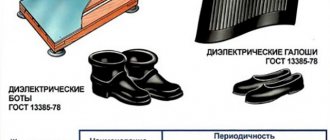

Dielectric galoshes are an auxiliary means of protection that prevents electric shock during work in closed electrical installations. Carrying out maintenance and repair work on open electrical installations is allowed in dielectric galoshes only in clear weather, due to the lack of precipitation. These personal protective equipment are suitable for work with voltages exceeding 1000 V; the permissible operating air temperature ranges from “- 30” to “+50” degrees.

Purpose of dielectric galoshes

Galoshes are used as additional personal protective equipment. They are necessary as a safety measure during operations carried out in the presence of basic personal or collective protective equipment. The main advantage of dielectric boots over dielectric galoshes is their free access to use, both in closed installations and in open facilities, without restrictions on voltage.

In addition, auxiliary shoes are used as a protective device against step voltages when in electrical installations with maximum current and voltage, including overhead power lines. Auxiliary products are applied directly to personal shoes, provided that they are dry.

Features of working with insulating pliers

There are a number of necessary safety measures, neglecting which is extremely dangerous. Insulating pliers are used mainly in enclosed spaces, and in open ones - use only in dry weather (use in rain, sleet, fog is strictly prohibited).

Recommendations for using this tool include the following rules:

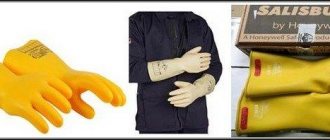

• When working with electrical installations of more than 1000 Volts, it is mandatory to use dielectric gloves. Face and eye protection (safety glasses) must be worn when removing and installing high voltage fuses.

• Working without special gloves is permissible in electrical installations up to 1 kV; you can only touch and hold the handle.

• When replacing fuses, the tool must be held with outstretched arms (it is forbidden to bend your elbows), without simultaneously touching two live parts or grounded and live parts of electrical equipment.

Used when operating in installations of no more than 35 kV (inclusive).

Classification

As a rule, protective equipment is distinguished by a bright color shade, which makes it stand out from other rubber shoes.

The model package contains:

- rubber top;

- monolithic corrugated sole;

- textile linings;

- internal inserts that retain their shape and protect against damage.

The determining indicator in the characteristics of dielectric shoes is the leakage current that occurs when the conductor comes into contact with ground through the insulation. For protective galoshes, the value of this indicator should not exceed 2.5 mA.

Factory designations of safety footwear sizes in the equivalent of the stichmas system.

Common sizes are not in every case able to satisfy the needs of performers; however, rare sizes 292 (otherwise - 39), as well as 352 (otherwise - 47) are not mass-produced. Such models can only be obtained by ordering individually. The current cost of dielectric galoshes today is 750 rubles.

Also read: How transformer oil is tested

Requirements

Special requirements prohibit the presence of foreign hard elements, all kinds of delaminations, as well as peeling or ruptures of materials that could compromise the integrity of the protective coating. Individual deviations from the norm, determined by the external appearance of galoshes, may be allowed if they are single in nature. The maximum permissible value for leakage current when testing dielectric galoshes must remain at 2.5 mA.

Materials for the manufacture of auxiliary protective equipment must comply with general requirements for both safety and labor protection.

- Leakage current indicators should not exceed permissible limits.

- It is prohibited to include elements that have toxic, explosive or fire hazards, as well as electromagnetic characteristics in the manufacturing materials.

- When in contact with aggressive surfaces, protective agents should not release toxic, radioactive or biological components.

Dielectric shoes must be marked with a special designation confirming the presence of protective qualities. Thus, for dielectric galoshes the designation “En” is used, and boots are worn o.

Check before use

Before use, protective overshoes are thoroughly inspected to identify current defects.

The surface of the product must exclude:

- peeling of finishing fragments;

- ruptures of the lining with the insole;

- divergence of seams in the lining;

- foreign hard elements;

- sulfur protrusions.

Protective equipment is applied directly to the shoes if they are dry and preferably clean. At the same time, it is important to ensure that personal shoes do not contain elements that could damage the protective surface. Upon completion of work, dielectric means must be cleaned and dried.

Each electrical installation must contain a set of several sizes of auxiliary dielectric means. During inspection, it is important to pay attention to the presence of a stamp indicating that the tests were carried out in a timely manner.

Frequency of inspections

For dielectric galoshes, scheduled tests are carried out every 12 months, applying a voltage of 3.5 kV for 1 minute.

Also read: First aid for electric shock

In addition, extraordinary inspections may be carried out in the following cases:

- as a result of a fall;

- after renovation;

- after replacing individual elements;

- if damage occurs.

Tests of auxiliary protective equipment are carried out according to approved instructions, the main provisions of which read:

- Mechanical tests should be carried out before electrical tests.

- Only qualified specialists who have passed special certification are involved in testing.

- Before checking, it is necessary to make sure that the factory markings are present and the integrity of the insulating surfaces.

If the test sample does not meet these conditions, tests cannot be carried out until the detected deficiencies are eliminated.

Safety regulations

These are the basic rules for using electrical protective equipment and are suitable for all types:

- If special protective equipment is required, its suitability must first be checked. Firstly, attention is paid to the appearance of the device and its insulation. It must be free of dirt and damage to the outer casing, including paint.

- The suitability of each protective isolating device is also regularly checked using dedicated electrical test equipment. Therefore, before using a protective product, it is necessary to check its expiration date - the date of the next test on the stamp of the identified sample.

Device safety check

- If the electrical protection device is dirty, the housing is damaged, or the periodic test period has expired, it should not be used as this may result in electric shock.

- The electrical protective equipment to be used performs insulating functions only when dry. When it is necessary to work outdoors, it is necessary to avoid the use of protective equipment that has been exposed to moisture (rain, rain, frost, snow).

- If it is necessary to work in a damp environment, an electrical protective device specially designed for this purpose must be used.

You may be interested in this Features of wire strippers

Application of an insulated rod

- Protective insulating pliers must be kept clean. This is also true for gloves, shoes and other protective equipment: if caustic liquids and lubricants stick to the rubber surface, they will soon become unusable.

- Insulating pliers are used to replace the fuse. In addition to insulated marking lines, insulated gloves and safety glasses or face shields should be used as an additional protective measure when replacing fuses above 1000 V.

- The load must be disconnected before replacing the fuse. The exception is network fuses, which do not have switching devices, and the fuses can be removed without disconnection.

Insulating pliers are a necessary tool when performing live work. They must be kept clean, protected from moisture and quality checked regularly. The safety of work and the life of the worker depend on this.

Tests

Dielectric galoshes are tested at a voltage of 3.5 kV, which is connected for 1 minute.

Next, the leakage current is measured by passing an electric current through the product. They do this as follows:

- Shoes are immersed in a container of water at a temperature of 15 to 35 degrees.

- Check that the edges of the object are above the surface of the water and that the interior remains dry. It is required that the water level be 2 centimeters below the edge of the object.

- An electrode grounded using a milliammeter is inserted into the inner cavity of the shoe.

- A current is connected to the test vessel for a period of 2 minutes, and the voltage is increased to 5 kV.

- When there are 30 seconds left before the test is completed, connect the milliammeter and take readings.

The circuit for testing dielectric gloves is similar for galoshes.

1 – connection to a voltage source; 2 – bath with water; 3 – water inside the glove and bath; 4 – electrodes (rod) for connecting water to two poles of the voltage source; 5 – distance from the edge of the glove to the water in the bath

If the magnitude of the leakage current revealed during the tests corresponds to acceptable standards, and the product avoided breakdowns, then the test results are considered satisfactory and the protective equipment is suitable for use.

The standards allow testing simultaneously for several pairs of dielectric overshoes using one vessel. If one of the objects turns out to be pierced during the testing period, it is removed without stopping the tests. All galoshes that pass the test receive a corresponding stamp with the date of the test.

Also read: Where does zero come from in a transformer?

Terms of use

You can clearly see how to use insulating pliers in the video below (watch from the 8th minute):

I would also like to note 3 nuances:

- When working under voltages above 1000 Volts, it is imperative to use dielectric gloves, as well as protective devices for the eyes and face. You can only touch the handle.

- In electrical installations up to 1 kV it is allowed to work without gloves, but to replace fuses you need to hold the tool at arm's length.

- It is prohibited to use ticks in open spaces in wet weather. Fog, sleet and rain are also weather conditions under which work is prohibited.

Storage

Auxiliary protective equipment should be stored in specially equipped warehouses that provide temperature conditions from “0” to “+30” degrees. Heating devices should be located no closer than 1 m.

The storage location should prevent contact of protective shoes with ultraviolet radiation, as well as with aggressive elements, such as:

- oil;

- petrol;

- acids;

- alkalis.

Accessory protective equipment should be stored and transported under conditions that will maintain its integrity and performance. This means that there must be no possibility of damage or moisture, as well as contamination.

Dielectric products made from rubber or polymer materials must be stored in closed cabinets. As a last resort, this can be done on racks, provided that there are no tools or other hard materials nearby.

Options

The main parameters of the clamps are the operating voltage and their size. These quantities are inextricably linked:

- At voltages up to 1 kV there are no size restrictions.

- At voltages from 1 to 10 kV, the insulating part must be at least 45 cm, the handles - from 15 cm.

- At voltages from 10,000 to 35,000 V, the size of the insulating part is from 75 cm, the handles are from 20.

You might be interested in: Testing wires with a multimeter

Clamps for different voltages