What is bulk density and what factors influence this indicator

Bulk density is a variable value. Under certain conditions, material of the same weight can occupy different volumes. Also, given the same volume, the mass can change.

The following factors influence the indicator most:

- Sizes and shape of grains

- Porosity of material

- Humidity

- Sealing during transport and storage

- Solid Density

In the continuation of the section you will find more detailed information about the influence of all these factors.

Grain size and shape

The smaller the particles, the more densely they are located in the sample. Therefore, materials such as sand, screenings and debris have the highest bulk density. The larger the grains, the more voids there are between them. For example, fine screenings (fractions 0-5) can have a bulk density of up to 1910 kg/m³, while coarse crushed stone (fractions 40-70) has a density of no more than 1170 kg/m³. This means that more small material will fit into the same container than large material.

In addition to size, the shape of the grains also plays an important role. Regularly shaped particles are best compacted. For example, the bulk density of cube-shaped crushed stone will always be high. If there are a lot of flaky grains (flat or needle-shaped), the indicator will immediately decrease.

Porosity

Porosity is characteristic of all bulk materials. It is measured by the volume of spaces between solid particles. Pores are open and closed. The number of open ones may decrease sharply during compaction (especially with low humidity of the material). Closed pores are found within solid particles; they are filled with air or moisture. The presence of such pores reduces the density and has little effect on its change during compaction. For example, there are a large number of closed pores in expanded clay, so its bulk density is always low.

Humidity

Humidity is one of the most important properties affecting performance. Water displaces air from the pores, the indicators of which are not taken into account when calculating bulk density. Therefore, in rainy weather or after storing the material under snow, its density increases.

Transportation and storage

Transportation and storage in a warehouse cause compaction of the material. Don't be surprised if you order 10 cubes and they only deliver 9.5. Vibration causes displacement of particles relative to each other, reduces porosity, and causes shrinkage. The same thing happens when stored in a warehouse - the material is compacted due to the pressure of its own weight. You can calculate how much the volume decreases using the compaction coefficient.

If you fill the hole with crushed stone, screenings or sand, its volume will also decrease over time. Therefore, you always need to purchase a slightly larger volume of material and calculate its future shrinkage using a coefficient. This indicator is not applicable for all materials. Usually it is indicated in GOST.

Below are the links, following which you will find coefficients for the following materials:

- Expanded clay

- PGS

- Sand

- soil mixture

- PShchS

- Crushed stone

Solid Density

The density of a solid is the most stable indicator. It depends solely on the physical and chemical properties of the material and does not change during transportation, storage, or increased humidity.

Pivot table

How much does a bucket weigh - the number of kilograms in one bucket. Full bucket weight for some products, materials, liquids, metals and substances. How many kg does the bucket weigh? Table 1: How much does a bucket weigh provides weight data (how much does it weigh) for a 10-liter bucket of such materials, bulk cargo, metals, products and substances as: boletus mushrooms, cement, slag, cement M 500, cones, cement M 400, crushed stone, cement mortar, kebab, coal, crushed tuff stone, coal nut, crushed stone, uranium, crushed stone 5-20, potatoes, crushed stone 20-40, potatoes, wood chips, expanded clay, gold, strawberries, grain, corn, earth, cranberries, ash, stones, golden sand, mixed feed, strawberries, coal, corn grain, bath stones, water, quartz sand, cherries, pine nuts, cherries, pine nuts, grapes, paint, Victoria, manure, trumpets, mushrooms, apricots, gravel, apricot, clay, asphalt, nails, sand, gravel mass, wheat, milk mushrooms, granotsev, popcorn, peas, ASG, pebbles, tomatoes, granite, tomato, walnuts, humus, gravel mass, pepper, platinum, perlite. The mass of 1 liter (one liter, 1 liter, the volume of a liter jar) is indicated in Table 1 as additional reference information.

READ ALSO: Squeezing a boil: can it be eliminated at home?

How to determine bulk density

Bulk density is determined in different ways. Some can be used even in field conditions, others are available only in specialized laboratories.

Weight method

This is the simplest way to determine the indicator. To carry it out, you need to have a funnel, a cylinder of a certain volume and scales. The material is poured into a funnel, from which it enters the cylinder. When the container is completely filled, the top layer is leveled with a special plate. The sample is then weighed and the mass to volume ratio is calculated.

The gravimetric method can also determine bulk density in the field. It is enough to have a container of known volume (for example, a bucket) and household scales. Pour the material into a bucket and weigh it. We get weight. Next, we calculate the bulk density.

For example, a 10 liter bucket has a volume of 0.01 m³. Crushed granite placed in this bucket weighs 18 kg. This means that the bulk density will be 1800 kg/m³. It is clear that the result will only be approximate, since in laboratory conditions the mass of the container and the mass of the sample are accurately weighed, the sample is poured from a certain height, and so on. But if you don’t have equipment or specialists at hand, you can determine the approximate bulk density in this way.

Cutting ring method

The bulk density of the soil is calculated using cutting rings with a known volume. A knife and two metal plates serve as auxiliary tools.

The sequence of the technique is as follows:

- Weigh the ring and plates

- Level the soil surface with a knife

- Lubricate the inner surface of the ring with technical oil

- Lower the ring into the ground until it completely fills the internal space

- Align the top edge with a knife

- Cut the soil from the bottom of the ring with a cone

- Carefully transfer the ring onto the plate using a knife and place it cone up

- Cut off the top layer of soil at the level of the ring

- Weigh the sample and subtract these rings and plates from its mass

- Divide the weight of the soil by the volume of the ring and obtain the bulk density

Laboratory methods

In scientific laboratories, indirect methods are used to determine bulk density by the attenuation of X-rays, radioactive or ultrasonic rays. When passing through different materials, they are partially absorbed. Using special instruments, the intensity of radiation is measured before and after passing through the sample.

Based on bulk density, materials are divided into groups:

- Light (less than 600 kg/m³)

- Medium (600-11 00 kg/m³)

- Heavy (1100-2000 kg/m³)

- Extra heavy (more than 2000 kg/m³)

Values of specific and volumetric weight of construction sand

Today, sand is one of the most common building materials. This is the main element of construction. Its purchase must be approached competently in order to know what amount of sand to take into account when purchasing and preparing mortars and concrete.

When using sands for concrete, we may be interested in

- specific gravity of sand

- volumetric weight of sand,

- strength of sand grains,

- the nature of their surface,

- grain shape,

- possible resistance of sands (depending on the mineralogical composition),

- coefficients of linear and volumetric expansion,

- hardness

- and abrasion (wearability) of grains, etc.

When designing the composition of concrete, it is necessary to know

The specific gravity of sand or specific gravity is the weight that fits in a unit volume. It is defined as the ratio of the mass of sand in a dry state and its occupied volume. In most cases, a volume of 1 cubic meter is used for sand.

This variable value can range from 2.55 to 2.65 units and differs for sand of different origins.

The volumetric bulk density of sand is widely used in its reception and transportation.

The volumetric weight of construction sand is a unit of volume in the natural state of the sand (with impurities, moisture).

Volumetric and specific gravity may differ, so during construction it is necessary to take into account all errors.

On average, the volumetric weight of sand is 1 cubic meter. m is 1500-1800 kg. According to GOST 8736-77 standards in 1 cubic meter. m contains 1.6 t.

In tables and reference books, the specific gravity of construction sand is indicated in grams per 1 cm³, kg m³ or in tons per m³.

The specific gravity of sand depends on the content of grains of various minerals in its mass, the specific gravities of which, according to P. I. Fadeev, are given in Table.

The last properties of sands have been most fully revealed. Thus, the specific gravity of quartz sands of alluvial origin (river sands) varies within small limits, usually from 2.64 to 2.70, averaging 2.66 in the absence of organic impurities (according to P.I. Fadeev).

According to his data, the specific gravity of aeolian sand in Western Kazakhstan is 2.71, and in the Astrakhan region - 2.74;

the specific gravity of sea sand in the Black Sea is 2.63, and in the Azov Sea - 2.78.

Table. Specific gravity of major minerals found in fishing lines

| Mineral | Specific gravity, g/cm3 | Mineral | Specific gravity, g/cm3 | ||

| from | before | from | before | ||

| Quartz | 2,65 | 2,66 | Augite | 3,20 | 3,60 |

| Microcline | 2,54 | 2,57 | Diopside | 3,11 | 3,42 |

| Orthoclase | 2,54 | 2,56 | Epidote | 3,25 | 3,50 |

| Calcite | 2,71 | 2,72 | Spinel | 3,52 | 3,71 |

| Dolomite | 2,80 | 2,90 | Disten | 3,56 | 3,67 |

| Anhydrite | 2,90 | 2,98 | Limonite | 3,60 | 4,00 |

| Glauconite | 2,20 | 2,84 | Pomegranate | 3,80 | — |

| Biotite | 2,70 | 3,10 | Rutile | 4,18 | 4,25 |

| Muscovite | 2,76 | 3,00 | Zircon | 4,20 | 4,86 |

| Hornblendes | 3,00 | 3,30 | Kaolin | 2,60 | 2,63 |

The volumetric bulk density of sand depends on

For dry sand, bulk volumetric gravity, specific gravity and voids are related by the following relationship: γн=(1-V/100) where:

Table. Specific gravity of various construction sands per m3.

| Sand name, type or variety. | Other name. | Specific gravity in grams per cm3. | Specific gravity in kg per m3. |

| Dry. | Dry sand. | 1.2 — 1.7 | 1200 — 1700 |

| River. | Sand from the river, sand mined from the river, sand from the bottom of the river. | 1.5 — 1.52 | 1500 — 1520 |

| River compacted. | Sand from the river, washed without clay fraction. | 1.59 | 1590 |

| River grain size 1.6 - 1.8. | Sand from the river, sand mined from the river, sand from the bottom of the river. | 1.5 | 1500 |

| River alluvium. | Sand from the river, sand washed up in the river, sand from the bottom of the river extracted using the alluvial method. | 1.65 | 1650 |

| River washed coarse-grained. | Coarse sand from the river washed. | 1.65 | 1400 — 1600 |

| Building. | sand for construction, sand for construction and finishing works, sand used and applied in construction. | 1.68 | 1680 |

| Construction dry friable. | Sand for construction, sand for construction and finishing works, sand used and used in construction. | 1.44 | 1440 |

| Construction dry compacted. | Compacted sand for construction, compacted sand for construction and finishing works, compacted sand used and applied in construction. | 1.68 | 1680 |

| Career. | Sand from a quarry, sand extracted by quarrying. | 1.5 | 1500 |

| Quarry fine-grained. | Fine sand from a quarry, fine sand extracted by quarrying. | 1.7 — 1.8 | 1700 — 1800 |

| Quartz regular. | Quartz sand. | 1.4 — 1.9 | 1400 — 1900 |

| Quartz dry. | Quartz sand. | 1.5 — 1.55 | 1500 — 1550 |

| Compacted quartz. | Quartz sand. | 1.6 — 1.7 | 1600 — 1700 |

| Nautical. | Sand from the sea, sand from the seabed. | 1.62 | 1620 |

| Gravelly. | Sand mixed with gravel. | 1.7 — 1.9 | 1700 — 1900 |

| Dusty. | Sand mixed with dust. | 1.6 — 1.75 | 1600 — 1750 |

| Dusty compacted. | Compacted sand mixed with dust. | 1.92 — 1.93 | 1920 — 1930 |

| Silty, water-saturated. | Sand mixed with dust. | 2.03 | 2030 |

| Natural. | Sand of natural origin, usually quartz. | 1.3 — 1.5 | 1300 — 1500 |

| Natural coarse grain. | Sand of natural origin, usually quartz. | 1.52 — 1.61 | 1520 — 1610 |

| Natural medium grain. | Sand of natural origin, usually quartz. | 1.54 — 1.64 | 1540 — 1640 |

| For construction work - normal humidity according to GOST. | Construction sand. | 1.55 — 1.7 | 1550 — 1700 |

| Expanded clay grade 500 - 1000. | Expanded clay sand. | 0.5 — 1.0 | 500 — 1000 |

| Expanded clay size of solid grains (particles) is fraction 0.3. | Expanded clay sand. | 0.42 — 0.6 | 420 — 600 |

| Expanded clay size of solid grains (particles) is fraction 0.5. | Expanded clay sand. | 0.4 — 0.55 | 400 — 550 |

| Mountain. | Quarry sand. | 1.5 — 1.58 | 1500 — 1580 |

| Fireclay. | Fireclay sand. | 1.4 | 1400 |

| Molding machine with normal humidity according to GOST. | Sand for molding parts, foundry sand, sand for molds and casting. | 1.71 | 1710 |

| Perlite. | Expanded perlite sand. | 0.075 — 0.4 | 75 — 400 |

| Perlite dry. | Dry perlite sand expanded. | 0.075 — 0.12 | 75 — 120 |

| Ravine. | Sand lying in ravines, sand from a ravine. | 1.4 | 1400 |

| Alluvial. | Washed sand, sand mined by washing. | 1.65 | 1650 |

| Medium size. | Medium grain sand. | 1.63 — 1.69 | 1630 — 1690 |

| Large. | Coarse sand. | 1.52 — 1.61 | 1520 — 1610 |

| Medium grain. | Medium grain sand. | 1.63 — 1.69 | 1630 — 1690 |

| Small. | Fine grain sand. | 1.7 — 1.8 | 1700 — 1800 |

| Washed. | Washed sand from which soil, clay and dust fractions have been removed. | 1.4 — 1.6 | 1400 — 1600 |

| Compacted. | Sand that has been artificially compacted and compacted. | 1.68 | 1680 |

| Medium density. | Sand of normal density, ordinary, medium density for construction work. | 1.6 | 1600 |

| Wet. | Sand with high water content. | 1.92 | 1920 |

| Wet compacted. | Sand with high water content is compacted. | 2.09 — 3.0 | 2090 — 3000 |

| Wet. | Sand with high humidity, different from normal according to GOST. | 2.08 | 2080 |

| Water-saturated. | Sand lying in the aquifer. | 3 — 3.2 | 3000 — 3200 |

| Enriched. | Sand after enrichment. | 1.5 — 1.52 | 1500 — 1520 |

| Slag. | Sand from slag. | 0.7 — 1.2 | 700 — 1200 |

| Porous sand from slag melts. | Slag sand. | 0.7 — 1.2 | 700 — 1200 |

| Swollen. | Perlite and vermiculite sands. | 0.075 — 0.4 | 75 — 400 |

| Vermiculite. | Swollen sands. | 0.075 — 0.4 | 75 — 400 |

| Inorganic porous. | Porous light sand of inorganic origin. | 1.4 | 1400 |

| Pumice. | Pumice sand. | 0.5 — 0.6 | 500 — 600 |

| Agloporite. | Sand obtained after burning out minerals - burning the original rock. | 0.6 — 1.1 | 600 — 1100 |

| Diatomite. | Diatomite sand. | 0.4 | 400 |

| Tuff. | Tuff sand. | 1.2 — 1.6 | 1200 — 1600 |

| Aeolian. | Natural sand formed naturally as a result of aeolian weathering of hard rocks. | 2.63 — 2.78 | 2630 — 2780 |

| The soil is sand. | Sand in natural occurrence, soil with a very high sand content. | 2.66 | 2660 |

| Sand and crushed stone. | Construction Materials. | sand 1.5 - 1.7 and crushed stone 1.6 - 1.8 | sand 1500 - 1700 and crushed stone 1600 - 1800 |

| Sand and cement. | Construction Materials. | sand 1.5 - 1.7 and cement 1.0 - 1.1 | sand 1500 - 1700 and cement 1000 - 1100 |

| Sand and gravel. | A mixture of sand and gravel. | 1.53 | 1530 |

| Sand and gravel mixture is compacted. | A mixture of sand and gravel. | 1.9 — 2.0 | 1900 — 2000 |

| Break of ordinary red clay brick. | Sand obtained by crushing red ceramic clay bricks. | 1.2 | 1200 |

| Mullite. | Mullite sand. | 1.8 | 1800 |

| Mullite-corundum. | Sand is mullite-corundum. | 2.2 | 2200 |

| Corundum. | Corundum sand. | 2.7 | 2700 |

| Cordierite. | Cordierite sand. | 1.3 | 1300 |

| Magnesite. | Magnesite sand. | 2 | 2000 |

| Periclase-spinel. | Periclase-spinel sand. | 2.8 | 2800 |

| From blast furnace slag. | Slag sand from blast furnace slag. | 0.6 — 2.2 | 600 — 2200 |

| From dump slag. | Slag sand from dump slag. | 0.6 — 2.2 | 600 — 2200 |

| From granulated slag. | Slag sand from granulated slag. | 0.6 — 2.2 | 600 — 2200 |

| Made from slag pumice. | Slag-pumice sand. | 1.2 | 1200 |

| From ferrotitanium slag. | Slag-pumice sand. | 1.7 | 1700 |

| Titanium-alumina. | Titanium-alumina sand. | 1.7 | 1700 |

| Basaltic. | Basalt sand. | 1.8 | 1800 |

| Diabase. | Diabase sand. | 1.8 | 1800 |

| Andesitic. | Andesite sand. | 1.7 | 1700 |

| Diorite. | Sand from diorite. | 1.7 | 1700 |

| From scrap heat-resistant concrete with fireclay filler. | Sand from scrap heat-resistant concrete with fireclay filler. | 1.4 | 1400 |

READ ALSO: Herpes type 5: symptoms, causes, diagnosis and treatment of herpes type 5

You can buy in bags and cubes, as well as in tons. Quartz sand is sold in bulk (carloads, machine quantities) and in packaging. Packaging can be very diverse: today the market offers containers from 2-4 kg to 1,500 liters.

For construction work in low-rise and private construction, a table of specific gravities not only in m3, but also in buckets will be convenient. It is always possible to more accurately indicate to workers how much of which materials to mix and in what proportions.

Video of the specific gravities of dry, wet, compacted, loose sand.

Since the specific gravity of sand changes almost insignificantly, the main influence on the volumetric weight of sand is its voidness.

Why is bulk density determined?

Knowing bulk density is important in the following situations:

- You know the volume of the hole or ditch that needs to be filled, and you want to know the weight of the material that needs to be purchased for this purpose

- There is material on sale in kilograms, but you need to know its volume

- You want to correctly calculate the number of transport units required to transport the purchased material

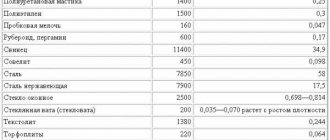

The indicator is taken into account when calculating the weight and volume of materials in our calculator. For your convenience, we have provided specific numbers in the table Bulk density of non-metallic materials.

Farming

The main goal of farmers involved in growing grain crops is to obtain maximum yields. When carrying out such work, it is necessary to take into account the climatic conditions of a particular region, the mechanical composition of the soil and the presence of nutrients in it. Many farmers do not know how much wheat weighs, but the weight of an individual grain will depend not only on all of the above influencing factors, but also on the variety used. In practice, when carrying out calculations, the weight of a troy grain (average value) is used. This figure is equated to 0.65 grams.

READ ALSO: Scars on the skin: causes, symptoms, diagnosis and treatment

Many farmers are interested in how much a cube of wheat weighs, especially if the grain is stored in a barn and its volume can be easily calculated without additional weighing. Here you can carry out simple calculations, for example, thaw a liter glass jar, pour wheat into this container and weigh it again. After carrying out such work, you can find out that 700-800 grams of grain will fit in a liter jar.

From the mathematics course we know that one cube contains 1000 liters, which means that 700-800 kilograms of wheat will fit in the described unit of volume. Such a significant discrepancy in weight can be associated not only with the characteristics of the variety, but also with the moisture content of the grain.

Now many agricultural workers buy grain by the bucket, rather than by weight. In this case, unscrupulous sellers can deceive their buyers. In order not to fall for such a trick, everyone should know how much a bucket of wheat weighs, and also be able to carry out the necessary calculations to calculate their own benefit. Let’s say a 10-liter bucket of grain costs 100 rubles, while a kilogram of the same product is sold for 10 rubles. We know that one liter contains 700-800 grams of grain, respectively, 7-8 kilograms will fit in a 10 liter bucket, but not 10 kg, so in this case it is better to buy by weight.