Such buildings have survived for several centuries, and this is another confirmation that brick is one of the most durable building materials, even if part of the building is located below the surface of the earth.

Let's look at how to properly build brick walls for underground structures (basement, cellar), the requirements for them and the stages of creation.

Feasibility of using the material

Brick is a popular material for private construction and provides many advantages when forming lower floors and basements:

- Excellent thermal conductivity . Brick is suitable for those who plan to use the cellar for storing food or things. It is also suitable for the construction of the walls of a future sauna, since it can allow air to pass through, providing ventilation and warmth inside the room.

- The material is very durable . If you plan to build a house “to last forever,” brick will help achieve this goal.

Easy installation . When you want to save a considerable amount of money on the services of builders, you can build a brick cellar with your own hands.- Moisture resistance. A brick cellar requires reliable waterproofing. As a result, a comfortable temperature and optimal humidity will be maintained inside the room.

- Not susceptible to attacks by rodents and insects . For a private home, the problem of mice, moles and other living creatures in the basement is always relevant. Inedible, hard brick at the base of the building helps solve it.

- Versatility. A brick cellar can be made cold for storing food or hot - equipped for a sauna. If after some time you want to use the room differently, there will be no problems with moving partitions, installing ventilation and other manipulations.

- Externally, such a cellar looks beautiful if the material is laid carefully and in compliance with all requirements. It is not necessary to use finishing materials, which will also save the budget.

- Such a cellar is not afraid of high loads at home and has good strength. If the building itself is made of heavy materials, the brick cellar walls will withstand the pressure.

To build a brick cellar, a dry area is required, preferably on a hill, so that groundwater is as far away as possible.

There are types of cellars:

- recessed - located directly under the building;

- semi-recessed - the entrance to it is close to the house, part is adjacent to the wall, the main part is immersed in the ground, the ceiling is sloped, is half underground, often this design has a separate entrance.

There are other options that cannot be used as a basement, we will not consider them.

When is it not appropriate to build?

If the house is located in a lowland or groundwater flows close to the surface, building a brick basement is not recommended. If there is an abundance of moisture, the material will quickly lose its physical properties and become covered with cracks. This threatens further destruction, the appearance of mold and cold on the lower floors of the building.

If construction occurs during the winter, it is not recommended to build a brick basement. The connecting solution will not perform its functions and the walls will quickly become unusable.

Requirements for brick structures

Rules that should be followed when building a brick basement:

The work is carried out in the warm season, at above-zero temperatures, so that the likelihood of flooding of the structure is minimal, and the solution fastens the elements together efficiently.- It is recommended to choose a site for construction on a hill or on a flat surface.

- Only the warm season is suitable for the construction of underground premises.

- The basement is equipped with ventilation, hydro- and thermal insulation, regardless of the purpose of the future building.

- The cellar should be located 50 cm above the level of underground groundwater. If, after the hole for the base is dug, moisture appears at its bottom, it is necessary to deepen the bottom another 50 cm, then waterproof it with clay, sand, crushed stone and special material. The standard height of the cellar base is 30 cm.

- The depth of the pit must exceed the height of the planned basement walls. This is done for convenience and to form the foundation/substrate of the future room.

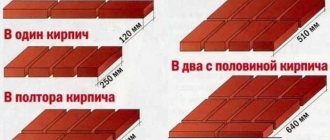

- Depending on the height of the cellar walls, their optimal thickness is determined. If the wall does not exceed 1.5 meters, laying ½ brick (12 cm thick) is sufficient. When the height exceeds 1.5 meters, support pillars for the masonry are installed; it is recommended to increase the thickness to 1 brick (25 cm thick) or to 2 bricks if the construction is planned to be massive, multi-story. Standard depth is 2-2.5 meters.

- If the cellar is recessed into the ground, reinforcement of the masonry is required so that the pressure from the soil does not damage it.

- It is recommended to consider a small dressing room and two doors for entering the underground room so that the optimal temperature is maintained in the main part.

- The basement can be used for different needs. For a vegetable storage area, an area of 8-12 m2 is sufficient; if the room is intended for other needs, the size of the area depends on the needs.

Before building a brick cellar, you need to determine the type of soil. If the soil is wet, water formed at the bottom during the formation of the pit, and even if it is removed, it appears again - it is not recommended to build a cellar in such a place.

Moisture will constantly accumulate inside and mold will appear. It is recommended to carry out an analysis in advance with the help of surveyors.

Selection and construction of the cellar floor

The freshly dug bottom of the cellar must be immediately leveled with a shovel, and lumps of earth, large parts of soil and debris must be swept out and removed from its corners. A layer of crushed stone 20 centimeters thick is laid on top of a level surface - this is the basis of the burial drainage system.

Then a mixture of fatty clay and water is made, and the resulting porridge-like consistency is coated with a layer of crushed stone until a so-called “drainage cushion” appears. In case of dry soil and low groundwater levels, it will be sufficient as a floor, but in order to once again protect the cellar lined with bricks from subsidence and flowability, it is better to fill the floor with concrete. In the case of building a large cellar, it is advisable to determine a place for supporting columns, also made of brick.

Material requirements

The main material for forming the walls of a cellar or basement must meet specific requirements, since it is located underground:

- Only red building bricks can be used for construction. Silicate is not suitable because of its fragility; it will not withstand pressure at home and is susceptible to moisture.

Solid brick is used to form the main walls of the cellar.

Hollow elements are suitable for the construction of basements under one-story houses. If the building is 2 floors or more high, only solid elements are used.- The brand depends on the number of storeys of the building. The best option is M250 and higher if the house has several floors. If the building is one-story, you can use M150 brick. The standard size is single. Re-disassembled masonry from another building is also used.

- The frost resistance index F determines how many freeze/thaw cycles the material can withstand. For a basement, the higher this figure, the better. Minimum threshold F 45.

Experienced masons are looking for bricks, which are popularly called “iron ore” for the construction of cellars. These specimens are usually rejected by factories because they are produced after excessive firing.

The surface of such a brick is graphite-colored; when cracked, the inside is matte. Such specimens meet all the requirements in terms of properties: they are absolutely impervious to moisture and can withstand pressure perfectly. The only drawback: it is difficult to split.

Choosing a brick type

Sand-lime brick for building a cellar?

Most often, a cellar is built from red brick . This brick is wear-resistant and has good sound insulation. It has increased resistance to almost all climatic influences. It is frost-resistant and durable. Such bricks also contribute to denser masonry and are perfectly held together with cement mortar.

However, red brick for a cellar, the price per piece of which ranges from 30 to 46 rubles per piece, is a rather expensive building material.

From the point of view of economy, silicate brick is much more preferable. It is also made from environmentally friendly sand and lime. It has excellent soundproofing properties and a wide range of colors. A silicate brick cellar will have increased strength and frost tolerance. The rich experience of working with it has been going on for several centuries, and it has proven itself excellent in the construction of lightweight one- and two-story houses with a shallow surface foundation. However, sand-lime brick is absolutely unstable in environments containing water and high temperatures. Thus, it is absolutely not suitable for building cellars in soil with high groundwater levels.

When choosing the type of brick, you should rely on the above information. When purchasing it, it is also worth remembering that sand-lime brick is lighter in weight than red brick - this fact will allow you to correctly calculate the volume of material transported at a time and the load-carrying capacity of the machine.

What is required for masonry?

What materials are used in construction:

- the brick itself;

- connection solution;

- cement, crushed stone, sand, clay - to strengthen the base and side walls of the pit;

- water;

- fittings

Construction Tools :

- trowel;

- Master OK;

- shovels, shovels and bayonets;

- square, tape measure, plumb line, building level;

- beacons and thread;

- double-sided hammer;

- concrete mixer or solution container.

Construction process

Preparatory work begins with digging a pit for the base of the cellar. Since the cellar area is small, using an excavator is not recommended. Digging is done manually using a shovel.

Preparing the base

After the pit has been cleared of tree roots and stones, its bottom and walls (if the soil is loose and crumbling) are strengthened with wet clay. Further:

On a base reinforced with a 10-centimeter layer of clay, pour and level 10 cm of wet sand. Tamp down thoroughly.- On top of the sand is a 10 cm layer of crushed stone, cover it with reinforcing mesh, and install formwork from boards. If the room is large, divide it into squares using a two-centimeter thick board.

- Pour a 7 cm thick concrete base. If the area is divided, pour in squares 5 cm high. Wait for the first layer to dry completely, moisten it periodically with water. Then pour the final single layer, level and wait until it dries completely.

- Remove the formwork and create a new one for the walls. The width depends on the type of masonry that will be used. Height 20 cm. Be sure to place according to the marks, observing the angles and correct geometry. Before pouring, check the accuracy of the diagonals using thread and beacons.

- Pour a concrete base under the perimeter walls of the cellar. Wait until they dry completely.

After forming the base for the construction of brick walls, it needs to be waterproofed. To do this, lay rolled waterproofing (for example, roofing felt) in 2 layers on top of the resulting structure. The joints of the first are covered with the material of the second layer. Carefully coat all connections with bitumen mastic or melt them.

Solution

To create a solution, you can use a ready-made mixture or create it from cement with sand and water . A high mass density is required, for which M400 grade cement and sand are used in a ratio of 1:4. To strengthen the composition, you can add a little clay. The mixture is diluted with water to medium viscosity.

Prepare the solution in batches so that it does not have time to harden during the work process. It is advisable to use a concrete mixer, which will keep the composition in good shape.

Stages of work

Stages of wall construction:

- The construction of walls begins from the corners, raising them by 4 rows. The exact geometry of the masonry is checked using a construction angle and thread. The first bricks are laid on dry ground and the masonry is strengthened with mortar between the elements.

- The intermediate space is laid in rows in a checkerboard pattern. The main task is that the seams in adjacent rows should not match. The masonry is shifted by ½ or ⅓ of the brick, depending on the type.

- After completing 4 rows, reinforced mesh is laid around the entire perimeter to strengthen the structure.

- The distance between the pit wall and the masonry is filled with clay and compacted.

- Repeat the steps, starting from the corners, again.

If the basement is low, up to 1.5 meters, you can create it in one go. If the walls exceed this height, it is recommended to lay them in stages - first 1-1.2 m, let the masonry dry, then continue.

To install floors, reinforcement is used - channels . These are metal U-shaped elements, which are complemented by wooden beams. For them, you will need to reinforce and strengthen the top of the last row of masonry with concrete.

Seam processing

If there are no plans to finish the walls inside the basement, the seams must be created beautiful and neat from the beginning. The process is called unstitching.

Stages:

- after the solution has hardened, clean off excess material using a stiff brush;

- take a little new mortar onto a flat trowel and gradually fill the seams with it using a narrow trowel, smooth it out nicely;

- To protect walls from moisture, use waterproofing impregnation.

For the walls themselves, in the absence of a finishing coating, injection waterproofing is used; it fills all microcracks and pores inside the brick, preventing the penetration of moisture.

Features of the masonry and fastening mortar of the cellar

Cellar diagram and list of building materials

The construction of the brickwork of the cellar begins at the moment the strip foundation finally dries. Its bottom is cleared of crumbled earth, and the earthen walls are smoothed as smoothly as possible with a trowel. This condition should especially be met when digging a pit with an excavator.

The owner had to purchase bricks for the cellar in advance. How to choose the best one? As mentioned above, red brick is best suited for lining a cellar. It is heat-resistant and resistant to all climatic conditions. Red brick masonry will create all the optimal conditions for storing food in the cellar.

In order for the bricks to adhere to each other as strongly as possible, it is necessary to make a binding solution in which the ratio of cement and sand would be 1:4. In addition to preparing the solution. Care should be taken to have a level or plumb line to control the stable height of the masonry rows.

How to properly brick a cellar? The bricks are laid out as closely as possible to each other, following a checkerboard pattern. The space between the wall and the bricks must be covered with a solution based on fatty clay and water. Clay is laid as the wall is built. The brick row should start from the corner; as the bricks are laid out, they are tapped and moved closer to each other with a trowel as tightly as possible. After completing each row, the space between the bricks and the earthen wall is covered with clay mortar and must be measured with a level.

Possible errors and their consequences

What can go wrong:

- Lack of waterproofing between the brickwork and the base. If water seeps into the basement through the floor, the concrete base can become saturated with it and transfer it through the capillaries of the materials into the wall. The brick is destroyed by moisture, cracks appear on the wall, and the masonry is deformed.

- Failure to comply with masonry geometry. A cellar with uneven corners and walls will not be able to withstand the pressure of the building. As a result, part of the wall will crack and gradually collapse, allowing moisture and cold into the room. The cellar will have to be liquidated.

- Failure to comply with the order. The displacement of bricks in adjacent rows is necessary so that the weight of the structure is distributed evenly. The consequences are the destruction of walls, disruption of the functionality of the basement.

- Wrong choice of material for construction. The brick must meet the requirements, otherwise the walls will not withstand the pressure or will allow moisture to pass through.

Reinforcement of the structure is mandatory, since the basement walls will have to withstand considerable load.

Construction of a cellar ventilation system

Supply and exhaust ventilation of above-ground cellar

The question “which brick is better for a cellar?” will lose all relevance without addressing the issue of cellar ventilation. Without a proper approach to this problem, the brickwork will overgrow with fungus and begin to collapse long before the cellar’s first birthday. To prevent this from happening, two plastic pipes are installed in the ceiling near two opposite walls from the street. One is located almost under the ceiling - and will remove humid air from the cellar. The other pipe ends near the cellar floor, and on the street it goes out near the ground - it will saturate the cellar with fresh air. Outside, both pipes are covered with rain caps and nets to keep out insects and small debris.

What determines the prices for basement construction?

The price of the work depends on the complexity and area of the structure . The type of masonry and the experience of the construction team also have an impact.

Average prices for laying brick cellar walls in Russian cities:

| Type of work | Moscow and Moscow Region, rub/m2 | St. Petersburg and Leningrad Region, rub/m2 | Krasnodar region, rub/m2 | Kazan and CO, rub/m2 |

| ½ brick masonry | 700 | 700 | 600 | 700 |

| 1 brick masonry | 1000 | 1000 | 800 | 900 |