Electrophore machine design

The first electrostatic machine appeared around 1650. It was designed by the German scientist, burgomaster of Magdeburg Otto von Guericke. The operation of this machine was based on the phenomenon of electrification of bodies by friction. Subsequently, a large number of different designs of electric friction machines were created, but they all had a common significant drawback: working with such machines required the application of very great physical effort.

The electrophoric machine was created in 1865 by the German experimental physicist August Toepler. Simultaneously with Toepler and independently of him, another German physicist, Wilhelm Goltz (1836-1913), invented the electrophore machine. Goltz's machine, compared to Toepler's machine, made it possible to obtain a larger potential difference and could be used as a source of direct electric current. At the same time, it had a simpler design. Between 1880 and 1883 it was improved by the English inventor James Wimshurst. The electrophore machines currently used for demonstrations are modifications of the Wimshurst machine.

Electrostatics is a branch of electrodynamics that studies the interaction of stationary electric charges. In the process of studying this science, an electrophore machine or Wimshurst generator is used as a demonstration auxiliary device. It is designed to produce large charges and high potential differences. Using the phenomenon of electromagnetic induction, electrical charges accumulate at the poles of the machine, and the potential difference across the spark gaps reaches several hundred thousand volts. Its prototype was created in 1865. The machine also consists of two discs rotating in opposite directions. On the racks of two Leyden jars. The outer linings of the cans are connected to each other by means of a movable plate located between two clamps, the inner ones are connected to separate conductors. The handles of the conductors are insulated to prevent electric shock when the position of the conductors relative to each other changes. Aluminum sectors are applied to the outer side of the discs. Counters come into contact with them. The discs are driven directly by a belt drive (Figure 1). All parts of the machine are mounted on plastic stands, which, together with Leyden jars, are mounted on a common wooden stand. When the disks rotate, one of the sectors carries a certain positive charge, and the sector opposite to it carries a negative charge. When the sectors move in different directions, their potentials increase due to the work performed against the forces of their electrostatic attraction. When the disks rotate, charge separation occurs. We see a discharge between the conductors and hear a crackling sound. The current strength depends on the speed of rotation of the disks. It is not great, but the tension is enormous. Therefore, contact with conductors is not allowed.

Picture 1

What are Leiden banks?

In many cases, charges accumulate on capacitors. They are called Leiden banks. After this, it is possible to reproduce much stronger discharges and sparks. The internal plates of each capacitor are connected to the conductors separately. The brushes that touch the disc sectors are integrated with the inner linings of the Leyden jars. The entire structure today is mounted on plastic racks. Together with the Leyden jars, the machine parts are mounted on a wooden stand. Considering the clarity of the design, an electrophore machine can be made quite simply with your own hands. Even a person who does not have a special technical education can assemble it and operate it for his own pleasure.

Electrophore machine design

How to clean a washing machine at home

2 coaxial disks rotate against each other, while carrying simple capacitors made of aluminum sectors. Thanks to random processes, at the initial moment a charge is formed in a section of one of the segments. The phenomenon is caused by the process of friction with air. Due to the symmetry of the design, the final sign cannot be predicted in advance.

The design uses 2 Leyden jars. They create a single system from series-connected capacitors. This has the effect of doubling the operating voltage requirements in each container. The same ratings should be selected, this is the key to uniform distribution of operating voltage.

Induction neutralizers are designed to relieve tension. The entire structure resembles a metal comb floating at some distance above the disk. Both disks with equivalent signs of the outer surface arrive at the charge removal point. The neutralizers are paired. After unloading, the charge of the segments is greatly reduced. In additional designs, the brush easily contacts the edge of the disc.

The operator, using the force of an electric drive or with his own hand, forcibly brings the repulsive elements of the system closer together. Charges interacting with each other try to position themselves as far away as possible. The process promotes a sharp increase in the surface charge density at all removal points.

Electricity is collected in Leyden jars from the combs of the neutralizers. There is a rapid increase in voltage. A spark gap attached to 2 electrodes helps to avoid failure of the system. It is possible to obtain arcs of varying strength by adjusting the distance between them. There is a relationship: the stronger the field strength between the 2 spark gaps, the more noisy the effect accompanies the process of emptying the Leyden jars.

The segments remain empty beyond the charge removal point. Along the flow of movement, potential equalizers or neutralizers are installed according to the principle of operation. Each opposite side of the disk has already given up charge to different brushes. At the moment of passing the removal point and after it, the residual signs of the charge are different.

A piece of thick copper wire with brushes of the finest wires, hovering at a low height or rubbing the segments, helps to close these opposites. The result is that the charges on both segments are equal to zero, all energy is converted according to the Joule-Lenz law into heat generated on the thickened copper core.

ANTIQUE Electrophore machine Electric generator Fizpribor USSR #Zh#

Electrophoric machine (Wimshurst generator (wrong: Wimshurst)) is an electrostatic generator, an electrical machine for generating high voltage, developed between 1880 and 1883 by British inventor James Wimshurst (English) (1832–1903). It uses the phenomenon of electrostatic induction, in which electrical charges accumulate at the poles of the machine (Leyden jars), the potential difference across the dischargers reaches several hundred thousand volts. Works using mechanical energy.Buy what is in the photo. Condition in the photo. Additional photos upon request.

Ask, ask questions. COMMUNICATION is the engine of trade!!!

There are reasonable BARGAINING and wholesale DISCOUNTS.

********** ********** ********** ********** **********

THANK YOU FOR VISITING MY PAGE!

Dear customers! Delivery is discussed before the bid, through the window to the seller, it depends on the contents of the shipment (letter, parcel, parcel), on the weight of the shipment, on the location of the addressee (distance) and is calculated according to postal rates + the cost of packaging materials (box, envelope, packaging) + insurance (by agreement with the buyer). I don’t send anything by simple letter. Be careful!

SEE PICTURES FOR THE CONDITION OF THE LOT. TO AVOID RUSH PURCHASES, PLEASE READ THE LOT, ITS PHOTOS AND DESCRIPTION CAREFULLY. IF YOU DO NOT UNDERSTAND ANYTHING, ASK FOR ADDITIONAL PHOTOS, ASK QUESTIONS FOR CLARIFICATION. IF AND THEN YOU BELIEVE THAT THE INFORMATION IS NOT RELIABLE, PLEASE REFRAIN FROM PURCHASING.

THE PRODUCTS ARE DISPLAYED IN PRIVATE SALE MODE, I AM NOT AN EXPERT ON ALL PRODUCT CATEGORIES. EVERYONE'S PREFERENCES, CONCEPTS AND REQUIREMENTS FOR PRODUCT QUALITY ARE DIFFERENT, SO THINK BEFORE YOU MAKE A PURCHASE TO AVOID DISAPPOINTMENT - DO YOU NEED THIS LOT. I WILL NOT CONSIDER CLAIMS AFTER PURCHASING THE LOT. AFTER THE PACKAGE IS TRANSFERRED TO THE DEPARTMENT, THERE ARE NO RETURNS OR EXCHANGES.

SOME PRODUCTS SOLD ARE ALREADY USED AND HAVE TRACES OF USAGE, SOME ARE COMPLETELY NEW BUT HAVE TRACES OF STORAGE TO VARYING DEGREES. DO NOT CONFUSE DISTANCE TRADE WITH TRADE OF USED GOODS. BY BUYING AN LOT OR PLACING A BID, YOU AGREE TO THE TERMS OF SALE DESCRIBED ABOVE, THE PRICE OF THE PRODUCT, AND THE COST OF DELIVERY.

PAYMENT FOR LOTS WITHIN 3 DAYS, SHIPPING BY MAIL, I SHIP WITHIN 5 DAYS EXCLUDING WEEKENDS AND HOLIDAYS.

I DO NOT WORK WITH COD ON PAYMENT, I AM NOT RESPONSIBLE FOR THE OPERATION OF THE MAIL. TO AVOID PROBLEMS YOU CAN USE INSURANCE, AFTER SENDING THE LOT I WILL PROVIDE A TRACK CODE TO TRACK THE MAIL.

THE AMOUNT OF SHIPPING AROUND THE COUNTRY IS DISCUSSED SEPARATELY, COMPLIED OF THE COST OF DELIVERY (AT MAIL RATES) + CONSUMABLES (ENVELOPE, BOX, PACKAGING) + INSURANCE (BY AGREEMENT WITH THE BUYER).

IF THE BUYER HAS NOT CONTACTED WITHIN 3 DAYS, THE LOT WILL BE RElisted AND THE BUYER WILL BE BLACKLISTED.

PAYMENT: S.B. CARD, PayPal.

ENJOY THE SHOPPING!

Electrophoric machine - electrostatic generator for experiments and physics classes PEG-20

We are pleased to present to the attention of young technicians and physicists, as well as physics teachers, an electrophoric machine - an electrostatic generator for experiments and physics classes PEG-20. This device is a static charge generator consisting of two wheels rotating in mutually opposite directions. Nowadays, this device is very often used by teachers in physics lessons to demonstrate the power of an electric arc. This device is a modern version of the Wimshurst generator and is an induction electrostatic machine. In it, a static charge is formed not through triboelectricity when friction is present, but through the induction of charges. The device is made of plastic and metal elements and has dimensions of 24 x 28.5 x 20 cm. The principle of use is very simple, just start twisting the appropriate handle and the device starts working. When the handle is rotated, the discs begin to move in opposite directions. The brushes begin to come into contact first with one and then with subsequent metal strips. With each revolution, more and more charge begins to accumulate, which ensures an increase in the potential at the contacts. As soon as the accumulated charge reaches its maximum value, further charge growth stops. For better accumulation, capacitors in the form of Leyden jars are used. After the charge has accumulated, bringing the contacts close enough to each other, a “discharge” occurs, which is clearly visible, after which the charge continues to grow again.

In everyday life, in this form, this device is not used, but serves only as a historical exhibit, illustrating the history of the emergence and development of scientific and technological progress and engineering. Laboratory demonstration shows various phenomena and effects of electricity. If you are a physics teacher or the director of an educational institution where students are clearly shown certain physical phenomena, then this electrophoric machine - an electrostatic generator for experiments and physics classes PEG-20 will become simply an indispensable tool for you in the field of getting to know electricity.

Precautionary measures:

Keep children away from the machine and do not allow children to play with this generator. Use this generator only if you are familiar with its capabilities and safety precautions. Since the machine generates high voltage, do not touch any metal parts while operating the machine. Remember to discharge the electrodes with the metal "Y" handle after completing the experiment. Do not turn the handle too much as the pulley system may be damaged. If a spark is not visible or heard, check the machine for moisture in the brushes. You can dry the car by holding it in the sun or next to a heating device (until the moisture is removed).. Specification:

Specification:

- Can be used to demonstrate experiments in physics classes

- Material: metal, plastic

- Size: 24 x 28.5 x 20 cm

- Weight: 1.4 kg.

Equipment:

Electrophoric machine - electrostatic generator for experiments and physics classes PEG-20 – 1 pc.

Electrophore machine

1. Purpose of the benefit

Used in physics lessons to obtain large charges and high potential differences when conducting demonstration experiments in electrostatics.

2. Delivery set

1. Device - 1 pc. 2. Drive handle - 1 pc. 3. Operation manual - 1 pc. 4. Packing box - 1 pc.

3. Main technical characteristics

Overall dimensions - 350x300x180 mm Weight - no more than 2 kg.

4. Device design and operating conditions

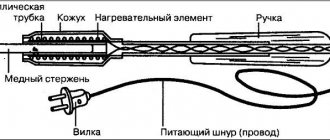

The main parts of the electrophore machine are two plastic disks rotating in opposite directions and two Leyden jars. The outer linings of the cans are connected to each other by a movable plate located between two clamps, and the inner ones are connected to separate conductors. Using the insulating handles, the conductors can be rotated and the distance between them can be changed. On the outside of the discs, aluminum sectors are applied, with brushes mounted in brush holders in contact. The disks are surrounded by metal combs connected to Leyden jars and to two spark gaps. The discs are driven into rotation using direct and cross belt drives. All parts of the machine are mounted on plastic stands, which, together with Leyden jars, are mounted on a common wooden stand. For normal operation of the device, it is necessary to ensure that one of the brush holders is installed to the horizontal diameter of the disk at an angle of approximately 45 degrees, the second - at a right angle to the first. If there is no accumulation of charges on the Leyden jars, it is recommended to initially charge the plastic disks by inserting a sheet of paper, or preferably a piece of thin cloth, into the gap between them, and by rotating the handle, get a spark between the spark gaps, and then pull out the paper. After completing the demonstration work, close the spark gaps to neutralize the accumulated charge.

5. Storage rules

The product should be stored in a dry room at room temperature (15-25C) with a relative humidity of 80%.

6. Certificate of acceptance

The device complies with the technical specifications of TU 79 RF 529-03 and is recognized as suitable for use. Release date '______' _______________ 20 ____

7. Warranty

The manufacturer guarantees that the device meets the requirements of the specifications, subject to the conditions of operation, transportation and storage. The warranty period is 1 (one) year from the date of commissioning of the device.

DIY electrostatic generator | 2 Schemes

How to clean a dishwasher at home: cleaning tips

The operating principle of a static electricity generator (also called electrophore machines) is that the disks rotate relative to each other in opposite directions and create positive and negative charges. When the disks rotate, as charges accumulate, a discharge occurs—lightning between the electrodes.

How it works - theory

The rotation of disks with metal sectors leads to the transfer of electrical charge inside the machine, which is stored in capacitors until a spark or leakage charge occurs.

The neutralizer does the following: it drags the charge from one half of the disk to the other and the disk is not just charged, but selectively charged - not over the entire plane.

In other words, the disk collects charges from the air, and the neutralizers redistribute them. The charge is removed by the brush, moves along the conductor to the opposite brush, and at the moment when a segment of the second disk appears opposite the segment, it jumps to it.

Next, this segment approaches the brush of the second neutralizer and the process is repeated, but on another disk. Thus, a circulation of charges occurs between the disks, during which the air between the segments is ionized and separated. As a result of pumping, the voltage increases; in addition, the machine has the effect of moving the capacitor plates apart, which also helps to increase the voltage.

A miniature device for creating such harmless lightning (but not for microelectronics) is easy to make with your own hands.

This electrostatic generator is capable of generating over 20,000 volts, but the low current makes it safe to use without special precautions.

Device characteristics

- Height: about 140mm

- Width: approximately 120 mm

- Power: 3V 0.3A

- Static charge: 20 kV

- Disc diameter: 120 mm

There is no need to turn anything by hand (as was the case in the prototype of the century before last) - everything is done by 2 electric motors. Just press the power button and wait a while until the charge accumulates on the electrodes.

Materials and components

You will need for installation: a soldering iron and solder, a screwdriver and pliers. Two motors from old CD players and all sorts of small fastenings.

The generator runs on two AA batteries and is capable of creating discharges 2 cm long. The most difficult thing here is the 120 mm discs. They need to be made according to this principle: take two laser discs from a CD or DVD. Glue the segments with aluminum tape (25 sectors). Glue the discs to the motors. Make brushes from aluminum strips.

If everything is done and configured as necessary, the spark will reach a size of about 20 mm, and the discharge will strike every 0.5 seconds.

How it works - theory

How to make a stun gun at home

The rotation of disks with metal sectors leads to the transfer of electrical charge inside the machine, which is stored in capacitors until a spark or leakage charge occurs.

The most important parts in an electrophore unit are neutralizers. These are two jumpers with brushes installed in a cross. If at least one of the four brushes is moved away from the segments, the machine stops working. Although it would seem that the disks are rotating, they are electrified by friction with the air, which means electricity is generated.

The neutralizer does the following: it drags the charge from one half of the disk to the other and the disk is not just charged, but selectively charged - not over the entire plane.

In other words, the disk collects charges from the air, and the neutralizers redistribute them. The charge is removed by the brush, moves along the conductor to the opposite brush, and at the moment when a segment of the second disk appears opposite the segment, it jumps to it.

Next, this segment approaches the brush of the second neutralizer and the process is repeated, but on another disk. Thus, a circulation of charges occurs between the disks, during which the air between the segments is ionized and separated. As a result of pumping, the voltage increases; in addition, the machine has the effect of moving the capacitor plates apart, which also helps to increase the voltage.

A miniature device for creating such harmless lightning (but not for microelectronics) is easy to make with your own hands.

This electrostatic generator is capable of generating over 20,000 volts, but the low current makes it safe to use without special precautions.

What are Leiden banks?

In many cases, charges accumulate on capacitors. They are called Leiden banks. After this, it is possible to reproduce much stronger discharges and sparks. The internal plates of each capacitor are connected to the conductors separately. The brushes that touch the disc sectors are integrated with the inner linings of the Leyden jars. The entire structure today is mounted on plastic racks. Together with the Leyden jars, the machine parts are mounted on a wooden stand. Considering the clarity of the design, an electrophore machine can be made quite simply with your own hands. Even a person who does not have a special technical education can assemble it and operate it for his own pleasure.

The basic operating principle of an electrophore machine

A detailed study of abstract physical concepts is impossible without the use of visual materials, visualization and experimentation. The use of an electrophore machine in physics lessons in high school allows one to form clear theoretical and practical concepts about electric current, the basic technical conditions for its appearance and long-term existence in a closed circuit.

The separation of machine charges is carried out due to the sequential transformation of mechanical energy. As the brushes move, friction occurs on the surface of the discs, due to which the charges are separated into positive and negative. If the electrodes approach, a discharge of electricity appears. At the time of the demonstration presentation, you have to intensively rotate the handle of the machine, which will allow you to continuously produce electric current.

A brief principle of operation of an electrophore machine is used in physics classes during the study of mechanical energy sources, as well as the processes of converting mechanical energy into electricity. The use of the device allows you to visually conduct an experiment directly within the framework of a standard lesson.

Do you have an application?

We will select all the equipment and furniture, prepare documents and deliver with a delay of 45 days.

What is the operation of an electrophore machine based on?

Using the mutual force of both disks - this is the main principle in this device. The effect of a potential difference, and then discharges and sparks, is achieved by the correct arrangement of sectors. Of course, there are developments that use blank disks, but they don’t issue anything like this. Such designs are often used in small educational institutions. The distance between the disks in a device such as an electrophore machine plays a vital role and has a significant impact on achieving the required voltage on the capacitors.

How does charge accumulation occur?

Let's assume that the first circle has a lack of free charges, which in our case means a lack of free electrons in the metal plates. When the second disk moves, its plates will alternately come into contact with the brushes on conductor 8, and, accordingly, an excess of free charge carriers will be formed on them.

This happens because the plates on both sides, between which the dielectric (the material of the disks) is located, are a flat capacitor, but a capacitor whose plates move. The electric charge on such a capacitor is induced, or in other words, induced.

Then the following happens. The plates of the second disk, having reached the brushes of contact 6, will give their electrons to a storage device in the form of a Leyden jar (capacitor). This Leyden jar will accumulate a charge -Q

.

Then it will be the turn of the next plates and so on. A similar process occurs on the first disk, since it also rotates, but in a different direction. Here we can say that free carriers are, as it were, pumped out of another Leyden jar, thereby forming a lack of electrons on it, which means it acquires a +Q

.

The more often the plates of both disks come into contact with the brushes on conductors 6 and 7, the greater the amount of charges accumulates on them. Leyden jars, if installed, will charge more and more until Coulomb forces begin to resist further accumulation of charges. This means that there is an accumulation limit, which can also be characterized by the potential difference (voltage) between the two contacts 6 and 7.

If you subsequently discharge both contacts that have accumulated +Q

and

-Q

, either on each other, or transfer the charge to another electrical capacitance, then further accumulation of charge will become possible again.

You can ask. Where does the initial charge come from?

The point is that it always exists. Any two conductors separated by a dielectric (gas, liquid, solid) always have a capacitance, and moreover, they have a potential difference, which indicates the presence of more free charge carriers on one such conductor than on the other.

The Wimshurst electrophoric machine is a self-excited machine, that is, it does not require the supply of any additional charge to start its operation.

Design

The design of James Wimhurst's invention is poorly described in open sources; often people are unable to explain how the electrophore machine works.

General idea

Two coaxial disks rotating against each other carry simple capacitors made from aluminum sectors. Due to random processes, at the initial moment, a charge is formed on one of the segments - evenly spaced in a circle. This is caused by friction processes with air or other reasons. Moreover, since the design is symmetrical, the sign is not predictable in advance. It is not recommended to install electrolytic capacitors in the electrophore machine.

Instead, two Leyden jars are used. Their outer foil plates are combined to create a single system of capacitors connected in series. This reduces the operating voltage requirements for each container by half. The denominations are selected as identical as possible. Otherwise, the operating voltage requirements will be distributed unevenly, leading to negative consequences.

The voltage from the disk segments is removed using induction neutralizers. The principle of operation is described below. Essentially, a structure resembling a metal comb floats above the disk at a certain height. The neutralizers are paired; both disks arrive at the charge removal point with an equivalent sign on the outer surface. After unloading, the charge of the segments drops significantly. This is due to the special design of induction neutralizers, leaving a surface charge density in the region of 0.2 - 6 μC per square meter. In selected designs, the brush lightly touches the edge of the disc.

The progressive increase in the surface charge density on the segments at the point of removal is due to the fact that systems are moving towards each other, creating electric fields whose strengths are directed in opposite directions. It turns out that with his own hand the operator (or through the force of an electric drive) forcibly brings the repulsive systems together. The interacting charges try to position themselves further away from each other. This causes a sharp increase in the surface charge density at the removal points.

From the neutralizer combs, electricity is collected in Leyden jars. The voltage rises quickly, in order to avoid system failure due to exceeding the permissible parameters of the capacitors, a spark gap is attached to the two electrodes. The distance between them is usually adjustable, which allows you to obtain an arc of varying strength. The higher the field strength between the spark gaps, the more noisy the process of emptying the Leyden jars.

After the charge removal point, the segments remain empty. At 30 degrees in the direction of motion of the disk there are potential equalizers, called neutralizers based on their operating principle. The authors of the review would call them equalizers. The opposite sides of the disk have already given up charge from different brushes. Consequently, after passing the removal point, the signs of the remaining charge on them are invariably different. And a piece of thick copper wire with brushes of thin wires, rubbing the segments or hovering at a low altitude, short-circuits the indicated opposites. As a result, the charge on both segments becomes zero, the energy is converted according to the Joule-Lenz law into heat released on a thick copper core.

After zeroing, the disks continue to move in the opposite direction. It turns out that a segment of one circle of rotation, freed from charge, turns out to be opposite the half-empty segment of another. The charge between the containers is immediately divided equally, because the disks are designed according to the same drawings. Therefore, they appear identical. The first disk releases half its charge and goes to the removal point. The second reaches the point of potential equalization of the first and there gives up half the charge.

Sometimes people are interested in the principle of operation of the device, because the first disk gave up the residual charge on the equalizer, the second did the same. Where can I get the energy to change the sign?

- https://odinelectric.ru/knowledgebase/chto-takoe-elektrofornaya-mashina-i-kak-ona-rabotaet

- https://fb.ru/article/136480/elektrofornaya-mashina—printsip-rabotyi-kak-sdelat-elektrofornuyu-mashinu-svoimi-rukami

- https://vashtehnik.ru/enciklopediya/elektrofornaya-mashina.html

Electrophore machine

An electrophore machine is a static charge generator consisting of two wheels rotating in mutually opposite directions. Often used by teachers in physics lessons to intimidate those studying with the force of an electric arc.

Design

The design of James Wimhurst's invention is poorly described in open sources; often people are unable to explain how the electrophore machine works.

General idea

Two coaxial disks rotating against each other carry simple capacitors made from aluminum sectors. Due to random processes, at the initial moment, a charge is formed on one of the segments - evenly spaced in a circle. This is caused by friction processes with air or other reasons. Moreover, since the design is symmetrical, the sign is not predictable in advance. It is not recommended to install electrolytic capacitors in the electrophore machine.

Instead, two Leyden jars are used. Their outer foil plates are combined to create a single system of capacitors connected in series. This reduces the operating voltage requirements for each container by half. The denominations are selected as identical as possible. Otherwise, the operating voltage requirements will be distributed unevenly, leading to negative consequences.

The voltage from the disk segments is removed using induction neutralizers. The principle of operation is described below. Essentially, a structure resembling a metal comb floats above the disk at a certain height.

The neutralizers are paired; both disks arrive at the charge removal point with an equivalent sign on the outer surface. After unloading, the charge of the segments drops significantly.

This is due to the special design of induction neutralizers, leaving a surface charge density in the region of 0.2 - 6 μC per square meter. In selected designs, the brush lightly touches the edge of the disc.

The progressive increase in the surface charge density on the segments at the point of removal is due to the fact that systems are moving towards each other, creating electric fields whose strengths are directed in opposite directions. It turns out that with his own hand the operator (or through the force of an electric drive) forcibly brings the repulsive systems together. The interacting charges try to position themselves further away from each other. This causes a sharp increase in the surface charge density at the removal points.

From the neutralizer combs, electricity is collected in Leyden jars. The voltage rises quickly, in order to avoid system failure due to exceeding the permissible parameters of the capacitors, a spark gap is attached to the two electrodes. The distance between them is usually adjustable, which allows you to obtain an arc of varying strength. The higher the field strength between the spark gaps, the more noisy the process of emptying the Leyden jars.

After the charge removal point, the segments remain empty. At 30 degrees in the direction of motion of the disk there are potential equalizers, called neutralizers based on their operating principle. The authors of the review would call them equalizers. The opposite sides of the disk have already given up charge from different brushes.

Consequently, after passing the removal point, the signs of the remaining charge on them are invariably different. And a piece of thick copper wire with brushes of thin wires, rubbing the segments or hovering at a low altitude, short-circuits the indicated opposites.

As a result, the charge on both segments becomes zero, the energy is converted according to the Joule-Lenz law into heat released on a thick copper core.

Induction neutralizers

Neutralizers can become dirty during operation. Therefore, cleaning is required periodically, otherwise the efficiency will be reduced. In the Wimhurst machine, the fact of a decrease in efficiency plays little role. If the machine does not work, it is worth checking the cleanliness of the needles. The design uses four induction neutralizers:

- The twin equalizers lie almost perpendicular to each other.

- One puller for each Leyden jar.

They are a brush made of thin wire or sharp toothed flat combs (combs). The base can be metal, which is used in the Wimhurst machine, or wood. The tips are always metal, the purpose is to quickly remove the charge to grounding as quickly as possible. Operating principle: as the tips approach the charged plane, the tension lines close on them, forming high values.

The increased density in the tip area promotes ionization of the air (without a spark) and the formation of charges of both signs, conducting current in the desired direction. The parameters of neutralizers strongly depend on the distance between the tips and the decrease in the radius of their curvature (sharpening). The wire brush neutralizers used in the Wimhurst machine are the least effective. The pullers have combs or needles. It is believed that for the latest neutralizers, maximum effectiveness is achieved under the following conditions:

- The ratio of the height of the needles to the distance between them is from 0.6 to 1.8.

- The length of the needles is 12 – 50 mm or more.

- The diameter of the needles is 0.5 – 1 mm.

Reducing the sharpening angle beyond 60 degrees (increasing curvature) in this case has little effect on the properties of the neutralizer. It is advisable to bring the needles at a distance of 5 mm to the surface. The closer, the faster the charge is removed. In fact, the minimum distance to the plane depends solely on the disc's own vibrations. Touching will not lead to system failure, but the service life will sharply decrease due to mechanical destruction of individual elements.

Contrary to the generally accepted opinion, created from endless demonstrations of the machine, it is better to mount the needles on a dielectric base. This step reduces the capacitance between the disk and the ridge, which increases the charge density: C = q/U. The charge is already given a priori; lowering the capacitance increases the potential difference (voltage), which facilitates the ionization process.

For safety, the neutralizer is equipped with a casing. It is worth recalling that other parts (besides the rotation handle) of the Wimhurst machine cannot be touched during operation. The edges of the casing are at least 50 mm away from the neutralizer needles.

The induction type of device is named for its action at a distance. The process is called electrostatic induction. This means that one charged object at a distance affects a second one without a charge. In a metal, electrons are weakly bound to the lattice and easily move in the direction where they are carried by the field. The effect is superficial for an obvious reason - tension lines cannot penetrate the metal. In another way: charges in the thickness of the conductor are redistributed until they completely neutralize the external field.

As a result, a charge is induced on the surface of the needle. The field strength lines close on it, simultaneously converging from everywhere, as shown in the figure. The potential difference increases immeasurably, causing ionization of the air. It is moderate; when the Wimhurst machine operates, there is usually no sparking on the brushes.

Electrophore machine design

This device consists of two disks that rotate towards each other. The operation of the electrophore machine is precisely to carry out such double reciprocal rotation. The disks contain conductive segments isolated from each other. Capacitors are formed using the linings of the sides of both disks. That is why an electrophore machine is sometimes called a capacitor machine. Neutralizers are located on the disks, which remove charges from the opposite elements of the disks to the ground using brushes. Collectors are on the left and right. It is to them that the generated signals taken by combs from the rear and front disks are received.

Rate this article:

How to make an electrophore machine at home

The electrophore machine works as a continuous source of electrical energy. This device is often used as an auxiliary device for demonstrating various electrical phenomena and effects. But what is its design and features?

Electrophore machine design

This device consists of two disks that rotate towards each other. The operation of the electrophore machine is precisely to carry out such double reciprocal rotation. The disks contain conductive segments isolated from each other.

Capacitors are formed using the linings of the sides of both disks. That is why an electrophore machine is sometimes called a capacitor machine. Neutralizers are located on the disks, which remove charges from the opposite elements of the disks to the ground using brushes. Collectors are on the left and right.

It is to them that the generated signals taken by combs from the rear and front disks are received.

In many cases, charges accumulate on capacitors. They are called Leiden banks. After this, it is possible to reproduce much stronger discharges and sparks. The internal plates of each capacitor are connected to the conductors separately. The brushes that touch the disc sectors are integrated with the inner linings of the Leyden jars.

The entire structure today is mounted on plastic racks. Together with the Leyden jars, the machine parts are mounted on a wooden stand. Considering the clarity of the design, an electrophore machine can be made quite simply with your own hands.

Even a person who does not have a special technical education can assemble it and operate it for his own pleasure.