Concrete columns are strong load-bearing structures, the main task of which is to provide structures with the required level of vertical rigidity and strength. As a rule, they act as part of a monolithic frame of a structure, supporting ceilings, terraces, balconies, etc. or as a decorative element for decorating the entrance group of the facade and building.

Columns can be metal, prefabricated or monolithic; the appropriate type of element is chosen depending on the required characteristics (primarily load-bearing capacity). The main task of the element is to become a support for various structural elements, ensure their vertical strength and evenly distribute the load, eliminate the risk of deformation and destruction, and in rare cases, decorate the interior.

You can install concrete columns for your home yourself. Subject to compliance with all production standards and the use of high-quality materials, the element will exactly meet the requirements and characteristics, effectively performing its assigned function.

Purpose of concrete columns

The element takes on and transfers to the foundation the load from higher structural parts. Reinforced concrete pillars become the support of the floors, connecting the structure between the base and the ceiling surface. The pillar supports a variety of terraces, balconies, porches, ceilings, making it possible to implement any design idea and significantly increasing the service life of the entire building.

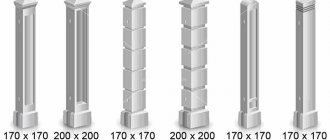

If we are talking about decorative design, then in this case concreting columns acts as a means of decorating the facade and interior. They are often made with column sills, consoles, capitals, decorated with stucco molding, original patterns, and various types of material processing.

Species and types

The shape of a concrete column can be: round, square, rectangular, which is determined by the cross-section of the support.

According to production technology:

1) Prefabricated concrete columns - produced at the factory, transported to the site, relatively inexpensive, provide quick installation, high speed of drying of the solution.

2) Monolithic columns - poured into molds directly on site. It is possible to control the quality of laying the solution and the flow of the mixture. But the production of such structural elements requires a lot of labor and time, and is quite expensive.

When choosing the type of column, it is very important to consider the type of marking of the finished reinforced concrete product of this type.

Column markings:

- T1 – for fixing concrete consoles installed perpendicular to the main columns.

- C1 – for the installation of lattice connections.

- L1 – for the installation of flights of stairs with three flights.

- L - stairs are connected with two flights.

- P - used in places where it is necessary to create a column under a crossbar (installed where there is a rotation of the general frame).

- SS – support with 2-4 edges for high-quality fastening of the rigid walls.

- C - for fastening various panels in contact with the reinforcement walls.

- T – concrete columns at the ends of building enclosing panels.

Making a concrete column

The use of decorative concrete columns must be considered at the design stage. This is done in order to select the correct proportions and materials depending on their purpose.

Stone columns with iron supporting structures can be used not only as architectural decoration. They can be used in a project to support structural elements of a building.

Decorative columns can be different in appearance, of any size and shape. They are made from solid and cast concrete pieces.

Custom-made concrete columns are manufactured in strict accordance with drawings drawn up taking into account the nature of their operation and the features of the project. Finished products are painted with concrete paint. It will need to be periodically updated in the future, as the top layer crumbles and fades over time.

Features of the construction of monolithic columns

Before starting the production of reinforced concrete supports, it is necessary to prepare a flat site, take care of tools and materials, mark and calculate everything, then carry out all construction work. The requirements for concrete mortar are simple - the mixture must be plastic and strong enough.

The shape and cross-section of concrete columns, the diameter of metal rods, and the grade of concrete depend on the volume of load acting on the element (taking into account the dead weight of the support), the climatic characteristics of the region, the number of storeys of the building, and the purpose of the object.

In the construction of a personal building, square supports are usually installed where it is necessary to take the load of the floors and transfer it to the foundation.

Creating monolithic columns:

- Formwork construction

- Installation of a metal frame

- Pouring columns with concrete, ensuring normal conditions for its drying

- Dismantling the formwork after the concrete solution has completely dried and gained strength

Preparation of tools and materials

To perform each stage of work on the production of concrete columns with high quality, it is necessary to prepare the following tools and devices: concrete pump, hammer, building level, rectangular corner, wooden spacers, screwdriver, vibrators, concrete mixer, tape measure.

Materials: metal wire, reinforced mesh or metal rods, screws and nails, wide boards, steel rod, anchors, cement, water, lime, sand.

The concrete mixture is delivered to the site in dry form or prepared according to a recipe: part cement, two parts gravel, crushed stone, sand, water (in sufficient quantity to obtain a homogeneous plastic mixture).

Installation of formwork

The formwork is constructed on four sides of the support, with the required internal dimensions. Boards and moisture-resistant plywood are suitable for work. The panels are leveled vertically and secured with screws or struts and wooden spacers. It is advisable to anchor the struts with support blocks in two directions, which will prevent shifting. Use a corner to check the evenness of right angles.

If it is intended to build a high concrete column, the formwork is made and installed on three sides, and the fourth is built up during the process of pouring the solution.

Many manufacturers offer to buy ready-made structures made of plastic, wood, and metal. Metal ones are usually reusable, quickly and easily assembled/disassembled, and guarantee the correct geometry. Wooden ones are made from bars and boards, but only square or rectangular shapes can be made from them. Round shapes are made of plastic. Disposable ones are made from cardboard; their shape can only be cylindrical.

Reinforcement

To install a concrete column, vertical reinforcement with a diameter of 12 millimeters is used. Typically these are four or six rods located at the corners of a square or rectangle. If the height of the reinforcement is more than 3 meters, create decking steps of 2 meters.

The reinforcement frame is assembled in various ways. If a square monolithic concrete column with low weight and volume is created, the frame is assembled into the future formwork form manually using the turning method. If the weight is large, then the rods are knitted in place, installing the rods separately. The finished structure is mounted using various supports and boards.

The rods in the frame, more than 2 meters long, are fastened together with metal knitting wire in increments of 20-40 centimeters. The capitals should be reinforced with reinforcing mesh.

Concreting

Concrete for pouring is usually made on site, from at least M400 grade cement, gravel, crushed stone, and sand. The mortar used for pouring foundations and monolithic walls is not suitable for the job. A good choice would be concrete with mobility P2 (in private construction), but if a densely reinforced column is being poured (construction of pillars for the construction of a factory, for example), P4 concrete is used.

There are different recipes, here is another one: part sand, 4 parts gravel or crushed stone, 1 part cement. During the concreting process, it is important to ensure that the frame is motionless and in its place. If necessary, the structure is adjusted and installed strictly vertically.

The concreting itself is carried out layer by layer, the thickness of one layer should be 30-50 centimeters, it is poured until the previous layer has set. 5-7 centimeters of mortar are not added to the top of the formwork.

When pouring concrete, be sure to ensure compaction of the mixture: this can be done with a special vibrator or manually, removing air pockets by tapping the formwork with a hammer or by pinning it into the solution with a metal rod. If the columns are more than 5 meters, technological breaks lasting 40-120 minutes are planned for shrinkage.

Dismantling of formwork

The period for concrete to gain strength is 28 days with optimal temperature conditions, plus or minus, depending on environmental conditions - humidity, proper care. On average, the standing period of columns is up to 10 days in the summer, when the side faces and corners are already formed. Only then can the formwork be dismantled. During the drying process of the concrete (28 days), it is prohibited to carry out any work related to the load on the column and its base or nearby parts of the structure.

Construction stages

Pouring columns with concrete implies the following construction stages:

Formwork for columns: shield, anchor, strut.

Reinforcement works

When arranging columns, installation of vertical reinforcement with an average diameter of 12 mm or more is usually used, consisting of 4 main bayonets (rods) placed in the shape of a square (at its main corners). For the convenience of installing reinforcement for columns with a height of more than 3 m, it is necessary to equip scaffolds with a flooring width of more than 1 m with fences within 0.8 m in height every 2 m in height. Frame bases of columns can be assembled in different ways.

With small sizes, volumes and weight, the frame of the columns can be installed in the future formwork box, which is done manually by turning the finished frame structure. If the diameter of the reinforcement is no more than 16-20 mm and it is quite heavy, then it would be more advisable to pre-assemble the base of the frame and then knit it in place, installing separate rods. When placing the finished column frame and its further fastening, all kinds of supports and boards are used.

It is advisable not to stand on their rods during bonding (or welding) work on the installation of vertical column frames. The reinforcing bars are fastened together with special clamps (metal wire) at a certain distance from each other, which is usually 40 cm.

Installation of formwork

In normal cases, a formwork box with the required internal dimensions (for example, 25x25 cm) is assembled. It should be fastened very carefully. The formwork is installed on 4 sides of the prepared reinforced column.

Wooden spacers with stakes are installed on all sides of the column. For large column sizes, the formwork is installed on 3 sides, and the remaining side is expanded during the concreting process. The formwork box (made of boards, plywood, etc.) must be leveled and secured with screws to hold the concrete solution inside. Using a corner, the conformity of right angles is checked.

Concreting

Working with concrete has its own nuances. When casting columns, one of the main parameters is the mobility of concrete. For standard monolithic columns, concrete with a mobility value of P2-P3 is used, and when pouring columns of densely reinforced structures, it is advisable to use concrete with a mobility value of P4 or higher. This type of concrete mixture is also called cast concrete. This type of concrete tolerates the process of laying into formwork quite well, even without the use of various vibrators and concrete pumps. As concrete is poured, it gradually increases.

Concrete is poured in equal horizontal layers, always laid in one direction. As the formwork is filled, the concrete solution is carefully compacted. You can compact the concrete mixture yourself using a metal rod. External or deep vibrators are used to compact the concrete mixture. At home, periodically tapping the exposed formwork with a hammer will help get rid of excess air bubbles in concrete. When carrying out the process of concreting columns, it is necessary to constantly monitor and adjust the reinforcement cage so that it is placed in the center.

The poured concrete mixture can consist of M400 cement (1 part), sand (2 parts), gravel or crushed stone (with a fineness level of at least 20 mm in a volume of 4 parts) and water until a homogeneous mass of the required consistency is obtained. After concreting the columns is completed, reinforcement is attached to them using anchor bolts.

Removing formwork. The formwork structure is disassembled after the concrete has reached its final strength.

We should also not forget that in order to achieve its properties, concrete requires special care, which involves creating optimal drying conditions and humidity levels.