Why do you need to know the volume of sand in 1 cubic meter/ton?

The volume of sand in 1 cubic meter/ton is an indicator of interest to both builders and owners of country houses. Correct calculation of the amount of materials is important not only when constructing buildings and structures, but also when arranging local areas.

You shouldn’t rely on guesswork: will KAMAZ with 10 tons bring the required volume of sand or not? Inaccurate numbers in calculations can lead to serious consequences:

- incorrect consistency of mortars;

- reduction in concrete quality;

- violations during hardening of concrete mixtures;

- reduction in the strength of finished structures;

- premature destruction of cement structures, etc.

For these and other reasons, it is important to know exactly how much sand is in 1 cube and how many cubic meters in one ton.

Construction sand: how many cubes per ton

Specific gravity of sand per 1 cubic meter. m volume is calculated using the formula:

m = V*p , where

m – mass of material;

V – volume;

p – density level.

Using this formula, you can find out from the table how many cubic meters of sand are in a ton, and what is its specific gravity within the generally accepted unit of volume. For 1 cu. m, the weight of the material is equated to its density, and the bulk density can usually be obtained from suppliers involved in sales and delivery.

To calculate the weight of sand, you need to know its volume and density.

On a note! Another indicator that influences weight is the level of humidity. Most often it is 6-7%. If the material is wet, this value increases to 20%. This difference must be added to the mass of sand.

Wood and wood weight

| Name of wood | How much does a bucket weigh, kg (weight of building material placed in one 10-liter bucket, kg) | How much does 1 cube weigh, kg (kg/m3) |

| Dry birch | – | 600-700 |

| Freshly cut birch | – | 880-1000 |

| Birch impregnated | – | 700 |

| Dry beech | – | 600-700 |

| Freshly cut beech | – | 970-1000 |

| Beech impregnated | – | 700 |

| Lining (wooden slats) | – | 600 |

| Dry elm | – | 700 |

| Freshly cut elm | – | 1000 |

| Gorbyl | – | 600-700 |

| Dry oak | – | 700-800 |

| Freshly cut oak | – | 1000-1030 |

| Dry spruce | – | 450-500 |

| Freshly cut spruce | – | 800-850 |

| Dry cedar | – | 450-500 |

| Freshly cut cedar | – | 850-880 |

| Dry maple | – | 700 |

| Freshly cut maple | – | 1000 |

| Beech parquet staves | – | 550 |

| Tree bark | 2,7-3,6 | 270-360 |

| Oak bark | 5-6 | 500-600 |

| Round semi-dry softwood timber | – | 650-700 |

| Round, raw softwood timber | – | 750 |

| Round sawn semi-dry softwood timber | – | 600 |

| Dry linden | – | 450-500 |

| Freshly cut linden | – | 790-800 |

| Dry alder | – | 500 |

| Freshly cut alder | – | 800 |

| Oak sawdust | 1,6 | 160 |

| Spruce sawdust | 1 | 100 |

| Pine sawdust | 1,5 | 150 |

| Dry aspen | – | 500-510 |

| Raw aspen | – | 600 |

| Freshly cut fir | – | 830-850 |

| Dry fir | – | 470-500 |

| Dry sycamore | – | 580 |

| Freshly cut sycamore | – | 850 |

| Straw cutting | 1,2-1,5 | 120-150 |

| Pine is dry | – | 400-600 |

| Freshly cut pine | – | 850-900 |

| Dry poplar | – | 500 |

| Freshly cut poplar | – | 800 |

| Dry apple tree | – | 670 |

| Freshly cut apple tree | – | 975 |

| Dry ash | – | 700-750 |

| Freshly cut ash | – | 925-1000 |

.

Types of sand and their weight

There are standard indicators that you can use when calculating the amount of material. In accordance with GOST, 1 cubic meter of construction sand weighs 1550–1700 kg or, as builders prefer to say, 18.5–20.4 kg per bucket.

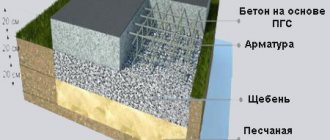

Dry loose sand in 1 cubic meter holds 1440 kg. A compacted square meter of sand weighs 1680 kg. The standard figure for wet material is 1920 kg.

Based on the location and method of extraction, natural sand is usually divided into three categories:

- River. It is mined at the bottom of rivers, it is clean, gray or yellow. Fractions 0.3–0.5 mm. It is used for mixing solutions and organizing drainage.

- Career. It is mined using the open-pit method. It is larger, with a fraction of 0.6–3.2 mm. It is used for the construction of foundations and sidewalk equipment. Large volumes of sand are sifted and washed. Used for preparing mixtures in finishing and plastering works. Material for preparing cement.

- Nautical. They are mined from the seabed. They are used in various fields, but high cost often prevents the use of the material.

In addition to natural sand, there is artificial sand: quartz, expanded clay, slag.

Specific gravity of different types of sand

| Type of sand | Weight of one cubic meter | Weight of one bucket |

| Career | 1500 kg | 18.3 kg |

| Nautical | 1620 kg | 19.4 kg |

| River | 1630 kg | 19.5 kg |

The table shows that river sand is the heaviest. This is explained by its fine fraction and higher density.

Sand Density

The density of sand depends on the number and size of air layers formed between the grains. Density is divided into:

- to technological;

- real;

- bulk;

- true/conditional.

Bulk density is the ratio of specific gravity to occupied volume. True or conditional value is the limit of the ratio of weight to volume minus pores and voids.

Density is 1.3–1.8 t/m2. The characteristic parameter for river sand is 1.3, for quarry sand it is 1.4.

Sand fraction size

Fraction is the average particle size. To determine it, bulk material is sifted through special sieves. According to this criterion, sand is divided:

- to small (1.5–2 mm);

- medium (2–2.5 mm);

- large (more than 2.5 mm).

Having dealt with all the components that affect the weight and volume of sand, you can move on to the basic formula.

| m = V*p, where m is mass, V is volume, P is density |

Bulk density can always be checked with suppliers.

Methods for classifying quartz sand

The starting point in the classification system is the properties of the material and how it is prepared. The following areas of classification of quartz sand are distinguished:

By size (fractional composition)

The numerical expression is the average particle size or range of particle sizes (fraction):

- pulverized quartz – represents a fraction of less than 0.1 mm (sifted into a sieve with a pore diameter of 0.1 mm) and is usually found when crushing quartz crystals;

- fine-grained sand – fraction 0.1-0.25 mm;

- medium sand – fraction 0.25-0.5 mm;

- coarse sand – fraction 0.5-1 (rarely up to 3) mm.

By enrichment

Quartz sand is divided into unenriched and enriched sand:

- unenriched sand is the original mineral that has not been processed to increase the silica content;

- enriched sand contains a several percent increased quartz content, obtained by removing most of the impurities. Thus, white quartz sand is purified from organic compounds, iron oxides and clay impurities by sifting, washing and drying.

Due to the nature of production, the main technical characteristics of the resulting material also differ. This in turn affects the possibilities of further use of quartz sand.

Enrichment technology

High purity of the quartz mixture is a necessary requirement in a number of technological processes. The initial stage of enrichment includes fractionation and washing - with their help, the coarsest impurities are removed.

The next stage is the use of special technologies, such as:

- gravitational enrichment is the main method, the essence of which is to separate the components of the mixture by density. Lighter particles are carried away by the water flow, while heavier ones settle to the bottom of the apparatus. The gravitational effect can be enhanced by centrifugation or the addition of chemical reagents that change the wettability of sand components;

- electric and magnetic separation - is the effect of electric current and magnetic field, leading to the separation of certain impurities. Thus, magnetic action is especially effective in removing iron particles that have magnetic properties.

The parameters of enriched sand fundamentally affect the quality of the work performed. Sand mixtures with the best properties are produced only by certified enterprises using standard technologies.

By color

It can be natural or painted. Natural quartz sand ranges in color from pale yellow to brownish yellow. Artificial coloring is carried out with stable paints based on synthetic binders, allowing you to create original multi-colored ornaments from sand. This sand can be colored or white.

By degree of preparation

Depending on technological requirements, sand can be produced in the following varieties:

- fractionated - represents a specific fraction of sand, the size of which is limited by technical regulations;

- dry – dried to an air-dry state. Together with fractionated sand, it can be used as a working fluid for sandblasting machines;

- calcined sand – completely dehydrated by calcination. Heating significantly above 100 °C ensures desorption of moisture even from the deep pores of quartz. Such sand is used in ready-made building mixtures that are stored for a long time - even a slight moisture content can render the entire mixture unusable;

- rounded quartz sand – has less abrasive properties and is therefore suitable for delicate applications, for example, sandboxes on playgrounds;

- molding quartz sand – used to produce cast quartz products and is characterized by a high degree of enrichment.

How much does a cube of sand cost?

The price depends on the quality of the material and the cost of the production effort invested in cleaning. The MSC-Region website contains comprehensive information about inexpensive prices during this period in Moscow and the Moscow region.

Quarry material is the cheapest; it is loaded by excavator from the mining site onto cars and transported to construction sites. If goods are sifted before sale, the cost increases. Washed is the best and ideal type of building material. It contains no impurities and debris, all lumps are broken, and it has optimal humidity (achieved by special drying after washing). The river material is also clean, but the corners are polished by prolonged exposure to water. An angular structure is required to obtain a strong grip. The limited amount of raw materials extracted from the reservoir does not allow the price to be lower than the washed quarry. Quartz is the most expensive. It is obtained artificially - by mechanical crushing of a natural mineral.

How much does a sand machine cost?

The answer depends on the quality and, most importantly, the volume that the buyer understands by the word 'machine'. ZIL accommodates four cubes, respectively:

cost of ZIL sand = 4 cubic meters × cost of 1 m3 + delivery.

KAMAZ holds 9 m3, and Euro KamAZ - 12 m3.

It is worth highlighting that delivery contains the lowest cost of gasoline and wear and tear on the car. If you order a similar vehicle for transporting other goods, the cost will be significantly higher.

“How much does KAMAZ sand cost?” - this is just a decision to bring in building materials. It is important to remember: each brand of machine has certain dimensions, which means that if the object is located in a built-up sector, then it makes sense to compare the throughput capabilities of the gate and the size of the machine.

How much does a ton of sand cost?

Depending on the density, the weight of one cube is 1200–2000 kg, and the average weight of a cube is 1600 kg, then it is easy to calculate the cost per ton:

From 1200 kg 200 kg is 16.7% (200/1200*100% = 16.7%). From 2000 kg 1000 kg 50% (1000/2000*100% = 50%).

Consequently, if the website only presents the price per cubic meter, then having found out the bulk density of sand, it is easy to understand how expensive one ton will cost.

Price per 1 m3 – (figure from the range from 16.7% to 50%) = price per 1 ton.

How much does one liter of sand weigh?

In order not to describe the conversion of cubic decimeters to liters, the answer will be short: 1.4–1.7 kg.

Floor screed, how much sand is required?

The main components of the screed are cement, fine aggregate and water. If we start from an unreinforced screed, then its height is 4 cm. To obtain the amount of mortar, the area (conventional value 20 m2) should be multiplied by 4 cm (20 m2 * 4 cm = 0.8 m3). The proportion of dry ingredients is 1ꓽ3 (binder to aggregate). Divide 0.8 cubic meters into four parts, you get 0.2 m3. For 0.2 m3 of cement, 0.6 m3 of the desired substance will be required, which will result in the amount of dry mixture.

Sand fraction size

How many cubes of material are in a bag of sand can be determined taking into account its grain composition. To do this, it is enough to sift the grains of sand using special sieves. As a result, you will be able to determine the level of gravel particles in the material that have certain dimensional data. Typically, the calculations use the particle size modulus of the material.

Table 1. Sand fineness modulus:

| Material type | Size of material fractions, mm |

| Small | 1,5-2 |

| Average | 2-2,5 |

| Large | more than 2.5 |

If you have fractions larger than 2.5 mm in size, most likely you are dealing with quarry or river sand; how much a cube of material weighs in this case will depend on water demand.

According to particle size, the material is divided into 2 classes:

- I – more than 1.5 mm;

- II – with any dimensional data.

The class of material and the size of its fractions determine how much 1 cubic meter of sand costs for construction work.

There are three sizes of sand fractions - fine, medium and coarse.

Density of quarry sand

There are quite a few operational characteristics of quarry sand, but the most important are considered to be:

1. Density of uncompacted natural sand fill (kg/m3), which is determined to measure the permissible moisture content; 2. Exact fraction density (g/m3).

Most often, reliable indicators of sand density usually mean the weight of 1 cube of sand, which is not compacted. In addition, not only the total volume of large fractions is taken into account, but also the resulting voids. That is why, the indicators of the uncompacted density of sand of the coarse fraction are generally an order of magnitude less than the corresponding values that relate to the fine-grained fraction. For example: the density of sand, which was mined by open-pit mining in quarries, reaches 1400/1500 kg/m3, and sometimes 1700-1800 kg/m3.

Technical criteria are considered a fixed standard GOST (8736) indicating that the density of quarry sand should vary within the normal range (up to 2.8 g/cm3). As a rule, bulk material with such indicators is added to the composition of various mortars, dry mixtures and concrete, and it is also widely in demand when arranging the base of highways, construction sites and airfield runways.

It is worth considering that its consumption during construction work will depend on the density of quarry sand. The same volume of bulk material involved and significantly lower overall density will mean that much less material will be required by weight - and this will save money. Simply put, when the bulk density is within 1400 kg/m3, there will be 1.4 tons of sand in a cube, but a density of 1800 kg/m3 will be 1.8 tons. In some cases, it is necessary to take into account a large number of voids, which often affects the shrinkage of the sand layer during the compaction process. Often, you need to take into account the additional costs of purchasing special binder mixtures, which are necessarily included in the concrete. The basic density of sand is mainly affected by the presence of various clay impurities and the level of humidity. The fewer impurities, the better the quarry sand.

During the weighing period the density of quarry sand ; for this purpose, cylindrical metal containers are used, which can hold up to 1 dm3 and 10 dm3. Already dried and sifted sand is immersed in the first vessel, and unsifted sand, which has not yet gone through the cleaning stage and contains a natural level of moisture, is immersed in the second. As a result, full and empty bowls are weighed and after that, the permissible value of the density of quarry sand is determined using a special formula.