Dielectric gloves, mittens, and leggings protect against current and must meet GOST standards. Dimensions (length, width), thickness are regulated by regulations. Strength, ability to isolate from electricity, withstand breakdowns and other characteristics are subject to periodic testing. The varieties are determined by the material (rubber, latex, rubber), the presence of seams, fingers, lining, and cuff parameters. Special leather and canvas gloves (linings) can be used together with electrically insulating gloves to protect them; there are also liners for insulation.

What are dielectric or electrical insulating gloves?

By dielectric (electrical insulating glove) we mean gloves made of polymers, rubbers, composites, provided for by electrical safety standards for personal protection for hands to protect against electric shock.

Appearance of a dielectric glove: rubber translucent or opaque, composite with long wide sleeves extending approximately half or more of the hand or less often with shorter cuffs. The names “gaiters” are also used, since this is the most commonly used size.

Dielectric gloves are sized to accommodate other clothing underneath. The thickness of the rubber is significant, since the current has a penetrating ability, and it also prevents the glove from shrinking, folding, creating folds, and gives them elasticity.

Application requirements

As with other personal protective equipment, there are certain rules for using dielectric gloves:

- We put on PPE in full length and depth, pulling it over the sleeves of outerwear.

- Pay attention to the markings. We need Ev for installations with voltages from 1000 V and above and En - up to 1000 V.

- The general length requirements for dielectric gloves are 35 centimeters and more. It is advisable that you can wear fabric gloves underneath them when working in the cold season. In terms of width, they should fit easily over outerwear, fit freely and not cause discomfort.

- Before use, it is necessary to inspect for single or multiple damage, dirt, moisture and puncture holes (twist dielectric gloves towards the fingers).

- A tightness test should always be carried out before use. The gloves should be inflated with air and inspected for tears, holes or cracks that could cause an electric shock.

- Do not roll up the edges of dielectric gloves. If you want to protect your hands from injury, blows and cuts, choose models made of leather or canvas.

- It is recommended to occasionally wash the product in a solution with soap or soda and then dry it.

- Pay attention to the service life of dielectric gloves and carry out overvoltage tests every six months.

It is also necessary to carry out organizational activities with all workers, during which they are told information about in which electrical installations dielectric gloves are used and other mandatory operating rules. When conducting instructions, it is necessary to emphasize and clarify what the length of dielectric gloves should be, how they should be worn and checked.

When dielectric mittens and leggings are used

The purpose and objectives of electrically insulating gloves are given by state standard 12.4.307 - protection against current (primarily industrial parameters) with voltage:

- up to 1 kV - the main means;

- over 1 kV - auxiliary.

Dielectric gloves are used when working with electrical installations (EP), typical examples:

- maintenance of pantographs from 800 V;

- replacement of high voltage safety units, lighting devices;

- manipulations with special fishing rods, rods when servicing power plants, with electrical insulating clamps, voltage indicators;

- interaction with the Verkhovna Rada;

- disconnecting terminals;

- hand protection (usually wearing gaiters) when using a fire extinguisher during fires at power plants.

GOST states that full protection is possible only for qualified specialists with experience in electrical equipment, familiar with the methods, and who have undergone instructions, including on the operation of this dielectric hermetic gloves.

Leather or canvas gauntlets are used together with dielectric gauntlets where mechanical influences and risk of damage are possible. But if the latter are composite, then you are allowed to limit yourself to only them.

Rules for using dielectric gloves

What are the main insulating protective equipment used in electrical installations up to 1000V?

Insulating electrical protective equipment is divided into basic and additional.

The main electrical protective equipment in electrical installations with voltages up to 1000V include:

insulating rods;

insulating and electrical clamps;

voltage indicators;

dielectric gloves;

isolated tool.

3 Internship

- production activities to gain work experience or improve qualifications in the specialty. Internship includes the following stages: - study by a specialist of the internship program; — an interview with the internship supervisor and supervisors of the relevant sections of the program; — acquisition of theoretical knowledge and practical skills within the time frame provided for by the internship program; — providing a detailed report on the results of the internship to the staff professional development department; — an interview to defend the acquired knowledge and skills.

Rules for using dielectric gloves.

Before using dielectric gloves, they must be inspected. During the inspection, pay attention to the following points:

Presence of test stamp Presence of mechanical damage Presence of contamination Wetting of gloves

presence of punctures and cracks in gloves

If mechanical damage, contamination and moisture can be detected by a simple visual inspection of gloves, then how can one determine whether dielectric gloves have punctures and cracks?

You can check dielectric gloves for punctures by simply twisting them towards your fingers.

What are the ways to protect dielectric gloves from unwanted mechanical damage?

To protect gloves from mechanical damage, you can wear leather or canvas mittens over them - these are acceptable precautions.

When performing electrical installation work wearing dielectric gloves, it is STRICTLY PROHIBITED to wrap their edges!

When using dielectric gloves, it is recommended to wash them with a soap or soda solution and then dry them thoroughly. This type of gloves is used to protect hands (fingers, palms) from electric shock while performing electrical installation work.

Dielectric gloves are the main insulating electrical protective agent in electrical installations up to 1000 V and an additional insulating electrical protective agent in electrical installations from 1000 V and above.

Dielectric gloves come in the following types: seamless with a seam five-fingered two-fingered

5 Prohibition posters

are used to prohibit actions with switching devices (on/off), so that when working on electrical equipment, voltage is not mistakenly applied to it.

“Working under tension. Do not turn it on again." "Dangerous! Electric field! Passage is prohibited without protective equipment” “Do not turn on. People are working"

Regulatory requirements for electrical insulating gloves

Dielectric gloves are regulated by the following acts:

- GOST standards:

- 12.4.103 - general concepts about hand protective equipment (hereinafter referred to as GOST, since the references are mainly to it);

- 12.4.307 - the main document, also applies to units with integrated mechanical reinforcement;

- EN 388 - protective models against mechanical influences for electrical insulating products;

- 12.4.183 - general concepts about materials and means;

- 12580, ISO 23529 - rubber, latex;

- THAT:

- 38.106977, 38.406456 - latex, En;

- SO 153-34.03.603-2003 - instructions for use.

Types, components and concepts

Types of dielectric gloves:

- bell cuff. With a bell segment. This size makes it easier to put on if you have thick clothes on your hands;

- composite (composite) - reinforced for resistance to mechanical influences;

- contour (contour) - in fact, it is a gaiter immediately (without transition), which simplifies bending;

- lined - with an internal textile layer attached to the elastomer;

- with increased length (long) - elongated, protecting up to and above the elbow (but not necessarily to the armpits, that is, the length may not take into account this segment of the body);

- mitten, also known as a mitten. Covers the entire hand, fingerless, but with a compartment for the thumb;

- without (casting) and with a seam (drilled, made by joining two sheets of rubber).

Types of gloves

The varieties of such workwear are insignificant. Gloves are usually made from sheet rubber (rubber) or latex and have one standard size. The width of such workwear should be chosen so that warm mittens can be worn under them (this is if the work is carried out in cold and frosty weather). If the temperature outside is negative, then knitted leggings should be worn under electrically insulating gloves. This will protect your hands from hypothermia and frostbite.

Protective equipment is divided into several types:

- two-fingered and five-fingered;

- seamless and with seam.

Important! In electrical installations, the use of insulating gloves that are marked “Ev” and “En” is permitted.

The designation “Ev” means that the material is capable of protecting human skin from electricity with voltages over 1000 V (of course, as an additional method of protection), and the designation “En” - accordingly, is considered the main protective coating against electric current with voltages up to 1000 V. This is according to GOST 12.4 .103-83.

Classification

Classification is carried out according to resistance to different substances (categories, special properties), voltage values (classes). According to table. 1 state standard 12.4.307 has the following categories:

By importance as means of protection:

- basic (up to 1 kV), marking En;

- additional (from 1 kV), Ev.

We illustrate the classes by voltage values:

Purpose of dielectric gloves

Protective equipment is part of an electrician’s overalls and is required when working with any electrical devices and electrical cables. The purpose of the products is to provide protection to the human body in case of contact with live current conductors.

Used for electrical work:

- connecting and disconnecting current collectors with voltages above 800 V;

- replacing high voltage fuses;

- working with fishing rods on electrical equipment;

- replacement of lighting fixtures;

- manipulations with the reversible element of the switchgear;

- disconnecting the transformer terminals.

In an emergency, use a fire extinguisher while protecting your hands with electrically insulating gloves.

Products are produced with the following markings:

- En - as the main means of protection at voltages below 1000 V;

- EV - used as an additional protective agent at installations above 1 kV.

Basic PPE

When working with high voltages, dielectric guards are used as an auxiliary protective equipment with electrical insulating clamps, rods, and high voltage indicators.

Construction and materials

The main material of the gaiter is elastomer (highly elastic elastic polymers, substances of natural or piece origin), this is sheet rubber, latex, rubber (usually piece), a composite can be added. The product may have a lining, many layers. Various compositions are used to increase chemical resistance. If there is a coating, it is of a different color. The corolla may be missing. Often, hermetic gloves are produced in a two-layer design.

Parts:

- gauntlet - from the wrist to the open area;

- cuff (cuff) - open segment;

- cuff roll - the outermost part of the cuff with reinforcement;

- fork - the place between 2 fingers next to each other;

- palm (palm) - the central part of the hand;

- wrist (wrist) - behind the cuff, the narrowest area.

Types of gloves

Most often, manufacturers make these gloves from sheet rubber or latex. All gloves have a universal size. If the temperature outside is negative, then for comfortable work you should wear knitted leggings under your gloves. This allows you to protect your hands from hypothermia and frostbite.

Electrician's gloves are made from dielectric materials

All protective equipment can be divided into the following types:

- Two-fingered and five-fingered.

- Seamless and seamed gloves.

Five-fingered and two-fingered dielectric mittens

In electrical installations, the use of insulating gloves that are marked “Ev” or “En” is permitted. The designation “Ev” on gloves means that the material is capable of protecting a person from electricity with voltages exceeding 1000 Volts. The designation “En” is considered the main protective coating against electric current with voltages up to 1000 Volts. These designations are specified in GOST 12.4.103-83.

Length and thickness

There are configurations with wide and regular cuffs, contour cuffs and with a transition to a gaiter, and so on. What length by class is determined by GOST.

The position of what the length of dielectric gloves should be is in the table. 2 GOST standards, the minimum is 35 cm. The dimensions take into account the possibility of lifting elements of clothing in cold climates, pulling work clothes over the sleeves (because of this, leggings are more common).

For contour models (with cuffs of this type), there is a difference in length between max. and min. standard sizes - 50±6 mm, for particularly long specimens - 100±12 mm. Palm circumference (in mm, size N in brackets): 178 (7), 191 (7.5), 203 (8), 216 (8.5), 229 (9), 241 (9.5), 254 (10), 257 (10.5), 279 (11), 291 (11.5), 305 (12). Tolerance (allowed deviations) ±13 mm. Upon individual order, other sizes can be installed; in any case, all products are certified.

The minimum thickness is determined based on the results of testing for electrical insulation qualities. The maximum value of the smooth section (but not the corrugated segment) must correspond to the table. 3 GOST.

The thickness is also determined by the need for bending, that is, this parameter must allow for a certain flexibility and elasticity. Extended models, as well as cat. A, H, Z and R may have a different value, but not lower than 0.6 mm.

2.10. INSTRUCTIONS FOR USE AND TESTING OF PROTECTION MEANS USED IN ELECTRICAL INSTALLATIONS

2.10. Dielectric gloves

Purpose and general requirements

2.10.1. Gloves are designed to protect hands from electric shock. They are used in electrical installations up to 1000 V as the main insulating electrical protective device, and in electrical installations above 1000 V as an additional one.

2.10.2. In electrical installations, gloves made of dielectric rubber, seamless or with a seam, five-fingered or two-fingered, can be used.

In electrical installations, it is allowed to use only gloves marked for the protective properties of Ev and En.

2.10.3. The length of gloves must be at least 350 mm.

The size of dielectric gloves should allow knitted gloves to be worn underneath them to protect hands from low temperatures when working in cold weather.

The width along the bottom edge of the gloves should allow them to be pulled over the sleeves of outerwear.

Performance tests

2.10.4. During operation, electrical tests of gloves are carried out. The gloves are immersed in a water bath at a temperature of (25 +/- 15) °C. Water is also poured into the gloves. The water level both outside and inside the gloves should be 45 - 55 mm below their upper edges, which should be dry.

The test voltage is applied between the bath body and the electrode, which is lowered into the water inside the glove. It is possible to test several gloves simultaneously, but it must be possible to control the current flowing through each glove under test.

Gloves are rejected if they are punctured or if the current flowing through them exceeds the normalized value.

A variant of the test setup diagram is shown in Fig. 2.3.

2.10.5. The standards and frequency of electrical testing of gloves are given in Appendix 7.

2.10.6. At the end of the test, the gloves are dried.

Terms of use

2.10.7. Before use, gloves should be inspected, paying attention to the absence of mechanical damage, contamination and moisture, and also check for punctures by twisting the gloves towards the fingers.

2.10.8. When working with gloves, their edges are not allowed to be turned up. To protect against mechanical damage, it is allowed to wear leather or canvas gloves and mittens over gloves.

2.10.9. Gloves in use should be washed periodically, as necessary, with soda or soap solution, followed by drying.

What shortcomings should be absent?

Inside and outside, any damage, defects revealed during tests, inspections - holes, bubbles, conductive non-rubber inclusions, folds, pinches, bulges created during use - are not allowed, except for the exceptions below.

Features due to the very shape of the model or production are acceptable, for example, marks left during formation similar to a cut, but in reality this is how the edge is positioned. The following are also considered within normal limits:

- depressions, convex segments, areas extruded by shapes - if they disappear when stretched;

- inclusions - if they remain in the same place when bending or stretching;

- inclusions of paint - up to 1 mm from the inside on the working segment.

The working surface is the space between the fingers and the fingers themselves, the palm. The surface of the last two segments can be made in such a way (thickening, corrugation, etc.) to enhance the holding qualities; this is not a flaw.

What must be endured

A certificate of compliance with GOST is mandatory and must be provided by the supplier. The document means that the product has been tested and can withstand the electrical, mechanical, climatic and other influence categories corresponding to its class.

After use in cold conditions in the ranges corresponding to those in which the tests were carried out, there should be no cracks, holes, etc.

Additional requirements for composite products:

Marking

Marking is mandatory and is applied directly to the gaiter itself or to a sticker resistant to aggressive environments. The designation contains:

- name and symbol “work under voltage” - 2 triangles in the shape of a herringbone; Composite options, in addition to it, are complemented by a hammer sign;

- data on the document according to which the products were manufactured (for example, technical specifications number);

- information about the manufacturer, his mark;

- protective qualities, resistance class (category);

- size;

- the full date of manufacture, which also displays the first test. An expiration date is often not specified, only test dates are indicated, and the glove is considered to be good until the next such event;

- reference to the act to which the product complies;

- sign for market circulation;

- classes;

- category;

- care, disposal standards;

- other information on the manufacturer’s TD and/or agreed with the consumer.

Some of the information on the label is displayed by signs.

Place of marking: cuff, no closer than 2.5 mm from its edge; for extended versions, this gap is from 30 cm, since it is possible to cut off a part to suit individual requests.

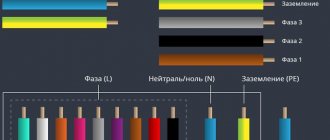

Correspondence table if color code is used in marking:

In addition to the factory markings, inspection stamps are placed:

Marks on the passage of regular mandatory checks and the dates of the next events can be placed directly on the glove; these designations, as well as any other markings placed after the manufacture of the product, should not cover the original (main) inscription.

Tests

Dielectric leggings are tested in special laboratories. Protective equipment must withstand a load of 6 kV for 60 seconds with a current flow of no more than 6 mA. The voltage is supplied from a transformer, one terminal of which is connected to the tank, the other is grounded. For testing, a packet switch with two positions is used through a gas-discharge lamp or a milliammeter with shunt grounds.

Also read: Formulation of Ohm's law for a section of an electrical circuit

1 – connection to a voltage source; 2 – bath with water; 3 – water inside the glove and bath; 4 – electrodes (rod) for connecting water to two poles of the voltage source; 5 – distance from the edge of the glove to the water in the bath

Research sequence:

- The tested products are placed in a metal container filled with water at a temperature of 25-35˚C. The waterproof gloves are positioned so that the upper part, 55 mm long, is above the surface of the water and remains dry, while the inner lower part is filled with liquid to the water level in the bath.

- Switch in first position. An electrical circuit is created - a transformer-gas-discharge lamp-electrode, which is placed in the glove. A switched-on lamp is an indicator of insulation breakdown due to a violation of integrity or insufficient dielectric properties of the product material. If there is no breakdown, the test continues.

- The switch is placed in the second position. The electrical circuit is a transformer-milliammeter-electrode located in the product and grounded through a milliammeter.

If the lamp lights up, the readings on the device are more than 6 mA, or the device needle oscillates, the gloves are considered unsuitable for use. Products that have passed the test are dried at room temperature. The research results are recorded in a technical journal. During their service life, protective products are tested twice.

What to pay attention to

Each pair is individually packaged, hermetically sealed, with sufficiently durable material for storage. On the outside of the package, the factory data, model features, class, cat., size are written down. Inside there are instructions with the following minimum information: how to store, use, dispose of, periodically inspect and test, GOST.

Tests, service life

Requirements, frequency of tests, verification period for dielectric gloves, methods for analyzing the condition are in GOST 12.4.307. Basic and thorough tests are carried out at the factory before delivery, as well as periodically by responsible persons during storage and operation at enterprises. In addition, before each donning, the user must check dielectric gloves, including inspection and twisting to the fingers.

The standard service life of dielectric gloves is 1 year, subject to testing every 6 months. The manufacturer has the right to set other periods, and this is allowed, since the products are certified, that is, the time frame is consistent with regulations. The warranty period is indicated on the manufacturer's stamp or in the product specification document; it usually meets the rules described above.

Test frequency

The product cannot be used if it:

- has not been tested within the last 12 months;

- was not tested within 6 months. after commissioning.

The date of manufacture refers to the day on which the initial testing was performed.

The composition of periodic tests: inspection, air testing, for physical and mechanical qualities, dielectric properties, low temperatures, punctures, aging, fire resistance, for the influence of category-determining factors (oil, acids, etc.). The manufacturer has the right to recommend methods and methods if there are any special features. After the tests, the gloves are stamped (but in such a way as not to cover the very first marking) with confirmation of their passing and the date, or a mark is placed on them as defective or unsuitable.

So, the first time, if we do not take into account testing at release, is tested when a new batch arrives; this is required in order for the product to be accepted for service, for service. Select any pair; if a breakdown is observed, take two pairs, conduct tests more carefully, and if the results are negative, reject the whole batch and return it to the manufacturer. If the results are positive, a stamp is placed on each specimen indicating the testing period (after 6 months). Based on the results of the procedure, an act (protocol) is drawn up, and the data is entered into a special journal.

Inspection

The absence of moisture, imperfections, and holes is analyzed visually and by touch. They also verify the presence of markings and certificates. The inspection is done in normal light without special equipment.

Length, width, circumference

The length is measured from the tip of the 2nd finger to the edge of the cuff with a metal ruler (0–500 mm, GOST 427) with millimeter graduations. The product is straightened, the cuff is perpendicular. The length difference for models with contour cuffs is determined on a straightened product along an axis parallel to the length of the measurements. The circumference is checked with a tape measure in a place 2 cm between the fingers - thumb and index.

Thickness measurements are taken at the following points:

- 4 or more on the palm;

- 4 or more on the back, but not on the cuff;

- 1 or more on the fingers: big and adjacent.

The points should not be closely grouped in one place and on segments (grooved and similar) to enhance grip. The procedure is carried out with a micrometer with a measured value. 0.02 mm, a thrust rod of 6 mm, a clamping foot ∅ 3.17±0.25 mm, the load of which is 0.83±0.03 N. During the procedure, the mitten is straightened between the thrust rod and the clamp.

Marking durability

The stamp is wiped for 15 seconds. a rag with a soap mixture, and after 15 seconds. - with isopropanol. A sign of normality is clarity and lack of vagueness. Signs made by engraving or molding are not tested; they are checked visually and by touch.

Physical and mechanical properties

For testing, samples conditioned according to ISO 23529 are taken. To analyze the elastic-strength properties of products with a lining, samples from varieties without it are used. Testing for tensile strength, maximum elongation before damage and rupture is carried out according to state standard 12580. Samples are cut out in the shape of double-sided spatulas, 4 pieces are made: from the palm, from the back, and one from the wrist.

Puncture resistance

Puncture resistance is analyzed using methods according to EN 388. The results are positive if they comply with table. 4 GOST. For products made from composites, the force must exceed 60 N.

Dielectric properties

Insulating qualities are determined by testing using test EC. This is the most detailed test with many conditions and stages. The procedure is described in R. 5.7 of GOST, we present it briefly:

- The glove is conditioned by keeping it in water for 16 hours and drying for 0.2±0.1 hours at +70 °C. After 1 hour, testing begins.

- The mittens are filled with water so that the resistance is 100 ohms and placed in the bathroom. The distances to the edge of the container are regulated by established standards (Table 6 of GOST). The top 55 mm remains dry, above water. The fluid level inside and outside is the same. Water in the product is one electrode connected to 1 power source, outside it is the second, with another.

- The installation (transformer) supplies voltage (of all types) to the mitten, the EC must have fuses.

- The leakage current is measured with a milliammeter probe placed in the glove.

- Alternating current is supplied, slowly increasing from the lowest value by 1 kV/s until the required value is reached, after which it is held for 3 minutes.

- The tests are passed if the normalized values are reached, they are maintained according to the standard time, the current leakage is within the limits according to GOST and if there is no breakdown.

One end of the circuit is grounded. If a single glove is being tested, the liquid in the container is connected to the grounded end of the high voltage circuit, to which an ammeter is also connected. The latter is also bypassed by an auto-closing switch, which maintains the circuit closed, except for the moment of measurement - this method creates continuity of connection with the ground.

If 2 gloves are tested at the same time, the electrodes inside them are grounded, the ammeter is then connected to the ground cable through an appropriate switching circuit so that measurements can be taken on each product separately.

Table showing what voltage rubber dielectric gloves are tested:

Other tests

The following tests are also carried out:

- for aging. Placed in a thermostat for 168 hours at t° +70 and humidity up to 20%;

- resistance to low temperatures. Placed in a chamber at t° −25 for 1 hour, after the sample is removed, it is placed between two polyethylene plates and a force of 100 N is applied to it for 30 s, and testing (but already dry) for leakage current is carried out;

- flame propagation resistance. The finger is cut off, filled with alabaster, after hardening, hung up and exposed to the burner flame for 10 seconds. After it is removed, observe the spread of the flame for 55 seconds. The mitten has passed the test if the fire does not reach the border on the sample at 55 mm from the edge (from the fingertip) within 5 seconds;

- additionally they test the resistance of each category, the substances and phenomena that determine it (oil, acids, very low temperatures, and so on) according to R. 5.10 of GOST.

Dielectric gloves: verification period and technology

According to safety regulations, the frequency of testing dielectric gloves is once every six months. Dielectric gloves are tested in a laboratory where they are subjected to a special test. For a minute, their properties are tested using a high voltage of 6 kV. Suitable gloves must conduct no more than 6mA, otherwise they are discarded.

- Testing dielectric gloves begins by lowering them into a metal container with warm or slightly cool water (about 20 degrees). Lower them so that their upper edges peek out half a centimeter. This is done so that the electrodes can be lowered into gloves with water inside. Of course, the edges protruding from above must be dry and clean.

- One terminal of the transformer is connected to a water tank, the second is needed for grounding. An electrode connected to ground through a milliammeter is lowered inside the gloves. This allows you not only to check the integrity of the product, but also to measure whether the glove transmits electricity, that is, whether it is safe to use at work.

- The voltage is supplied from a transformer, one wire is connected to a container of water, and the other is connected to a two-position switch. The first position: the transformer-discharge lamp-electrode circuit, the second: the transformer-milliammeter-electrode circuit.

Operating rules

Let's look at the rules for using dielectric gloves point by point, what standards must be adhered to in order to prevent the use of a damaged product with degraded quality. The procedure for inspection and storage is established by regulations and the manufacturer.

Storage

Before use and in the intervals between testing, gloves are kept in closed rooms, warehouses in containers, individually packaged at +10°... +35° C, humidity up to 40–60%. Requirements for the location: protected from direct sun, ultraviolet radiation, heat radiation, and compounds that have a detrimental effect (including evaporation) on polymers (petroleum, oils, turpentine, solvents, strong acids). During transportation, when there are temperature fluctuations, the batch is waited for a day before disassembling.

Temperature

Conventional dielectric gloves are used at temperatures from −25 to +55, for cat. C operating mode −40… +50. Other ranges may be specified by the manufacturer and are allowed during product certification.

Precautions

If leather gloves are worn over them, their size should be such as not to deform the dielectric underneath. When using the upper edges of the hermetic gloves, it is forbidden to wrap, bend or fold them. The minimum gap between the cuff of the first and the top of the cuff of the second is no less than that prescribed in clause A. 1 of GOST.

The absence of damage to leather (canvas) protection (holes, cracks and any others) that reduce the security of dielectric products is a mandatory requirement. It is also necessary to ensure that they are free of contamination that creates the risk of the listed disadvantages. Before use, contaminated leather products are inspected and cleaned, and the internal surface is always checked - there should be no sharp, protruding parts.

Dielectric gloves must be cleaned after use, especially if they are contaminated with petroleum products or fuels and lubricants. The procedure must be carried out promptly so that the substances do not have time to cause harm. In this case, follow the manufacturer's instructions or use compounds that do not destroy latex or rubber (wash with soda, soap solution). Wet gloves are thoroughly dried at temperatures up to +65.

Terms of use

6. Before use, gloves should be inspected, paying attention to the absence of mechanical damage, contamination and moisture, and also check for punctures by twisting the gloves towards the fingers.

7. When working with gloves, their edges are not allowed to be turned up. To protect against mechanical damage, it is allowed to wear leather or canvas gloves and mittens over gloves.

8. Gloves in use should be washed periodically, as necessary, with a soda solution and then dried.

Check before use

Checking dielectric gloves before use includes:

- inspection;

- air check;

- checking the test date on the stamp or in the TD, passport;

- make sure it is dry;

- analyze by marking the size, class, category for the work performed.

There is a standard way to check dielectric gloves for punctures with air: by twisting them towards the fingers.

What should dielectric gloves be like?

Dielectric gloves are made from thick rubber or latex (GOST 12.4.183-91). The main condition is that they must be without seams or have a seam made of sheet rubber. In shape they resemble ordinary rubber gloves (with five fingers), and sometimes they are “dielectric gloves”.

The length and size of gloves are also important. On average, the length is 35 centimeters, and they should fit the palm, but sit loosely. After all, it’s not uncommon that when working, you have to put on a wool or cotton “lining” underneath them, without which it will be very difficult and inconvenient to work in the cold season. The width of the gloves should be such that they can be pulled over the sleeves.

Important points

Before carrying out work, dielectric gloves must be checked for damage. Remember, even a small and seemingly insignificant puncture that is hardly noticeable to the eye can cost you your life, so we do not recommend neglecting this procedure. To detect damage, both gloves are simply twisted towards the fingers. In this case, punctures and large cracks immediately become noticeable.

In addition, you must check whether there is dirt or moisture on the gloves. After all, if they are dirty, they will easily conduct current, which means they will become completely useless in terms of protection against electric shock. Depending on the nature of the work and use, gloves are either thoroughly disinfected or simply washed well with soap or soda. Of course, they must be dried before use.

Sometimes, to protect gloves from mechanical damage, leather gloves or canvas mittens are put on top.

An important fact is that folding up dielectric gloves is strictly prohibited!

Please also note that when purchasing this protective equipment, you must study the labeling. It is allowed to work in electrical installations only with dielectric gloves marked “Ev” or “En”. Now let's turn to the timing of testing dielectric gloves and the correctness of this test.