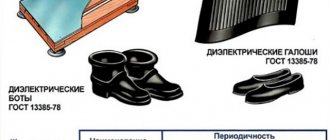

Purpose of dielectric bot

Used as an additional means of personal protection against the risk of exposure to electric current during work. The main purpose is a means of protection against step voltage. Dielectric bots are used for installation, repair and maintenance work in all types of electrical installations. Their use is not limited to dry rooms. According to the PUE, in dry weather, safety shoes are allowed to be used for electrical work outdoors.

The process of checking dielectric galoshes and bot

Electrical protective equipment is tested according to operational test standards to avoid accidents. During the production process, safety shoes are subjected to regular and extraordinary tests. Extraordinary checks are carried out; inspection of safety shoes reveals any damage. Tests are carried out according to approved regulatory documents by specially trained and certified personnel.

Test periods and frequency

The frequency of checking polymer bots is at least 3 times every 12 months. In some cases, the period is increased to 6 months. Ideally, footwear testing should be carried out before any work in an electrical installation.

The time allocated for testing protective equipment is one minute.

Is there a need to test new bots?

Electrical protective equipment received for use from manufacturers or warehouses, that is, new, must be tested in accordance with performance test standards.

How are bots different from galoshes?

Dielectric boots serve the same purpose, but their use is limited to a maximum permissible voltage of 1000 V. Dielectric boots can be used both in this range and in switchgear with higher voltages.

Restriction on the use of galoshes - the possibility of performing work only indoors with sufficient ventilation. Electrical insulating boots are more universal: their use in open areas is limited only in the presence of precipitation.

Products are produced with the following markings:

- Ev - dielectric bots;

- En - dielectric galoshes.

Visual differences: the boots are taller and have cuffs. The thickness of the corrugated sole is at least 5.7 mm, for galoshes - 3.6 mm. The lining of galoshes made of dielectric rubber is made of lined fabric, while those of electrically insulating boots are made of harsh twill.

The maximum leakage current is a characteristic for assessing dielectric protective equipment: for galoshes - 2 mA, for boots - 7.5 mA.

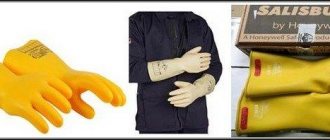

How to use bots

Boots, dielectric gloves and socks are used in high-risk areas. At the same time, the building should not be wet or dusty, otherwise the effectiveness of the boots is significantly reduced. Step-by-step instructions on how to use electrician shoes:

- They are worn only over regular shoes. Make sure your boots are clean first. If it is not possible to wear the usual sneakers or galoshes, then use rubberized socks;

- If the room is under step voltage, then before walking on the floor, you need to spread special mats or rubber plates on it - this will protect against high current;

- The manufacturer indicates on the sole not only the expiration date, but also the operating conditions. All boots and galoshes are divided into two groups: those that are used at temperatures from -15 to 40 degrees, and -50 to +80;

- It is advisable to use all possible insulating devices together: gloves, socks and shoes.

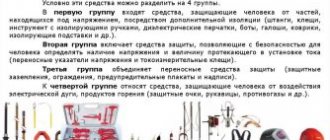

Classification

Dielectric boots can be glued or molded. The height of the product must be at least 16 cm, and it must have top cuffs. In addition to the rubber base, their inner part is lined with textile material and equipped with insoles. The production of molded products is allowed without lining.

Also read: Purpose of voltage indicators

The sole must be grooved, with a rubber thickness in the heel of at least 8.4 mm, and a thickness in the boot of at least 3.9 mm. Boots made of dielectric rubber have a size range of 29.2-35.2 and are worn over dry work shoes.

Dimensions for galoshes, but similar for boots:

In addition to the size, the sole indicates the operating conditions:

- -15 to +40˚С;

- -50 to +80˚С.

The cost of the product varies significantly depending on the quality and brand of the manufacturer. The price range is 650-1500 rubles. When purchasing, you should pay attention to the presence of a certificate for the product.

Price overview

You can buy dielectric boots at any electrical appliance store; their price depends on the brand and level of protection provided (for example, Rostov special store). Sales are also carried out in factories where protective measures are produced.

| City | Cost of rubber molded dielectric boots |

| St. Petersburg | 535 |

| Almaty | 540 |

| Moscow | 540 |

| Ekaterinburg | 530 |

| Krasnodar | 535 |

| Chelyabinsk | 535 |

| Samara | 535 |

Before purchasing, always check the certificate of conformity of the bots, their fire rating and the voltage at which they provide maximum protection.

Good afternoon, dear readers of the site “vse-elektrichestvo.ru”. We have already talked about dielectric gloves and now it’s time to talk about dielectric boots for electricians.

Dielectric boots for an electrician

Dielectric shoes today include:

- dielectric boots;

- dielectric galoshes.

Dielectric galoshes 1000 Volt

Typically, dielectric overshoes are used to protect a person from step voltage or step voltage.

It is important to know! Step voltage is the voltage between two points on the surface of the earth, which is taken to be equal to the length of a person’s step.

Dielectric boots and galoshes are only additional insulating means in open and closed electrical installations. Today, in electrical installations it is allowed to use only safety shoes that meet all GOST requirements. Dielectric bots are allowed to be used in all voltage classes. Dielectric galoshes, in turn, can only be used in electrical installations up to 1000 Volts. Designation for protective properties:

All dielectric bots have a lapel

The color of dielectric boots and galoshes usually differs from the color of other shoes that are made of rubber. On dielectric boots you will notice a flap. The height of the bot must be at least 16 cm.

Requirements for bots

Dielectric boots are manufactured in accordance with the requirements of GOST 13385-78, GOST 15152-69 with resistance to fungal spores (tropical version). Dielectric shoes are cast from special rubber, which differs in color from other rubber shoes. The presence of foreign solid fractions is not allowed in the rubber composition. The protection material is characterized by low conductivity, but is not protected from mechanical influences and is not resistant to contact with petroleum products.

A stamp is placed on the side of the boot containing the following information:

- product designation;

- date of manufacture, batch number;

- warranty period of operation;

- next testing date.

The blue circle is a table with the date of the last test, who tested it, etc.

Bots that have expired and are not tested at the proper time are subject to write-off.

Types of special rubber shoes

Dielectric shoes include:

Glued rubber galoshes

Glued overshoes are multilayer ring-shaped products. They consist of:

- rubber upper;

- similar grooved sole;

- backdrop made of paper or twill;

- thick knitted lining;

- internal elements that create additional strength.

Rubber color is beige or light gray.

Important: when working in regions with a tropical climate, textile material must be impregnated with an antiseptic.

Glued rubber boots

Dielectric boots differ from galoshes by the presence of a flap at the top. The flap is necessary to protect against liquid penetration.

The following requirements apply to the production of a bot:

- the height of the product must be at least 16 centimeters (including the folded collar);

- the thickness of the plantar part is at least 0.6 centimeters;

- The lining must be made of dielectric material.

Molded rubber boots

The production of molded models involves the production of blanks from a certain rubber composition, their further assembly, molding and vulcanization. At the final stage, burrs, press-outs and other deviations from the norm are removed. The entire product is cleaned.

According to GOST 13385-78, molded boots do not have internal reinforcing parts and a textile lining. Lapels are present, as in adhesive products.

PVC molded rubber boots

The design of the boots consists of:

- boot, narrower at the bottom and widened at the top;

- corrugated sole with a heel made of polymer material (rubber or PVC);

- internal textile lining.

Important : regardless of the type of shoes, the material used should not contain any hard or soft foreign bodies or bubbles (with the exception of the toe part), peeled elements, protrusion of rubber or PVC through the lining fabric, delamination of individual internal parts and other errors.

Check before use

Before using shoes in the process of electrical work, an external inspection of the condition of protective products is carried out. Dielectric bots must have the following characteristics:

- presence of a stamp with the test date indicating successful testing;

- visual inspection confirms the integrity of the product - no mechanical damage (ruptures, punctures);

- the internal gasket must adhere firmly to the rubber base, be intact, and not peel off;

- it should be possible to open or close the lapels;

- dielectric shoes must be well dried and clean.

Also read: What is the permissible oil temperature in a power transformer

Before use, contaminated products are washed in soapy water and dried at 20-25˚C.

Tests

Bots with dielectric properties are tested in special high-voltage electrical measurement laboratories, where they are tested on a high-voltage stand. Based on the results of the research, a mark is placed with the date of the next test and the maximum permissible voltage.

Technological test sequence:

- Place the shoes to be tested in a reservoir of warm water with the soles down. The liquid should not reach the upper dry edges of 4.5-5.5 cm. The inside of the products is filled with water at the same level as the liquid in the tank.

- A voltage of 15 kV is supplied through a transformer to an electrode in a container with water and to an electrode placed in the interior of the product being tested.

- Then the circuit is closed through the cable within 1 minute. with a grounded milliammeter. Its readings indicate electrical leakage and should not exceed 7.5 mA.

The circuit for testing dielectric gloves is similar for bots.

1 – connection to a voltage source; 2 – bath with water; 3 – water inside the glove and bath; 4 – electrodes (rod) for connecting water to two poles of the voltage source; 5 – distance from the edge of the glove to the water in the bath

If the instrument reading is too high or the needle fluctuates sharply, the test is considered negative and the product is rejected. The stamp is crossed out with red paint. If the milliammeter values are below acceptable values, the tests are considered successful. The boots are dried, and the test readings are recorded in the technical journal.

Frequency of inspections

For dielectric galoshes, scheduled tests are carried out every 12 months, applying a voltage of 3.5 kV for 1 minute.

Also read: How to determine phase and zero with and without instruments

In addition, extraordinary inspections may be carried out in the following cases:

- as a result of a fall;

- after renovation;

- after replacing individual elements;

- if damage occurs.

Tests of auxiliary protective equipment are carried out according to approved instructions, the main provisions of which read:

- Mechanical tests should be carried out before electrical tests.

- Only qualified specialists who have passed special certification are involved in testing.

- Before checking, it is necessary to make sure that the factory markings are present and the integrity of the insulating surfaces.

If the test sample does not meet these conditions, tests cannot be carried out until the detected deficiencies are eliminated.

Storage

When a batch of products is delivered to the warehouse, it is left unpacked for 24 hours; the temperature of the received sets must correspond to the ambient temperature.

Rubber protective products are stored in warehouses at a positive temperature but not higher than +25˚С, in a place protected from exposure to ultraviolet rays, at a distance of at least 1 m from heating devices. Dielectric boots should not be exposed to aggressive liquids during storage. Safety shoes must not be stored together with PVC boots.

Also read: Automatic transfer of reserve - ATS

Dielectric boots fully perform the electrical insulating protective function against electric shock to a person, subject to the conditions of use and storage, operation of certified products of proper quality without damage, which have passed scheduled tests within the specified time frame.

Storage and operating conditions

Storing safety shoes is a responsible process. The following conditions must be met:

- the presence of a dark closed room;

- the ambient temperature must be above 0 degrees Celsius (exceeding the 20-degree mark will negatively affect the quality of rubber products);

- availability of racks or wooden shelves in the warehouse;

- relative humidity requirements – 50-70%;

- The presence of special clothing and safety footwear in the immediate vicinity of heating units is unacceptable. It is allowed to keep items to be worn in relation to heating systems at a distance of one meter or more;

- close proximity to chemically aggressive environments: acids, alkalis, some liquids, technical oils can cause substances to enter the surface of products with subsequent damage.

Important: electrically resistant shoes are used in accordance with the rules for using protective equipment used in power plants. It is necessary to ensure that it does not receive mechanical damage due to exposure to hard, cutting objects, or chemically aggressive substances.

In a simplified version, it should be borne in mind that boots or galoshes are worn over existing clean and dry shoes. After completion of the work, the rubber products are removed and left on the territory of the electrical installation. If necessary, they are cleaned of dirt and dried.