Timber and aerated concrete are very different materials, and yet often before construction you have to choose between them. The fact is that in many respects they are quite similar - for example, in speed and ease of installation. But there are also a number of parameters in which they differ greatly. Next, the similarities and differences of materials will be considered, after which it will become clear in what conditions it is preferable to use timber, and in what conditions - aerated concrete. Sometimes they are even combined.

Timber and its features

Most often, timber is preferred because it is a natural and environmentally friendly material, while aerated concrete does not inspire such confidence. The main advantages of timber are:

- It's easy to process.

- It has good density and strength indicators - balanced enough for construction.

- Thermal insulation qualities are excellent.

- Wall cladding is not required - they look good without it.

- Thanks to wooden walls, an optimal microclimate for people is established. The air circulates through them, so there is no feeling that it is heavy and damp, as well as, on the contrary, excessive dryness.

- Wood contains phytoncides - they disinfect the air inside the house, and it also acquires a pleasant smell.

If construction takes place in winter, then timber becomes a particularly preferred material. At the same time, it should be prepared not in advance, but also in winter: such timber is drier and stronger than summer timber, and is much less susceptible to the harmful influence of microorganisms, and its shrinkage will be more uniform. Considering that in winter materials are cheaper, and builders have less work to do, so it’s easier to negotiate with them - this is an important detail when choosing.

But timber also has disadvantages. Among them:

- Long shrinkage. It is especially active in the first 3 months, and in some cases longer – 6-8 months. All this time the house should stand empty and without decoration. Shrinkage will continue after this, up to 3 years, but will proceed much less intensely.

- Wood is not the most reliable of materials. It is susceptible to combustion, mold, microorganisms, and insects. All this will have to be actively fought in order to extend the life allotted to the house.

- Low resistance to moisture. At high humidity, the timber gradually becomes damp and swells, becoming less durable.

- It may crack over time.

- If sawn timber is approximately the same price as aerated concrete, then profiled and glued timber will cost more. But the shrinkage of glued wood is much less, and it is more resistant to cracking.

Depending on the type of wood, the properties of the timber may vary - this should be taken into account during construction. So, for a bath you need to choose a tree that is resistant to moisture. The most commonly used species are: linden - creates a particularly good microclimate in the house; larch is resistant to moisture and pests, houses made from it can last a long time; aspen – also resistant to moisture and temperature changes; spruce and pine are widespread, durable, and rarely rot.

Pros and cons of aerated concrete

Pros.

- Easy (everything can be learned by comparison) construction: blocks are easy to saw and process; The walls are being built quickly.

- Gas blocks are smooth, which simplifies finishing.

- A house made of aerated blocks will be durable. This is a stone house.

- Aerated concrete, thanks to the pores inside, has excellent thermal insulation properties and sound insulation at a high level. Often this is enough, and there is no need to additionally insulate and insulate the house from noise.

- Resistant to fire.

- Aerated concrete is harmless and environmentally friendly.

Minuses.

- Fragility. It would seem that the material is not heavy, and you can save on the foundation. But no. The slightest deformation of the foundation equals a crack along the entire wall.

- Hygroscopicity. Aerated concrete cannot be wetted. Moisture is absorbed by it very quickly, which leads to a sharp deterioration in all characteristics. Up to the destruction of the house.

- It is not easy to carry out internal work; special fasteners are required.

Properties of aerated concrete

The most important feature of this material is that air pores are formed inside it during manufacturing. Thanks to them, the weight becomes significantly lower, which makes it possible to use large blocks for construction and reduces the cost. The construction technology is similar to brickwork, but since large blocks are used, the process moves much faster.

Aerated concrete has a number of advantages, and in addition to this:

- Aerated blocks are easy to process, which allows you to quickly build even a house with a complex configuration, in which you need to arrange various kinks and design arches.

- High level of thermal insulation. It depends on the density of the materials: blocks from D500 to D800 are usually used for housing (the number here indicates the density in kg/cm3), and the level of thermal insulation becomes higher as the density decreases. When using D500 blocks, there is no need to additionally insulate the building in a temperate climate, and besides, not many resources are needed for heating.

- Aerated blocks combine low weight and strength.

- Fire resistance - aerated concrete contains only non-flammable components.

- Despite prejudices, in terms of environmental friendliness, aerated concrete is one of the best materials, highly resistant to microorganisms, and especially not caused by insects.

It also has disadvantages:

- Hygroscopicity - when saturated with moisture, the characteristics decrease, so wall finishing is required.

- The complexity of calculations before construction is higher than when using most other materials. The more floors are planned, the more complicated the calculations will be, while as a load-bearing material, aerated concrete of normal density can only be used for one-story buildings - in other cases it is necessary to combine it.

- It is also important to carry out very accurate calculations before construction because even a slight deformation can lead to the appearance of cracks. If they are small, then no problems will arise during operation, but the appearance of the structure will suffer.

- Aerated concrete requires finishing, and immediately after completion of construction - first internal, and then external. Even if construction is interrupted due to cold weather, conservation will be required.

There is also an important property that cannot be clearly recognized as either a plus or a minus: low thermal inertia. That is, aerated concrete is easy to warm up, but it also cools down quickly. Thermal inertia depends on density, and therefore is less pronounced when building from D800.

Characteristics of aerated concrete

Aerated concrete is light and durable concrete wall blocks, inside of which pore cavities with a diameter of 1 to 2-3 mm are evenly distributed.

Depending on the production technology, there are two main types of this material:

- autoclaved aerated concrete - wall blocks made from this material are subjected to high-temperature treatment with steam under a pressure of 12 atm.

- non-autoclaved aerated concrete, made by pouring the solution into molds, curing it, and then cutting it into blocks of the required sizes.

Figure 3. Aerated concrete blocks

Autoclaved aerated concrete comes in three categories - thermal insulation, structural-thermal insulation, structural.

The characteristics of autoclaved aerated concrete are presented in the following table:

| Name of characteristics | Categories of autoclaved aerated concrete | ||

| thermal insulation | structural and thermal insulation | structural | |

| Raw material | Quartz sand, cement, lime, aluminum powder, water | ||

| Density | 300-500 kg/m3 | 500-900 kg/m3 | 100-1200 kg/m3 |

| Compressive strength | From 10-14 to 200-262 kg/cm2 (MPa) | ||

| Thermal water content | 0.048-0.084 W/(m °C) | 0.096-0.19 W/(m °C) | 0.22-0.28 W/(m °C) |

| Shrinkage | No more than 0.5 mm/m | ||

| Water absorption | No more than 20% | ||

| Vapor permeability | 0.25-0.30 mg/(m h Pa) | 0.14-0.23 mg/(m h Pa) | 0.09-0.12 mg/(m h Pa) |

| Noise insulation index for wall thicknesses from 100 to 300 mm | From 29 to 52-55 dB | ||

| Frost resistance coefficient F | 15-25 | ||

| Flammability class | A1 (fireproof materials) | ||

Comparison of timber and aerated concrete

To determine which material is better, a comparison will be made based on a number of basic parameters to determine the winner. It’s worth noting right away: for some reasons, timber has an advantage, for others, aerated concrete, therefore, there is no universal solution, and everything will depend on which parameters are more important to you.

Convenience and speed of construction

Better than aerated concrete. You can build a house from it in a week or two, immediately decorate it, equip it and start living in it. If you have experience, there is no need to involve professionals - the amount of work is not that great. It is not only possible, but also necessary to build quickly - breaks are undesirable.

A house made of timber takes longer to build and requires more skills, however, the difference is not so great - building a house made of stone is much more difficult. More importantly, it takes a long time to settle, which means many months will pass from the start of construction to occupancy.

Environmental friendliness

Timber is better, but not always. The timber itself is completely environmentally friendly and completely harmless, in addition, the oils of the tree have a beneficial effect on the air - this is the main thing that allows us to recognize the material as better. However, in order to protect the wood and extend the life of the house, it is treated with various materials - and they are not always environmentally friendly.

On the other hand, aerated concrete does not require such treatment, and it also contains completely harmless materials such as sand and silicate. Due to the absence of organic matter, there will definitely be no allergies to it, microorganisms and mold will not grow in it, so you will not breathe harmful fumes. Still, one cannot be completely sure that only harmless materials were used in production - but this also applies to the impregnation of timber.

Appearance

Better timber. The walls look good even without finishing, but aerated concrete needs it for protection. In addition, it can crack, which will also not decorate the house at all.

Resistance and durability

Better than aerated concrete. This material is fireproof at the same level as ordinary concrete, resistant to fungus, insects, mold - all these qualities are unusual for wood, it burns easily and is often attacked by pests. To prevent this from happening, she needs treatment, but even she does not always cope completely.

Both materials need protection from moisture, but water damages aerated concrete more and faster. The service life of aerated concrete can vary greatly depending on its quality: in some cases it is only 25 years, in others it can reach 70-80 (manufacturers even assure that it can last up to 100 years). In this respect it is comparable to timber.

Economical

Approximate equality. The cost of construction when using aerated concrete is on average lower, but not by much - this difference is compensated by the need for finishing.

Which is cheaper?

In general, on average (well, there are too many introductions), houses made of timber and aerated concrete cost the same. However, there is room for maneuver. Let's talk about those stages of work where the difference in money is obvious.

Where is a house made of timber cheaper than a house made of aerated concrete?

Wall decoration . You can save a lot. If desired, only protective impregnations are sufficient. Finishing walls made of aerated concrete is a separate big story.

Saving on mortars and building mixtures . The technology for assembling a wooden house does not involve the use of these components.

How is a house made of aerated concrete cheaper than a house made of timber?

Construction of walls . Workers to build a house from aerated blocks will cost you a little less than when building a house from timber. But that is not all. If you don’t understand anything about construction, then you won’t be able to build a quality house from timber yourself. And from gas blocks - you can! Yes, you will need to brush up on the theory a little, fortunately there are enough resources on the Internet. Yes, you cannot do without consultations and supervision of specialists. But you can do the laying of aerated concrete blocks yourself. And this is a significant saving.

Transportation of building materials. A tree is always a big machine. Aerated blocks, of course, are also better transported by truck. But, nevertheless, smaller cars are also possible.

Homeowner reviews

Homeowners note all the previously discussed properties of these materials. It is worth proceeding from the fact that some of their advantages are more important in some conditions, and others - in others. Many people point out that the quality of the foundation is not so critical for timber: even if cracks form on it, they do not spread to the wall, unlike houses made of aerated concrete, in which case cracks can become a big problem. On the other hand, more problems arise with insulating the timber.

Also, homeowners often note that they need to be very careful about the quality of the timber: not every sawmill maintains drying times and harvests wood according to all the rules. If you come across timber harvested during sap flow, or from the edge of the forest, this is difficult to determine when purchasing, but then it can become a problem when the house is already built.

But there are more complaints about aerated concrete: this is due to the fact that it is fragile and can crack in the cold, and in general the material is very demanding on the project - it must be composed perfectly and, if the aerated concrete itself is good, the house will last a long time. In addition, D500 aerated concrete, most often used in the construction of one-story houses, does not have high frost resistance, which means its service life is quite short - up to 30 years. Higher density aerated concrete, while more durable, does not provide adequate thermal insulation.

In many cases, complaints about this material are related to non-compliance with construction conditions: for example, sometimes construction is stopped for several months and the house remains unfinished. It is not surprising that after completion the walls quickly begin to crumble, and the atmosphere in the house becomes uncomfortable and foreign odors do not disappear for a long time.

To summarize, reviews about timber are usually positive, while reviews about aerated concrete are more contradictory. But this does not mean that timber is always better: aerated concrete is more difficult to use, despite the deceptive simplicity of construction from it. If you handle the materials correctly, there will be few problems with them.

A house made of timber or aerated concrete: what is the fastest way to build a house before the cold weather?

We are building a house on the eve of cold weather

Autumn came unexpectedly as always. How to install a house faster and have time to move in before the cold weather sets in, read our material.

The hottest construction period is coming to an end. If the Tsoktoev family in the “Real Construction” project approached the construction of a house long before the onset of summer, then, for sure, there are those Ulan-Ude residents who did not have time to do this, and the cold will come very soon. How to build a house faster and also save money? In this article we will try to analyze all the materials and nuances that will help you build a house and move into it in a couple of months.

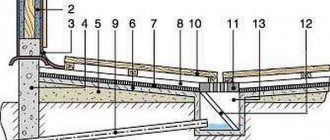

Make it before the cold weather: bury the rings for the water supply and put the box

Choosing material

Of the two most common - wooden beams and aerated concrete, recently Ulan-Ude residents began to give preference to the latter. Which material is better, given that the house needs to be built yesterday?

The honest answer to this question is clear - there are no ideal materials: each has its own advantages and disadvantages.

Houses from timber have been built for hundreds of years and, no matter how far technological progress goes, there will always be adherents of centuries-old traditions. The “work experience” of aerated concrete is more modest - its first analogue was patented in Sweden in 1924. In Russia, aerated concrete became widespread much later, which does not in the least prevent it from being the sales leader among building materials today. It’s worth driving around Ulan-Ude and you will increasingly see houses, garages and even bathhouses built from aerated concrete.

As you understand, choosing between timber and aerated concrete is easy when, firstly, there is nothing more desirable and important for you than the cozy atmosphere of a wooden house, and secondly, you are ready to wait a whole year for it to settle down. In this case, the solution is obvious. But for those who are guided not by emotions, but by facts and in the dispute between lyricists and physicists prefer the latter, we provide more serious arguments. Especially if you need to do it before the cold weather sets in.

Let's consider both materials according to fundamental criteria:

Convenience and speed of construction

When choosing a house made of timber, remember: you should start finishing it no earlier than in a year. This is approximately the amount of time it takes for a wooden house to shrink. Yes, you can ignore this rule, hurry up now and... get a very unexpected result with a minus sign. Therefore, we advise everyone who dreams of a beautiful and comfortable house made of timber to be patient. And winter is already coming. Remember this?

The situation with houses made of autoclaved aerated concrete is much more optimistic. They are built extremely quickly - building a house from aerated concrete will take less than a month. If you start now, you can just make it until October. Aerated concrete blocks are easy to process and are equipped with convenient grips, which allows you to erect a building in the shortest possible time, even without professional help from specialists. You can build a house from aerated concrete yourself. This is already a huge savings - you don’t need to hire a crew. And most importantly, almost immediately after construction you can begin installing utilities, finishing the house, and even installing windows.

In addition, the scope of application of aerated concrete is much wider. It is equally suitable for building a one-, two-, or three-story house, a small outbuilding, a garage or even a bathhouse.

Doesn't sink in water, doesn't burn in fire

As you all know very well, any timber easily allows moisture to pass through, and if not handled correctly, it rots and becomes moldy. Over time, wooden walls and ceilings can become deformed, crack and warp. To extend its service life, the timber is treated with various substances: fire retardants and antiseptics. Moreover, it is necessary regularly . This treatment extends the life of the wood, but costs money. In addition, the desired “environmental friendliness” of the house is reduced - these impregnations are harmful not only to mushrooms and insects, but also to humans.

Houses made of aerated concrete blocks are free from all the above-mentioned troubles: rotting, fungus, deformation and the annoying attention of representatives of the animal world. The very first houses made of aerated concrete are still in excellent shape, providing the best proof of the durability of this material.

Advantages and disadvantages of timber buildings

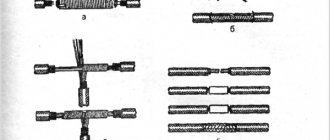

The unsurpassed performance and physical properties of wood have made it competitive, despite the saturation of the market with new materials. One of its manifestations in construction is timber. It can be natural, profiled and glued.

Regular timber is obtained from a tree trunk, trimming it on four sides. The word profiled itself indicates that such a beam has a certain profile in cross-section. It is more convenient to install than a regular one, the connections are stronger and more reliable. However, both of these materials require special treatment.

To prevent the walls of a cobblestone house from deforming or cracking, the wood must have standard humidity and the correct geometric dimensions. In addition, finishing of such a house can begin no earlier than six months after its construction. It needs to stand and withstand shrinkage processes.

The least capricious is laminated timber. It is obtained by gluing thin wooden plates with special compounds under pressure. The result is a building material suitable for the construction of half-timbered buildings or log-type houses. Glued laminated timber is endowed with the following characteristics:

- environmental cleanliness;

- durability (subject to high-quality treatment with antiseptics and fire retardants);

- excellent thermal insulation properties;

- resistance to fire, fungi, mold, rot;

- This material is not subject to shrinkage and cracking.

In addition, if high-quality wood is used, then it itself is endowed with natural beauty. And the interior decoration does not need to be done; a little cosmetics and suitable decoration are enough. However, it is almost twice as expensive as natural timber. If the cost of laminated veneer lumber is compared with the price of aerated concrete blocks, then the level will be approximately the same. The answer to the question of whether timber or aerated concrete is cheaper cannot be unambiguous. Natural timber turns out to be cheaper, and laminated wood costs approximately the same as aerated concrete blocks.