In the 21st century, electricity has penetrated even the most remote corners of the planet, and it’s no secret that its transportation to its destination is carried out by wire. There are many types of them, differing in purpose, labeling, technical characteristics and cost. For installation of open and hidden electrical wiring, special installation products are used.

One of the most reliable conductors used for laying communication and complex power networks is considered to be the PuGV wire. It has excellent flexibility and is color coded. This article will focus on him.

What is a PUGV wire (what does it look like + explanation)?

The PUGV wire is a single-core product with polyvinyl chloride insulation and no additional sheath.

PuGV wire

In 2010, the new GOST R53768-2010 came into force, according to which the marking of wires was changed and the PV-3 wire changed its name to PuGV wire, the abbreviation of which encrypts the following information:

- “P” is a common name for cable conductors.

- “u” is an installation-type product used for electrical installation of conductor lines.

- “G” means the flexibility of the wire. This symbol is assigned to cables that belong to flexibility class 5 according to GOST 22483-2012.

- “B” - indicates the cable insulation is made of polyvinyl chloride.

Important! There may also be additional symbols at the end, which are an indicator of fire safety, but if they are absent, this will mean that the cable, when laid alone, will not spread and support combustion.

- “ng” – the cable will not spread fire when laid in groups.

- “HF” - indicates that corrosive gases will not be released during combustion.

- “HFLTx” - when burned, the wire material releases a small amount of gas, corrosive substances and dust.

Note! The letter part is followed by numbers. They indicate the cross-section of the current-carrying part of the wire. This number varies from 0.5 to 240.0. Sometimes you can find another symbol, for example, “1x1”, where the first number is responsible for the number of cores, and the second for the cross-section.

Features and Benefits

The power conductor PuGV is manufactured in accordance with the technical requirements specified in international standards. The increased flexibility of the product allows it to be used for high-quality installation of electrical lines inside boxes (cable channels) and various corrugated pipes.

It was already written above that a single gasket eliminates the possibility of fire. The duration of operation, subject to all conditions, is at least 20 years, and this period is calculated starting from the date of release of the product.

When visually inspecting the wire, you should find information about the manufacturer. Marking in the form of an abbreviation, instead of the outer sheath, is applied to the insulating material of the cores . There are two ways to do this - in relief and using a stamp. The cable marking must be continuous over a distance of no more than 500 mm. Based on these data, the electrician must find out the length of the wire in the coil, manufacturer, date of manufacture, weight and GOST number. Do not forget about the presence of various certification marks.

Design features

When examining the design of the power conductor, the first thing that catches your eye is the presence of one strand of tinned copper wire. This structure ensures simplicity and ease of installation and allows the cable to be used when laying a route with a large number of sharp bends.

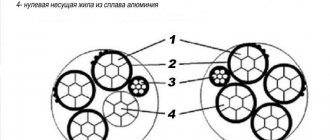

More details about the design of the PuGV wire:

- Despite the single-core design, the conductor consists of several wires. All copper rods are twisted together. Due to the wires of the smallest cross-section, the entire cable as a whole is as flexible as possible.

- The number of copper wires directly depends on the cross-section of the wire. For a cable with a current-carrying core cross-section of 0.5-35 sq. mm at least seven rods must be used. A simple relationship is usually observed: the higher the cross-sectional area, the more wires are used to form the core. Their specific quantity is regulated separately by each manufacturer.

- Power conductor with a cross section of 50-95 square meters. mm is made of at least 20 copper rods. For a thicker cable, their number can exceed 40 pieces.

- One manufacturer of PuGV with a cross section of 50 sq. mm forms a core of 50 copper wires (for each, this value is approximately 1 sq. mm), the other - of 25 (in this case, the area increases to 2 sq. mm).

- In order to somehow regulate and restrain the imagination of manufacturers, standards were adopted around the world. For a cable with a cross-sectional area of the current-carrying core of 0.5 sq. mm, the cross-section of individual wires should not exceed 0.21 sq. mm. If a 10 sq.m. wire is made. mm, then this value increases to 0.41 sq. mm. Finally, for the thickest cable with a cross-section of 240 sq. mm, copper rods of 0.51 sq. mm are taken. mm.

- Each wire is produced with high-quality PVC insulation. For products with a larger cross-section, the insulation thickness is higher.

- International standards specify the nominal thickness of the insulating layer, the minimum permissible value and the maximum outer diameter of the finished product. The value is also indicated in the technical data sheet.

The table below shows the dependence of the nominal insulation thickness on the core cross-section:

The color of the PuGV wire refers to its design features. Unlike the others, this parameter is not regulated or standardized in any way, so manufacturers are free to choose any color that comes to their mind. However, for tropical power conductors, there is a regulation according to which it is not recommended to use natural colors. Please note that this phrase is only a recommendation. For all other cases there is not even one.

However, a general trend is observed: conductors intended for ground connections are usually colored yellow-green. For every 15 cm of wire length, yellow and green colors should be no more than 70 and no less than 30%, respectively.

Application of PUGV wire

Despite the fact that the PuGV cable is single-core, it is classified as a multifunctional conductor. This is due to the cross-section of the current-carrying core, which can be 0.5 or 240 square meters. mm. The range is large, so the wire is suitable for both power and switching lines. With the help of PuGV, outdated aluminum wiring is replaced.

Important! If the power line is installed in an open area, then the PGV wire should be placed in protective structures. These include corrugated plastic or metal pipes, boxes, trays, cable channels. Here it is important to achieve maximum protection of the cable surface from exposure to ultraviolet rays.

However, in most cases, PuGV is used for wiring small electrical circuits that are hidden under protective materials, including plaster, various cladding, suspended and suspended ceiling structures. Quite often the wire is laid in brickwork or a monolithic concrete block.

Advantages and disadvantages of PUGV wire

This type of wire has a large number of advantages:

- High level of flexibility - it is assigned flexibility category 5, which provides a very wide scope of application. Can be used both for domestic needs and for connecting equipment, installing electrical systems, and powering devices.

- High resistance to external factors such as moisture, mechanical shocks, temperature or pressure changes, development and occurrence of mold, etc.

- Thanks to the fire retardants included in the insulation, the wire has the property of self-extinguishing. And, in case of sparking, it will not burn, but will just melt. It can be used in fire hazardous areas as it will not support combustion.

- Low cost.

- Due to treatment with a special repellent impregnation, it is protected from rodents and is practically not subject to any damage from pests.

You might be interested in Weight about wire VVGng A LS

However, the cable is not without its drawbacks. For example, it has a single layer of insulation, which under certain conditions of laying the wire is not enough. But this problem can be solved by using additional tubes, cable ducts or corrugations during installation. The second disadvantage is the mechanical “memory” of the core.

Important! If a wire is given a certain shape, installed and operated in this position for some time, it becomes fragile.

Corrugation

Features of storage and laying

An important factor influencing the quality and durability of PuGV wire is its proper storage. Humidity and dampness in storage areas can increase corrosion of copper strands and increase conductor resistivity. This, in turn, leads to its early decommissioning.

For laying, wires are tied into bundles and placed in shafts, boxes, or threaded into pipes or metal hoses. This installation method extends the service life and protects against damage.

Technical characteristics of PUGV

An installation wire of this type has a number of important characteristics:

- Short-term overheating - the insulation maintains its mechanical and dielectric parameters in an emergency situation, for example, when the system is overloaded or overheated to 150 degrees Celsius.

- Permissible mechanical elongation of insulation - indicates the ability of the polyvinyl chloride layer to change its geometric characteristics. But provided that it does not exceed 50% of the length. So that the wire can be easily bent in this range.

- Resistance of the insulation layer to single impacts, vibration and acoustic influences. However, it does not tolerate ultraviolet radiation well.

- Conductivity - this value is different for each brand, and it can vary depending on the temperature difference of the cable. It is determined by the resistance of the copper conductor.

| Nominal cross-section (mm2) | Minimum number of wires in the core (pcs.) | Wire outer diameter (mm) | Maximum electrical resistance of the core at direct current and temperature 20°C (Mohm/km) |

| 0,5 | 7 | 2,0 | 39,6 |

| 0,75 | 7 | 2,2 | 25,5 |

| 1 | 7 | 2,3 | 21,8 |

| 1,5 | 7 | 2,8 | 14,0 |

| 2,0 | 15 | 3,1 | 9,97 |

| 2,5 | 19 | 3,5 | 8,05 |

| 4,0 | 19 | 4 | 4,89 |

| 6,0 | 19 | 4,6 | 3,11 |

| 10 | 49 | 6,3 | 2,0 |

| 16 | 49 | 7,5 | 1,21 |

| 25 | 77 | 9,9 | 0,809 |

| 35 | 105 | 10,9 | 0,551 |

| 50 | 144 | 13,3 | 0,394 |

| 70 | 210 | 15,5 | 0,277 |

| 95 | 285 | 17,6 | 0,203 |

| 120 | 360 | 19,5 | 0,162 |

| 150 | 444 | 21,2 | 0,129 |

| 185 | 555 | 23,8 | 0,104 |

| 240 | 760 | 27,1 | 0,0808 |

Table 1 – Dependence of the parameters of the PuGV cable on the number of wires and their cross-section.

- Electrical insulation resistance - this characteristic is tested during production. The cable is lowered into the input and a voltage of 2.5 kV is applied for 5 minutes.

- Allowable bending radius - allows you to find out how much a given conductor can be bent. This characteristic is checked after manufacturing and the information is then entered into the product passport.

- Operating temperature – this parameter is responsible for the temperature requirement at which normal operation of the wire is possible. It ranges from -50 to +70 degrees Celsius. Also, it is worth noting that the cable can be operated at high ambient humidity, but not more than 98%.

Important! The wire should be installed at a temperature not lower than -15 degrees, but it is better to install it at values above 0.

You may be interested in this Features of the KG cable

Compound

The PuGV wire is single-core, and thanks to this it has a fairly simple design. This is a conductor whose design includes several copper wires. Proper flexibility of the wire with a large total cross-section is achieved by twisting wires of smaller cross-sections together.

The cores are made from tinned copper wire, and the wire insulation is made from polyvinyl chloride plastic.

Wire composition

Depending on the cross-section of the cable, the number of wires varies. Wires with a cross-section from 0.5 mm2 to 35.0 mm2 have a minimum of 7 wires. Their quantity is determined by the manufacturer, according to technical regulations.

Color

The color palette of the insulating sheath of the PuGV wire can be different, and its coating is made continuous. It is allowed to paint the wire in the form of 2 longitudinal stripes of different colors, arranged diametrically. The ground cable is yellow-green, the phase cable is brown, and the neutral cable is blue. Important! Typically, color marking is discussed when placing an order, however, if there are no instructions in this regard, the manufacturer reserves the right to choose its own color marking for the wires.

Shell colors

Where is the PUGV wire used (purpose)?

Along with excellent electrical properties, the cable is characterized by low cost and increased flexibility.

The characteristics of PuGV wire allow it to be used in many areas. The wire can be used when installing lighting lines, electrical panels, and also as power conductors for stationary connections of machines, machine tools and internal electrical installations. Its high degree of flexibility makes it very convenient to assemble and connect circuits in hard-to-reach places, inside electronic devices, to connect power and signal circuits.

Electrical panel

It is possible to carry out installation work where the cable will be placed under layers of plaster, in brickwork or inside concrete, using a closed installation method.

Suitable for assembling circuits inside lamps and chandeliers, but provided that they do not get too hot and the lighting devices will not be installed in rooms with high temperatures. For such purposes, it is better to use more heat-resistant wires.

It is possible to use a conductor for non-stationary installation of electrical equipment.

Characteristics

The production of flexible wires is regulated by GOST 31947-2012 . It came into effect on January 1 , 2014 . The document establishes the permissible rated voltage:

- Variable: up to 450 / 750 V at rated frequency up to 400 Hz.

- Constant: up to 1000 V.

It is clear that there is enough voltage to lay a home electrical network. Under load, the “degree” of the copper core increases. Therefore, manufacturers are required to ensure a long-term permissible heating temperature of at least 70 °C.

In accordance with the standard, PUGV should not lose its operational characteristics for 15 years. This is the service life.

How to use the wire correctly?

When laying the PUGV externally, it must be placed in corrugated tubes or cable channels. This is necessary to eliminate the possibility of cracking of the insulation under the influence of ultraviolet rays, as well as to prevent mechanical damage. It should be remembered that when laying the wire, the ambient temperature must not be lower than -15 °C. If this indicator is lower, the cable will lose its strength. Ignoring this rule may result in damage to the insulation when bending.

Important! When laying routes, it is necessary to monitor the bending radius of the wire. It must be at least 5 outer diameters of the wire, which is taken into account along with the insulation.

Bend radius

Pay attention to the selection tips:

- First of all, it is necessary to inspect the cable and make sure that there are no mechanical damages or defects, and also that the cross-section coincides with the declared value.

- Using a regular multimeter, you can easily check the resistance.

- Every 500 mm, the wire is marked, indicating its type, manufacturer and production date.

You might be interested in VVG GOST wire

Important! If the cable is sold in a coil, the following information must be marked on it: production date, coil weight, product length, label with the manufacturer’s brand and controller stamp.

Marking

Wire colors

The color range of PUGV is varied. The color of the insulation must be solid. It can also be represented by two longitudinal stripes. The stripes have a natural color and are located diametrically relative to each other. If the cable is used for grounding, the insulation turns yellow-green. Neutral wires are painted blue. In general, coloring is specified in advance in the order.

If this does not happen, and there is no specific color information in the order, the manufacturer will supply at its discretion. This option is acceptable when supplying products with insulation of transitional and mixed colors, subject to the condition of no more than 10% of the total batch volume.

Manufacturers of wire PUGV

The cable products market is represented by a fairly wide range, but this does not mean that the products have a high quality guarantee. Many companies do not comply with GOSTs. There are three main enterprises where high-quality cables are produced, which have proven themselves on the positive side in this market:

Kavkazcable.

JSC Kabelny is one of the ten largest cable production plants in Russia. This is a modern and highly mechanized enterprise equipped with advanced equipment. The plant produces about 800 different items: control cables, control cables, for submersible electric pumps, signaling and interlocking cables, telephone cables for rural and urban communications, power cables with plastic insulation, installation and lighting wires, etc.

The following cooperate with them: Russian Railways OJSC and many other largest institutions in the country.

Energy cable.

Cable is located in Elektrougli, Moscow region. Created according to the project of the All-Russian Research Institute of the Cable Industry and the Institute of the Ministry of Atomic Energy of the Russian Federation. This is a powerful and modern enterprise that successfully competes with the best manufacturers in Russia and neighboring countries. The plant uses modern technologies and equipment from many well-known foreign companies and has established itself as an enterprise that produces high-quality equipment at reasonable prices. Thanks to its capabilities, the company always fulfills orders on time and can deliver products to all regions of Russia.

Kamkabel.

Kamkabel is one of the main domestic consumers of aluminum and copper. The growth rate of the enterprise's volumes significantly exceeds the average indicators of other companies. Over the past years, Kamsky Kabel has occupied a leading position in the processing of copper and aluminum among cable product manufacturers. Kamkabel confidently occupies a leading position among other cable factories in Russia and the CIS countries in terms of production volume. Kamkabel’s powerful testing base and modern technological equipment ensure the production of reliable and high-quality cables with various types of insulation.

PuGV wire is used to solve a variety of problems both in production and at home. It has good electrical properties, reasonable price and excellent flexibility.