A shower stall is a necessary element of modern life, especially in small spaces. Sooner or later there comes a time when the structure needs to be dismantled due to upcoming repairs or relocation. The process may seem laborious, but there is a detailed guide that answers the beginner's question - how to disassemble the shower stall yourself.

By dismantling it yourself, you can save a lot of money and also be confident in the proper quality and accuracy of the work done. Proper dismantling guarantees trouble-free re-installation of the device.

On the Internet you can find many examples of video files that describe in detail the process of disassembling a shower stall.

Assembling a shower cabin with your own hands

Shower cabin assembly

Now let's try to assemble the shower cabin with our own hands. The kit includes instructions for assembling the shower cabin.

Everything is clearly described there. But there are manufacturers who provide little information.

Therefore, here are some tips for installing a shower cabin:

- find a spacious place where you can assemble a shower stall;

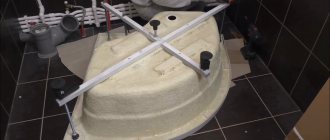

- first the shower tray is installed;

- adjust the tray horizontally using a level, twisting the legs;

- When installing, use sealant;

- After installing the shower tray, install the side walls;

- the side walls are attached to the rear using bolts (two or more);

- after installing the side walls, install the shower panel;

- the shower panel is attached to the side walls using self-tapping screws;

- then the frame is placed on a pallet;

- we fix the back walls to the walls of the bathroom using sealant;

- after this the roof is installed;

- the roof is fixed with self-tapping screws or bolts;

- then we install the doors.

There are showers with Turkish, Finnish bath and tropical shower functions. These shower cabins have a steam generator and a fan.

The steam generator provides the sauna with the required temperature. When the temperature rises above the required level, the steam generator turns off.

Thus, the cabin overheating protection function is activated. Some steam generators have the function of purifying water from lime deposits.

Some cabins turn off the steam generator when there is insufficient water. The fan serves to distribute steam evenly in the shower stall. And also to remove this steam from the cabin.

It is best to entrust the electrical part of the installation to a qualified electrician. Connect an FM/CD player in any convenient place.

Test and then connect on site. It should be mentioned that the shower stall requires separate electrical wiring, as do the air conditioner and water heater. This can only be entrusted to a professional. Thus, the electrical part of the shower stall is connected.

We looked at the design and installation of a shower stall. Go ahead.

Broken door rollers - how to solve the problem?

Failure of rollers is a key reason for the cessation of normal operation of doors. Small parts carry a lot of stress, so breakdowns happen often. If the rollers creak or the box doors begin to jam, parts need to be replaced.

When purchasing spare parts, you need to pay attention to the diameter of the wheels. In this case, the difference in size should be no more than 5 mm. It is also necessary to have other information: the width of the groove, the distance at which the box door moves inward. If you want to purchase high-quality rollers, give preference to products made of brass or stainless steel. Replacement of wheels is carried out as follows:

- dismantling doors;

- removing the rollers - to carry out this process you will need a Phillips screwdriver and pliers;

- at the next stage, new parts are installed and the fixing nuts are tightened;

- door installation;

- adjusting the rollers - how well this process is carried out determines the tightness of the sashes and the ease of their sliding along the guides.

Repairing shower cabins with your own hands (replacing rollers) is a simple job that any man can do. If you want to protect yourself from future breakdowns, you need to treat the wheels with an anti-corrosion agent. Then they will not rust when exposed to water.

Video: quickly repairing a roller in a shower stall

A few words should be said about the fact that any metal parts of the booths are covered with rust. If you find a damaged area, follow these steps:

- sanding the area affected by rust;

- auto putty treatment;

- cleaning the treated area;

- degreasing the surface - acetone and ammonia are suitable for this purpose;

- painting damage - spray paint is used.

Instructions for dismantling the cabin

First, let's figure out what elements the shower consists of:

- Side strips and door;

- Pallet and frame.

Let's look at how to disassemble a shower stall yourself.

Doors

According to the design, the doors are hung on rollers, which are inserted into the guide. In order to remove them, loosen the screw on the top roller, since it is this that regulates the height of the door, and by tightening this element, the roller is fixed in the guide.

Next, we also remove the roller from the lower guide, and the door will be fixed only to the upper moving element. They lift it up and take it off. The door is quite heavy, so it is better to ask a friend for assistance.

Panels

Let's look at how they are attached to the frame. Fastenings are made with special elements. On one side, it is attached to the body panel, and on the other, it is pressed against the central pillar.

Having loosened all fastenings, carefully press the glass inside the booth. This process can be complicated, since the slots on the screw head will be torn off, and it will become impossible to unscrew it, but to do this, move the stand to the side and release the panel on one side

During the operation of the structure, gaskets and seals stick to the metal, so they are cut out using a knife.

Frame

The screws that secure it to the wall are unscrewed. Using a knife, cut off the silicone. The frame is removed with the panel (made of glass) and laid on the floor. The design of the shower stall assumes that the slats located on the sides consist of two parts. One is attached to the wall, and the second is a frame. The guides are dismantled and the screws located under them are unscrewed. After this you receive the following details:

- Lower and upper arches;

- Guides (slats) - 2 pcs;

- Central pillar;

- Frame strip - 2 pcs.

Pallet

If it is on legs, then dismantling it is quite simple. But if it is located in a screed, then this will be more difficult to do. They also take into account the fact that the area around the pallet is most often finished with ceramic tiles or mosaics and therefore this work is entrusted to specialists.

But if you decide to complete the work without calling professionals, then tear off the protective tape around the entire perimeter of the pallet and remove the silicone, then tear the pallet off the frame.

To release it from the screed you will need a bump stop. After completing this work, remove any remaining silicone and glue.

Let's look at how to disassemble a shower head yourself. I would like to note that this process is easy, since you need to unscrew the bolts and clean it of lime deposits. But you can clean it without disassembling it. To do this, bring the water in the pan to a boil, add ½ teaspoon of citric acid to it and lower the nozzle into it and keep it there for several minutes.

As you can see from the article, dismantling a shower is not such a difficult task, the main thing is to follow the instructions and then there will be no difficulties. But if you don’t dare to do this work yourself, then call specialists.

Do-it-yourself shower stall: solving the issue with the tray and side walls

In fact, this type of shower cabin does not need a tray - the water is simply poured onto the bathroom floor and removed from it through the so-called drain. It is for this reason that the very first thing that needs to be done in the bathroom where such a shower cabin is supposed to be installed is high-quality waterproofing of the floor. This point especially applies to apartment residents - water cannot be given a single chance to penetrate to the floor below. In addition, it is still necessary to prevent the penetration of moisture into the walls adjacent to the shower - they also need to be properly waterproofed to at least a height of 2 m.

The floor is completely cleared of old screed, then waterproofing is done from scratch, it is laid in at least three layers. It will be enough to cover the walls with bitumen mastic. Next, the shower cabin drain is installed and screed is poured over the entire area of the bathroom.

How to make a shower with your own hands photo

Now let's talk about the pallet. For its manufacture, brick is used and it is created together with the adjacent walls. Essentially, making a shower stall with your own hands involves building a small fence to prevent water from spreading all over the floor of the bathtub. In this regard, it is much more convenient to make such a cabin in the corner of the room - for this you only need to lay out one wall and a small parapet 10 cm high. For these purposes, it is better to use brick - this approach to the matter will be cheaper than constructing structures from plasterboard. And most importantly, you will get a fairly strong and reliable design.

How to make a shower tray with your own hands photo

And again we return to waterproofing the floor. Only now you need to create it directly inside the shower cabin. The principle is the same - first bitumen mastic, then two, or better yet three layers of modern rubberized material. You can, of course, do it the old fashioned way, completely plastering the internal surfaces of the resulting room with cement-sand mortar with the addition of liquid glass. If you decide to make waterproofing from modern materials, then on top of it (on the floor) you will need to pour a screed with a thickness of at least 50mm. Do not forget about the slope of the floor - you will need to direct the water flowing down it straight into the drain.

DIY shower cabin: tray

Do-it-yourself disassembly and disconnection from communications

To ensure dismantling takes place without the help of a specialist, follow these steps:

| Type of manipulation | Progress | Note |

| Power outage | Disconnect the power cable from the device | It is strictly forbidden to skip this point! De-energizing the cabin will make further work safe. |

| Disconnecting the cold and hot water supply hose | Tighten the valves on the cold and hot water supply pipes, disconnect the liner | It is not necessary to remove the shut-off valves: it will be useful for installing a new cabin |

| Disconnection from the sewer | If a siphon was used, remove the corrugation; if an adjustable tee was used, unscrew the clamps and threaded connections. |

At the end of the first stage of dismantling, disconnect the small elements of the shower cabin located inside the device: control panel, mirrors, shelves, towel holder, mixer and other accessories. Before starting disassembly, make sure that the initial stage of work is completed in full.

Photo 1. This model of shower cabin has many electrical elements, so the first step when dismantling is to turn off the power.

Disassembly instructions: how to remove the apron, doors and control panel

The next step is to dismantle the cabin itself, the sequence of actions is:

Treatment of joints and joints with a special agent to remove sealant. It can also be cleaned with a utility knife, but traces of silicone will not be completely removed. It is more convenient to use a special product that will gently and effectively remove excess from the seams.

Important! The product is active for 15 minutes. If the work is not completed within this period, it must be applied again.

Removing doors. The movement of the doors is carried out using rollers. To dismantle, loosen the upper rollers by lifting the door leaf up, remove it from the lower guides, and remove it from the upper guide. The door leaf is heavy, it is advisable to carry out the work with an assistant.

Important! The doors are removed from the inside, so when removing them, watch the edges of the door so as not to scratch the internal surfaces. Removing the side panels

Fastening the panels to the frame is simple: on one side they are inserted into the wall strip of the general structure, on the other they are pressed against the central post. It is held in place at the top and bottom using fasteners, with the removal of which the dismantling of the panels begins. Hold the panel and remove the screws that secure the stand. Then move the stand itself, releasing the panel

Removing the side panels. Fastening the panels to the frame is simple: on one side they are inserted into the wall strip of the general structure, on the other they are pressed against the central post. It is held in place at the top and bottom using fasteners, with the removal of which the dismantling of the panels begins. Hold the panel and remove the screws that secure the stand. Then move the stand itself, releasing the panel.

Important! Try not to press too hard on the glass while working. This may cause damage to the material.

- Dismantling the frame. To begin, unscrew the screws, unfasten the planks from the walls, and remove any remaining silicone. Next, remove the upper part of the structure, and then the entire frame from the pallet, gradually unscrewing the screws.

- Removing the pallet.

Let's consider several options for pallets and dismantling methods:

| Pallet type | Dismantling method | Note |

| Tall, on legs | Removal by unscrewing fasteners. | Low degree of complexity; with careful work, the parts retain their original appearance. |

| Short |

| The difficulty lies in the impossibility of keeping the pallet in working condition. |

Dismantling shower cabins with different tray heights has a lot in common. A distinctive feature of this procedure is the presence of an apron (decorative screen) on the pallets on legs, the disassembly of which is best left to a specialist.

Mixer

There is a separate review on faucet repair. In order not to duplicate information, we will simply mention that most of the structures can be disassembled without dismantling them from the back wall of the shower stall. Inside there is a replaceable cartridge, which is usually the cause of all the troubles. The product is disassembled and the mechanism is lubricated with a silicone compound.

Shower box mixer

Procedure

Precise adherence to the procedure allows you to avoid common mistakes. Having started disassembling the structure, you need to carry out each stage correctly, adhering to the standard instructions.

Removing the door

Most types of shower cabins have the same design, and the doors move on special roller mechanisms placed in guides. Removing the doors requires first loosening the screws holding the rollers on the top. After unscrewing the screws, remove the lower rollers from the guides by slightly lifting and pulling out the door. For convenience, it is better to carry out this manipulation with an assistant, since a large door can be difficult to lift and hold on your own.

Removing panels

Glass or plastic panels are fixed to the frame on both sides using fasteners. If the panel is located close to the wall, then it is secured to the side with racks or strips. When removing the panels, remove the fasteners from both sides, then hold the panel and unscrew the screws holding the stand. Having moved the part, remove the panel and lightly press down the glass or plastic to pull the material out of the side groove and completely remove the panel. Following these instructions, remove all side panels.

It is important to consider that in some situations the process of removing panels can be problematic due to the presence of silicone seals. As a result of prolonged use of the shower cabin, the seals are firmly held on the glass and plastic components of the sanitary equipment

When faced with this problem, you need to carefully cut the seals using a wallpaper knife.

Frame disassembly

To dismantle the frame, separate the planks from the walls by unscrewing the screws, then remove traces of silicone by treating with a solvent and scraping with a knife. Next, you need to remove the upper part of the frame, which will make it easier to carry out the rest of the work. The frame is removed from the pallet and all screws are unscrewed for comprehensive dismantling.

Removing the pallet

When disassembling a pallet, there are two options depending on the features of the original assembly. If during installation the pallet was placed on a brick base, then dismantling it will not be particularly difficult. When the pallet is mounted directly into the floor, some effort will be required to disassemble it. It is easier to dismantle a tray with high edges. The sequence of actions for dismantling is as follows:

Remove protection and sealant residues by applying a solvent. Carefully try to pull out the pallet. It is important to be careful, since the plastic element can be easily damaged. If you cannot remove the pallet by hand, use a pry bar to lift it. After pulling the pallet out of the screed, traces of glue, silicone and other building compounds are cleaned from its body.

How to disassemble a watering can

The need to disassemble the watering can may arise if the structure becomes clogged. First, the watering can is disconnected from the hose, and if the components are new, this will not require any effort. If the structure is rusty, then it is better to use a wrench to unscrew it. Then remove the plug from the central part of the watering can by prying it off with a sharp knife. After removing the plug, access to the screw will be available, which needs to be unscrewed with a screwdriver. If a large amount of deposits has accumulated on the surface of the screw, then first clean the recess with a blade. After unscrewing the screw, disconnect the mesh from the body.

Problems that should only be solved by a specialist

Despite the fact that many breakdowns can be fixed on your own, in some situations, repairs and maintenance of shower cabins should be carried out by a professional technician.

You should not repair the shower stall electronics yourself. If problems are detected in the operation of this unit, it is better to invite a professional technician. If the warranty period of the cabin, which is confirmed by a receipt and a package of attached documents, has not expired, then the repair will be free. After the warranty period expires, it is recommended to contact companies that specialize in repairing plumbing equipment to troubleshoot the shower stall.

A specialist must also change the glass parts of the booth, its tray, as well as complete installation and dismantling of plumbing fixtures. Without appropriate experience and knowledge in this area, you can waste a lot of time and effort.

If the shower stall suddenly breaks down, then if a repair problem arises, first of all you need to study the prices for the problematic parts.

There are situations when complete replacement of one or another element is much cheaper than restoration work. In conclusion, it should be noted that the operation of a shower cabin requires the constant presence of high humidity, sudden changes in temperature, and regular mechanical stress. In addition, tap water is not clean, even after passing through filters. Regular preventive cleaning, ventilation of the room and quality control of the supplied water will ensure the flawless operation of a simple shower stall or an expensive hydromassage box, as well as avoid problems associated with repairs.

Cleaning products

To clean the head of a regular or more difficult to clean rain shower on your own, you can use:

- special chemicals;

- folk remedies.

Application of chemical compounds

How to clean a shower sprayer from limescale and scale deposits? The easiest way is to use household chemicals, which differ:

- speed of cleaning;

- absence of negative impact on the body and other structural elements;

- efficiency.

The most popular means are:

- Cillit Bang;

- Toilet duckling;

- Mister Muscle;

Lime remover

Cleaning of scale and lime using household chemicals must be carried out in accordance with the instructions indicated on the packaging and in compliance with all safety rules.

Folk remedies

How to clean the inside of a watering can in the absence of specialized products? You can use traditional methods, among which the following are popular:

- vinegar. To carry out the procedure, use 7% vinegar. The use of essence is prohibited, as it negatively affects the body of the plumbing fixture. Cleaning is done as follows:

- the solution is prepared;

- all elements of the watering can are immersed in the solution for 6 – 10 hours (can be left overnight);

Using Vinegar

The elements are washed with running water.

For greater efficiency, the vinegar solution can be periodically heated to a temperature of 55° - 60°C.

- lemon acid. Cleaning is carried out according to a similar scheme. For full effect, it is enough to soak the watering can in the solution (1 sachet of citric acid is required for 1 liter of water) for 2 – 3 hours;

Technology of using citric acid

- a solution of soda, ammonia and table vinegar. For 1 liter of water you will need 3 tablespoons of soda, 350 ml of 9% vinegar and 150 ml of ammonia. For quick effects, it is recommended to heat the prepared solution to 60°C. Cleaning time ranges from 40 minutes to 1 hour;

- oxalic acid. In extreme situations, with a high degree of contamination, cleaning can be done using a solution of oxalic acid, which is purchased at a pharmacy. To prepare the solution you will need 1 liter of water and 2 tablespoons of acid. Processing time is 20 – 60 minutes.

Aggressive cleaning agent

When cleaning plumbing equipment by any means, it should be carried out exclusively with rubber gloves, since acid and other active substances can damage the skin of your hands.

After complete removal of contaminants, reassemble in reverse order.

When assembling, it is important not to forget to install all the O-rings and, if necessary, seal the connections of the shower head with the shower hose

To ensure that cleaning of plumbing equipment does not take much time, it is recommended to carry it out once every 6–8 months (if filters are available) and once every 4–5 months if such equipment is not available.

Disconnection from communications

The process of independently disconnecting the shower stall from the water supply system and electrical network will require special attention. The sequence for disconnecting a multifunctional plumbing device from communications is as follows:

- disconnecting the structure from the electrical network;

- turning off the hot water supply taps and the cold water system;

- disconnecting flexible hoses and water supply connectors;

- disconnecting the shower hydrobox or stall from the sewer system;

- disassembly of additional components, represented by shelves, dispensers and towel holders.

Cabin disassembly process

At the next stage, the control taps for cold water supply and hot water supply are closed, and the filling hoses are also unscrewed. If it is intended to connect a new multifunctional plumbing device, then taps and tees are not removed. The conclusion of disconnecting communications is to disconnect the shower stall from the sewer system.

Using a double siphon when installing will require removing the drain pipe from the siphon part. Installing the system using an adjustable tee is more complex, so disconnecting involves unscrewing the clamps and threads.

Review of common breakdowns

Economical shower cabins with a minimum of functions or expensive hydromassage boxes are designed for daily hygiene - taking a shower.

Some of them can be used as a bath. These are complex devices consisting of many parts. There are a lot of modifications of boxes: from open ones, reminiscent of a regular shower with protective partitions, to closed, sealed and stuffed with electronics.

Image gallery

Photo from

The simplest version of a shower stall

Model with plastic tray

Inexpensive shower cubicle 90*90

Shower hydrobox with a set of additional functions

Both simple models, built with your own hands without a traditional pallet, and complex factory designs break, but some of the problems are common. For example, any of the presented cabins may have a cracked protective screen or a faucet that may fail.

List of breakdowns that users of shower boxes most often encounter:

- wear of the ladder or water seal installed under the bottom;

- deformation of the pallet or the appearance of cracks on its surface;

- mechanical damage to doors or protective screens;

- damage to door rollers or hinges responsible for opening;

- failure of shower equipment - watering can, hose, mixer.

In complex electronically controlled models, electrical parts may break or software failure may occur.

Only specialists can deal with electronics on their own; broken glass, a drainage device or a deformed shower tray are best replaced, but minor damage can be repaired yourself.

For example, even an amateur can repair rollers, restore a pan, clean a plumbing filter, or remove scratches on a plastic screen.

The cabin is leaking - what to do?

Incorrect installation

In most cases, the cause of leaks lies in improper installation and poor quality of seams. To eliminate the problem, it is necessary to carry out work to seal the components. This process goes as follows:

- The old sealant is removed from the cabin - a sharp knife is used for this. You need to act as carefully as possible, trying not to scratch the surface;

- dismantling the cabin frame - components are washed with soapy water, dried and degreased with a solvent;

- at the next stage, a new sealant is applied;

- a few minutes after applying the composition, you can begin assembling the structure;

- at the final stage, the joints are once again treated with sealant, and the excess is wiped off with a dry cloth.

When taking hygiene procedures, water splashes onto the walls and other elements. As a result, if not properly maintained, limescale deposits appear, the seals lose their elasticity, crack and begin to leak water. To prevent this from happening, you need to regularly use special care products. Then repairing shower cabins with your own hands will not interest you.

Preparation for dismantling

To disassemble the equipment, you do not need complex tools; you should only find the following devices and tools in advance:

- sharp knife with a thin blade. If you have a wallpaper knife, use it;

- screwdrivers of various sizes;

- keys (adjustable and plumbing);

- solvent for silicone sealant. You can also use gasoline.

During all work, be careful and careful. Carry out manipulations without haste, because if you do everything correctly, then minimal marks will remain on the parts, which means you can install the cabin in the country or even offer it on the secondary market, even at a discount.

Leak test

Checking the tightness of the connection is carried out in a state that has not yet been reassembled. You first need to fill the pan with warm water after it has completely dried. The device is placed on the floor covered with some kind of fabric or paper, this makes it easier to see whether moisture remains. If it is not there, then you can proceed to the second test - filling it with ice and hot water. If the pan reacts normally to water of different temperatures, then you need to check its exposure. It is necessary to stand in it, walk around, that is, apply the maximum weight with which they will act on the plumbing.

Preparatory work

repair work updating the layer of waterproof sealant

If, when assembling and connecting particularly technically complex structures, the help of qualified specialists may be required, then it is quite possible to disassemble such a device yourself, using the most minimal, traditional set of working tools.

The standard tools required for dismantling include a sharp construction knife, a set of screwdrivers or a screwdriver, as well as a softening agent for subsequent removal of the sealant.

Before proceeding with dismantling, it is necessary to clean all surfaces of the shower stall with special detergents, drain the water, and also wipe the structural elements dry with a soft and clean rag.

Malfunction of rollers on sliding curtains

Another common breakdown is the malfunction of the rollers on sliding curtains (doors). This causes creaking, jamming of doors and their difficult opening, which leads to the impossibility of normal functioning of the cabin. There is only one way out - their immediate replacement.

Important! High-quality rollers are made of stainless steel or brass.

To replace faulty rollers with new ones, you must:

- Carefully remove the sliding curtains.

- Remove the broken rollers using pliers and a screwdriver.

- Install the purchased parts, adjust the nuts.

To replace the roller you need to select a part of the appropriate size

- Install sliding curtains.

- Check the functionality of the new design elements and the quality of the craftsman’s work.

Important! To prevent corrosion of metal elements, it is necessary to treat them with a special substance that will resist the formation of rust.

How to properly disassemble and clean a shower head

Before you begin repairing a failed device, you need to prepare some tools:

- gas key;

- a pin wrench that should have come with the watering can;

- Phillips screwdriver.

There is such a set in almost every apartment, so there shouldn’t be any problems finding the necessary things.

Note! Be extremely careful during assembly and disassembly

The watering can consists of a large number of small parts that are easy to break or lose due to carelessness

After all the tools are collected, you can begin the process of disassembling the shower head. Algorithm of actions:

turn off the water in the shower; turn off the shower mode on the tap; unscrew the nut that connects the watering can to the hose; carefully inspect the water diffuser panel, marking the mounting points. Usually there are no more than 5 of them, and they are located in special recesses in the body; unscrew the connecting elements using a special key supplied with the watering can. If you don't have one, pick up a pin wrench from your home tool kit. If you don't have a pin wrench, regular scissors or a knife will do; the unscrewing process can be started with any screw, the main thing is to do it sequentially, clockwise; once the top cover of the shower head is removed, you will have access to the swirl box, which is attached to the back of the shower head with a screw; take a Phillips screwdriver and unscrew the screw; Next, it is necessary to carefully dismantle the movable dividers and partitions designed to disperse the water flow. This should be done carefully so as not to lose or break fragile parts; take out the swirler; we take out the spring responsible for switching the water pressure dissipation mode, if it is provided for in the design

Perform this operation carefully so as not to stretch or tear the part.

If the swirl box is secured with latches, it is not recommended to open it yourself

The latches are extremely fragile and will become unusable with any careless movement. It is not possible to restore them after a breakdown

In order to clean the insides of the watering can from plaque, you are allowed to use:

- Vinegar solution. We take a container for soaking clogged parts and pour 200-300 milliliters of 9% vinegar into it. We dilute with water and lower the parts of the watering can into the resulting solution. It is necessary to soak for at least 10 hours, otherwise the result will not meet your expectations.

- Lemon acid. Dilute citric acid in warm water and lower the disassembled watering can into it. We wait 30 minutes and remove the parts outside. We wash them in water and wipe them dry with a cloth.

Watering cans, hoses

We see no point in repairing watering cans, and hoses for a thousand rubles are available in any store (except general stores). It's easier to buy than to repair. Watering cans are mostly collapsible. Either the entire perforated section as a whole is unscrewed, or there is a screw in the center protected by a plastic plug. As a rule, watering can repair is possible in all cases. If it leaks, small cracks are sealed with silicone sealant. This will once and for all make it impossible to get inside the watering can, but such a need does not happen often.

Reassembly is not difficult. Please note that the body of the watering can is firmly attached to the threaded connection, and it is not easy to disconnect it from the hose. Avoid using the gas wrench directly to avoid breaking the fragile plastic. After removing the perforated section of the watering can, you can clean it with a thin wire. This significantly improves the passage of water.

The cost of a new watering can starts from 1,500 rubles. Once in your life you can buy one for your combined bathroom when you get to the local regional center.

Additional tips and tricks

Plumbers insist that absolutely not all breakdowns can be repaired. In many cases, especially if we are talking about a pallet from a low price category, which is made of practical but short-lived acrylic, it is easier not to waste time, but to immediately buy a new copy. But if the pallet is quite expensive, and the cracks themselves can most likely be eliminated, then it makes sense to do repairs using expensive adhesives.

Also recommended:

- Carefully select products for cleaning and degreasing the tray.

- Carry out work only in a ventilated area.

Use the device when completely dry. For branded adhesives this period is about 1-2 days.

Share link:

Why is the drain leaking and what to do?

Causes:

- Error during installation: joints were installed incorrectly, sealant was applied poorly.

- Formation of a crack in a plastic pipe due to improper cleaning during repair or installation.

- A gap appears at the top of the drain after prolonged use. Unfortunately, the plastic device is not very durable, and after prolonged use, the top part may become loose and begin to leak water.

- High pressure on siphon joints due to blockage. If a blockage has formed and there is a large amount of water in the pan, then due to the high water pressure in some models, the joints may begin to leak water.

If the drain begins to leak, then a complete replacement is not always the only way out. Repair will help solve the problem.

First you need to find out where exactly the leak is occurring. If cracks are found, it is recommended to use an adhesive bandage to eliminate them:

- Turn off the water and dry the damaged area with a hairdryer.

- Take a thick material for the patch. This could be a piece of rubber or plastic.

- Using epoxy glue, glue the patch to the damaged area. Dry.

Important! After gluing the pipe, you cannot use the shower stall for 24 hours. If water leaks at the joints of the siphon, then it must be carefully disassembled, cleaned, and a new sealant applied.

If water leaks at the joints of the siphon, then it must be carefully disassembled, cleaned, and a new sealant applied.

Door roller repair

The rollers cannot be seen immediately, since they are located at the bottom of the plastic or glass door and are covered with decorative overlays.

Despite the tight closing lining, water still penetrates into the rollers. The result of contact of metal parts with water is known to everyone - bearings become covered with rust or become clogged with lime and other contaminants found in tap water.

The need to repair or clean the rollers is indicated by difficult opening of the door, the appearance of strange sounds of the door opening, or its partial blocking. You can solve the problem of how to fix a shower stall yourself. To do this, you should prepare a rust remover, kerosene, grease, a screwdriver and pliers.

The shower roller repair process is as follows:

- First you need to remove the decorative trim.

- Next you need to unscrew the fasteners and remove the roller.

- Now remove the seal, allowing access to the bearing.

- The selected product must be used to remove traces of rust.

- Then you need to treat the bearing with kerosene.

- The bearing is lubricated and the seal is installed.

- Check the performance of the roller.

- Place the roller in place and install the decorative trim.

Finally, you should open and close the door several times to check the quality of the work done. After proper repair, the door should open smoothly, without extraneous sounds, delays or jerks.

The process of cleaning rollers largely depends on the neglect of the situation. If the problem is solved at the first stage of its occurrence, then there will be no difficulties with repairs. Otherwise, restoring the performance of the rollers becomes somewhat more difficult. Of course, you can purchase new parts, but it may be difficult to select the size.

Cabin disassembly

To significantly facilitate the independent disassembly of the shower stall, it is advisable to use a special solvent composition to treat all joints on which silicone sealant is present. For this purpose, you will need to carefully coat the joints with a solvent, and then proceed to quickly but carefully dismantle the structure.

Cabin assembled

You can replace the ready-made sealant remover with a traditional solvent or gasoline, which helps soften the waterproofing composition, after which it can be easily cut off with a sharp knife.

With high tray

The main difference between shower cabins with high trays is the presence of a special protective screen that directly covers the bowl, which makes the appearance of such a design aesthetic and complete.

As a rule, such a screen is fixed with standard brackets, so during the dismantling process, the element can be easily removed and, if necessary, reinstalled in its proper place.

It should be remembered that a high tray is always installed on a special support that has legs, so it is very easy to move the bowl yourself and then move it to a new place.

With low tray

It is quite easy and simple to independently dismantle the pallet, which is installed directly on the floor surface. As a rule, for the simplest shower trays in design, it is necessary to snap off the front panel, which is slightly compressed on both sides. In this case, the sealed layer can be removed using a special solvent or cut off using a sharp construction knife.

Low tray

It is important to note that special compounds designed to soften silicone sealant act for a very limited period of time, most often no more than a quarter of an hour, so all work must be completed quickly and accurately

Removing the pallet

Some difficulties may arise when independently disassembling a shower stall with a tray installed using a concrete screed.

In this case, it is recommended to use a pry bar, through which the pallet is removed from the supporting frame base after the protective tape and layer of silicone sealant have been completely removed.

Careful and competent dismantling of the multifunctional plumbing fixture allows for trouble-free re-installation of the shower stall structure.

And the correct dismantling of the shower stall frame allows you to completely preserve the entire geometry of such a plumbing device, which is very important if it is necessary to install the structure in another place.

Suitable adhesives

For repairs, it is recommended to purchase such compounds.

Desmokol

Desmokol is used in the shoe industry. This effective product glues not only polymers, but also wood, leather, iron and other materials. Suitable for repairing a shower stall only if it is not subject to sagging later. Otherwise, the result will be short-term.

Gelcoat

Its gel-like structure is convenient. First, a layer of fiberglass impregnated with the composition is laid out. Then it is covered with another layer. Thus, wait until it dries completely.

Epoxy adhesive

Epoxy adhesive differs in that it consists of a resin and a hardener of the same name. It can be one-component (ready for use immediately) or two-component (must be mixed in certain proportions with other compounds). In order to glue a pallet with it, you need to take:

- fiberglass;

- solvent;

- polyurethane foam;

- respirator;

- putty knife;

- scissors.

The bottom line is that you first need to degrease and then dry the surface. Epoxy glue is poured for 24 hours, left, combined with the surface and left again for this period of time.

Shower siphon repair

A broken siphon results in an unpleasant odor in the shower stall. In order to repair the siphon in the shower, remove the tray screen, unscrew the top part of the siphon and replace it with a new one.

Replacing a sewer siphon is a very labor-intensive process. During this type of work you will need rubber gaskets and special tools. It may also be necessary to clear a blocked bend. To do this, disassemble and clean the siphon.