- 1 Technical requirements

- 2 Coating materials

- 3 Laying and compaction procedure

- 4 Maintenance of asphalt concrete pavement

- 5 Laying asphalt concrete on old concrete or asphalt

- 6 Conclusion

Asphalt coating is considered one of the most popular and durable. This is an excellent method to repair a road or make a new road layer. The technology for performing this process is of two types - manual and using special construction equipment. If the scope of work is not too extensive, then using the first option is preferable.

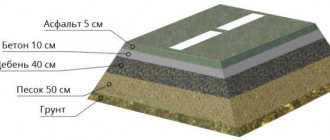

Crushed stone mixture is used as a base for concrete asphalt. However, this is not necessary; such a mixture can be replaced with a concrete base. Asphalt of this type is characterized by some of the highest strength, durability, and ability to withstand the effects of atmospheric phenomena. Laying such a coating is the last point in the production process for repairing highways and roads.

Before starting the main process, it is worth carrying out organizational and preliminary work. These also include arrangement of the work site and soil stabilization.

Technical requirements

The technological process for laying defense asphalt is not as simple as it might seem at first glance. Such work requires skills, experience and knowledge. Before you begin laying or repairing the road surface, you need to study the necessary manuals, documents, instructions, and GOSTs. The following are only the main GOSTs:

- GOST 7473-85. This document describes the necessary rules, requirements and technical nuances. It is these standards that must be taken as a starting point during the production of concrete solutions.

- GOST 9128-97. This document provides requirements for different types of concrete solutions used for highways and airfields.

- GOST 28013-89. This document provides requirements for the production of asphalt concrete solutions.

- GOST 30412-96. This document describes methods and materials for accurately measuring slope and roughness angles for public roads and airfields.

- GOST 30413-96. This document was written directly for public roads; it describes a method for finding the indicator of adhesion between the wheels of cars and the road surface.

However, you need to study not only the above manuals, but also pay attention to the standardization of CMEA . It specifies the general requirements and parameters of public roads. If you do not comply with the requirements specified in the documentation, then this risks the fact that the installed coating will soon become covered with cracks, and unevenness will appear on the surface.

Return to contents

Technical standards and requirements

As one would expect, the most important thing when laying any type of asphalt, even the one that is to be considered today, namely asphalt concrete, is the understanding of the technology and compliance with standards and SNIPs. In addition, carrying out such work requires the builder to have specific skills, knowledge and experience.

Before carrying out repairs, be sure to familiarize yourself with the rules, guidelines and GOSTs proposed for performing such work. But, keep in mind that you need to study not only generally accepted GOSTs, but also CMEA standardization. It contains information about the parameters of specific roads, technological and operational requirements for them. You must understand that ignoring the prescribed norms and rules is fraught with the fact that the laid asphalt or the prepared base will become covered with cracks after some time, and unevenness and pits will begin to form on the surface.

I would also like to remind you of the main theses of the technological process:

- In the case of an extensive amount of work, an exclusively automated method should be used, that is, including the use of special machines and equipment.

- In cases where, on the contrary, the amount of work is small, it is advisable to use the manual laying method; this applies, for example, to small sidewalks.

Coating materials

Laying asphalt pavement on a crushed stone bed.

It is difficult to overestimate the importance of materials. After all, the economic side of the technological process primarily depends on their choice. It is important to know that it is not always wise to save on materials.

The market offers customers a huge assortment. Nowadays you can easily purchase a solution that can strengthen the soil well, which will affect its durability and strength. The consumer will be able to use the road surface for a longer time. Thanks to its special composition, the solution glues soil particles together, and this makes the soil strong and like stone.

Before pouring the concrete solution onto the soil, it is important to carry out some preliminary manipulations:

- Plants must be removed from the top layer of soil, and the soil must be compacted using a roller. It is better to use a roller that weighs at least 1.5 tons. The soil surface must be extremely smooth, the permissible maximum error of the slope angle is no more than 3 centimeters for every three meters.

- It is recommended to treat the soil with specialized sterilization solutions; this is necessary in order to prevent the germination of grass, weeds and flowers.

- Before laying the concrete solution, it is imperative to first lay the drainage layer. The drainage layer is made of crushed stone and quarry sand; it is important that there are several such layers and the width of each of them is not less than 10 centimeters. Crushed stone drainage must be thoroughly compacted. To improve shrinkage, it is recommended to water the base with water. It is necessary that the sand is compacted by at least 90%.

Return to contents

Specifics of technology for laying road slabs and coatings

Laying slabs is the fastest and most efficient way to create roads.

What is especially important is that the material can be used repeatedly, so temporary roads are often prepared from it. The slabs and their installation do not require large investments, but they allow you to do the work quickly and efficiently.

This technique has several main advantages:

- Quick installation of slabs;

- There is no need to use heavy equipment to lay asphalt;

- The coating is immediately ready for use;

- Reusable.

How to lay road slabs correctly. Main stages of installation

Initially, you need to choose the right material to use for the masonry. This will prevent rapid wear of the material. It is important that the thickness of the slab is at least 14 cm; the inside must be covered with reinforcement, otherwise the slab will fail very soon. The density of the product should be at the level of 2.2 - 2.5 t/m. Any form can be selected.

For roads, it is desirable that the slab has a slight corrugation, this will provide better grip on the surface even in icy conditions. A smooth surface is ideal for tracked vehicles.

The quality of concrete in the manufacture of slabs is of paramount importance, since it is the main material of the slabs, which must withstand heavy loads.

For Russia, concrete with low temperature resistance class F150 is considered the optimal indicator. Mounting loops are necessary not only for installation, but also for further removal of the coating.

Not only the quality of the material plays a key role, but also the installation method. When performing installation, you must follow the instructions and create the correct platform for the slabs. This will ensure maximum durability and minimal wear on the slabs.

Initially, the soil is prepared for the installation of slabs:

- The top layer of soil must be removed immediately;

- Then everything is leveled to one level using road equipment;

- With the help of special equipment, a trench is dug with a depth of about 30 - 50 cm, it all depends on the bearing capacity of the soil and the equipment that will use this coating;

- To prevent weeds from appearing on the road, as well as to eliminate the risk of soil erosion, geotextiles are installed under the bottom of the trench;

- A mound of crushed stone 10 cm deep is placed on top of the material;

- Another 20 cm of sand is poured on top;

- Next, the sand cushion is filled with water;

- Now the surface is thoroughly compacted. For this purpose, special equipment or a manual vibrating plate can be used. For large areas it is better to use a roller. During the compaction process, it is necessary to control the soil level to prevent the slabs from moving.

Only after careful preparation of the surface can the installation of slabs be carried out.

To do this, based on the size and weight of the coating, you need to have special lifting equipment, which can be rented.

- The slabs are brought to the site and the necessary special equipment is adjusted;

- Next, a cord is stretched, which should create the correct level for laying the slabs; it must be pulled along the side of the road. The use of a cord is mandatory to create an even coating;

- With the help of machinery, the slab is lifted, and workers guide it and lay it along the cord;

- Next, another slab is laid and joined to the previous one. It is important to carry out consistent installation of the coating. Installation may involve the use of gaps or have a one-piece design;

- Sand is poured into the cracks that appear between the elements to prevent the active growth of weeds and to create a cushion between the slabs for a more durable installation;

- To prevent the formation of cracks, expansion is carried out using a wet solution, and a film is applied to the slabs;

- If there is a need for greater strength of the road, it is possible that heavy equipment will move along it or the route is intended for trucks, the coating is strengthened. The easiest way to increase rigidity is to replace the sand bed with cement mortar. An alternative option is to weld the mounting hinges between the plates for structural stability.

The resulting coating can be used for a variety of tasks:

- Arrangement of pedestrian paths;

- Formation of parking lots;

- Creating loaded routes;

- Replacing the permanent road with a temporary one until work is completed on the central one;

- For the movement of special vehicles;

- Formation of an access road to the enterprise.

Laying and compaction procedure

Installation of asphalt on a concrete base.

It is important to carry out the technological process associated with laying asphalt road surfaces according to the instructions. As soon as the concrete solution is delivered or prepared, it is necessary to immediately begin the coating and it is advisable to lay it all at once. Delay is not acceptable; this requirement is one of the main ones in all GOSTs.

If there is a large volume of work to be done, for example, the development of public roads, then it is advisable to use special installation equipment - auto pavers and rollers. However, if the work to be done is small, for example, arranging a sidewalk, then you can get by with mops and shovels. In addition, it is not always possible to compact coatings with even a small roller. In such a situation, the best solution would be to use vibrating plates.

If you plan to carry out the work on your personal yard or dacha, then most likely you will not use the services of special designers. However, this does not mean that you should not follow certain standards for coverage widths. Depending on the type of coating, this indicator varies:

- for paths in the garden, the layer width should be approximately 4 centimeters;

- for driveways, the width should be at least 5 centimeters.

The quality of installation of foundations and concrete depends on the correct execution of technological processes. It is important that the base is done on time and thoroughly compacted. Compaction can be performed using several technologies - using vibration, using a roller and using manual compaction. Specialized techniques may also vary. It could be:

- automated roller;

- manual roller;

- vibrating roller;

- vibrating plate.

According to the requirements specified in GOST 9128-2009, the temperature regime for laying the concrete mixture should not be less than 100C. This temperature ensures better compaction of the formed coating. After all, the lower the temperature in the concrete solution, the harder it is to compact it, and as a result, longer work with the roller will be required. In order to prevent the mixture from sticking to the vibrating plate or other equipment, you must first water them with water.

To ensure that the coating surface is equally smooth, it is necessary to carefully monitor the number of passes of the roller. This number must be the same. To prevent damage to the concrete coating, the roller should not perform reverse movements. If the stages of the technological process are carried out carefully, then asphalting the road surface will not be at all difficult.

Return to contents

Technology of laying asphalt on a concrete base

A detailed description of the technology for laying asphalt on a concrete base is prescribed in various SNiPs, as well as regulatory, technical and legal materials. These documents contain the requirements that apply to each stage of the technological process, as well as measures to control repair work.

The technological process of laying asphalt on concrete includes the following stages:

- preparatory activities;

- cleaning the surface from dirt and dust;

- surface treatment (priming) with bitumen emulsion

- laying the asphalt concrete mixture itself with a thickness of 4-7 cm;

- compaction of the road surface using special equipment.

The list of mandatory preparatory work for the foundation includes:

- removal of vegetation, roots, biological residues, etc. from the site of work to create a public road;

- removal of old asphalt (if the road is characterized by low traffic, it is allowed to lay asphalt on the old surface);

- base compaction;

- treating the soil road layer with a special mixture that protects the future route from deformation;

- installation of a drainage system using sand, gravel or a layer of crushed stone;

- construction work to create access roads to the work site;

- upon completion of work, compact the road surface with a roller and water it with water (to ensure shrinkage of the base).

In order to prevent the appearance of defects in the asphalt pavement as a result of construction work, the technological process imposes additional requirements on the temperature of laying the material: only hot asphalt must be used. It is characterized by increased plasticity and resistance to temperature changes, which allows the use of this technology for laying asphalt in conditions of high traffic intensity, near railway tracks, as well as the creation of various types of roads in places with a continental climate.

According to SNiP requirements, the temperature of laying asphalt must be at least 120 degrees Celsius.

The main condition for laying concrete (according to GOST) is that the entire complex of work must be carried out as soon as possible, while the base must be prepared in advance, and concrete must be poured immediately after receiving the solution.

Depending on the method of compacting the road surface, there are 3 types of laying technology:

- vibration;

- leveling the surface with a roller.

To carry out work on the construction of public roads, the use of special equipment will be required:

- auto stackers;

- skating rinks;

- vibrating plates.

For a small amount of work, for example, arranging a private local area or creating a short sidewalk, manual compaction is sufficient. The new asphalt surface can be compacted perfectly using a mop and a vibrating plate.

To meet all process criteria, it is important to control the number of passes on the asphalt of the skating rink. In order for the coating to be perfectly preserved throughout the entire period of operation, it is necessary to withstand the same number of passes of special equipment.

To properly lay asphalt on a concrete base, a highly qualified work team and a sufficient amount of construction equipment are required. For all types of work, the Transcom company engages only experienced and professional specialists who ensure compliance with the required installation temperature, as well as the sequence of work. In Moscow and St. Petersburg we have special equipment of various brands, which allows us to guarantee high quality asphalt pavement on a concrete base.

Benefits of technology

The technology of laying asphalt on a concrete pavement is characterized by the following advantages compared to other approaches:

- high speed of hardening of the concrete base;

- little time is needed to complete the work;

- easy maintenance of asphalt pavement;

- easy repair of damage and defects of the road surface.

Maintenance of asphalt concrete pavement

Sealing damaged asphalt with bitumen.

If you want the finished road surface to have a long service life and not have to re-concrete everything, you will have to follow some maintenance recommendations.

Heavy equipment or cars cannot be driven on the new asphalt. It is strictly forbidden to drive tracked vehicles on it. Due to its properties, this coating is too soft for such vehicles, and the tracks will leave damage on the surface. In the future, these dents will provoke destruction and the asphalt will have to be repaired or re-asphalted.

This prohibition is especially relevant at high ambient temperatures. This happens due to the fact that in hot weather the asphalt softens even more and is much more susceptible to the negative effects of technology. If defects, cracks or other damage are found on the surface, they should be repaired as quickly as possible in order to prevent further destruction of the road surface.

Return to contents

Coating care

If you want the road to be used for a long time and without minor repairs, remember that proper and timely maintenance is necessary. Heavy vehicles should not be allowed to drive on the new surface in hot weather, or minimize this factor by blocking traffic during the day and allowing passage at night. Under no circumstances should any tracked vehicles be allowed to move freely on the road. Asphalt concrete is too soft for such transport, and the roads are not designed for such a load. When moving, heavy equipment makes dents, so-called ruts, which is why holes and bumps subsequently begin to appear.

In the end, what I wanted to emphasize is that the technological process itself depends not only on the expected volume of work, but also on the location of the installation, what class of road and surface as a whole is expected in this area. Taking these factors into account, we can determine the following: do you need such a strong “cushion” on your site? After all, it is preferable to lay asphalt on a concrete base on public roads and highways, so villages or even garden plots can be a cheaper option.

Laying asphalt concrete on old concrete or asphalt

A base made from old asphalt can also be used. This option is acceptable instead of forming a new foundation with additional financial expenses. Initially, it is necessary to thoroughly clean the old road surface from all kinds of dirt and asphalt fragments. To proceed to the next stage of the technological process, it is important that the base is as clean as possible. If the coating has cracks, they need to be cleaned, slightly deepened and widened.

After this, you need to take the bitumen material and heat it well. When the bitumen has warmed up enough, you can begin further work. Bituminous material is poured along the perimeter of the road surface and thoroughly spread using a special engine. The result should be a strip half a meter wide, but it is important that the edges are well coated with bituminous material. Such stripes must be made over the entire area of the road surface. After this stage, work continues as with standard laying of asphalt concrete.

Return to contents