There is not a single structure without walls. But before you start building them, it is important to decide what material will be used. Making a choice is quite difficult, since there are many options - from traditional wood to modern block products. Today we will look at and compare two materials.

What is a brick?

This is an artificial stone that has the correct shape, is made from mineral components (from baked clay or cement, sand and lime) and is exposed to high temperatures in kilns. Brick can be silicate and ceramic. These two types differ in water resistance, frost resistance and cost (silicate brick is cheaper). In addition, brick is divided into solid and hollow (slotted). In addition, porous large-format blocks, etc. are also produced.

Installation of brickwork

One should understand a certain convention of the proposed layouts, since, given the variety of modern building materials, brick is not something homogeneous and unified. There are silicate and ceramic bricks that differ in water resistance, frost resistance and cost (sand-lime brick is cheaper). In turn, they are divided into solid or hollow (slotted), there are also large-format porous blocks, etc. But in general, all of the above correctly describes the pros and cons of brickwork.

Installation of brickwork is carried out as follows: first, the level, thickness of the joints and the required number of laying layers are determined. The first layer of bricks is laid out “dry” to check the thickness of the seams and the possible longitudinal dimensions of the bricks used. Using a plumb line and level, the verticality of the side elements and the horizontality of the laid layers of bricks are checked. When laying, avoid excessive contamination of bricks by splashes of mortar.

Brickwork Tools

To successfully build brickwork we will need:

- drill, hammer, hammer drill;

- plumb line and tape measure;

- trowel;

- rule and level;

- scraping and jointing;

- mortar of sand-cement mixture.

Advantages of brick

According to experts, the popularity of this material is due more to tradition than to the presence of special unique qualities. However, some of the advantages include:

- high strength;

- good sound insulation;

- environmental safety.

Walls made of brick are highly durable. Due to its size, this building material can be used for masonry using various decorative elements and complex configurations.

Difference in cost of materials

The main task when starting construction is to calculate the costs of purchasing materials, taking into account the required quantity for building a house. Experts suggest collecting certain data before purchasing:

- Construction of walls from foam blocks. The standard foam block has a density of D600 and dimensions of 300 x 200 x 600 mm. Per sq. m of masonry will require 70 kg of masonry mixture M100 and 11 foam blocks. The cost of a good foam block is calculated at 2,900 rubles per cubic meter. m. A cube includes about 27.77 pieces, and the average cost per block is 104.42 rubles. Minimum cost per sq. m. is 1351.62 rubles.

- Construction of brick walls. For calculations, use double brick or artificial porous stone. This is one of the reliable materials with a long service life. The brick parameters are 51 x 26 x 21.9 cm. The thickness of the walls should be at least 50 cm, which fully corresponds to the same value of porous brick. Per sq. meter you will need 22.45 liters of masonry mixture and 17 double bricks. The lowest cost for a solution of brand M100 will be 2300 rubles. for every cube meter. You also need to pay about 98 rubles. per brick. As a result, costs will amount to 1,717 rubles per sq. m. m.

As a result, it becomes clear that the cost of walls made of blocks is lower than that of brick construction. The difference increases rapidly if you make calculations for the entire building. The choice of foam block brick depends on your own budget and building construction capabilities.

Flaws

In addition to its advantages, brick also has some disadvantages.

- Firstly, this material is capable of absorbing moisture well (this mainly applies to sand-lime brick), which can cause dampness.

- Secondly, its weight is quite large, so special equipment is needed to transport it. In addition, in the first years after construction, a certain shrinkage of the foundation of the structure occurs.

- Thirdly, since the size of the brick is small, increased labor costs occur (the number of operations during its laying increases), especially when compared with aerated concrete blocks.

- Fourthly, brick is considered one of the most expensive building materials, and if we also include the cost of insulation, then the price of brickwork will be one and a half to two times higher than masonry made from aerated concrete blocks.

Brick

It is the most popular building material. Its advantage is that it is light, durable and brick buildings are usually durable. It is not at all difficult to create decorative elements from it and erect buildings of intricate configurations.

And of course, this material, along with its pros, also has its cons. It is not moisture resistant, which leads to the formation of dampness in the room. To prevent dampness, the walls need to be built thick.

It has a special heat capacity, but this is also its disadvantage. If your home has not been heated for some time, it will be quite difficult to warm it up.

Advantages of foam blocks

- This is a fairly strong and durable building material, the service life of which can reach 50 years or even more.

- The low weight of the products greatly facilitates installation work and, accordingly, affects the speed of wall construction.

- Due to its porous structure, this material has low thermal conductivity.

- High degree of safety and environmental friendliness.

- Foam concrete houses are well protected from external sounds, which is very convenient if the building is being built near a railway or highway.

- The building material has an affordable price, which is important in our time.

- Foam blocks are easy to process: grinding, cutting.

- The presence of a large number of pores allows the house to “breathe”, creating a healthy microclimate indoors.

- Walls made of foam blocks are erected quite quickly. Unlike brick, foam block has much larger dimensions.

Conclusion

What do we ultimately come to: advertising brochures promise us a building material that is completely unique in its qualities, which, when tested, turns out to be the most ordinary. And its price is not so low, and it’s difficult to call it light, and it’s not even worth talking about strength.

In almost all indicators, such as environmental friendliness, strength, frost resistance, moisture absorption - and for our region they are very important, because we do not live in Africa or in the desert - foam block is significantly inferior to brick. This, in turn, means that a house made of foam block is not durable, it needs good drainage, walls made of foam block need additional external finishing to avoid their destruction from environmental influences. In addition, if you bought cheap foam blocks, then the built house is dangerous to the health of the people living in it.

Think about it, is the initial cheapness so important to you, which can result in many, many problems in the end? Or is it still worth paying attention to a brick that has not been tested by time and has served faithfully not just for years, but for centuries.

Flaws

Like any other building material, foam blocks have their drawbacks.

- Internal and external walls made of foam concrete require cladding, since their appearance is not entirely aesthetic.

- You need to choose a manufacturer very carefully.

- The low weight of the building material is not only an advantage, but also a disadvantage, since its strength is lower than that of brick. However, when constructing two-story cottages this does not matter.

- When laying, the thickness of the mortar increases, which significantly reduces sound insulation.

Now you can find out what the difference is between foam block and brick. To do this, we will compare the following important characteristics of these materials:

- thermal conductivity;

- strength;

- environmental friendliness;

- water absorption;

- installation features;

- price.

Brief overview of building bricks: scope and features

For a long period of time, it has occupied one of the leading positions in the ranking suitable for the construction of walls. Such popularity is typical not only for the domestic market, but also for European countries with a high level of development of the construction industry.

Let's look at the main characteristics and find out what attracts builders and developers so much?

Distinctive characteristics of various types of products

The product has a fairly voluminous branch of classifications, from which the following varieties and groups are distinguished:

- In accordance with the standard taxonomy, products of the first, second and third classes are distinguished. The first class is ordinary, used in the construction of load-bearing walls. The second is for the construction of partitions between rooms, row buildings and fences. The third class is used for cladding the building.

- The structure of products is characterized by the presence or absence of voids; accordingly, the material is divided into hollow and solid.

- Depending on the size, it can be single, one-and-a-half and double.

- The surface type is available in two versions: smooth or grooved.

With such an abundance of choice, no developer will remain indifferent.

Range

Having made sure that there is a sufficient range of shapes, types and sizes, we will analyze the main properties and find out whether it meets all the requirements for the construction of a durable, practical and visually attractive building.

Table 1. Characteristics:

| Type and structure | Strength grade | Frost resistance grade | Density | Thermal conductivity | Porosity |

| 125-150 | F15–F50 | On average 1400 kg/m3 | 0.7 W/m-K | 6-8% |

| From 125 to 250 | F15-F50 | On average – 1800 kg/m3 | 0.7 W/m-K | 8% |

| From 75 to 300 | F15-F50 | 1000-1450 kg/m3 | 0.3-0.5 W/m-K | 6-8% |

| From 75 to 300 | F15-F50 | 1600-1900 kg/m3 | 0.6-0.7 W/m-K | 8% |

| From 75 to 250 | F35-F75 | 1300-1400 kg/m3 | 0.3-0.6 W/m-K | 6-14% |

| 125, 150 | F35-F75 | 1300-1450 kg/m3 | 0.2 W/m-K 5-0.26 | 6-14% |

| From 75 to 250 | F15-F50 | 1700-1900 kg/m3 | 0.6 W/m-K | 8% |

| From 400 to 1000 | F50-F100 | 1900-2100 kg/m3 | 1.16 W/m-K | Up to 5% |

| From 50 to 150 | F15-F50 | 1100-1150 kg/m3 | 0.3-0.6 W/m-K | 6-10% |

As can be seen from the table, brick has all the necessary properties that act as a guarantor of durability, practicality and structural strength.

Advantages and disadvantages

Building brick is a worthy competitor, however, in addition to the advantages, there are also disadvantages.

Poor quality products

Advice! When choosing, pay special attention to its appearance in order to avoid the unfortunate purchase of a defective product. This often manifests itself in excessive fragility, darkened spots, and lack of geometry.

Table 2. Advantages and disadvantages:

| Advantages | Flaws |

| Sufficiently long service life. According to manufacturers, the house can last 130-150 years. | Relatively high price. Building a house will cost much more than, for example, from blocks. |

| The modern market offers a wide selection of colors and shades. Therefore, everyone can choose the most suitable option for themselves. | Capable of high levels of moisture absorption. It is not recommended to use it for the construction of buildings with high humidity, as this will lead to a decrease in service life. |

| The variety of shapes and sizes will not leave any buyer indifferent. | Masonry work takes more time. |

| The product has fairly high resistance to external influences, which significantly increases its competitiveness. | If there is a shortage, it becomes difficult to select the exact shade from another batch. |

| Belongs to the non-flammable class. | Among budget economy class products, geometry violations are often encountered. |

| High thermal capacity of the walls: they cool slowly, retaining heat, and also cool down for a long time, restraining the sultry heat in summer. | The appearance of efflorescence in the form of a white coating on the surface of the wall. |

| Soundproofing. The product is better than most at protecting the room from unwanted sounds from the outside. | Cost of delivery. This is a fairly heavy product, and since the carrying capacity of any vehicle is limited, it is impossible to bring enough to build a house in one trip. This entails additional costs. |

| One cannot fail to note the appearance of the buildings. Undoubtedly it is beautiful. Also, the walls do not require treatment with antiseptics. | Relatively high thermal conductivity. |

In general, the quantity and quality of advantages attract the consumer, given that many of the disadvantages are characteristic of the vast majority of wall materials to a greater or lesser extent.

Sharing option

Brick and foam block: comparison of their properties

From year to year, foam blocks are becoming more and more popular and are considered a reliable and profitable building material for the construction of all kinds of low-rise buildings.

What is better - a house made of brick or foam block? It is worth noting that in many respects foam block leaves brick far behind.

- The thermal insulation properties of foam concrete are almost three times higher. That is, buildings erected from this material are able to perfectly retain heat inside the room. So additional insulation may not be necessary at all. For brick buildings this procedure is mandatory. Brick has much greater thermal conductivity; in addition, it often becomes damp, which indicates the need for thermal insulation and regular heating of the premises.

- The moisture resistance of these building materials is almost the same. equivalent. What is better - foam blocks or bricks? Both are a reliable barrier to moisture.

- In terms of environmental cleanliness, foam block materials are at a higher level and are closer to natural wood. In addition, the porous structure of such products allows the walls to “breathe”.

- When choosing: brick or foam blocks, the latter material takes precedence in many respects. The installation process is much faster, easier and more economical. Compared to brick, the size of a foam block is approximately 20 times larger, which means that laying the blocks will take much less time.

- Despite the fact that foam blocks have an inconspicuous appearance, they lend themselves well to processing (milling, sawing, etc.), which makes it possible to implement various architectural solutions (an elegant arch, a multi-stage facade overlay, etc.). You can also build quite a solid home from brick, since today there are many different types and colors of this building material. What to choose: foam block or brick? The first of them opens up more possibilities when decorating the exterior of a house also because they allow any finishing (for example, plastering, painting, siding).

- The large weight of brick buildings requires, before starting construction work, to make a detailed analysis of the site and determine the bearing capacity of the soil. As a rule, a brick house requires laying a strong foundation, which significantly increases time, financial and labor costs. The weight of a house made of foam blocks is several times less than their bricks, so there is no need to lay a strong foundation. And this is a significant saving, especially considering that almost half of the funds allocated for the construction of a building, as a rule, goes directly to the foundation. Therefore, what is better for construction - foam blocks or bricks? The answer is obvious.

- Perhaps the only indicator where foam concrete is inferior to brick is strength. That is why brick is most often used for the construction of multi-story buildings. And after a while, if possible, you can build a second one-story mansion, a bathhouse or a garage nearby - a foam block extension to a brick house is a great idea! If desired, you can build a house from both foam block and brick at the same time. (the load-bearing walls will be brick, and the foam block will act as a thermal insulation layer). You can also use blocks as the main material for building walls, and the brick will serve as a decorative layer.

All these characteristics apply only to high-quality building materials. Despite the fact that the technology for the production of foam concrete materials is quite simple, and in order to create high-quality products with the properties listed above, ingredients with certain characteristics must be used, the technology and dosage of the components must be strictly followed.

Unfortunately, certification is not required for the manufacture of block products, so there is a high probability of purchasing a fake. That is why it is best to purchase this building material from well-known manufacturers with a high reputation.

When purchasing materials, you need to pay attention to their appearance. There should be no streaks or cracks. In addition, the color of the products must be uniform.

Performance ratio

Both materials are excellent for construction.

Foam concrete began to be used more and more often. Such a box will make the house stable and reliable. If you compare brick and foam concrete, it will become clear that foam concrete is absolutely not inferior to brick. Also, what is better - foam concrete or brick? It has been proven that buildings made of foam concrete are several times warmer than buildings made of brick. If you build from the first material, then there is no need for additional insulation of the house. But if you build walls from a second material, then insulation is mandatory.

Since brick has the property of accumulating moisture in houses, during cold times it is necessary to constantly maintain a sufficient temperature in the building. And to maintain a stable temperature, it is necessary not only to constantly heat the room, but during construction to make the walls thicker. As a result, this entails large financial investments. And when using a foam block, this is not a problem, because you will need much less of it.

If we carry out an analysis between buildings made of these types of material:

- The choice between foam block and brick forces you to give preference to the first option. Construction operations with this choice proceed much faster, with significant savings in resources and finances. If we take into account the size of foam concrete, it is easy to identify a size that is 15-20 times larger than brick. From this it becomes clear that it is possible to save glue or mortar when laying.

- These building materials have the same resistance to moisture.

- If we take into account the environmental friendliness of the materials, then foam concrete is most similar in characteristics to natural wood. Their porous structure perfectly contributes to better air ventilation in the building. In rooms made of such material it is always comfortable, regardless of the weather or season.

- Foam concrete with such characteristics is subject to various finishing. Thanks to this, you can create a variety of architectural projects without fear.

One of the advantages of brick is that it can be used for decorative decoration.

Due to the availability of a huge range of colors, as well as types of bricks, the opportunity arose to build a beautiful, large house. Other building materials have characteristics that make it possible to produce various finishes - cladding with decorative elements, plastering, painting walls.

A brick building has a lot of weight, this must be taken into account even before the construction of the house begins. Initially, it is worth conducting soil studies and an accurate analysis of the nuances of the geographical location of the site. This building material requires the construction of a strong, stable foundation, and this is fraught with much greater financial costs.

Houses made of foam concrete do not require very powerful foundations, since their mass is relatively small. But, unfortunately, this material is not characterized by such strength as brick. Only because of this, multi-story buildings are built only from stronger materials. The choice of foam concrete will be much better only when a low house is to be built. Such a building can stand for decades.

When buying foam concrete, you need to pay attention to the reputation of the seller and manufacturer. After all, only from trusted manufacturers can you purchase material of excellent quality. It is imperative to pay attention to such details as the absence of cracks on the surface of the blocks and uniform shade.

If we compare foam concrete and brick in terms of cost, then after carrying out the necessary research and calculations it will become clear that foam concrete is much more profitable.

Return to contents

Advantages and disadvantages of brick and foam block

It's hard to say which is better - brick or foam concrete. Brick buildings are considered very reliable and strong. In addition, the constructed building will be “breathable”, since the brick has a good ability to pass air. But, on the other hand, they are exposed to various aggressive environmental factors, including biological ones. For example, this applies to fungus and mold.

The advantages of brick include the following:

- good sound insulation properties;

- absolute environmental friendliness;

- strength.

Brick walls are distinguished by their reliability and stability. In addition, due to its small size, such material can be used for decorative wall decoration, as it will be possible to make various parts from it. This material is also excellent for difficult architecture.

But, on the other hand, brick also has its drawbacks. Firstly, it is considered very heavy, so in order to transport it, you will have to use special equipment. Secondly, the material is capable of absorbing water, which subsequently leads to the formation of fungus and mold on the walls. Thirdly, it is also necessary to take into account the shrinkage of the foundation. In addition, due to the small size of each block, it will take longer to build a house.

If we compare what is cheaper - brick or foam block, then the latter option wins. Using foam concrete in construction is a more profitable option from a financial point of view. These blocks are much larger in size, so it will take less time to build an entire wall than using bricks. In addition, fewer blocks will be needed. The work itself on laying foam concrete is also paid much cheaper.

As for the properties of such blocks, they largely depend on how the material and the blocks from it were made. If the technology is broken, then you should not expect a quality product. In this case, foam concrete will not be better than brick. Unscrupulous manufacturers often mix in cheaper additives to make more profit. This is why you need to be very careful when choosing foam blocks. If you choose it correctly, the walls will last a very long time, and cracks will not appear on them.

Foam concrete is in no way inferior to brick, but in terms of quality characteristics it has more advantages. In addition, the low cost is also a plus. Thanks to the above, it is becoming increasingly popular in construction. But you need to take into account that foam concrete is not as beautiful in appearance as bricks, but this problem can be easily solved - you just need to use various decorative materials for cladding.

It is important to remember that certification is optional for block parts, so the likelihood of purchasing a fake is very high. It is best to purchase such a product only from trusted manufacturers and sellers. You definitely need to evaluate the appearance of the product. There are no cracks or breaks in quality blocks. The color of the product must be uniform.

Advantages of combined use

The combined use of bricks and foam blocks can be used for construction:

- Residential buildings;

- Ban;

- Outbuildings;

- Garages.

This combination provides many advantages over structures made only of foam blocks or bricks:

- Increasing the thermal insulation parameters of load-bearing structures.

- Reducing the load on the building foundation.

- Creating an aesthetic appearance.

- Reducing the construction time of a house.

- Reducing the cost of construction in general.

- Increasing the service life of the building.

The combination of these materials has many advantages

A house made of bricks and foam blocks will be an environmentally friendly structure with an excellent microclimate inside.

How can you combine these materials?

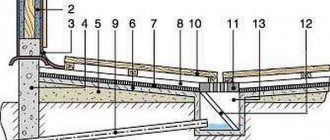

In principle, there are not so many combination options:

- Load-bearing walls are made of foam blocks, which are lined with brick. This construction method is the most widespread.

- A multi-layer design involves the presence of external and internal walls made of bricks with the gap between them filled with foam blocks. The brick takes on the main load from the walls, ceilings and roof. This makes it possible to increase the thermal insulation parameters of wall structures while simultaneously reducing the thickness of the masonry and the load on the foundation. This option also allows you to use heavy roofing materials, for example, ceramic tiles,

- The foundation or basement level of the house can be made of brick.

- As an option - installation of foam blocks on the attic floor on brick walls.

Most often, foam blocks are simply lined with bricks

The ground floor can be made of brick

An attic made of foam blocks on brick structures is an excellent solution for combining materials

Armopoyas made of bricks on foam blocks - photo

Bricks can also be used as a reinforcing belt between floors. A row of bricks is laid on the foam blocks. It will take on the load from the floor slabs.

Foam concrete or brick?

When a person thinks about building his own home, he is faced with a difficult choice of building materials. Making a choice in this matter is quite difficult, because there is a huge assortment on the market - wood, brick, foam concrete, gas silicate. In this article we will look at the two most popular materials used in construction - foam concrete and brick.