- 1 What is it? Compound

- 2 Advantages and disadvantages

- 3 Types

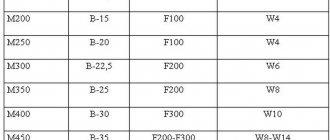

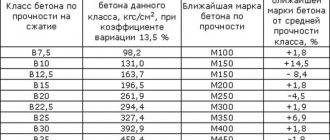

- 4 Explanation of markings

- 5 Brands and applications

- 6 Manufacturing methods

- 7 Large manufacturers

- 8 Conclusion

Concrete mortar is used in all types of construction. It may have different properties, depending on the purpose for which it is made. More often, the solution is mixed at the construction site, but in order to achieve maximum strength of the concrete structure, it is constructed from a factory-made material called ready-mixed concrete.

What's happened? Compound

Ready-mix concrete is a solution made at a factory and delivered ready-made to the construction site. This function is assigned to concrete mixer trucks, which have the necessary equipment that allows them to transport ready-to-use mixtures to any distance and terrain. It is also called BSG - ready-mixed concrete.

This solution is obtained by mixing the components in the required proportions:

- cement;

- water;

- sand;

- crushed stone

The proportions of the constituent components depend on the desired result. Various additives can also be added to BSG to improve the properties of the concrete solution. This mixture differs from the material prepared on site in that production is constantly monitored: from the preparation of materials to the transportation of ready-made concrete. To determine the required recipe, not only the knowledge of trained personnel is used, but also precise technology.

Factory workers change the composition during the production process depending on the specific properties of the components. The main components are water and cement. They provide the viscosity of the solution and make it monolithic. To ensure the correct water-cement ratio, it is necessary to take into account not only the amount of water and cement, but also factors such as the moisture content of sand and aggregates.

Return to contents

What is ready-mix concrete and mortar?

Ready-to-use cement-based mortar is required at any construction site in large quantities. You can use an electric concrete mixer or a hand tool to mix it in batches as you go. But this method is too labor-intensive when it is necessary to fill foundations, screeds, blind areas, and large-volume platforms. In this case, it is much easier, more convenient and more profitable to order ready-mixed concrete (which does not require mixing and is ready for use) with delivery to the site. Our company offers ready-mixed concrete of ten grades.

The same applies to building cement mortars - when constructing multi-storey brick buildings, regular mixing of masonry mortar in small portions is not beneficial. By ordering a ready-made mortar machine, you can carry out masonry work much faster.

The ZhBI-4 plant offers the preparation of four grades of mortars:

- M-100,

- M-150,

- M-200,

- M-300.

Advantages and disadvantages

Pros of use: high quality product. In order to obtain the same high-quality product at the construction site, you must:

- protect aggregates from dirt;

- maintain the required temperature;

- strictly observe the proportions of the components;

- constantly monitor the process of mixing the solution;

- use only high-quality components;

- Follow the order of adding components.

The disadvantage of using ready-mixed concrete is the price.

Return to contents

What it is

This mixture is prepared at the factory and transported to construction sites using concrete mixer trucks. To produce this composition, the following components are used:

- cement;

- water;

- sand;

- crushed stone

The proportions depend on the desired result. It is possible to add other substances that improve the characteristics of the solution. The quality of this mixture is superior to that prepared on site, since all stages are controlled: from production to transportation. We use precise recipes, special equipment and qualified workers.

To change the properties of the composition, various combinations of components (especially cement and water) are used. These substances provide the viscosity of the solution and make it monolithic. In addition, indicators such as the moisture content of sand and aggregates should be taken into account.

Kinds

Ready-mix concrete is also classified by filler.

Ready-mix concrete is classified according to the following basic properties:

- aggregate;

- material structure;

- cement density;

- required strength.

These characteristics divide concrete into:

- lungs;

- heavy: regular; especially heavy;

- special purpose.

Return to contents

Explanation of markings

The brand indicates the average strength, and the class indicates the strength with a coefficient of variation. The production of ready-mixed concrete must take into account the markings, which indicate the properties of concrete: strength - B; frost resistance – F; hardness – F; water resistance – W; mobility - P. Exact data about each brand is regulated by GOST. Grade M means maximum compressive strength of the material. Mobility (P) varies from 1 to 5:

- 1-2 – dry concrete, for delivery of which a dump truck is used;

- 3-4 – used for pouring monolithic structures; a concrete pump is used for casting;

- 4-5 are often manufactured in factories with the addition of plasticizers. Although mobility can be increased by adding water, using additives is a more economical method.

Frost resistance (F) is measured in the range of 25-1000, which determines the number of defrosts - frosts, from which the quality of the structure does not deteriorate. Water resistance (W) is measured from 2 to 20. The lower the class, the worse the level of water resistance.

Return to contents

How the marking is deciphered

By brand is meant the average value of strength, and by class is the strength with coefficients for variations. Concrete manufacturers must take into account the markings used to indicate concrete properties:

- “B” – strength indicator;

- “F” – frost resistance;

- “F” – degree of hardness;

- “W” – moisture resistance;

- “P” – degree of mobility.

By the way, the exact information about each brand is determined by GOST.

For example, you can often hear the question, what is ready-mixed concrete P3? This means that the mixture belongs to the third group in terms of mobility. The value can vary from 1 to 5:

- 1 – 2 – dry concrete mixtures. Dump trucks are used for their delivery;

- 3 – 4 – such compositions are poured into monolithic structures using concrete pumps;

- 4 – 5 – in most cases, the production of such compositions involves factory conditions. Plasticizing components are added to the mixture to increase the degree of mobility. This is much more economical than using ordinary water for such purposes.

Resistance to low temperature conditions is indicated by the range 25 – 1,000, which indicates the number of freeze-thaw cycles during which the quality characteristics of the structures do not decrease. Moisture resistance is measured by parameters from 2 to 20. The lower the class, the worse the level of moisture absorption.

Brands and applications

- M-100. The solution is used in preparing the construction of monolithic load-bearing structures and laying floors on the ground. Ready-mixed concrete is designed to protect against leakage of the cement mixture from the load-bearing structure, this allows the structure to maintain the required strength. Concrete is laid by pouring and delivered by concrete mixer trucks.

- M-150. Used for preparing floor screeds, for laying concrete sidewalks, strip foundations, and monolithic slabs.

- M-200. Most often used in the construction of low-rise buildings, prefabricated reinforced concrete structures, pouring foundations, and building road surfaces.

- M -250. Belongs to class B-20. It is used in casting staircase blocks, laying monolithic foundations, and building fences and sidewalks.

- M-300. Used in the construction of road surfaces, collector systems, strip and slab foundations. The above brands are made using crushed stone from gravel, lime or granite.

- M-350. Ready-mixed concrete is used to cast blocks of load-bearing walls, columns and floor slabs, and to lay a monolithic foundation. Crushed granite or gravel is used as filler.

M-400. To produce such material, crushed granite stone, plasticizers and other additives are used. This is high-strength concrete, from which bridges, bank vaults and other structures are made that must have additional stability.- M-450. The solution is used for the construction of structures that are constantly subject to static and dynamic loads (for example, hydraulic structures). The material hardens quickly, which is why additives are used in production to slow down this process. This is done so that it can be used in large volumes of work.

- M-500. The material has a high level of strength, which allows it to be used in hydraulic engineering and in the construction of other premises with high stability requirements. Plasticizers and crushed granite are added to this solution.

- M-550. It is used in the manufacture of prefabricated reinforced concrete structures with high load-bearing qualities, most often in industry.

- M-600. Used in the construction of particularly complex structures.

Return to contents

Technical characteristics of ready-mixed concrete

The nominal weight of a cube of concrete is 2400 kg.

Main technical characteristics:

- M – brand. The value is measured in megapascals, kgf/sq.cm. Indicates the compressive strength of a hardened material. Designated as M 100, M 200, etc.

- B – class. Shows strength while providing a coefficient of variation.

- F – frost resistance. The number of freezing/thawing cycles is 25-1000.

- P – mobility, cone settlement, workability. Coefficient - 1-5. Designates dry mixtures (P1, P2) with a cone draft of 1-4, 5-9 cm, as well as P3, P4, used in monolithic, large-scale construction. They increase the coefficient by adding water, but then the grade decreases. In production conditions, an increase to the P5 level is achieved by introducing chemicals. additives that do not harm the rest of the mixture.

- W – waterproof. It fluctuates between 2-20.

Manufacturing methods

The exact composition of the solution is determined by the desired properties. For example, to make M-200 concrete, you need to use M400 cement in the proportions 1 cement: 3 crushed stone: 5 sand: 0.5 water. If you take a different cement, you get a different class of concrete. The water-cement ratio in concrete is maintained in the range of 0.3-0.5. When making mortar on a construction site, this is where mistakes are most often made, which reduces the strength of the material.

All the necessary components are mixed in a concrete mixer for 120 seconds at the highest speed.

Return to contents