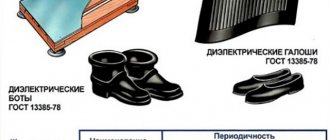

Purpose of dielectric gloves

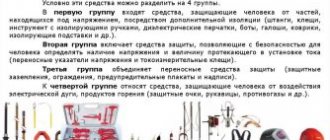

Protective equipment is part of an electrician’s overalls and is required when working with any electrical devices and electrical cables. The purpose of the products is to provide protection to the human body in case of contact with live current conductors.

Used for electrical work:

- connecting and disconnecting current collectors with voltages above 800 V;

- replacing high voltage fuses;

- working with fishing rods on electrical equipment;

- replacement of lighting fixtures;

- manipulations with the reversible element of the switchgear;

- disconnecting the transformer terminals.

In an emergency, use a fire extinguisher while protecting your hands with electrically insulating gloves.

Products are produced with the following markings:

- En - as the main means of protection at voltages below 1000 V;

- EV - used as an additional protective agent at installations above 1 kV.

Basic PPE

When working with high voltages, dielectric guards are used as an auxiliary protective equipment with electrical insulating clamps, rods, and high voltage indicators.

What are gloves made of?

One of the most effective means of protecting personnel from current is dielectric gloves. The rubber from which they are made has increased elasticity. These gloves are divided into two categories. The first protects against voltages not exceeding 1000 volts and is the primary protective measure.

The second, accordingly, will protect against voltage that is higher than this indicator, and is considered an additional means of protection. They differ in wall thickness. Latex dielectric gloves have no seams and are made exclusively from natural materials. Rubber ones, in turn, have a seam, but are much cheaper compared to their latex counterparts.

Considering in more detail the issue of materials for making gloves, it is necessary to determine what advantages certain types of raw materials have. Thus, it will be possible to select a protective equipment suitable for a specific type of work. In any case, the specialist should have several pairs of gloves.

Latex is considered one of the best dielectric materials. It can withstand voltages up to 7500 volts, but this indicator often depends on the manufacturer. Seamless gloves are extremely resistant to aggressive environments. For example, they allow you to work with acids. In addition, such gloves will not deform at low temperatures.

Buying gloves is a necessary measure for people working with electricity. Therefore, you need to work only with trusted manufacturers to avoid purchasing low-quality goods.

Classification

Dielectric gloves are made of sheet rubber or latex. The material must have low electrical conductivity and high ductility. Gaiters are produced seamless and with a seam (rubber only), two-fingered and five-fingered.

Glove length and thickness

Three types of protective products are available:

- for fine work - thickness of at least 4 mm;

- ordinary;

- for tough work - thickness of at least 9 mm.

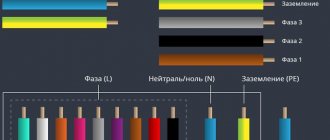

According to GOST, the length of dielectric gloves is 35 mm. The size is selected taking into account the possibility of lifting knitted gloves inside in cold weather and pulling the bells of the product onto the sleeves of overalls. The blue rectangle is a table, the contents of which are described below.

Also read: First aid for electric shock

What documents regulate the production

Manufacturers are mainly guided by GOST 12.4.183-91 “Materials for hand protection” when making dielectric gloves. Technical requirements". According to this document, for example, gloves for electricians must be made exclusively from natural rubber.

GOST does not regulate only the production of gloves with seams. When manufacturing such products, enterprises are guided by the provisions of TU7-89. Such products are made from pieces of sheet rubber using the stamping method.

Such products are classified according to GOST 12.4.103-83. Dielectric gloves, according to this document, are reusable products.

When manufacturing protective equipment, other rules and regulations must be observed. For example, according to GOST 12.4.252-2013, dielectric gloves should allow easy manipulation of the fingers. The degree of freedom of movement of the latter is determined according to a special table.

Of course, not only dielectric gloves are manufactured in compliance with certain standards. GOST 13385-78 regulates, for example, the production of shoes for electricians. In compliance with the standards provided for in this document, boots, galoshes and boots are manufactured.

Thus, according to GOST, shoes for electricians are manufactured, as well as rubber, silicone, and dielectric seamless latex gloves. GOST 4997-75 is another document regulating the production of protective equipment. According to the standards, rubber and silicone mats are made from this document.

Requirements for gloves

Electrical insulating products are made in a two-layer design of different colors with markings on the outside. The stamp contains the following information:

- product name;

- date of manufacture;

- batch number;

- date of the next survey;

- type, marking;

- warranty period of operation.

Protective products are made from natural rubber. When performing electrical work, it is allowed to use only specialized products manufactured in accordance with the specifications. Hermetic gloves with an expired expiration date that have not been tested within the specified time frame are subject to rejection.

Check before use

Before starting electrical installation work, the condition of protective equipment is checked each time. Electrical insulating gloves must meet the requirements:

- The date on the stamp indicates the tests were carried out according to the specified deadlines;

- The integrity of the product is preserved - there are no punctures or microcracks. This is verified by twisting the glove in the direction of the fingers; filling the object with air confirms the tightness.

- Must be dry and free from contamination.

- Gloves must be suitable in size, the thickness of the rubber must correspond to the nature of the work performed.

Before use, contaminated products are washed in soda or soap solution and dried thoroughly at room temperature. In some cases, it is permissible to wear leather or canvas mittens over dielectric gloves. It is prohibited to bend the top edges of the protective equipment.

Check before use

Checking dielectric gloves before use includes:

- inspection;

- air check;

- checking the test date on the stamp or in the TD, passport;

- make sure it is dry;

- analyze by marking the size, class, category for the work performed.

There is a standard way to check dielectric gloves for punctures with air: by twisting them towards the fingers.

Frequency of inspections

The service life of dielectric gloves is one year (subject to tests carried out once every 6 months). The warranty period is indicated on the packaging.

The first time tests are carried out upon receipt of a new batch of electrical protective products. They take one pair and test them. If an insulation breakdown occurs, take two pairs of protective gloves and test more thoroughly. If the products fail the test again, the entire batch is rejected and returned to the manufacturer.

Upon successful completion of testing, a stamp is placed on each pair of gloves indicating the testing period (after six months). The results of the checks are recorded on a special form.

Tests

Dielectric leggings are tested in special laboratories. Protective equipment must withstand a load of 6 kV for 60 seconds with a current flow of no more than 6 mA. The voltage is supplied from a transformer, one terminal of which is connected to the tank, the other is grounded. For testing, a packet switch with two positions is used through a gas-discharge lamp or a milliammeter with shunt grounds.

Also read: Purpose of dielectric galoshes in electrical installations

1 – connection to a voltage source; 2 – bath with water; 3 – water inside the glove and bath; 4 – electrodes (rod) for connecting water to two poles of the voltage source; 5 – distance from the edge of the glove to the water in the bath

Research sequence:

- The tested products are placed in a metal container filled with water at a temperature of 25-35˚C. The waterproof gloves are positioned so that the upper part, 55 mm long, is above the surface of the water and remains dry, while the inner lower part is filled with liquid to the water level in the bath.

- Switch in first position. An electrical circuit is created - a transformer-gas-discharge lamp-electrode, which is placed in the glove. A switched-on lamp is an indicator of insulation breakdown due to a violation of integrity or insufficient dielectric properties of the product material. If there is no breakdown, the test continues.

- The switch is placed in the second position. The electrical circuit is a transformer-milliammeter-electrode located in the product and grounded through a milliammeter.

If the lamp lights up, the readings on the device are more than 6 mA, or the device needle oscillates, the gloves are considered unsuitable for use. Products that have passed the test are dried at room temperature. The research results are recorded in a technical journal. During their service life, protective products are tested twice.

Glove protection classes

Each type of work gloves includes several categories, and each category includes several classes. For example, gloves against mechanical damage may have protection against abrasion, breakthrough, blades, and puncture. Abrasion protection has four classes, and blade protection has 5 classes. The grades indicate how many operating cycles it took during testing to tear, puncture or cut through the product. Chemical protection classes depend on the time it takes for a hazardous substance to penetrate the material: class 1 gloves can withstand 10 minutes of acid or alkali, and class 6 gloves can withstand 480 minutes. When determining fire protection classes, the time during which the material smolders is taken as a basis.

Storage

When transporting products with changes in ambient temperature, the batch is left unpacked in the warehouse. The analysis of received kits can begin within 24 hours.

Rubber is destroyed under the influence of ultraviolet radiation, heat, mineral oils, gasoline, and alkaline solutions. The storage room must be protected from direct sunlight, have a temperature from -30 to +40˚С, and a humidity of 40-60%. Increased dust content in the warehouse is eliminated. Gloves should be kept away from heating devices and central heating radiators.

Dielectric gloves perform protective functions against electric shock if the operating rules are followed and high-quality, undamaged products are used that have been tested within the specified time frame.

What are dielectric or electrical insulating gloves?

By dielectric (electrical insulating glove) we mean gloves made of polymers, rubbers, composites, provided for by electrical safety standards for personal protection for hands to protect against electric shock.

Appearance of a dielectric glove: rubber translucent or opaque, composite with long wide sleeves extending approximately half or more of the hand or less often with shorter cuffs. The names “gaiters” are also used, since this is the most commonly used size.

Dielectric gloves are sized to accommodate other clothing underneath. The thickness of the rubber is significant, since the current has a penetrating ability, and it also prevents the glove from shrinking, folding, creating folds, and gives them elasticity.