of soil followed by cleaning the subgrade from foreign elements, debris and moisture.

- 3. Leveling and compacting the earthen base.

- 4. Laying geotextiles to separate technological layers, reinforcement and prevent plant germination.

- 5. Pour a layer of sand and then compact it

. Necessary to stabilize the base. - 6. Laying geogrid to increase strength and uniform redistribution of vertical load.

- 7. Laying a crushed stone layer with its subsequent compaction

. If the crushed stone is not of mixed fractions, the larger fractions are poured first, then the smaller ones. This is necessary to achieve maximum density. - 8. Pouring the crushed stone layer with liquid bitumen emulsions for high-quality adhesion of the layers (0.5 l / 1 m2).

- 9. Laying cold asphalt with subsequent compaction. The initial layer height should also be 2 centimeters higher, which is compensated by a decrease in thickness during compaction.

Tamping is carried out using special equipment or manual equipment. In some cases, individuals compact asphalt concrete with vehicle wheels, but this method does not always provide a sufficient coefficient of asphalt compaction.