Protective equipment in electrical installations

During the operation of electrical installations, conditions arise under which, despite the most advanced design of the installations, the safety of the worker is not ensured, and therefore the use of special protective equipment is required.

These include devices, devices, portable and transportable devices that serve to protect personnel working in electrical installations from electric shock, electric field, combustion products, falls from a height, etc.

These means are not structural parts of electrical installations; they complement fences, interlocks, alarms, grounding, grounding and other devices.

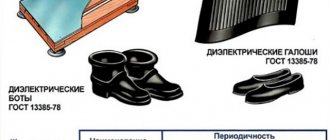

The protective equipment used in electrical installations can be divided into four groups: insulating, fencing, shielding and safety. The first three groups are intended to protect personnel from electric shock and the harmful effects of an electric field and are called electrical protective equipment.

Insulating electrical protective equipment isolates a person from live parts, as well as from the ground.

Fencing electrical protective equipment is intended for temporary fencing of live parts that may be accidentally touched or approached at a dangerous distance, as well as to prevent erroneous operations with switching devices. These include temporary portable shields and cage fencing, insulating pads, temporary portable grounding and warning posters.

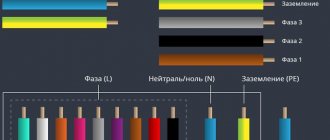

Shielding electrical protective equipment serves to eliminate the harmful effects of industrial frequency electric fields on workers. These include individual shielding kits (suits with hats, shoes and gloves), portable shielding devices (screens) and shielding fabric products (umbrellas, tents, etc.).

Safety protective equipment is intended for individual protection of workers from the harmful effects of non-electrical factors - light, thermal and mechanical, as well as from combustion products and falls from a height. These include safety glasses and shields, special mittens made of flame-retardant fabric, safety helmets, gas masks, safety belts, safety ropes, and claws.

The choice of necessary protective equipment is regulated by safety regulations for the operation of electrical installations, labor protection standards and regulations and other regulatory and technical documents, and is also determined by local conditions based on the requirements of these documents.

Protective equipment must be stored and transported under conditions that ensure their serviceability and suitability for use, so they must be protected from moisture, contamination and mechanical damage.

After manufacturing and during operation, protective equipment is subjected to tests - electrical and mechanical. Test results are recorded in special journals. All protective equipment that has passed the test must be stamped.

General rules for using protective equipment used during the operation of electrical installations:

- electrical protective equipment should be used for their intended purpose in electrical installations with a voltage no higher than that for which they are designed;

- basic electrical protective equipment is designed for use in closed installations, and in open electrical installations and on overhead lines - only in dry weather;

- Before using protective equipment, personnel must check their serviceability, the absence of external damage, clean and wipe off dust, and check the expiration date on the stamp. Do not use protective equipment whose expiration date has expired.

The operation of electrical installations must be carried out by electrical technical personnel, which are divided into administrative and technical, operational, maintenance and operational repair personnel.

Operating personnel inspect electrical equipment, prepare the workplace, perform maintenance, including operational switching, permit work and supervise workers.

Repair personnel perform all types of work on its repair, reconstruction and installation.

Operations and repair personnel combine the functions of operational and repair personnel at electrical installations assigned to them.

Administrative and technical personnel organize all of the listed types of work and are directly involved in these works. All persons included in the electrical technical personnel must have a qualification group for electrical safety, assigned to them based on the results of certification by a special commission after special training. Persons under 18 years of age are not allowed to work in electrical installations.

Schedules must be drawn up for all types of electrical equipment repairs. The frequency and duration of all types of repairs are established by the Rules for the technical operation of consumer electrical installations.

Before the equipment is brought out for major repairs, statements of scope of work must be drawn up and, in accordance with them, the necessary materials and spare parts must be prepared: technical documentation for the work must be drawn up and approved: tools and devices must be completed and in good condition: workplaces have been prepared, etc. In case of particularly dangerous work from the point of view of electric shock, a work permit must be issued.

XII. RULES FOR SWITCHING IN ELECTRICAL INSTALLATIONS

XII. Operations with online locking

166. Operational interlocking must be carried out to prevent erroneous operations with switching devices and grounding disconnectors during switching processes in electrical installations.

167. In electrical installations where the interlocking is not complete (bus grounding disconnectors are interlocked only with voltage transformer disconnectors and do not have locking devices with bus disconnectors of all connections of this section, SS), the drives of busbar grounding disconnectors must be locked with locks, the procedure for storing keys from which is determined by the local instructions for switching in electrical installations, approved by the owner of the electric power facility (its branch) for the NSO, the electric power facility. In this case, when a section or secondary bus is taken out for repair, the inclusion of grounding disconnectors on the busbars, as well as operations with the busbar disconnectors of connections removed for repair, should be carried out only after checking the electrical connection diagram at the installation site of the switching devices.

168. To prevent erroneous operations associated with the possibility of supplying voltage to the switched-on grounding disconnectors from the opposite side of the power line in the absence of blocking between the grounding disconnectors towards the power line and switching devices located at opposite ends of the power line, dispatch personnel of the DC, operating personnel of the control center, NSO, which controls power lines or T (AT) (in cases where the operational maintenance of switchgears of different voltage classes to which the T (AT) is connected is divided between the operational personnel of several electric power industry entities (divisions of one electric power industry entity) and there is no blocking between the grounding disconnectors and switching devices of different voltage classes T (AT)), must inform the operating personnel of switching objects about the off position:

all disconnectors from which voltage can be supplied to the power lines, T (AT) before turning on the grounding disconnectors (when taking out the power lines, T (AT) for repairs);

grounding disconnectors on opposite sides of power lines, T (AT) before turning on linear (bypass), transformer disconnectors (when putting power lines, T (AT) into operation).

169. During switching in electrical installations, all operational interlock devices must be in operation. Locking locks must be sealed.

170. In the event that a blocking prohibits the execution of any operation, switching operations in electrical installations must be suspended and the following must be checked:

the correctness of the selected connections and switching devices (grounding disconnectors);

the positions of other switching devices, grounding disconnectors interlocked with this switching device (grounding disconnector);

the correctness and sufficiency of the operations performed for equipment protected by interlocking;

the presence of voltage in the blocking circuits and the serviceability of the electromagnetic key;

serviceability (checked visually) of the mechanical part of the switching device drive (grounding switch).

If the check does not establish the reason why the blocking does not allow the operation to be performed, then switching in electrical installations must be stopped. In this case, the personnel who gave the command (permission, confirmation) to carry out switching must be given a message about the termination of switching in electrical installations, and an entry must be made in the operational log in accordance with the requirements of paragraph 77 of the Rules.

171. Operating personnel directly performing switching operations in electrical installations are prohibited from independently disabling the operational interlock.

Unblocking is permitted only after checking at the installation site the actual position of switching devices, grounding disconnectors and finding out the reason for the blocking failure with the permission of a person authorized to do so by the administrative document of the owner of the electric power facility (its branch). In this case, the switching form must be drawn up anew with the release operations included in it. If the need for release arises, and the operations were performed without a switching form, a switching form must be drawn up with the release operations included in it.

172. All cases of unlocking of interlocking devices must be recorded in the operational journal, maintained by the operational personnel of the electric power facility.

173. To prevent the phenomenon of ferroresonance, unblocking operations are allowed. These operations must be entered into programs and switching forms, including standard ones. In this case, the release record is not entered into the operational journal.

Electromagnetic blocking. Definition, design, principle of operation

Relay protection devices protect equipment in emergency modes. One of the main reasons for emergencies at energy facilities, in particular at distribution substations, is operational errors by operating personnel. The main task of management in this case is to eliminate the occurrence of this negative situation.

But, as many years of practice have shown, it will not be possible to solve this problem completely. This is connected, first of all, with such a concept as the “human factor”. Whatever one may say, a person is not a robot and by his nature can make mistakes, including during operational switching on substation equipment. The solution to the problem in this case is the use of electromagnetic interlocking on electrical installation equipment.

electromagnetic blocking circuits

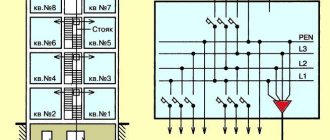

Electromagnetic blocking circuits consist of separate logic circuits that can be analyzed independently of each other. To read electromagnetic blocking diagrams, you need to remember the rule: diagrams are drawn for the disconnected position of switching devices.

As an example, consider a piece of circuitry with two bus systems, one line connected to them, and a bus coupling switch.

When drawing up diagrams, you must follow several rules:

· Disconnectors can only be turned off when the connection switches are turned off;

· Bus disconnectors can be switched off when bus systems are combined;

· Disconnectors cannot be connected to the busbar section until the next disconnector with the grounding blades turned on;

· Grounding knives can be turned on when disconnectors adjacent to the installation site of the grounding knife are turned off.

The diagram drawn here is only for a manual drive, since we see only block locks that operating personnel unlock and can then manually operate the switching device. However, the manual drive is used only at voltages up to 220 kV. Therefore, we must look at how we will implement blocking with disconnectors and knives with remote or local control in the presence of engines.

Parallel to the block locks, electromagnetic blocking relay windings are placed in the electromagnetic blocking circuit (you all know them well, they are located in the disconnector drive cabinets).

The contacts of these relays are located in the key circuits for remote and local control of the drives of disconnectors and knives and supply voltage to the winding of the starters.

The contactors of the starters, in turn, supply three-phase alternating voltage to the drive motors and the operating personnel begin to turn off or turn on the devices.

Naturally, none of this will happen if the logical chains that we examined in the main circuit do not come together.

Actions of operational personnel when operations are prohibited by the operational blocking:

- Check the correctness of the selected connection and your actions;

- Integrity of fuses in blocking circuits (or switched position of circuit breakers);

- Serviceability of the electromagnetic key;

- If everything is correct, the blocking is considered faulty and must be released with the permission of the person who has the right to do so, by order of the enterprise and with the rewriting of the operational switching form.

Possible malfunctions of the electromagnetic locking:

· The KSA of the disconnector or grounding knife was not transferred;

· Break in the cable;

· The power supply is turned off;

· The electromagnetic key is faulty.