A single-line diagram of the power supply of a workshop is the main document when designing the power supply of an industrial enterprise, as well as any other facility, from a private home to a large shopping center. Any production or device that requires electrical energy to operate has a diagram that indicates the location of the elements and their interconnection. To understand the principle of plant power supply, a detailed diagram is often redundant and difficult to understand.

To simplify, a standard for constructing single-line diagrams was developed, which, despite some simplifications, give a complete picture of the structure of power distribution and the relationship between all elements of the network. Simplifying the diagram in no way reduces the information content; on the contrary, a drawing freed from unnecessary details allows a much faster and more complete assessment of the structure and construction of the electrical network. Any electrician at any enterprise can navigate a single-line diagram much faster than a detailed one.

We have previously written about all stages of design.

Construction principles

The main feature of a single line diagram is the way it displays power lines and the devices connected to them. Regardless of the number of phases, one line will be drawn on the electrical diagram. Also, the devices do not have a detailed picture of the connection of each phase. In order to understand the number of phases, the power supply line is crossed out with slashes according to the number of phases. For example, instead of a three-line power line, on the diagram you need to draw one line with three slashes or one line with the number 3. Instead of crossing out, there may be a corresponding inscription next to it. In captions to devices, the name of the connected phases is indicated in abbreviated form.

All single-line diagrams have the same construction principle, be it a diagram of a carpentry shop or a metal products production plant.

Power supply systems for industrial enterprises and principles of their construction

Definition 1

The power supply system is a set of sources, as well as means of conversion, distribution and transmission of electrical energy.

In order to provide an industrial enterprise with electrical energy, it is necessary to connect it to the energy system networks with subsequent distribution of electricity within the enterprise to individual divisions. Enterprise power supply networks are divided into internal power supply networks (intra-factory, inter-shop, etc.) and external power supply networks (from the point of connection to the energy system to receiving points). The principles for constructing a power supply system for an industrial enterprise are as follows:

Finished works on a similar topic

Coursework Electrical supply to industrial enterprises 460 ₽ Abstract Electrical supply to industrial enterprises 240 ₽ Test paper Electrical supply to industrial enterprises 210 ₽

Receive completed work or specialist advice on your educational project Find out the cost

- High voltage sources should be as close as possible to consumers of electrical energy, and its receivers should be dispersed over several points on the territory of the enterprise.

- The choice of components of the power supply circuit should be based on the condition of their constant operation under load. With this operating mode, the reliability of the enterprise's power supply increases and losses are reduced.

- The design of the power supply system of an industrial enterprise must provide for separate operation of parallel circuits (power lines, transformers, etc.), due to lower short-circuit currents.

- When developing a diagram of an enterprise's power supply system, the principle of partitioning should be applied at all levels of the system.

- The power supply system diagram must provide for the possibility of carrying out installation work by assembling components (industrial method).

- The power supply system diagram must provide for technical metering of electrical energy.

Are you an expert in this subject area? We invite you to become the author of the Directory Working Conditions

Types of single line diagrams

In the electrical design process, two types of single-line electrical diagrams are used:

- Calculated.

- Executive.

Complex single-line power supply diagrams

There are no fundamental differences between the listed types. The calculated single-line diagram is performed at the design stage of a power supply facility. During the construction process, it may be necessary to change some elements, the order of connection, and switching. All changes are recorded in the as-built diagram, which will then become the main document of the operated facility. It is the as-built diagram that appears in the package of documents when putting the facility into operation, since it most fully reflects the current state of the network and power receivers. Enterprise electricians deal exclusively with the executive circuit.

Complex single-line diagrams of the power supply of a large enterprise cannot be placed on one drawing, so a structural block diagram of the connection is placed on the main sheet, and complete single-line diagrams of each block are placed on the additional sheets.

The design and executive single-line diagrams are constructed on the basis of calculated data on the power consumption of consumers, requirements for the reliability of power supply, and protection against electric shock.

Construction and repairs are carried out on the basis of installation diagrams, which take into account the exact location of all network elements and supply lines, but without details of their characteristics.

Categories of electrical receivers and ensuring reliability of power supply

1.2.17. Categories of power receivers for reliability of power supply are determined during the design of the power supply system on the basis of regulatory documentation, as well as the technological part of the project.

1.2.18. With regard to ensuring the reliability of power supply, power receivers are divided into the following three categories. Electrical receivers of the first category are electrical receivers, the interruption of power supply to which may entail a danger to human life, a threat to state security, significant material damage, disruption of a complex technological process, disruption of the functioning of particularly important elements of public utilities, communications and television facilities.

From the first category of electrical receivers, a special group of electrical receivers is distinguished, the uninterrupted operation of which is necessary for an accident-free shutdown of production in order to prevent threats to human life, explosions and fires.

Electrical receivers of the second category are electrical consumers whose power supply interruption leads to a massive undersupply of products, massive downtime of workers, machinery and industrial transport, disruption of the normal activities of a significant number of urban and rural residents.

Electrical receivers of the third category - all other electrical consumers that do not fall within the definitions of the first and second categories.

1.2.19. Electric receivers of the first category in normal modes must be provided with electricity from two independent, mutually redundant power sources, and an interruption in their power supply in the event of a power failure from one of the power sources can be allowed only for the duration of automatic power restoration. To supply power to a special group of electrical receivers of the first category, additional power must be provided from a third independent, mutually redundant power source. As a third independent power source for a special group of electrical receivers and as a second independent power source for the remaining electrical receivers of the first category, local power plants, power plants of power systems (in particular, generator voltage buses), uninterruptible power supply units intended for these purposes, batteries and etc. If power supply redundancy cannot ensure the continuity of the technological process or if power supply redundancy is not economically feasible, technological redundancy must be implemented, for example, by installing mutually redundant technological units, special devices for emergency shutdown of the technological process, operating in the event of a power supply failure. If feasibility studies are available, it is recommended that the power supply to power receivers of the first category with a particularly complex continuous technological process require a long time to restore normal operation from two independent mutually redundant power sources, which are subject to additional requirements determined by the features of the technological process.

1.2.20. Electrical receivers of the second category in normal modes must be provided with electricity from two independent, mutually redundant power sources.

For power receivers of the second category, in the event of a power supply failure from one of the power sources, interruptions in power supply are allowed for the time required to turn on the backup power by the actions of the duty personnel or the mobile operational team.

1.2.21. For electrical receivers of the third category, power supply can be provided from a single power source, provided that power supply interruptions necessary to repair or replace a damaged element of the power supply system do not exceed 1 day.

Legend

Symbols on a single-line diagram

Symbols on electrical diagrams are strictly standardized. All designations are described in detail in ESKD - the Unified System of Design Documentation. ESKD, in turn, is based on the requirements of the relevant GOSTs.

Similar items, such as switches and circuit breakers, have similar symbols. The differences lie in some details that should not be forgotten. The same applies to all other elements: relay coils, contactors, measuring instruments, and so on.

When drawing up a single-line diagram, the use of non-standard symbols is strictly prohibited in order to avoid confusion and ambiguous interpretation.

This situation may arise when using various software to draw diagrams. Developed mainly abroad, such programs have libraries of graphic images of elements that do not comply with domestic regulatory documentation.

Basic concepts that include certain types of power supply circuits

A trunk is a line that is relatively long and combines several consumers. It is precisely this principle of the device that implies the electrical wiring project for an apartment, where lighting devices and connection points are placed on a common cable. The wire through which the device and the main line are connected is called a branch. If we talk about the line that connects the regional electrical network with a switchboard, transformer or substation, then any type of power supply circuit is designated as a feeder.

The objects for which projects are being developed are divided into three categories. The first is assigned the highest degree of importance, corresponding to the need to maintain human life support or the integrity of valuable equipment. If the city in which the electrical project is being developed is Moscow, then boiler houses, medical and children's educational institutions, and public transport enterprises can be considered as such.

An example of a children's garden power supply project

Back

Forward

These objects are always connected to two feeders and are equipped with automatic switching. For consumers of the second category, switching is done manually, and for the third category there is no backup power source.

What should be shown on a single line diagram

A drawing of a single-line diagram of an enterprise must provide comprehensive information about the characteristics of power lines, down to the brand, cross-section and length of supply wires, information about the types of switching and converting devices, metering devices and power consumers. For consumers, not only the power consumption is indicated, but also its reactive component, that is, cosφ. As an example, we can give a diagram of a turning shop, where a large number of asynchronous motors are concentrated, which are powerful consumers with high cosφ. Power supply to such consumers requires the installation of a power corrector. So, the list of necessary notations:

- Class, type and voltage of the supply line from which power is supplied.

- Boundaries of the areas of responsibility of consumers and energy supply organizations.

- Type and characteristics of electricity converters (transformers, substations).

- Type and characteristics of input and distribution boards.

- Devices that take into account electricity.

- Switching devices.

- Backup power supply devices.

- Type of traction substation (TS), if available.

- Location and characteristics of circuit breakers (fuses and RCDs).

- Characteristics of electricity consumers (category of reliability requirements, power consumption, cosφ).

- Length, brand and technical characteristics of supply lines.

A single line diagram does not show the electrical wiring layout, but only the general details of the electrical system.

The power supply circuit of the woodworking shop, like most similar shops, is carried out according to the principle of load distribution along the entire length of the line. Mainline power supply circuits have a similar principle, in contrast to radial ones, when the entire load is concentrated at the end of the supply line.

General requirements

1.2.11. When designing power supply systems and reconstructing electrical installations, the following issues should be considered:

- prospects for the development of energy systems and power supply systems, taking into account the rational combination of newly constructed electrical networks with existing and newly constructed networks of other voltage classes;

- ensuring an integrated centralized power supply to all consumers of electrical energy located within the coverage area of electrical networks, regardless of their affiliation;

- limitation of short-circuit currents to limit levels determined for the future;

- reduction of electrical energy losses;

- compliance of decisions made with environmental protection conditions.

At the same time, external and internal power supplies should be considered in combination, taking into account the capabilities and economic feasibility of technological redundancy.

When addressing redundancy issues, one should take into account the overload capacity of electrical installation elements, as well as the availability of reserves in process equipment.

1.2.12. When addressing issues of development of power supply systems, repair, emergency and post-emergency modes should be taken into account.

1.2.13. When choosing independent, mutually redundant power sources that are objects of the power system, one should take into account the likelihood of a simultaneous dependent short-term decrease or complete disappearance of voltage during the operation of relay protection and automation in the event of damage in the electrical part of the power system, as well as a simultaneous long-term loss of voltage on these power sources during severe system failures. accidents.

1.2.14. Requirements 1.2.11-1.2.13 must be taken into account at all intermediate stages of development of energy systems and power supply systems.

1.2.15. The design of electrical networks should be carried out taking into account the type of their service (permanent duty, duty at home, mobile teams, etc.).

1.2.16. The operation of electrical networks with a voltage of 2-35 kV can be provided either with an isolated neutral or with a neutral grounded through an arc suppression reactor or resistor.

Compensation for capacitive ground fault current should be applied for the values of this current in normal modes:

- in networks with a voltage of 3-20 kV, having reinforced concrete and metal supports on overhead power lines, and in all networks with a voltage of 35 kV - more than 10 A;

- in networks that do not have reinforced concrete and metal supports on overhead power lines: more than 30 A at a voltage of 3-6 kV;

- more than 20 A at a voltage of 10 kV;

- more than 15 A at a voltage of 15-20 kV;

in generator voltage circuits of 6-20 kV generator-transformer blocks - more than 5A.

The operation of electrical networks with a voltage of 110 kV can be provided with both a solidly grounded and an effectively grounded neutral.

Electrical networks with voltages of 220 kV and higher must operate only with a solidly grounded neutral.

Normative documents

The basis for drawing up single-line diagrams is the ESKD, which is approved by GOST 2.702-75. The ESKD formalizes the basic requirements for the standards for drawing up diagrams.

Conventional graphic elements and their designations are regulated by GOST 2.710-81, which contains a description of all components of the electrical network. The designations and configuration of individual elements can be established by internal enterprise standards.

Drawing up a single-line diagram is an extremely important undertaking. But even if everything is drawn up correctly, the schematic diagram does not guarantee that it will pass all the necessary approvals, since its preparation should only be carried out by those organizations that have permission to do this kind of work.

is engaged in the development and maintenance of all types of documentation for the design of electrical networks of any type and facility. You can find out the cost of services, deadlines and the procedure for coordinating stages of work, view completed projects and obtain other comprehensive information about the company’s activities by any means of communication from the “Contacts” page.

Requirements for the power supply system of an industrial enterprise

The main requirement for the power supply system of an industrial enterprise is its efficiency, which is associated with annual costs and expenses. These may also include losses of electrical energy and unplanned costs of materials. In order to ensure reliable and economical operation of the system, mutual redundancy of existing networks and pooling of power supplied to various objects are used.

If an industrial enterprise has its own power station, step-down substation and other sources of electricity, non-factory consumers must be taken into account. All electrical substations and networks are included in a single complex of an industrial enterprise, along with production premises and communications. Because of this, the design of the electrical supply system must be linked to the technological and construction parts through an overall master plan.

The highest demands are placed on the power supply systems of metallurgical, chemical and other energy-intensive enterprises, because these enterprises have high total capacities of electrical receivers and consumers. Their total capacity can reach 1.5 - 2 thousand megawatts.

Do you need to select scientific articles for your academic work? Specify a topic and receive a response in 15 minutes get help

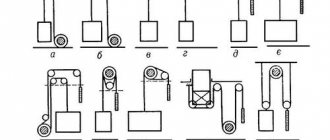

Ring circuits

If traction substations are located near the power supply source, ring circuits are used. If we compare the ring and radial schemes, the first connection method is cheaper, since it has fewer cable lines and protective equipment. When the power plant from which voltage is supplied is turned off, in a ring circuit the power supply to all traction substations in the chain is interrupted, and in a radial circuit only one substation is turned off. But in terms of system reliability, it is inferior to the radial one, since when the power source is turned off, the entire line of traction substations is turned off.

Below you can use the online calculator to calculate the cost of designing power supply networks: