With the onset of spring, more and more often you can see people with metal detectors on the banks of rivers. Most of them are engaged in “gold mining” purely out of curiosity and passion. But a certain percentage actually earn a lot of money from searching for rare things. The secret to the success of such research is not only in experience, information and intuition, but also in the quality of the equipment with which they are equipped. A professional instrument is expensive, and if you have a basic knowledge of radio mechanics, you have probably thought more than once about how to make a metal detector with your own hands. The editors of Seti.guru will come to your aid and tell you today how to assemble the device yourself using diagrams.

If you follow our recommendations, then, quite possibly, very soon you will be able to boast of such a “catch”

Metal detector and its structure

Professional metal detector Garrett AT Pro for searching military trophies and coins

This model costs more than 32,000 rubles, and, of course, non-professionals will not be able to afford such a device. Therefore, we suggest studying the design of a metal detector in order to assemble a variation of such a device yourself. So, the simplest metal detector consists of the following elements.

Design elements of a standard metal detector

The operating principle of such metal detectors is based on the transmission and reception of electromagnetic waves. The main elements of a device of this type are two coils: one is transmitting, and the second is receiving.

The principle of operation of the metal detector

The metal detector works like this: the magnetic field lines of the primary field (A) of red color pass through the metal object (B) and create a secondary field (green lines) in it. This secondary field is picked up by the receiver and the detector sends an audible signal to the operator. Based on the principle of operation of emitters, electronic devices of this type can be divided into:

- Simple, working on the “receive-transmit” principle.

- Induction.

- Pulse.

- Generating.

The cheapest devices belong to the first type.

The simplest metal detector will make you lose a couple of extra pounds. You'll be walking and digging a lot

An induction metal detector has one coil that sends and receives a signal simultaneously. But devices with pulse induction differ in that they generate a transmitter current, which turns on for a while and then turns off abruptly. The coil field generates pulsed eddy currents in the object, which are detected by analyzing the attenuation of the pulse induced in the receiver coil. This cycle repeats continuously, perhaps hundreds of thousands of times per second.

General structure of the metal detector

This device operates on the principles of changing the characteristics of the electromagnetic field when foreign objects appear in the work area. The classic scheme involves the use of the following components:

- a generator that creates oscillations in a certain frequency range;

- induction coil;

- receiver with an amplification path;

- signal decoding unit;

- visual and audio indicators;

- frame on which the working components of the installation are fixed.

Typical metal detector design

Coil

This functional element simultaneously emits and receives electromagnetic waves. To make a high-quality homemade product, you should study factory analogues. Experienced experts recommend paying attention to the following details:

- round models provide a larger coverage area;

- oval - more convenient to use;

- by installing a large coil you can increase the search efficiency (working depth) by 15-25%;

- small – provide a narrow radiation pattern, which simplifies the detection of several small objects;

- better uniformity of the cylinder-shaped working area is created by a double coil (DD);

- The ring-shaped coil has a cone-shaped radiation pattern.

Types of coils

Electronic circuit

In the simplest devices, a generator, a receiver, and a power supply are installed on one compact printed circuit board. Field changes are recorded using an audio frequency signal.

More complex metal detector circuits with discrimination provide dynamic processing of incoming information. Such devices are able to determine the difference between a steel screw and a silver coin. This selectivity greatly improves search efficiency because it automatically eliminates wasteful, time-consuming excavation work.

How does a metal detector work depending on its purpose and technical device?

The operating principle of a metal detector varies depending on the type of device. Let's consider the main ones:

- Dynamic type devices . The simplest type of device that continuously scans the field. The main feature of working with such a device is that you must be in motion all the time, otherwise the signal will disappear. Such devices are easy to use, however, they are poorly sensitive.

- Pulse type devices. They have great sensitivity. Often, such a device comes with several additional coils for adjustment to different types of soils and metals. Requires certain skills to set up. Among the devices of this class we can distinguish electronic devices operating at low frequencies - no higher than 3 kHz.

Sometimes treasure hunters get lucky and find very interesting things.

- Electronic devices , on the one hand, do not respond (or give a weak response) to unwanted signals: wet sand, small pieces of metal, shot, for example, and, on the other hand, provide good sensitivity when searching for hidden water pipes and central heating routes, and also coins and other metal objects.

- Depth detectors are designed to search for objects located at impressive depths. They can detect metal objects at a depth of up to 6 meters, while other models “pierce” only up to 3. For example, the Jeohunter 3D depth detector is capable of searching and detecting voids and metals, while showing objects found in the ground in 3- measured form.

The Jeohunter 3D depth detector monitor shows what is under your feet in real time.

Depth detectors operate on two coils, one is parallel to the ground surface, the other is perpendicular.

- Stationary detectors are frames installed at particularly important protected sites. They detect any metal objects in people's bags and pockets that pass through the circuit.

Metal detector in the subway. You have probably passed through such a detector more than once, having previously emptied all the pockets

Principle of operation

Any metal detector works on the simple principle of interaction of its own magnetic field (MF) with the Earth’s magnetic field. Interaction is based on detecting metal objects. Metal, which has the property of magnetization, falls into the field of action of the metal detector due to the difference in magnetic fields.

Metals such as gold, silver, copper have ferritic properties. They just don't magnetize. For this reason, the detector cannot detect their magnetic field. Fixation occurs on the principle of determining vortex electromagnetic flows passing through the metal and forming “Foucault” elements on its surface, or vortices with a certain frequency. Pulse detectors identify a ferrite object by its electrical conductivity. The greater the conductivity, the higher the vibrational frequency from its surface.

Modern metal detectors are equipped with different types of discrimination functions. Each type allows the determination of ferritic alloy, and at the same time it can screen out “industrial debris”.

- Variable type discrimination. It is based on the processing of received signals from an object according to the degree of its electrical conductivity. For greater accuracy, the user independently configures the device. The setting allows you to select the most promising signals. Metal detectors with a similar function are equipped with a visual indicator, which has a scale with a clear division into signal types and their corresponding metals. Variable discrimination allows you to detect only objects larger than 1–3 centimeters. Various inclusions, small nuggets, sand, fragments of chains, etc., are not found by such devices.

- Selective type. Detectors with this feature can be configured to only receive a specific signal. Thus, the device will not react, for example, to copper, aluminum, silver, detecting only gold in the soil. This type is very useful when working in trashy areas. A large amount of small metal debris will not interfere, allowing you to detect only the necessary frequency signals.

- Two-dimensional type. The most modern technology. Allows you to identify ferritic alloys around which an accumulation of ferrous metal is formed. The control unit is responsible for recognition, which makes a preliminary calculation of the electrical conductivity of the entire object in the scanned area.

It is also worth considering the total soil moisture, its composition, and hardness.

Metal detectors with a discriminator are more energy-intensive and functional. Refers to pulse devices. The additional feature makes the devices more powerful. The operating frequency varies from 9 to 25 kHz. The pulse operating principle allows such devices to detect ferritic alloys at depths of up to 2 meters or more.

Which metal detectors are suitable for making yourself at home?

The simplest devices that you can assemble yourself include devices that operate on the principle of reception and transmission. There are schemes that even a novice radio amateur can do; for this you just need to select a certain set of parts.

Parts for a metal detector can be found in any garage.

There are many video instructions on the Internet with detailed explanations of how to make a simple metal detector with your own hands. Here are the most popular ones:

- Metal detector "Pirate".

- Metal detector - butterfly.

- Emitter without microcircuits (IC).

- Series of metal detectors "Terminator".

However, despite the fact that some entertainers are trying to offer systems for assembling a metal detector from a phone, such designs will not pass the battle test. It’s easier to buy a children’s metal detector toy, it will be more useful.

This toy allows you to detect a coin or a nail at a shallow depth, as well as find a missing needle on the carpet. Such devices most often react to “base” metal

And now more about how to make a simple metal detector with your own hands using the example of the “Pirate” design.

Do-it-yourself simple metal detector

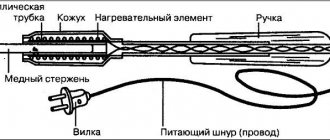

The metal detector circuit is not complicated, and you can find it either on the vast world wide web or in specialized literature. Above is a list of radio elements that are useful for assembling a metal detector with your own hands at home. You can assemble a simple metal detector with your own hands using a soldering iron or other available method. The main thing is that the parts should not touch the body of the device. To ensure the operation of the assembled metal detector, power supplies of 9 - 12 volts are used.

To wind the coil, use a wire with a cross-sectional diameter within 0.3 mm; of course, this will depend on the chosen circuit. By the way, the wound coil must be protected from exposure to extraneous radiation. To do this, shield it with your own hands using ordinary food foil.

The simplest metal detector at home

To flash the controller firmware, special programs are used, which can also be found on the Internet.

Homemade metal detector “Pirate”: diagram and detailed description of the assembly

Homemade products based on the “Pirate” series metal detector are among the most popular among radio amateurs. Thanks to the good performance of the device, it can “detect” an object at a depth of 200 mm (for small items) and 1500 mm (large items).

Parts for assembling a metal detector

The Pirate metal detector is a pulse type device. To make the device you will need to purchase:

- Materials for making the body, rod (you can use a plastic pipe), holder, and so on.

- Wires and electrical tape.

- Headphones (suitable for the player).

- Transistors – 3 pieces: BC557, IRF740, BC547.

- Microcircuits: K157UD2 and NE

- Ceramic capacitor - 1 nF.

- 2 film capacitors - 100 nF.

- Electrolytic capacitors: 10 μF (16 V) – 2 pieces, 2200 μF (16 V) – 1 piece, 1 μF (16 V) – 2 pieces, 220 μF (16 V) – 1 piece.

- Resistors – 7 pieces per 1; 1.6; 47; 62; 100; 120; 470 kOhm and 6 pieces for 10, 100, 150, 220, 470, 390 Ohm, 2 pieces for 2 Ohm.

- 2 diodes 1N148.

DIY metal detector circuits

The classic circuit of the “Pirate” series metal detector is built using the NE555 microcircuit. The operation of the device depends on a comparator, one output of which is connected to the IC pulse generator, the second to the coil, and the output to the speaker. If metal objects are detected, the signal from the coil is sent to the comparator, and then to the speaker, which notifies the operator of the presence of the desired objects.

Receiving node on the Pirate chip

The board can be placed in a simple junction box, which can be purchased at an electrical store. If such a tool is not enough for you, you can try to make a more advanced device; a diagram for making a gold-oriented metal detector will help you.

Diagram of the ultra-sensitive metal detector Pirate-4

How to assemble a metal detector without using microcircuits

This device uses Soviet-style transistors KT-361 and KT-315 to generate signals (you can use similar radio components).

How to assemble a metal detector circuit board with your own hands

The pulse generator is assembled on the NE555 chip. By selecting C1 and 2 and R2 and 3, the frequency is adjusted. The pulses obtained as a result of scanning are transmitted to transistor T1, and it transmits the signal to transistor T2. The audio frequency is amplified using the BC547 transistor to the collector, and headphones are connected.

Pirate metal detector board with speaker

To place radio components, a printed circuit is used, which can be easily made independently. To do this, we use a piece of sheet getinax covered with copper electrical foil. We transfer the connecting parts onto it, mark the fastening points, and drill holes. We cover the tracks with a protective varnish, and after drying, we lower the future board into ferric chloride for etching. This is necessary to remove unprotected areas of copper foil.

How to make a metal detector coil with your own hands

For the base you will need a ring with a diameter of about 200 mm (ordinary wooden hoops can be used as the base), on which 0.5 mm wire is wound. To increase the depth of metal detection, the coil frame should be in the range of 260−270 mm, and the number of turns should be 21−22 vol. If you don't have anything suitable on hand, you can wind a reel on a wooden base.

Copper wire spool on wooden base

| Illustration | Description of action |

| For winding, prepare a board with guides. The distance between them is equal to the diameter of the base on which you will attach the reel. | |

| Wind the wire around the perimeter of the fastenings in 20-30 turns. Secure the winding with electrical tape in several places. | |

| Remove the winding from the base and give it a rounded shape; if necessary, additionally fasten the winding in several more places. | |

| Connect the circuit to the device and test its operation. |

Twisted pair coil in 5 minutes

We will need: 1 twisted pair 5 cat 24 AVG (2.5 mm), knife, soldering iron, solder and multitester.

| Illustration | Description of action |

| Twist the wire into two skeins. Leave 10 cm on each side. | |

| Strip the winding and free the wires for connection. | |

| We connect the wires according to the diagram. | |

| For better fastening, solder them with a soldering iron. | |

| Test the coil in the same manner as the copper wire device. The winding terminals must be soldered to a stranded wire with a diameter in the range of 0.5-0.7 mm. |

What parts and tools are needed

Resistors:

- R1, R10, R22, R35 = 100 kOhm

- R2 = 3.3 kOhm

- R3, R7, R8, R13, R14, R21, R33 = 1 kOhm

- R4, R5 = 100 Ohm

- R6 = 390 Ohm 1 W (quenching)

- R9 = 1 MOhm

- R11, R20, R23 = 22 kOhm

- R12 = 10 kOhm

- R15, R16, R17 = 220 kOhm

- R18 = 47 kOhm

- R26, R29 = 51 kOhm

- R28 = 240 kOhm

- R32 = 75 kOhm

- R34 = 30 Ohm

- R25 = 50 kOhm (variable resistor)

- R10 = 100 kOhm (variable resistor)

- R33 = 1 kOhm (variable resistor, potentiometer for volume control)

- P-5 = 10 kOhm (potentiometer for threshold adjustment)

Capacitors:

- C1 = 0.022 µF

- C2 = 1000 µF 25 V

- C3, C4, C8, C16 = 0.1 µF

- C5, C6, C7 = 0.47 µF

- C9, C10, C11, C12 = 0.001 µF

- C13, C14, C15 = 220 µF 10 V

Transistors:

- Q1 = 2n3906

- Q2 = IRF-9640

- Q6 = MPSA-13

Diodes:

- D1, D2, D3 = 1N4148

- D6 = 1N4001

- D7 = 1N5819

- D5 = 1N755 (Zener diode)

Integrated circuits:

- U1 = TLC555

- U2 = NE5534

- U7 = CD4066

- U3 = LM358

- U4 = MC14093

- U5 = 78L05

- U6 = ICL7660

For a search coil with a diameter of 23 cm:

Requires 0.5mm copper wire. You should get 24-25 turns. You can experiment with the wire and coil shape. The length will depend on this. For the standard version, take at least 4 meters.

For boom and control unit:

Plastic tubes or light stainless steel are best suited. The frame should not be too light, so as not to rise up, but also not heavy, so as not to sink. In this matter, it is better to trust your feelings and tastes. The main thing is that the frame material behaves well in salt water and does not collapse in an aggressive environment.

For assembly:

Soldering iron, wires, electrical tape, silicone sealant, scissors, hacksaw and other tools.

Brief instructions for setting up a DIY metal detector “Pirate”

Once the main elements of the metal detector are ready, we proceed to assembly. We attach all the components to the metal detector rod: the body with the coil, the receiving and transmitting unit and the handle. If you did everything correctly, then additional manipulations with the device will not be required, since it initially has maximum sensitivity. Fine tuning is performed using variable resistor R13. Normal operation of the detector should be ensured with the regulator in the middle position. If you have an oscilloscope, then use it to measure the frequency at the gate of transistor T2, which should be 120−150 Hz, and the pulse duration should be 130−150 μs.

Checking and setting up the metal detector

After all the components of the metal detector are connected, you can begin checking and setting it up. The sensitivity of the device is adjusted by rotating the potentiometer knobs. You need to ensure that a slight crackling sound is heard in the speakers. This is absolutely normal, since it is almost impossible to eliminate all electromagnetic interference.

Then they begin testing on real metal objects. A well-tuned metal detector should detect a metal plate with a diameter of 25 mm (which corresponds to a 5 ruble coin) from a distance of about 30 cm.

After testing the device on coins, you can test the distance from which the detector operates on larger or smaller pieces of metal. This will allow you to prepare for work in real “field” conditions.

Do-it-yourself metal detector “Terminator 3”: detailed diagram and video instructions for assembly

The Terminator 3 metal detector has occupied an honorable place among homemade metal detectors for many years. The two-tone device operates on the principle of induction balance.

Terminator 3 Scheme

Its main features are: low power consumption, metal discrimination, non-ferrous metals mode, gold only mode and very good search depth characteristics, compared to semi-professional branded metal detectors. We offer you the most detailed description of the assembly of such a device from folk craftsman Viktor Goncharov.

Assembly steps

Let's start with the most difficult part - creating a printed circuit board.

- Then we install all the necessary electronic elements on the board. We solder exactly as in the diagram.

- Connect the power source. It would be better if it was a powerful rechargeable battery rather than Krona batteries.

- We install the finished board with the power supply in a sealed container. If necessary, we place LED light bulbs on the surface of the container and fill all joints with silicone sealant. We attach the container to a pre-assembled rod.

- We wind the search coil. For this you can use a 3 liter jar. We select a plastic case for it, then fill the wound wire with silicone sealant. Use this winding pattern:

- Solder the leads from the coil to the stranded wire.

The underwater homemade metal detector does not have a control unit as such.

How to make a metal detector with your own hands with metal discrimination

Metal discrimination is the ability of the device to distinguish between the detected material and classify it. Discrimination is based on different electrical conductivities of metals. The simplest methods for determining the types of metals were implemented in old instruments and entry-level devices and had two modes - “all metals” and “non-ferrous”. The discrimination function allows the operator to respond to a phase shift of a certain magnitude, compared to a configured (reference) level. In this case, the device cannot distinguish between non-ferrous metals.

With such a metal detector, a shovel will only come in handy when you find exactly what you were looking for

Learn how to make a homemade professional metal detector using improvised materials in this video:

Features of deep metal detectors

Metal detectors of this type can detect objects at great depths. A good metal detector, made by yourself, looks to a depth of 6 meters. However, in this case the size of the find must be substantial. These detectors work best for detecting old shells or large enough debris.

This man is not an alien from outer space, he just really wants to find a lot of gold

There are two types of deep metal detectors: frame and transceiver on a rod. The first type of device is capable of covering a large area of land for scanning, however, in this case, the efficiency and focus of the search is reduced. The second version of the detector is a point detector; it works directed inward over a small diameter. You need to work with it slowly and carefully. If your goal is to build such a metal detector, the following video can tell you how to do it.

If you have experience in assembling such a device and using it, tell others about it!

Main nuances

To make an underwater metal detector with your own hands, you need to prepare a 0.5 mm thick PETV wire in advance. The master should get 25 turns. You can experiment with the wire and coil shape. For a classic product you will need 25 meters of PETV. To build a control unit and a rod, you need to use a stainless steel or plastic tube. This requirement must be observed, since other materials under water will be negatively affected by corrosion. If the master builds a structure from stainless steel and plastic, then the finished product will compare favorably with all analogues due to its long service life. The main frame should not be too light, otherwise it will constantly float. In order for a home-made underwater metal detector to be reliable and comfortable to use, it must cope with the negative effects of salty sea water.