What is a sodium lamp

A sodium lamp is understood as a lighting device with the designation HPS and the decoding “sodium arc tubular” lamp. The element is reliable, simple and accessible. Many companies still produce them, which indicates that there is demand.

The devices first appeared in the thirties, but they were quickly replaced by metal halide sources. The elements are used for street lighting, illumination of agricultural crops, in gyms and underground passages.

Appearance of a sodium lamp

For a long time, sodium elements were installed in street lamps and highway lighting systems. Now the devices are being replaced with LEDs. However, a large number of designers prefer sodium sources due to their availability, long service life, high power and light output.

HPS lamps are often installed in enterprises together with metal halide lamps. Sodium lighting produces warm colors and is more comfortable to work with.

Disposal requirements

Since the burner contains hazardous substances such as xenon, sodium and mercury, they must be properly disposed of. Despite the same appearance as other lamps, the burner and bulb have a dangerous chemical composition. As a result, the aluminum or glass will be damaged during processing. According to current legislation, management companies or those organizations that service the housing stock must dispose of such light sources.

Note! Due to failure to fulfill obligations, utility companies may pay a fine of 100,000 rubles or more.

Requirements for the disposal of a light source operating on sodium vapor

In general, a high-pressure sodium lamp is a light source that is actively used to illuminate large spaces due to its high efficiency. Its distinctive feature is yellow light and a high price-quality ratio. There are high and low pressure. Consists of a base and a burner. Actively used in industry, street and garden lighting. Not suitable for home use due to toxicity. Has strict requirements for operation and disposal.

Varieties

All sodium lamps are divided into high and low pressure elements. The main difference is the pressure level in the flask and the difference with the atmospheric indicator. This determines the specifics of the equipment’s operation and application in specific situations.

High pressure

There are three types of high pressure elements:

- HPS is the most common high pressure sodium arc lamp found in street lamps.

- DNaZ is a type of DNAT that has a mirror coating on the inner wall of the flask. The element is characterized by lower power, but increased light output.

- DRI (DRIZ) – a device with radiating additives. May have a mirror layer on the flask. Relatively good color reproduction, but some colors look dull.

Types of gas discharge lamps

Low

Low-pressure sodium lamps were not popular with users from the very beginning and are no longer used. Even increased energy efficiency was not a reason to use it. The reason is poor color rendering, which makes it difficult to identify the color and sometimes the shape of an object.

At the same time, they are reliable, consume little energy, and produce excellent light. Suitable in rare cases exclusively for street lighting.

Key features of sodium discharge lamps

It is believed that sodium light bulbs have the highest light output, which implies impressive efficiency. The products are characterized, among other things, by a long service life. During operation, the light output decreases slightly. The operating parameters (of high-pressure lamps) depend little on the ambient temperature (overheating is eliminated by a properly implemented design). Sodium light bulbs are in demand for street lighting. There are serious disadvantages:

- Not very reliable color rendition (coefficient values – 25). This has long been considered the main limitation for the use of discharge lamps in everyday life. Human skin looks extremely bad in such lighting.

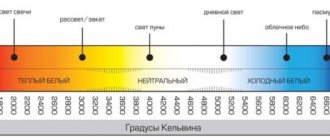

- Discharge in sodium vapor is characterized by deep pulsation, which leads to rapid visual fatigue. The flickering effect is harmful to the nervous system and several aspects of human health. The mentioned phenomenon is explained by the complete inertia-free arc in sodium vapor - the glow repeats the law of the applied voltage (in the network there is usually a sinusoid with a frequency of 50 Hz).

- As the life resource is consumed, the power consumption of the sodium lamp gradually increases and increases by 40% relative to the initial one.

- The ballast of sodium lamps is bulky (takes up a lot of space) and is characterized by large losses (up to 60% of the total energy consumed).

- The presence of a starting choke determines a low power transfer coefficient (up to 0.35). Which requires a solid block of compensating capacitors to eliminate the reactive part.

Lighting device

The above explains the use of sodium light bulbs mainly for night lighting, especially for non-residential objects: workshops, warehouses, railway stations. Additionally - for storage facilities, highways, architectural structures. The yellow light of a low-pressure sodium lamp allows a person to distinguish details at a relatively low radiation intensity, and penetrates excellently through fog in bad weather conditions. This specificity makes it possible to create a variety of signal installations based on the described devices.

Some of the above disadvantages can be eliminated by using inverter-type electronic ballasts. This reduces energy consumption; due to the absence of a starting choke, the power factor reaches 0.95. Of course, the mass of electronic ballast is small. This is known to a person who knows about the advantages of LED and discharge lamps with E27 Edison thread. All electronics fit into the plinth here.

The service life of high-pressure sodium lamps ranges from 12 to 28 thousand hours. These are competitive values, in terms of workdays it is 4 – 9.5 years. Gradually, the voltage drop across the lamps increases at a rate of 1 - 5 V annually. What causes the refusal?

The bulb of low pressure lamps is usually cylindrical. For high-pressure products - sometimes mushroom-shaped with an internal reflector or ellipsoidal. In the latter case, the glow spectra are graded according to power: for its average values, the pressure in the flask is maximum, explaining the mentioned division. The spectral characteristics are affected by the mains voltage (unless electronic ballast is used). The service life is also critical to the amplitude: an increase or decrease in voltage by only 5% leads to a sharp aging of the product.

For ordinary consumers, lamps with improved color rendering are of interest. The corresponding product coefficient reaches 83, which is recognized as an excellent indicator. For example, for LED light bulbs, typical values are 70 or more. The latter are widely used in everyday life; there are few people willing to complain about such parameters. And given the cost-effectiveness of sodium light bulbs, we believe that the devices will become a worthy competitor to other families of lighting devices.

Lamp operation

Specifications

The main ones include luminous flux, luminous efficiency and operating time. There is a direct relationship between the power of the element and the resource - high-power models last longer.

Below are the technical characteristics of popular HPS sources with a power of 150, 250 and 400 W. All of them are connected to the lamp using an E40 type socket at a voltage of 120 V.

DNAT 150

Technical characteristics of the lamp DNaT 150

| Power, W | Flow, Lm | Light output, lm/W | Length, mm | Diameter, mm | Resource, h |

| 150 | 14 500 | 100 | 211 | 48 | 6 000 |

DNAT 250

Technical characteristics of the lamp DNaT 250

| Power, W | Flow, Lm | Light output, lm/W | Length, mm | Diameter, mm | Resource, h |

| 250 | 25 000 | 100 | 250 | 48 | 10 000 |

DNAT 400

Technical characteristics of the lamp DNaT 400

| Power, W | Flow, Lm | Light output, lm/W | Length, mm | Diameter, mm | Resource, h |

| 400 | 47 000 | 125 | 278 | 48 | 15 000 |

Low pressure sodium lamps

Low pressure lamps are extremely efficient. The wavelengths indicated above become dominant, but are far from the only ones in the glow spectrum. For low-pressure lamps, most of the lines lie in the area of sensitivity of the eye. This means the light is as bright as possible. In other words, low pressure lamps have an attractive efficiency.

In laboratory models, the efficiency reaches 50-60%. As a result, the luminous efficiency rises to 400 lm/W (the theoretical limit for the current level of technology is 500 lm/W).

For comparison. A 9 W EKF LED light bulb (analogous to a 75 W filament) produces a flux of 830 lm. The figure is considered a good indicator of energy saving. Although the luminous efficiency, as you might guess, is “only” 92 lm/W. It becomes clear how effective low-pressure sodium lamps, invented long ago, in 1931.

In practice, sacrifices have to be made (Philips bulbs are still good and achieve a luminous efficiency of 133-178 lm/W). The temperature of the flask rises to the required 270-300 degrees Celsius due to special measures for thermal insulation (exceeding the radius of the flask over the maximum effective one) and a slight increase in the operating current to the optimum. As a result, the efficiency of real products produced for mass sale does not reach the above limits. But it remains high for sodium light bulbs to be called energy efficient.

Thermal insulation is sometimes supplemented with other measures. A reflective shirt made of semiconductor materials allows useful yellow radiation to pass out, but reflects infrared radiation inward. The temperature inside rises further. But the design of a sodium lamp is more complicated.

Ignition of the arc is facilitated by adding some neon and argon. This greatly reduces the voltage developed by the driver. Due to the presence of impurities, the glass of the flask does not absorb argon. The radius of the lamp is taken slightly larger than optimal and is 15-25 mm. The oxide cathode is usually bifilar or sintered (sintered from powder). The material used is tungsten activated by alkali (alkaline earth) metals.

Low pressure lamp

Design Features

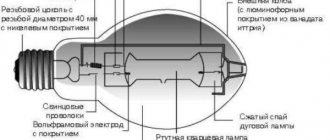

All sodium lamps consist of a high-strength aluminum oxide bulb connected to two electrodes. The element material can withstand high temperatures and is resistant to sodium vapor. The flask is filled with a mixture of inert gases, mercury, sodium and xenon. The presence of argon in the gas mixture facilitates the formation of a charge, and mercury and xenon serve to improve light output.

The design looks like a flask within a flask. The burner is installed in a smaller flask, and a vacuum is created in it. Connects to the network via a socket. The external element performs the function of a thermos, protecting the internal parts from the negative effects of low ambient temperatures and reducing heat loss.

Burner

The burner is the most important element of any HPS lamp. It is a thin glass cylinder, maximally resistant to temperature changes and chemical influences. Electrodes are inserted into the flask on both sides.

During the production of the burner, special attention is paid to its complete vacuumization. During equipment operation, the base heats up to 1300 degrees and even a small amount of oxygen entering this area can lead to an explosion.

DNAT 250 lamp with depressurized bulb

The burner is made of polycrystalline aluminum oxide (polycor). The material is highly dense, resistant to sodium vapor, and transmits about 90% of all visible radiation. Electrodes are made from molybdenum. Increasing the power of the element requires increasing the size of the burner.

It is difficult to maintain a vacuum in the flask, since thermal expansion inevitably creates microscopic gaps through which air passes. To prevent this, use gaskets.

Base

The lamp is connected to the mains through the base. Most often, an Edison screw connection marked E is used. For HPS with a power of 70 and 100 W, E27 sockets are used, for 150, 250 and 400 W - E40. The number next to the letter designation indicates the diameter of the connection.

For a long time, sodium lamps were equipped only with screw bases, but not so long ago a new Double Ended connection appeared, providing contacts on both sides of the cylindrical bulb.

Double Ended plinth

Operating principle

An arc discharge must be maintained inside the sodium lamp bulb. For generation, a pulsed ignition device (IZD) is used. During switching on, the pulse can reach a power of 2-5 kW.

Under the influence of voltage, a breakdown occurs with the formation of a discharge. It takes about ten minutes to warm up the burner and reach the rated power of the device. At this time, the brightness increases and normalizes.

How DNAT works

In modern elements you can find a built-in choke, which limits the arc current and guarantees a stable supply of energy without ripples and other undesirable moments.

How to connect a sodium lamp

Due to the special structure of gas-discharge lamps, it is not possible to simply connect them to a household electrical network, since the available voltage is not enough to start. In addition, the arc current must be limited. And sodium lamps are no exception. In this regard, it is necessary to use a ballast or ballast in the circuit. They can be electromagnetic (EMP) or electronic (EPG). In practice in Western countries, such devices are called Magnetic Ballast (for electronic ballasts) and Digital Ballast (for electronic ballasts). In some cases, it is impossible to do without the use of a pulse ignition device or IZU. The use of electronic ballasts for sodium lamps 250 is necessary for their heating and further uninterrupted operation. In this case, the startup itself takes 3-5 minutes, and the sodium lighting sources gain full power within another 10 minutes. It is noteworthy that at the moment the lamp is started, its rated voltage increases almost 2 times.

Areas of application

Sodium lamps are used when economic considerations are more important than color rendering. They are not suitable for residential premises, public buildings and production workshops. In addition to poor color rendering, the lamp is dangerous if it malfunctions.

Can be used for seedling growth

DNAT is used to organize street or greenhouse lighting, illumination of architectural monuments and buildings. They are especially common in large cities. They can be recognized by their yellowish-golden hue. The most common elements are 250 and 400 W.

Relatively recently, low-power sodium lamps with a color rendering index of 80 appeared on the market. This indicator is significantly higher than that of other similar models. Therefore, such lamps are effective for lighting decoration in public places.

Sodium light sources are used in the final stages of seedling growth in greenhouses, where shades of blue are often present. Radiation of a significant proportion of the ultraviolet spectrum promotes plant growth. It is important to handle the elements with care, because... destruction of the flask can ruin the entire crop and spoil the soil.

Designers often use sodium elements to imitate fire or the light of the sun.

Where is it used?

Power is the main technical light characteristic of dnat. Thanks to it, it is possible to illuminate greenhouses, flower beds and plant nurseries with similar light sources. To grow plants you need to use 150 or 250 watt dnat. But such sources should not be placed closer than 50 centimeters. Lamps with high power should not be used in greenhouses and flower beds, as they can destroy the flowers.

You might be interested in this: Features of the HPS lamp

Note! As for lighting streets, underground passages, indoor sports complexes, a 150 or 70 watt source is used to perform these tasks.

Use in gardens and greenhouses

Connection diagrams

Depending on the IZU, the schemes differ. The IZU can be two-pin or three-pin. Below are diagrams for both cases.

Connection via two-pin IZU

In the connection diagrams for sodium lamps, the inductor is always connected in series, while the igniter is connected in parallel.

Connection via a three-pin IZU

Power reactance during startup requires the inclusion of a capacitor in the circuit to reduce noise and inrush current. Typically an element with a capacity of 18-40 μF is used. The capacitor is connected in parallel to the power source. The capacitor stabilizes the voltage and slows down the degradation of the electrodes.

Use of a capacitor in a circuit

Sodium lamps: technical specifications and working principle

Photo 1 - Sylvania E40 400W, working life 20,000 hours

Sodium discharge lamps are used for lighting:

- utilitarian;

- street;

- decorative;

- architectural.

For lighting inside production areas, NL can be used if there are no requirements for a high color rendering index of the light source.

Photo 2 - Osram E27 50W, service life of at least 50,000 hours

For domestic use, NL is not used due to flicker, which appears when the frequency that powers the network is doubled.

According to their spectrum, they are perfect for growing fruit-bearing plants, and good harvest will be guaranteed.

Photo 3 - PHILIPS SON-T 70W/220 E27 1CT/12, maximum service life - 28,000 hours

Depending on the partial pressure of sodium vapor, NLs are:

- high pressure (HLBP);

- low pressure (LPLP).

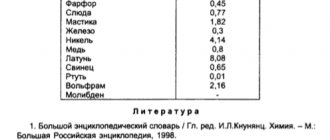

The benefits of NL are understandable - today they remain an effective electrical source of light. The characteristic of NLs is their luminous efficiency, which is measured in lm/W:

- 150 - NLVD;

- 200 – NLND.

Photo 4 - General Electric E40 1000W, service life - 24,000 hours

Technical specifications of NL:

- power;

- voltage;

- stream of light;

- type of base;

- length and diameter.

NL design: oxide electrodes are soldered to the two ends of a U-shaped tube made of special borosilicate glass.

Main! This type of glass is resistant to sodium vapor.

Precautionary measures

When using sodium discharge lamps, it is important to remember:

- It is unacceptable to turn off the power to the element immediately after it has been turned on. You need to wait at least 1-2 minutes. Failure to comply with this recommendation may result in complete startup failure.

- The room with the lighting element must have a ventilation system. This is due to the increased heat transfer of the device and the presence of harmful substances in it.

- Do not touch the lamp or reflector with bare hands during operation as this will cause serious burns.

- It is advisable to use gloves when installing the flask. Fatty deposits when heated can cause the flask to explode. It is prohibited for water to enter open elements.

- The ballast used together with the light bulb can heat up to temperatures of about 150 degrees. It is recommended to place it under a fireproof casing to protect it from moisture and debris.

- Do not touch conductive elements with bare hands or allow them to get wet. It is also recommended to periodically check the wiring for damage, burns or short circuits. In this case, the wires must be special, designed to work with extremely high voltages.

Safety regulations

Since the sodium source gets very hot during operation, certain rules must be followed. Thus, it is not recommended to touch the light source for 10 minutes after the lamp has been turned off. Also, do not touch the light bulb with your bare hands, as this will leave grease. When heated, it will turn into a dark spot and damage the case.

The penultimate rule concerns the need to provide ventilation to the light source, since it needs to be cooled. It is also worth placing the lamp at a great distance from fire hazardous objects. The last rule is that it is imperative to protect the light source from impacts, since due to its explosion, fragments will fly off over a long period.

Note! If the burner is damaged, the room will be filled with mercury and will need to be disinfected.

It is worth pointing out that sometimes the lamp goes out due to the fact that it has a poor contact or a voltage surge occurs with an interturn short circuit and a violation of the coil insulation. To correct the problem, the ballast must be replaced. If a new light starts blinking, then the problem is that the device is not warming up sufficiently. Sometimes there is a crackling sound and the source stops igniting. In this case, the wire that goes from the source to the ignition device breaks, and it is necessary to check the wiring and strip the contacts. When performing all of these actions, you must follow simple safety rules.

You may be interested in everything about incandescent lamps

Carrying out work with rubber gloves as a guarantee of safety when connecting lighting equipment

Disposal

Disposal of devices

Sodium is a volatile substance that ignites easily when exposed to air. In addition, the elements contain mercury, a dangerous radioactive element that can cause severe poisoning. For this reason, it is unacceptable to simply throw away sodium lighting sources. They must be disposed of as potentially hazardous waste along with other energy-saving lamps.

In large cities, recycling bins are provided. If this is not possible, contact your nearest lighting repair shop, manufacturing facility, or hazardous waste collection service.