Types of breakdowns and their causes

Typical breakdowns: partial or complete absence of lighting, short-term blinking or spontaneous shutdown, failure.

Reasons : The temperature reached above 50 degrees, the contact between the filament itself and the holder broke, if the paid version is not a lamp version, the contacts on the board peeled off.

The LED has burned out, partially or completely. Reason : Overvoltage in the network, capacitor burnt out (breakdown). Typically, failure occurs in cheap board options.

There are additional reasons leading to device failure, namely: a short circuit in the circuit, incorrect connection to the network, non-compliance with the device connection diagram during installation.

Poor soldering of circuit contacts, LEDs to the board, weak fastening of wires in the base of the lamps. Poor soldering of conductive elements (wires, busbars). Reason : Factory defect.

Many LED chandeliers with remote control are repaired precisely for this reason.

The main causes of failure of LED lamps

The circuit under consideration uses the simplest electronic components that rarely fail. According to statistics, the electrolytic smoothing capacitor is most often damaged. Problems arise if parts are used “sparingly” without a reserve for the voltage rating.

There are also insufficient quality solder connections. They are destroyed after several on/off cycles as a result of thermal expansion/contraction. Repair of LED lamps may be needed more often if they are installed in a room with high humidity. In lamps of this type there are no contact groups, which are damaged when a film of oxides forms. Therefore, here, too, the cause of failure will be defective soldering.

Sometimes heat removal is poorly organized. Under such conditions, LEDs are not able to perform their functions for a long time. It is unacceptable if a plastic fake is installed instead of a metal radiator. It makes sense to repair such products only with complete replacement of unusable parts of the structure. In case of incompetent assembly, they “save” thermal paste or do not use it at all. In this case, even a high-quality aluminum radiator will not perform its functions with maximum efficiency.

Read also: How to identify a faulty capacitor on a board

Preparation for repair of LED devices

Before repairing an LED lamp, the device must be removed. You will need some tools; a thin screwdriver with a flat end, cross-shaped. If the connection was made using twists, you will need pliers with insulated handles, insulating tape and a multimeter to check the contacts. Tweezers are useful when working with small parts.

You will need a soldering iron with a thin tip and solder (it is advisable to use a special nozzle). A drill with a 2.5 mm drill can also be useful to disconnect the base part of the lamp by drilling out the fasteners. Several thin wires, 10 cm long. Attention! It is prohibited to carry out electrical work without special protected tools!

Design of LED chandeliers and visual inspection

Chandeliers with remote control appeared not so long ago. Few people are familiar with their device. When repairing LED ceiling chandeliers, you need to know the design, just in general terms. Let's take a closer look at what it may consist of.

A simple LED chandelier consists of a housing, a controller unit or a driver. It is used as a voltage rectifier. It contains terminals, or terminal clamps, to which the mains power is connected. Then wires run from the block to the lamps. There can be from one wire, for a regular lamp, to 12 for a designer version of the device.

A more complex version of the product consists of an antenna, a control unit for the lighting itself, a voltage regulator or several units that perform automatic adjustment. Raster lamps can have several drivers and different types of LED elements and lamps. The inspection and repair of components depends on the specific type of lighting fixture.

Why you need to know or find out the design before you start repairing an LED chandelier. The reason is simple, you need to determine where the control units are located, inside the chandelier or in the lighting element itself, the lamp. Here we need the same LED chandelier circuit.

Repairing an LED chandelier operating without a remote control is easier. There is nothing complicated in it, they are assembled according to one type: one or more diodes (a compact bridge is possible), electrolytes (capacitors), a pair of resistances (resistors), and a coil with a winding. This is the simplest scheme without protection, there are many options, but now we will analyze the simplest scheme.

- After removing the lamp, inspect the board for the presence of visible defects, broken wires; the absence of such is a good sign.

- Remove the shade or decoration around the lamp, and unscrew the lighting elements. Inspect the base; burnt areas indicate poor contact. If there are any, try clearing them with a knife.

- Repack the terminal blocks or twists, tighten the screws on all parts. Having found no visible defects, we move on to inspecting the lamps. A variant of a block lamp, where the relays and lamps are located next to each other on a large board, is considered as a repair of the lamp described below.

- Repairing an LED chandelier with your own hands begins with determining the location of the breakdown or break.

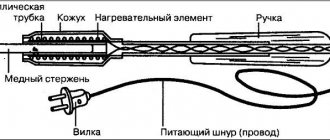

Elements of LED light sources

Before disassembling a failed LED lamp into its component parts, be sure to study its structure and operating principle. Standard equipment of this type consists of an electronic power board, a light filter and a housing with a base. Cheaper models use conventional capacitors instead of current and voltage limiters.

One lamp can contain several dozen LEDs, which are connected in series or in parallel. In the second case, the design turns out to be expensive (a separate resistor is connected to each LED diode or group), so not everyone can afford it.

The operating principle of an LED is almost identical to a semiconductor element. The current between the anode and cathode moves in a straight line, which leads to the formation of a glow. Each LED individually is characterized by a minimum power, which is why several are used at once. To create the required luminous flux, a phosphor coating is used, which transforms the light into a spectrum visible to the human eye.

High-quality models contain a high-tech driver that performs the function of a converter along with a diode group. The primary voltage goes to a transformer, which reduces the current characteristics. At the output of the element we obtain the direct current necessary to power the LED diodes. In order to reduce ripple in the circuit, an auxiliary capacitor is used.

Read also: Smoke generator from a chimney pipe

Despite the numerous varieties, differences in devices, and the number of LEDs used, all lighting devices of this type are characterized by the same design, which simplifies their maintenance.

The easiest way to check a lamp's LED circuit

First we try to disassemble the lamp itself. There are collapsible models, but sometimes you will need to heat them with a hairdryer or trim the body. First, of course, a visual inspection. As a rule, a burnt-out LED is different in color or has a burnt leg and the LED solder pads are burnt or peeled off.

Method 1.

It is better to supply power with a separate power supply to the lamp. Typically 3.7 volts is supplied to each LED, but there are other ratings. Please note that the voltage changes depending on the number of LEDs. To quickly check the LED elements of an ice lamp using improvised methods, you can use any 3-volt battery and paper clips by connecting the contacts. Just observe the polarity of the connection.

Having connected the contacts to the paper clip and observing the polarity, we check the LEDs one by one

We also use a similar testing device when checking the built-in lighting of a lamp.

Checking all backlight LEDs for functionality

The failure of one LED will result in all of them being turned off!

Method 2.

The device needs to ring all undamaged LEDs in the circuit. But there is an easier way: connect the lamp to the power supply and carry out simple manipulations

- Close (throw a jumper) the contacts of each LED one by one with tweezers or a wire with stripped and tinned contacts.

- The lamp will light up when you find (close the contacts) on the burnt out LED. If this does not happen, look further down the chain.

- Check the board for the cause of burnouts, swelling of capacitors, carefully check the tracks on the regulator board itself. Solder the broken contacts.

You cannot replace an LED with a jumper when there are less than 10 of them in the overall circuit; the capacitors will be overloaded; block LEDs will burn out when there are 3 of them in one case. They can be identified by three dark dots inside a yellow or white crystal.

LED lamp repair

It is important to know that the LED has polarity and when replacing it, you need to install it correctly on the board. All LEDs are printed soldered, that is, immersed in tin.

Typically, a soldering gun is used to seal the LED. At home, although it is difficult, it is possible to apply more tin with a soldering iron.

To install, just install it on a printed circuit board and heat its ends with contact pads with a soldering iron. With powerful soldering, you will have to additionally heat the board from the bottom with a soldering iron. It is important not to overheat the LED element when soldering!

Video:

A possible way to repair LED lamps using conductive paste.

Video:

More driver circuits

Below I will post some information on diagrams and repairs from me (author of the SamElectric.ru blog)

LED floodlight Navigator, discussed in the article About the repair of LED floodlights (the link was already given at the beginning of the article).

The circuit is standard, the output current varies due to the ratings of the piping elements and the power of the transformer:

LED Driver MT7930 Typical. Typical electrical circuit diagram for an LED spotlight

The diagram is taken from the datasheet for this chip, here it is:

• LED Driver MT 7930. Typical application / Description, typical switching circuit and microcircuit parameters for drivers of LED modules and matrices., pdf, 661.17 kB, downloaded: 3235 times. /

Details in the datasheet It describes what and how to change in order to obtain the desired output current of the driver.

Here is a more detailed driver diagram, closer to reality:

LED Driver MT7930. Electrical circuit diagram

Do you see the formula to the left of the diagram? It shows what the output current depends on. First of all, from the resistor Rs, which is located at the source of the transistor and consists of three parallel resistors. These resistors, and at the same time the transistor, burn out.

Having the diagram, you can begin repairing the driver.

But even without a diagram, we can immediately say that first of all we need to pay attention to:

- input circuits,

- diode bridge,

- electrolytes,

- power transistor,

- soldering

Next, you need to check the power supply to the microcircuit, which is supplied in two steps - first from the diode bridge, then (after normal startup) - from the feedback winding of the output transformer.

I myself have repaired just such drivers several times. Sometimes the only thing that helped was a complete replacement of the microcircuit, transistor and almost the entire wiring. This is very labor-intensive and economically unjustified. As a rule – it’s much easier and cheaper – I bought and installed a new Led Driver, or refused repairs altogether.

Ice lamp circuit

The usual circuit of an inexpensive Chinese lamp for 220 volts. Instead of a reliable driver, they contain a simple transformerless power supply circuit with capacitors and a rectifier.

The network voltage is first reduced by a non-polar metal film capacitor, rectified, and then smoothed and increased to the desired level. The load current is limited by a conventional SMD resistor, which is located on the printed circuit board with LEDs. When diagnosing and repairing LED lamps of this type, it is important to follow safety precautions, because all elements of the electrical circuit are potentially under high voltage. By carelessly touching the live part of the circuit with your finger, you can get an electric shock, and a slipped multimeter probe can short-circuit the wires with unpleasant consequences.

Troubleshooting a remote controlled chandelier

Often, repairs to LED chandeliers need to be done due to overheating of the matrix itself. First, unscrew the fasteners and visually inspect the inside of the chandelier. Then they carefully try to move the board in place. Determine whether there is a break in the wires from the control unit, or whether the wire has burnt out due to overvoltage. If it's burnt out, solder it back in place. We check all the details one by one.

Then you will need an original chandelier diagram. Without it, you can only repair chandeliers without remote control. If there is a remote control unit, change the batteries in it with new elements. LED chandeliers with a control panel are common; here you will need an exact diagram of the chandelier controller to identify a breakdown.

The chandelier control unit is usually tightly sealed into a shell, and manufacturers draw circuits on it. These are just diagrams for connecting wires and lighting elements.

There are also blocks with a collapsible body, then the option is simplified. If the unit is not collapsible, use a tester to check the output signal to the lighting elements (LEDs). If there is no voltage supply, the reason may be a breakdown of the signal receiver. We disassemble it, visually check the contacts and tracks on the board, the integrity of the parts. If voltage is supplied to one lighting branch, then there is a breakdown in the control unit, and not in the signal receiver itself.

The burnt part can be unsoldered and ringed, first, all the resistances (see diagram) by placing an OM symbol on the device. Then the capacitance of the capacitors, fortunately there are symbols on them, polarity and type are also important when checking.

Designation on the diagram

If a discrepancy in the nominal value is detected, we resolder it.

The chandelier control unit is responsible for the intensity and burning modes of the LED elements. Violation of one of the circuits (in the lampshade version of the lamp) does not disable the unit; the fuse may have blown.

But still, check the blocks to see if there are melted places on them, yes, replace it with a new one. If the wires are connected incorrectly, only the parts in the power supply will burn. The regulator block is protected from excessive loads. It can be called according to the diagram.

Video:

Preliminary device diagnostics

The LED module usually does not light up due to breaks in the general wiring, malfunctions in the switch system, lack of contact in the socket, or problems with the lamp itself.

To understand the issue, you need to conduct a preliminary diagnosis and understand where the problem is located.

When the lamp does not light up when the switch is activated, you need to unscrew it from the socket and screw in another one, not necessarily a diode one.

If the situation has changed and the light appears, then the lamp itself is faulty. No light coming in means there is a problem with the wiring.

The next step is to use a multimeter to find out whether there is voltage in the electrical circuit.

To do this, just lean the device against the cartridge part with the switch activated and look at the indicators. They should be at 220 V . If the numbers are different, then a fault zone has been detected.

When the presence of the correct voltage is confirmed, but the lamp still does not light, you should check whether there is contact between the base and the socket antennae. If disturbances occur in this area, an arc occurs and carbon deposits form on the antenna elements.

To remove it, you need to turn off the voltage, clean off the incorrect formations, and carefully bend the antennae themselves. After all these steps, you can screw the work lamp into the socket and check the result.

If there is no voltage at the contacts of the cartridge, it must be removed and checked to see if there is a phase on the wiring itself. If it is present when the switch is activated, the cartridge must be replaced.

Read also: Do-it-yourself repair of LED lamps era

When it is not there, you should pay close attention to the switch and look for the problem there.

If all the above-described elements, components and parts have confirmed their serviceability as a result of the test, it becomes absolutely clear that the problem is in the LED lamp.

Cooling radiators

Many models of regulators, drivers and power supplies of LED lamps come with cooling radiators. They have a seat through which a microcircuit or other control element gives off heat. Most lamps have radiators.

The lack of special lubricant and thermal paste is the reason for overheating of the majority (up to 15%) of boards and units. Unscrew and check whether it is applied along the plane of the seat.

Thermal paste is applied in a thin layer over the entire surface of the seat; a large amount will only worsen heat transfer. By screwing an additional thin aluminum plate to the radiator, you can increase heat transfer, while the installation is carried out without blocking the main air flows passing through it.