Standards for equipping with protective equipment.

Personnel servicing electrical installations must be provided with all necessary protective equipment, trained in the rules of use and must use them to ensure work safety. Protective equipment should be located as inventory in the premises of electrical installations (switchgears, power plant workshops, at transformer substations, in distribution points of electrical networks, etc.) or be part of the inventory of operational field teams, maintenance teams of mobile high-voltage laboratories, etc. etc., and also issued for individual use. Inventory protective equipment is distributed between facilities and operational field teams in accordance with the operational management system, local conditions and acquisition standards. For example, in the main room of a traction substation - at the control panel, where the operational duty officer is located, from where he is sent to carry out operational switching, the following set of protective equipment should be located (Table 3). Storage order. Protective equipment is subject to the destructive effects of the external environment: sunlight, chemicals, mechanical stress, etc. The rules establish a procedure for maintaining protective equipment to ensure its serviceability and suitability for use. The conditions that ensure compliance with this order are, first of all, protection from moisture, contamination, drying out and mechanical damage, for which they must be stored indoors. Table 3 Set of protective equipment on the control panel of the traction substation

| Name of the protective equipment | Quantity |

| 1 | 2 |

| Voltage indicator | 1 PC. for each voltage class above 1000 V and 2 pcs. for voltage up to 1000 V |

| Insulating clamps for voltages above 1000 V (in the absence of a universal rod) | 1 piece each for each voltage class (if there are fuses for these voltages) |

| Insulating clamps for voltages up to 1000 V | 1 PC. |

| Clamp meter | According to local conditions |

| Dielectric gloves | Two pairs |

| Dielectric galoshes | Two pairs |

| 1 | 2 |

| Isolated tool | 1 kit |

| Portable grounding | According to local conditions |

| Dielectric carpets and insulating pads | According to local conditions |

| Safety posters and signs (portable) | Same |

| Safety helmets | 1 PC. for every worker |

| Respirators | 2 pcs. |

| Protective glasses | Two pairs |

Rubber protective equipment in use should be stored in a dry room at a temperature of 0 - 30 ° C in special cabinets, on racks, shelves, drawers, etc. separate from the tools. They must be protected from the effects of oils, gasoline, acids, alkalis and other substances that destroy rubber, as well as from direct exposure to sunlight and heat radiation from heating devices (no closer than one meter from them). Insulating rods and clamps are stored in conditions that prevent their deflection and contact with walls, i.e. in limbo. Special places for storing portable groundings are numbered in the same way as the contact points themselves. Protective equipment is placed in specially designated places, as a rule, at the entrance to the premises, as well as on control panels. Storage areas must have lists of protective equipment. Storage areas must be equipped with hooks or brackets for rods, insulating clamps, protective equipment, posters and safety signs, as well as cabinets, racks, etc. for dielectric gloves, boots, galoshes, carpets and stands, mittens, safety belts and ropes, goggles and masks, gas masks, voltage indicators, etc. Separately from other tools, protective equipment intended for the work of operational field teams and maintenance teams is stored in boxes, bags or cases. Those protective equipment that allow you to work under voltage should be kept in dry, ventilated areas.

electrical safety

Home Company News Set of protection means for switchgear voltage up to 1000V and above

We are often asked: “What protection means should be equipped with switchgears (electrical installations/panelboard/substations) up to 1000V and above 1000V?”

The selection of the necessary electrical protective equipment, means of protection from high-intensity electric fields and personal protective equipment is regulated by these rules, “Safety Rules for the Operation of Electrical Installations”, “Safety Rules for the Operation of Consumer Electrical Installations”, “Sanitary Standards for the Performance of Work in Conditions of Exposure to Electric Fields of Industrial frequency", "Guidelines for the protection of personnel servicing switchgears and overhead power lines of alternating current voltages of 400, 500 and 750 kV from exposure to electric fields" and other relevant regulatory and technical documents taking into account local conditions.

When choosing specific types of personal protective equipment, you should use the appropriate PPE catalogs and recommendations for their use.

According to Appendix 8 of the order of the Ministry of Energy of the Russian Federation dated 06/30/2003 261 on approval of the Instructions for the use and testing of protective equipment used in electrical installations, our company offers two ready-made sets of electrical protective equipment in electrical installations up to 1000V and over 1000V (including transformer substations, switchboards and control panels):

Kit for switchgears with voltage up to 1000V (KSZ-1)

| Name of protective equipment | Quantity |

| Insulating rod SHO-1 or universal SHOU-1 | 2 pcs. |

| Low voltage indicator UNNU-25-1000 (or UNNO-1M) | 2 pcs. |

| Insulating pliers KVP-2 (or KI-1000) | 2 pcs. |

| Dielectric gloves | Two pairs |

| Dielectric bots | Two pairs |

| Set of posters (7 pcs. or 13 pcs.) | 1 set |

| Safety glasses | 1 PC. |

| Dielectric rug (size at customer’s discretion) | 1 PC. |

| Portable grounding ZPP-1/3 with section. 16mm2 | 1 PC. |

| Testing of PPE and verification of protective equipment with a protocol for the organization | 1 PC. |

Kit for switchgears with voltages above 1000V (KSZ-2)

| Name of protective equipment | Quantity |

| Insulating rod SHO-15 or universal SHOU-15 | 2 pcs. |

| High voltage indicator UVNSZ 6-10 | 2 pcs. |

| Clamp meter (multimeter) | 2 pcs. |

| Dielectric gloves | Two pairs |

| Dielectric bots | Two pairs |

| Set of posters (7 pcs. or 13 pcs.) | 1 set |

| Safety glasses | 1 PC. |

| Dielectric rug 750x750 | 1 PC. |

| Portable grounding ZPP-15-3/1 with section. 25mm2 | 1 PC. |

| Testing of PPE and verification of protective equipment with a protocol for the organization | 1 PC. |

Notes:

1. Acquisition standards are minimum and mandatory. Technical managers and workers responsible for electrical facilities are given the right, depending on local conditions, to increase the number and expand the range of protective equipment.

2. When placing RU equipment up to and above 1000 V on different floors or in several rooms separated from each other by doors or other rooms, the specified number of protective equipment applies to the entire RU as a whole.

3. RUs of the same voltage, with no more than four in number, located within the same building and serviced by the same personnel, can be provided with one set of protective equipment, excluding protective fences and portable grounding.

4. Mast-mounted substations, package transformer substations and switchgear switchgear are equipped with protective equipment according to local conditions.

Before putting the protective equipment into operation, it is necessary to verify and carry out tests; the frequency with which this procedure is carried out regularly is indicated below. Rugs and coasters are not tested, but they are subject to inspection once a year or once every 2 years, respectively. In general, before each use of protective equipment, it is necessary to conduct a visual inspection for possible damage.

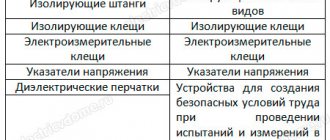

| Name of the protective equipment | Verification frequency |

| Insulating rods | Once every 24 months |

| Insulating pliers | Once every 24 months |

| Clamp meter | Once every 24 months |

| Voltage indicators up to and above 1000 V | Once every 12 months |

| Dielectric gloves | Once every 6 months |

| Dielectric galoshes | Once every 12 months |

| Dielectric boots | Once every 36 months |

| Hand insulating tool | Once every 12 months |

| Claws and manholes | Once every 12 months |

| Safety belts | Once every 6 months |

Basic devices

The main ones are those whose insulation can withstand the voltage of an electrical installation for a long time, as well as those devices that make it possible to touch current-carrying elements. They are tested under voltage taking into account the relevant electrical installation in which they are used.

The main devices for working with voltages of more than 1000 volts include: measuring clamps, rods, insulating means (platforms, stepladders, cables, rods). The main safety devices in installations up to 1000 volts are rods, insulating pliers, gloves, hand tools with insulating handles and voltage indicators.

Materials that absorb moisture (for example, wood) must be coated with a moisture-resistant composition and have a surface without scratches, peeling or splitting.

Basic and additional electrical protective insulating means with voltages up to and above 1000 V.

The main insulating electrical protective agent is an insulating electrical protective agent, the insulation of which can withstand the operating voltage of the electrical installation for a long time and which allows working on live parts that are energized.

An additional insulating electrical protective agent is an insulating electrical protective agent, which in itself cannot provide protection against electric shock at a given voltage, but complements the main means of protection, and also serves as protection against touch voltage and step voltage.

The main insulating electrical protective equipment for electrical installations with voltages over 1000V include:

— insulating rods of all types;

- insulating pliers;

— voltage indicators;

— devices and devices to ensure the safety of work during measurements and tests in electrical installations (voltage indicators for checking phase coincidence, electrical clamps, devices for puncturing cables, etc.);

- special protective equipment, insulating devices and devices for work under voltage in electrical installations with voltages of 110 kV and above (except for rods for transferring and equalizing potential)

Additional insulating electrical protective equipment for electrical installations with voltages over 1000V include:

— dielectric gloves and boots;

— dielectric carpets and insulating supports;

— insulating caps and linings;

— rods for transferring and leveling potential;

— ladders, insulating fiberglass stepladders.

The main insulating electrical protective equipment for electrical installations with voltages up to 1000V include:

— insulating rods of all types;

- insulating pliers;

— voltage indicators;

— electrical clamps;

— dielectric gloves;

- hand-held insulating tool,

Additional insulating electrical protective equipment for electrical installations with voltages up to 1000V include:

— dielectric galoshes;

— dielectric carpets and insulating supports;

— insulating caps, coverings and linings;

— ladders, insulating fiberglass stepladders.

6 Fire safety requirements for the operation of electrical receivers and electrical installation products.

1.4.4. When operating existing electrical installations, it is prohibited:

use electrical energy receivers (power receivers) in conditions that do not comply with the requirements of the manufacturer’s instructions, or have faults that, in accordance with the operating instructions, can lead to a fire, as well as operate electrical wires and cables with damaged insulation or loss of protective properties;

use damaged sockets, switches, and other electrical installation products;

wrap electric lamps and lamps with paper, cloth and other flammable materials, as well as operate lamps with removed caps (diffusers) provided for by the design of the lamp;

use electric irons, electric stoves, electric kettles and other electric heating devices that do not have thermal protection devices, without stands made of non-flammable heat-insulating materials that eliminate the risk of fire;

use non-standard (homemade) electric heating devices, use uncalibrated fuse links or other homemade overload and short circuit protection devices;

place (store) flammable (including flammable) substances and materials near electrical panels, electric motors and starting equipment.

1.4.7.

It is prohibited to operate electric heating devices if the thermostats provided for by the design are missing or malfunctioning.

1.4.2.

Classification and purpose of electrical protective equipment

Electrical protective products include those used against direct electric shock. They provide reliable electrical safety when working with various electrical installations and switchgear.

- The main means of protection in electrical installations include a list of insulating electrical protective equipment that has insulation capable of withstanding the operating voltage of the network for a long time. They allow you to safely perform work on live parts that are energized.

- Additional ones also include insulating electrical protection means. However, unlike the main ones, they do not directly protect against electric shock, but only complement them, thereby increasing the degree of protection of working people. In addition, additional means protect personnel from electric shock due to step voltage and touch voltage.

- In accordance with the voltage class, all types of electrical protective equipment are divided into those used at voltages up to 1000 volts and over 1000 volts.

Electrical protection for voltages over 1000 volts

Protective equipment in electrical installations used when working with voltages greater than 1000 volts include various types of insulating rods and clamps, high voltage indicators, as well as various types of devices used in testing and electrical measurements in switchgears.

Various devices and special protective equipment used in electrical installations with voltages exceeding 110 kilovolts are classified separately. This list does not include rods used to level and transfer potential.

Electrical protection for voltages up to 1000 volts

The main means of protection in electrical installations up to 1000V include insulating clamps and rods, electrical clamps, low voltage indicators, dielectric gloves, as well as various types of manual insulating tools.

Additional protective equipment

The classification of additional electrical protective equipment is carried out in the same way. When working with voltages above 1000 volts, personnel must use dielectric gloves, boots and mats. If necessary, insulating supports, caps and linings, as well as rods for leveling and transferring potential are used.

When working at height, personnel must use insulated stepladders and ladders made of fiberglass and other dielectric materials. Additional electrical protection means for voltages up to 1000 volts are represented by the same products as for voltages above 1000 V.

Requirements for certain types

Personal protective equipment must be kept in perfect condition

The general set of protective equipment according to the PUE includes not only special equipment, but also a special current tool. Its main purpose is to protect a person working in electrical networks from direct contact with high potential. There are a number of special requirements for specific types of protective equipment of any type, listed below:

- The individual items included in the equipment (rubber gloves, for example, as well as rubberized shoes and other things) are kept in perfectly clean condition. Only in this case are they able to perform their functions, which consist in reliably isolating the human body from open conductive parts of electrical equipment.

- Protective devices with grip handles (they are used when working in electrical installations with any voltage) must have restrictive rings on their holders.

- With the tool, he grasps the handles only in areas located up to the restrictive ring.

The last requirement is due to the fact that the standards define the maximum permissible gap to live parts, which is considered safe. In this case, special attention is paid to the insulated part of the holder, the length of which is made sufficient to provide guaranteed protection against electric shock

What types of personal protective equipment are there (electrical safety)

Protective means used in electrical installations are divided into several main types depending on the voltage used, as well as basic and additional in the work, which are also defined as the method of carrying out the work.

When carrying out constant work with electrical equipment, for example, in the profession of an electrician or other work directly related to the danger of electric shock, such a set must meet all quality standards and be fully available at the enterprise.

General means of neutralizing the negative effects of electric current

Basic electrical protective equipment

The main means of protecting personnel from electric shock also have a gradation depending on work under different voltages. Accordingly, depending on the safety requirements, the requirements for the quality and composition of the materials of such instruments also differ. The main difference from additional ones is the ability to constantly carry out work activities without the need to de-energize electrical equipment.

Protective clothing used while working on installations

Up to 1000 W

When working on equipment with voltages not reaching 1000 volts, the following are used:

- special rubberized gloves made using modern polymers that can withstand high stress for a long time;

- insulating rods made using dielectric metal, which are attached to the source of electricity and serve as the main grounding conductor, resulting in safe operation;

- special pliers that can be used in places. Where the use of a barbell is not possible. These pliers are also used to carry out repair work;

- special equipment with voltage indicators for measuring current strength and voltage.

Voltage indicators used in installations up to 1000V

From 1000 W

The requirements for this category are higher, since voltage over 1000V is almost guaranteed to lead to the death of an employee as a result of receiving an electric shock:

- high voltage indicators that can show an indication of such high voltage. Such devices have powerful insulation and only show voltages above 1 kilovolt;

- high-voltage insulating rods are made of a special material that can withstand increased loads, as well as special pliers with which an electrician is able to carry out work;

Such tools should only be used in conjunction with personal protective equipment that also ensures the safety of the worker. These things include special wooden pallets that isolate electric current within a certain area. Also, during activities with high voltage, skin protection in the form of special jackets and overalls made of non-conductive material is a mandatory attribute. Eye protection against sparks is also mandatory.

Voltage meters used in installations with high voltages over 1000V

Personal protective equipment

Dielectric gloves

Equipment for personal protection of workers:

- protective helmets to protect the heads of working personnel;

- goggles and shields to protect eyes and face;

- gas masks of various types and classic respirators for respiratory protection;

- cotton gloves and mittens to protect hands.

This list also includes protective equipment that prevents a working person from accidentally falling from a height. These include safety belts and safety ropes.

Protective equipment is a mandatory attribute of special units involved in the maintenance of existing electrical installations. Protective tools and special equipment are also in demand when carrying out operational switchovers and urgent repair work.

1.2. Procedure and general rules for using protective equipment

1.2.1. Personnel carrying out work in electrical installations must be provided with all necessary protective equipment, trained in the rules of use and must use them to ensure the safety of work. Protective equipment must be located as inventory in the premises of electrical installations or be included in the inventory of field teams. Protective equipment may also be issued for individual use. 1.2.2. When working, you should use only protective equipment that is marked with the manufacturer, name or type of product and year of manufacture, as well as a test stamp. 1.2.3. Inventory protective equipment is distributed between facilities (electrical installations) and between field teams in accordance with the operating system, local conditions and acquisition standards (Appendix 8). Such distribution, indicating the storage locations of protective equipment, must be recorded in lists approved by the technical manager of the organization or the employee responsible for electrical equipment. 1.2.4. If protective equipment is found to be unsuitable, it is subject to confiscation. The removal of unsuitable protective equipment must be recorded in the logbook for recording and maintaining protective equipment (the recommended form is given in Appendix 1) or in operational documentation. 1.2.5. Workers who have received protective equipment for individual use are responsible for their correct use and timely monitoring of their condition. 1.2.6. Insulating electrical protective equipment should be used only for their intended purpose in electrical installations with a voltage not higher than that for which they are designed (the highest permissible operating voltage), in accordance with the operating manuals, instructions, passports, etc. for specific means of protection. 1.2.7. Insulating electrical protective equipment is designed for use in closed electrical installations, and in open electrical installations - only in dry weather. They are not allowed to be used in drizzle or precipitation. Outdoors in wet weather, only protective equipment of a special design designed to work in such conditions should be used. Such protective equipment is manufactured, tested and used in accordance with specifications and instructions. 1.2.8. Before each use of the protective equipment, personnel are required to check its serviceability, the absence of external damage and contamination, and also check the expiration date on the stamp. It is not allowed to use protective equipment that has expired. 1.2.9. When using electrical protective equipment, it is not allowed to touch their working part, as well as the insulating part behind the restrictive ring or stop. << Previous page++ Contents ++Next page >>

How are electrical installations equipped with protective equipment?

Personnel servicing electrical installations must be equipped with protective equipment to ensure the safety of servicing these electrical installations.

Protective equipment should be located as inventory in switchgears and workshops of power plants, at substations, in transformer and distribution points of electrical networks, or may be included in the inventory of operational field teams, RMS, centralized repair teams, mobile laboratories, etc.

Inventory protective equipment is distributed between facilities, operational field teams, RMS, etc. in accordance with the operating system, local conditions and acquisition standards.

This distribution must be recorded in lists approved by the chief engineer of the enterprise.

Responsibility for the timely provision of electrical installations with tested protective equipment, the organization of proper storage and the creation of the necessary reserve, the timely conduct of periodic inspections and tests, the removal of unsuitable equipment, the replenishment of stock from the stock and the organization of accounting of protective equipment lies with the head of the workshop, service, substation, network section, and foreman. the area in charge of electrical installations or workplaces, and for the enterprise as a whole - the chief engineer.

Persons who have received protective equipment for individual use are responsible for their correct use and timely rejection.

If it is discovered that the protective equipment issued for a separate electrical installation is unsuitable, the maintenance personnel must immediately remove it, informing their immediate superior or the person responsible for the electrical equipment, and make an entry in the logbook for recording and maintaining the protective equipment or in operational documentation.

Insulating pliers

In accordance with electrical safety requirements, work related to the replacement of equipment such as fuses or insulating strips must be carried out using insulating pliers.

This device has good protection indicators and can be used at high voltages up to 35 kV.

The device itself is divided into three parts:

- lever;

- insulating part;

- working part.

If the working part of the pliers is made of metal, then, as a rule, it should not be very large, since smaller sizes help to avoid unauthorized contact with live parts, which can lead to a short circuit. The dimensions of the insulating part of this device are not standardized. The exception is those clamps that are used in installations above 1 kV, since their size is directly proportional to the voltage.

Insulating pliers are designed for replacing fuses, removing and installing insulating strips, etc. in electrical installations

It is worth noting that, according to safety requirements, this electrical protective agent can only be used in dry weather. There are no restrictions on the use of insulating clamps inside a building.

This tool must be operated with dielectric gloves, and when dismantling the fuse, the worker must have special safety glasses with him. Like any other means of protection against electric shock, dielectric clamps must undergo timely testing for suitability for use.

According to the requirements of the PUE, this electrical protective device must be tested once every 2 years.

Electrical protective equipment in electrical installations up to 1000 V

Before starting to work with the pointer, it is necessary to check its serviceability by briefly touching live parts that are known to be energized. The insulating part of the ticks must be made of the materials specified in paragraph. Light and sound signals can be continuous or intermittent and must be reliably recognizable.

When using alarm devices, it is necessary to remember that just as the absence of a signal is not a mandatory sign of the absence of voltage, the presence of a signal is not a mandatory sign of the presence of voltage on the power line. Single-pole indicators operating when capacitive current flows are intended for electrical installations with alternating current only. When using electrical protective equipment, it is not allowed to touch their working part, as well as the insulating part beyond the limiting ring or stop. Their main function is reliable protection against electric shock, so all products must strictly comply with state standards.

The size of dielectronic gloves should allow them to be worn under knitted gloves to protect hands from low temperatures when working in cool weather.

On the use and testing of protective equipment used in electrical installations (2017).

Additional

When working in electrical installations up to 1 kV, it is sufficient to use at least one additional protective device. The list includes the following items:

- Dielectric boots, galoshes and boots. The first two products can only be used when working in electrical installations up to 1000 Volts; in bots it is allowed to work at any voltage. These electrical protective equipment are needed to isolate the worker from the base on which he is standing.

- Dielectric mats and tracks. The purpose is similar to the previous version; it can be used in closed electrical devices of any voltage.

- Insulating stands. Prevents direct human contact with the floor. For voltages less than 1 kV, it is permissible to use electrical protective stands without porcelain insulators.

- Insulating caps, coverings and linings. Provide protection to humans from electric shock and prevent the occurrence of short circuits. An example of use is shown in the picture:

- Bars for leveling and transferring potential. They are used respectively in order to transfer the potential of the overhead line to the electrician’s workplace, as well as to equalize the potential between the individual shielding kit and large-sized devices for which the potential value is not constant.

- Dielectric stepladders and ladders. Allows you to protect a person from electric shock when working in electrical installations. The ladders are made of fiberglass, which isolates the worker from the base on which the ladder itself stands.

Finally, we recommend watching a useful video on the topic:

Overview of protective equipment used in EC

All listed electrical protective equipment in electrical installations up to 1000 V (both basic and additional) must be checked, as well as periodically tested for dielectric properties. We will definitely talk about this in future articles!

It will also be useful to read:

- Tests on the operation of electrical installations

- First aid rules for electric shock

- How to make an electrician's knife with your own hands

Protective equipment used in electrical installations

Hello, dear readers of the Electrician's Notes website.

The purpose of my article today is to bring to you information about protective equipment in electrical installations.

I will say right away that all protective equipment used in electrical installations must meet the requirements of the relevant GOSTs.

When working in switchgears, the following types of protective equipment are used:

1. Electrical protective equipment

2. Means of protection against electric fields

3. Personal protective equipment

Let's look at each tool in more detail.

Electrical protective equipment when working in electrical installations

First, let's get acquainted with this definition.

Electrical protective equipment is a means of protection that is used against electric shock and is necessary to ensure effective electrical safety when working in switchgear.

All electrical protective equipment is divided into 2 groups:

The main electrical protective equipment is insulating electrical protective equipment, in which the insulation is capable of withstanding the operating voltage of the network for a long time, and with the help of which it is allowed to carry out live work on live parts.

Additional electrical protective equipment is an insulating electrical protective equipment that does not protect a person from electric shock, but is only an addition to the main protective equipment. They are also designed to protect workers from step voltage and touch voltage.

Electrical protective equipment is divided according to voltage class:

- up to 1000 (V)

- above 1000 (V)

Basic electrical protective equipment above 1000 (V)

Here is a list of all insulating electrical protective equipment belonging to the basic category above 1000 (V).

Basic electrical protective equipment up to 1000 (V)

Here is a list of all insulating electrical protective equipment belonging to the basic category up to 1000 (V).

Additional electrical protective equipment above 1000 (V)

Here is a list of all insulating electrical protective equipment belonging to the additional category above 1000 (B).

Here is a list of all insulating electrical protective equipment belonging to the category additional up to 1000 (V).

- dielectric galoshes

- dielectric mat

- insulating stand

- insulating caps, coverings and linings

- rods for leveling and transferring potential

- insulating fiberglass (dielectric) stepladders and ladders

Protection against electric fields

The second type of protective equipment is protection against high-intensity electric fields.

These include:

1. Individual shielding kit - required to perform work on the ground potential in the outdoor switchgear (open switchgear) and on the potential of the overhead power line (overhead power line)

2. Various shielding devices (portable and removable)

3. Posters and safety signs:

- prohibiting

- warning

- prescriptive

- pointing

4. Portable grounding

Personal protective equipment (PPE)

Well, we’ve reached the third type of protective equipment - personal protective equipment, i.e. protective equipment used by one person.

These include:

- safety plastic helmets

- protective glasses

- fencing panels

- various respirators and gas masks

- mittens

- safety belts and safety ropes

- kits for protecting workers from electric arcs (heat-resistant Nomex suits)

Read the article about how I went to the opening of the professional workwear store “Energokontrakt”, where many options for personal protective equipment were presented, both for energy workers and for fire services (EMERCOM), oil workers, railway workers, etc.

Afterword

In this article, I introduced you to three types of protective equipment used in electrical installations. We will talk about each means of protection in more detail in the following articles. After reading all the material, you will learn how to independently select and use protective equipment depending on the conditions of the work being performed.

Insulating rods

The device consists of three parts: insulating, working and handle. The device is used on elements with passing current, or near them. The working elements can be clamps, tips and other structures, depending on the purpose. The universal head is made removable to perform different operations. It reliably fixes interchangeable devices. The rod becomes a monitoring device after attaching a voltage indicator to it. The number of links used on the insulating part may vary. Telescopic devices are convenient, but solid structures are also used. The weight load on the hand is standardized and selected so that one or two people can work.

Using rods, they check the quality of insulation, replace fuses, install various parts, carry out operations with disconnectors, measure electrical parameters, apply grounding, etc.

Using a barbell, you can free a person who has suffered from electric current.

The devices of various types of rods and the requirements for them are standardized.

In Fig. and a rod with a clamp is shown and all the components of the device are marked.

Rods used in electrical installations: a – operational; b – portable grounding

Portable grounding connections contain clamps for connection to live parts or wires (Fig. b). They can be removable or permanent.

Tests of rods are carried out under high voltage applied to their insulating parts. The parameters are presented in the table above. Voltage is applied between the working part and a removable electrode, which is temporarily attached near the stop between the handle and the insulating part (Fig. a).

Rod performance test diagram

The voltage value is regulated by an autotransformer installed at the input of the device (voltage regulator). The passing current is checked with a milliammeter, protected from overload using a spark gap (P) (Fig. b).

Standards for equipping with ASU protective equipment

Standards for equipping the premises with protective equipment (SZ) where input-distribution devices (VRU, UVR) with any number of inputs are installed must meet the requirements specified in PUE-7, PTEEP, SO 153-34.03.603-2003, “Safety Rules for operation of electrical installations”, “Sanitary standards for performing work under conditions of exposure to industrial frequency electric fields” and other current regulatory and technical documents.

The maintenance service provides everything necessary. The technical documentation indicates the minimum number of SZ. Depending on the ASU voltage, layout and operating conditions, this minimum standard can be supplemented both in terms of the number of SZ and the nomenclature.

The SZ equipment standards are intended for managers of companies and institutions of any form of ownership, specialists and workers performing work in the ASU.

The ASU is used to receive, distribute, account for electrical energy consumption and monitor the correct load distribution. With the help of devices installed at the input, if necessary, they turn off and turn on the equipment connected to it in a particular area.

The ASU device is assembled according to different schemes, for different voltage values and equipped with equipment from different manufacturers. The correct functioning of both the entire device as a whole and its individual components must be periodically monitored, and in the event of emergency situations, the necessary measures must be taken to eliminate them.

In the room where the ASU is installed, there must be working and emergency lighting, 220 V sockets with a protective contact installed and power for portable power tools using step-down transformers 220/12 or 220/42 V. There should also be a first aid kit with unexpired medications for providing first aid to victims.

Electrical Hazards

A person at a distance cannot detect electrical voltage with his senses. There are three types of effects on the human body:

- thermal - burns, heating of parts of the body;

- chemical - decomposition of blood, lymph with a change in their properties;

- biological - muscles and tissues contract, even to the point of convulsions.

Protective means

Important! By affecting the muscles of the heart and lungs, electric current can disrupt the functioning of the respiratory organs and circulatory system, and lead to cardiac arrest. Two types of damage: Two types of damage:

Two types of damage:

- Electrical injuries expressed as damage to parts of the body - burns, damage to the iris of the eyes, metallization of the skin.

- Electric shocks are a general damage to the body.

Providing assistance in case of electric shock

The consequences of electric shock are determined by the magnitude of the current and voltage, the time of exposure and the individual characteristics of the person.

Requirements

To a hand-held insulated tool

The tool includes the following elements:

- screwdrivers;

- pliers;

- pliers;

- wire cutters;

- keys;

- assembler's knives.

This tool can be made in two versions:

- made of conductive material, wholly or partially covered with insulating material;

- made of insulating material with metal inserts.

The purchased tool must be checked for compliance with the following requirements:

- the insulating layer must be permanent and made of durable, moisture-resistant material;

- the insulation of the screwdriver shaft should end no closer than 10 mm from the end of its tip;

- pliers, wire cutters and pliers on the handles must have stops of at least 5-10 mm;

- For assembly knives, the insulating handle must be at least 10 cm. On the side of the working part of the knife there must be a stop of at least 5 mm.

To dielectric gloves

Gloves can be seamless, with a seam, three-fingered or five-fingered. Their length should be about 350 mm, the size should allow gloves to be put on fabric mittens, and the width should allow them to be pulled over the sleeves of clothing.

When purchasing gloves, you must check them for mechanical damage and contamination, as well as for punctures.

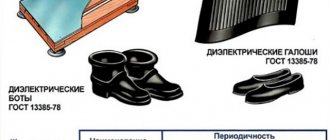

To safety shoes

Special footwear includes boots and galoshes. Galoshes are used when working in networks up to 1000 V, and bots are used in any networks. Safety shoes should consist of a rubber upper, grooved sole and textile lining. Boots must be at least 160 mm high, and, in addition, they must have cuffs.

Additional electrical protective equipment above 1000 V

In addition to the basic equipment, additional protection is required for full and safe work as an electrician. Additional electrical protection measures over 1000 (V) include:

- Dielectric gloves, galoshes, mats, shield or stand, cap and pads. Gloves protect the worker’s hands from electric current. In electrical installations, dielectric overshoes are used to protect the worker from the current that may pass through the base. The rug performs the same function as galoshes. Particularly relevant if the floor is wet. A stand is required when working above 1000 (V). They protect against current, if there is one at the base. Dielectric caps and overlays are PPE that are used to prevent short circuits.

- Barbells for equalizing potential. Used to transfer stress.

- Stairs made of fiberglass. They are safe because no current passes through them.

Set of protective equipment in electrical panels

The list of protective equipment is prescribed in PTEEP and in the Instructions for the operation and testing of protective equipment in electrical installations.

Before starting work on startup and acceptance, it is necessary to meet the conditions for the safe and reliable operation of the power facility:

- the staff of electrical and electrical engineering personnel has been staffed and their training and knowledge testing has been carried out,

- operational instructions, technical documentation for accounting and reporting, operational schemes and labor protection instructions have been developed and approved,

- tools, materials and spare parts, as well as protective equipment, have been prepared and tested.

The electrical installation organization includes in the specification a set of protective equipment only on the basis of the technical specifications at the request of the customer. In most cases, protective equipment is supplied by the operation service.

For switchgears with voltages up to 1000 V, a set of protective equipment is required, which consists of:

- universal or operational insulating rod (the number depends on the conditions)

- 2 pcs. voltage indicators,

- insulating pincers,

- 2 pairs of dielectric gloves,

- 2 pairs of dielectric galoshes,

- insulating stand or dielectric carpet (the quantity depends on local conditions),

- insulating pads, protective barriers, portable signs and posters (the quantity depends on local conditions),

- 1 PC. safety glasses or shields,

- Portable grounding (the number depends on local conditions).

In addition, the following conditions must be provided in the electrical panel room:

Source