Aug 15 • Articles • •

(

408 votes, average: 4.84 out of 5)

HPS lamps: a light source that was retired too early.

As we promised, an article about HPS (High Pressure Sodium Tubular Arc) lamps has finally arrived. Anyone who has worked or is working in the field of lighting technology knows firsthand about the HPS lamp. But if anyone doesn’t know, let’s explain it in simple terms: HPS lamps are like a Kalashnikov assault rifle for lighting streets and illuminating plants - a time-tested and reliable, but not without its shortcomings, light source.

Actually, this article about HPS lamps is more for beginners; material presented competently, but in an accessible language: without schematic diagrams of connection and a complete explanation of the basics of maintaining the discharge column in the burner of a HPS lamp. But we are sure that specialists will also like the sketch.

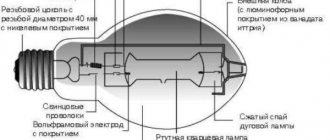

Actually, the subject: one of the invariations of the HPS lamp

Almost 100% of the world's roads (no one, of course, counted) until recently were illuminated by HPS lamps, until they began to be cut out of their supports in favor of LED lamps. However, even now, experienced designers prefer to stick a sodium lamp into the project out of harm’s way, because LEDs are 1. really more expensive, 2. not that much energy efficient and 3. still unpredictable, because The number of new LED manufacturers is simply off the charts. But more on that later.

Another option for a HPS lamp

HPS lamps come in different powers - from 50 to 1000 W (rarely, but they are found with a power of 2000 and 4000 W), which seems to hint at their “industrial” use rather than “household”. Basically, HPS lamps are used in luminaires for illuminating streets and roads, less often - in production in combination with white light sources (for example, with MGL lamps to achieve warmer light and greater energy efficiency). In the most perverted cases, they are put into production in their pure form. And then - before the first injury or the call “where to go.”

That rare case when HPS lamps are used in the wrong place

But the most indispensable application is lighting greenhouses, or supplementary lighting of plants (which, in fact, is the same thing, but the second is scientific).

Terminology

This is why we don’t like Wikipedia, because what they write there is either superficial and not clear, or boring and with all the details - which is also not clear to the uninitiated. The most offensive thing is that the essence of the name of the HPS lamp is given only as a decoding of the abbreviation, but here everything is much more interesting.

HPS lamps all over the world (except Russia) are called as they should be called - HPS Lamp (High-Pressure Sodium Lamp), that is, high-pressure sodium lamps (HPS). We also call them that, but no one uses this term. In the Soviet Union, when NLVDs first appeared, various factories began to produce them. The modifications and capacities were different and they had to be distinguished somehow.

A copy of the DNAT 250 lamp produced by the Lisma lamp plant

There were indeed many differences: the shape (ellipsoidal/tubular) and transparency (matte/transparent) of the bulbs, the lamp power (75/150/250/400/600/1000), the presence or absence of mirror coating in one of the hemispheres. So the Soviet-made NLVD had many names. The most common are HPS lamps with various power attachments (150, 250, etc.).

HPS lamp option with two burners for increased service life and quick “hot start”

It was something like branding. For example, now in Russia there are DNAT-250 lamps (with a note, “of such and such production”), and in Germany (and all over the world thanks to export, marketing and quality) there is a lamp, for example, VIALOX NAV-T 250 W SUPER 4Y manufactured by Osram.

Osram Vialox NAV T 250 lamp

So, by and large, HPS lamps are just variations of the lamp model, and not a type of light source . But the type of light source is NLVD, which includes lamps DNaT, DNa3 (with mirror coating) and even DNaS (with a light-diffusing bulb, so that it is less blinding). And, except for specialists, few people know this. That's it.

A cleverly twisted bourgeois HPS lamp with a corrected spectrum - an MGL burner has been added

By the way, if anyone is interested, you can look into the lamp museum (the site is in English, but with a lot of pictures) - there are countless different lamps collected here, incl. and sodium, throughout the history of the era of electric lighting. Very informative.

Features of sodium lamps

The main advantages of using HPS lighting:

- a large amount of light emitted;

- efficiency;

- lamps can serve as an additional source of heating;

- durability - about 20,000 hours of operation.

There is also a small drawback - the release of a large amount of heat during operation. But this disadvantage can be leveled out with the help of additional equipment - there are both ventilated and non-ventilated lamps for sodium lamps of the type DNaT(Z) on the market.

Connecting a HPS lamp

The connection is also primitive to the point of disgrace, as is the device of the lamp. So we won’t dwell on this for long and will only present one of the most typical diagrams for connecting a HPS lamp.

Typical connection diagram for a HPS lamp

Although here it is worth mentioning that in reality there are a huge number of options for connecting a HPS lamp. A compensating capacitor is also a mandatory connection component. As a rule, connection diagrams are indicated on the IZU blocks. But the picture above shows the simplest schematic connection option.

Connection

Since igniting the burner requires a high pulse voltage (sometimes up to 1000 V), this complicates the connection diagrams for sodium lamps. It is necessary to use additional equipment. Ballasts for low-pressure hydraulic valves are of two types: Emballasts (electromagnetic) and electronic ballasts (electronic).

IZUs are connected to the lamp circuit in parallel, and the chokes are connected in series, sometimes through a pulse ignition device.

Figure 6 shows the NLVD connection.

Figure 6. NLVD connection diagram

Pay attention to how the choke (ballast) and IZU are connected.

Please note that when connecting yourself, you must comply with the requirement: the length of the wire from the inductor to the lamp base should not exceed 100 cm.

Some foreign manufacturers supply the market with sodium lighting devices with built-in starting devices in the lamp bulb.

Advantages of a HPS lamp

Energy efficiency of HPS lamp

This light source is still considered one of the cheapest and most energy efficient (2016). Yes, yes, you shouldn’t make eyes like that. They are quite competitive with LEDs, incl. and according to the lm/W parameter. So, from the best representatives of the industry with a power of 250 W it is quite possible to get up to 130 lm/W (proof). And from a lamp - up to 90...110 lm/W, depending on the manufacturer, diffuser, reflector, ballast and quality of the supply network.

A copy of the DNAT 1000 lamp made by the Russian company Reflux. 150 lm/W by the way.

Interestingly, the higher the power and luminous flux of a HPS lamp, the higher their light output. For example, there are almost no 50-watt lamps above 80 lm/W. But with DNAT 1000 you can safely get 150 lm/W - that’s crazy. Once again, just two years ago such parameters for LEDs in mass production were unimaginable.

Dependence of the luminous efficiency of a HPS lamp on its power

It is not entirely correct to simply talk about a lamp without a lamp, because only in it you can see all the pros and cons of the HPS lamp. The energy efficiency of lamps with sodium lamps is clearly illustrated by the characteristics declared by lamp manufacturers on their websites (they rarely lie). But we also have our own measured data obtained from the laboratory during testing of luminaires for the rating: – SBP KYRO 2 250 – 84 lm/W, – ZhKU20-150-001 Orion XO with GE lamp – 81 lm/W, – ZhKU15 -150-101B - 87 lm/W. Now comes the most interesting part. If we talk about direct replacement, i.e. when the old sodium lamp was removed and a new LED was hung in its place, you must understand that a lamp with a 150 W HPS lamp can never be replaced with a 50 or 70 W LED. The same applies to 250 W sodium lamps - they cannot be replaced with 100 and even 150 W LEDs (we are talking about ordinary lamps, and not about custom-made lamps with ideal characteristics and a luminous efficiency of 150 lm/W from the lighting device).

Price of HPS lamp

The cost of a HPS lamp varies from 300 to 10,000 rubles, depending on the power, manufacturer, seller and some other variables. An average 250 W light bulb costs around 1000 rubles (±700). But it’s also not entirely interesting to talk about the price of an abstract HPS lamp. It is interesting to talk about the cost of a lamp as part of a lamp with ballasts (starting and control equipment), a base, protective glass, etc.

So, for example, a 250 W lamp with a sodium lamp (23.4 kilolumens, 275 W, 7 kg, 85 lm/W) costs some 5800 wooden ones. This, for a second, is 250 rubles per 1000 lumens of luminous flux (5800/23.4=247). For comparison, its LED analogues cost an average of 30 thousand rubles, which is 1200 or more rubles per kilolumen . Those. LED light costs 5 or more times more than sodium light. Agree, it’s not entirely fair competition with LEDs, especially against the backdrop of not the lowest cost of the euro-dollar in the history of our vastness.

Operating temperatures of the HPS lamp.

DNAT lamps are one of the high-pressure light sources (along with DRL, MGL, LEP - light emitting plasma and others). This, in particular, determines the high operating temperatures of the burner. It can heat up to ~1300 °C. But it's a burner. It is hidden in a shell - a transparent flask made of refractory glass. In turn, the latter can heat up to ~300...400 °C. All this, combined with a fairly simple circuitry for igniting the lamp, allows the lamp to start and operate in a very wide temperature range: -60...+45°C (different manufacturers have different ranges).

Visual demonstration of the temperature of the HPS lamp

Most ballasts for HPS lamps include chokes, which can also operate at very high temperatures (up to +130 °C on the winding in normal mode and up to +200 °C in emergency mode). Which, for example, cannot be said about most drivers of LED lamps. This is us, again, by the way.

Proven technologies

In 15 years, the HPS lamp (as a technology in the broad sense of the word) will turn 100 years old. Yes, there was a period when the lamp was not a “high pressure sodium lamp”. But they were first able to ignite sodium vapor under low pressure and produce light in the visible spectrum in the 30s of the last century. What are we talking about? Moreover, over 100 years (the main achievements have been in the last 20 years), HPS lamps have been brought to the ideal level as much as possible.

Over the years, the light source has been cured of all possible “childhood diseases”, they have learned to dim it, eliminated pulsations with electronic ballasts, straightened the spectrum (MGL is a development of the technology of high-pressure sodium lamps) and the burners have been brought to perfection. But the most important thing is that in almost every country there is at least one manufacturer of lamps for these lamps. And in the most developed ones there are dozens of them. The designs of luminaires for HPS lamps have also been brought to the ideal (the most outstanding ones have an efficiency of 95%), reducing to a minimum losses on the reflector, protective glass and ballasts.

Weight of the HPS lamp (and lamps for it at high and ultra-high power)

The weight of the HPS lamp is not large. Some manufacturers, which is typical, do not even indicate it in the specifications. Depending on the power, it ranges from 150 to 500 grams. But as in the case of other parameters, we are more interested in the weight of the lamp with all the accessories (ballasts, protective cap or glass, base, fasteners).

The street lamp for the DNAT-400 lamp weighs 8 kg. By the way, this lamp (from the link provided) illuminates the entire Moscow Ring Road. Taking into account its luminous flux of 42,000 lumens, we are looking for an LED analogue from another manufacturer (Galad’s outdoor LEDs are of very high quality and with tempered glass - lamps of a higher level). Here, almost NoName Chinese lamp, the lightest we could find, with the same luminous flux (43,000 lumens) weighs 11 kg. We emphasize - the lightest, with a radiator that claims to be of high-quality heat dissipation. More or less serious lamps with casting and normal glass weigh 20-40 kg. They will object to us that there are already many LED solutions based on heat pipes, but not everything is simple with them either. High-quality heat pipes are rare, and low-quality ones are happy to rot in the open air in our climatic conditions - approx. ed.

Areas of application

- external lighting of large open spaces, streets, suburban highways;

- lighting of tunnels, sports facilities, construction and container sites;

- lighting of train stations and airports where people stay for a short time;

- lighting of architectural structures;

- lighting of warehouse and production facilities, for which there is no need to ensure high color rendering indicators;

- use in car headlights to improve visibility in fog and snow;

- NLVDs are used in crop production for year-round illumination of plants, which significantly increases growth rates and yields.

Street lighting with sodium lamps

The use of sodium lamps in crop production. Sodium lamps are most often used to illuminate plants in greenhouses, flower beds and greenhouses. The spectral composition of light created by a gas discharge in sodium vapor is optimally suited for growing fruit-bearing plants. The best choice is the high pressure sodium lamp version of the DNaT brand (sodium arc lamp). Numerous studies have shown that for productive plant growth, light with wavelengths of 470–670 nm is required. The spectral composition of the NLVD contains such peaks.

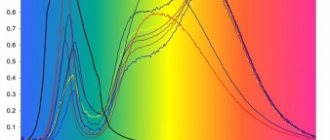

Spectral composition of the DNAT 400 lamp

HPS lamps have a very high light output: with a lamp power of 400–600 W, the light output reaches 140 lm/W.

Lamps with power ranging from 75 to 1,000 W are available. For crop production, lamps from 75 to 400 W are sufficient. At higher power, the leaves will overheat. The design of luminaires for HPS lamps must provide protection from contamination and water ingress. To prevent the lamp from overheating, it is necessary to provide for free air circulation to remove heat. It should be noted that the efficiency of the lighting system is influenced by a properly selected reflector (reflector). The best reflective efficiency indicators are for luminaires whose reflective surface is in the shape of a parabola.

Giant companies in the lighting market: Osram, Sylvania, Philips pay serious attention to the production of arc lamps for crop production. Their products are adapted for plant growing purposes; they provide optimal spectral characteristics and increased (compared to conventional HPS) light flux by 7–10%.

The use of NLVD is especially effective when growing light-loving plants such as tomatoes and peppers. It is enough to simply connect a HPS lamp to ensure a rapid increase in the volume of leaf mass, active flowering and the formation of a large number of fruits and flowers.

The use of sodium lamps in greenhouses

An example of the use of sodium lamps in greenhouses

Disadvantages of HPS lamps

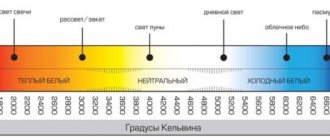

Color rendering index of HPS lamp

Perhaps this is the biggest disadvantage, often reducing all its advantages to nothing. In the lamp samples we measured, the value of the general color rendering index was: – SBP KYRO 2 250 – Ra = 27, – ZhKU20-150-001 Orion XO with GE lamp – Ra = 15, – ZhKU15-150-101B – Ra = 19. But here It is worth making an amendment that the color rendering index of the lamp, as well as the color temperature, may differ slightly from the same parameters of the lamp, since the protective glass makes its own adjustments. Especially if it is made of low-quality material and becomes cloudy, yellow or green over time. The most resistant in this sense are tempered borosilicate glasses (the same SBP KYRO). But this seriously makes the lamp heavier, increases the requirements for housing rigidity, and generally increases the cost. So all manufacturers look for a compromise in price/quality in different ways.

Comparison of the spectral composition of the radiation of a standard DNAT 1000 lamp and a standard LED (green line)

The “curve” of the color rendering index is due to the gas that is ignited inside the burner. Without going into all the serious chemical composition, let's just say that it is sodium vapor (although the composition there is much more complex). Initially (in low-pressure sodium lamps) the spectrum was even worse, but in the 60s there was a breakthrough in this area. Now we have a pronounced peak in the orange region of the spectrum. The almost complete absence of green and blue components in the lamp’s radiation will lead to the fact that at night on the street illuminated by sodium lamps, we most likely will not distinguish a dark blue car from a dark green one.

If we talk only about energy efficiency, cost and safety, by and large the driver does not need to distinguish colors at night (there is still no clear opinion from the scientific community on this issue). This is indirectly indicated by the fact that the color rendering index (as well as color temperature) on roads is not standardized in regulatory documents. Although there is a suspicion that the standard was written for existing technologies (under NLVD, NLND). Well, just like it is now (under LEDs). But if we talk about the level and quality of life, then the low color rendering index of the HPS lamp, whatever one may say, is the main reason for the relatively rapid displacement of sodium by LEDs from highways, parks, squares and open parking lots.

HPS lamp pulsation coefficient

The pulsations of the light flux from a HPS lamp are merciless. Depending on the ballast, the pulsation coefficient (PF) of the light flux can vary from 15 to 40%. On electronic ballasts, the gearbox can be zero. But due to their high cost, they are rarely used: historically, in street lamps for mass use, performance, reliability and maintainability are often much more important than the quality of light.

It is important to note that CP in street lighting is not standardized. However, these pulsations should be taken into account (and the illumination pulsation coefficient should be calculated) in industrial lighting, when a combined MGL + HPS lighting installation is made.

Long start and hot ignition

One of the very significant disadvantages of a HPS lamp is the long ignition of the burner. Depending on the ambient temperature, the type of ignition unit and the lamp manufacturer, the time it takes for a HPS lamp to reach operating mode ranges from 5 to 10 minutes. You have probably noticed more than once that when sodium street lights are turned on, for the first minute they shine very dimly and, by the way, with white light. Then the brightness gradually increases, and the spectrum acquires a characteristic amber hue.

Ignition of the HPS lamp

Moreover, if the HPS lamp is abruptly turned off and then turned on, it may not light up and not return to operating mode. The burner needs to cool down. This is the “hot start” problem. To solve this problem, at facilities where short-term voltage dips often occur, electronic ballasts and lamps with two burners are used.

Application area

Depending on the type of lamps, their areas of application are also distinguished. The use of these devices in the agricultural sector is associated with the peculiarity of their spectrum, which is very close to ultraviolet radiation. In greenhouses, plant nurseries and flower beds, manufacturers recommend using 150 W or 250 W HPS lamps. If you use HPS 400 W, then you must remember the minimum distance between the device and the plant (50 meters).

When installing street lamps, as well as devices for sports complexes, tunnels and passages, HPS 70 W and 150 W are most often used. One of the conditions for successful operation in this case is the presence of protection from moisture and dust.

As for the quality of color rendering, in this parameter sodium arc lamps are inferior to LED spotlights. HPS 150 W has a color rendering index of 20-30 Ra. For cold LED lamps it is 80 Ra, and for warm ones it is 90-100 Ra. LEDs also benefit in terms of contrast.

Application of a HPS lamp

As already mentioned, if we put aside all sorts of perversions, HPS lamps are used mainly in lamps for lighting roads and for supplementary illumination of plants.

Road lighting

The main reason why road workers are hooked on HPS lamps is their incredible energy efficiency and unpretentiousness. Now, of course, a parameter of 100...130 lm/W from a lamp will not surprise anyone, but in the middle of the last century it was a breakthrough.

But the funny thing is that this light source at that time was not the most energy efficient. HPS lamps were high pressure sodium lamps (HPS). And their predecessor - a low-pressure sodium lamp (LPNS) - doubled the light output of a newborn. That is, it produced up to 200 lm/W (by the way, this is still an almost unattainable result, even for LEDs in mass production and at an affordable price).

Actually, the ancestor of the HPS lamp is the low-pressure sodium lamp

But NLND had an even narrower spectrum (well, completely crimson-orange), so the market simply turned a blind eye to such minor losses and accepted the new lamp with open arms, because the colors of objects in its rays became at least somehow distinguishable.

Most highways, open parking lots, and interchanges all over the world are now illuminated with HPS lamps. Actually, here it is:

Non-illusory proof of the involvement of the HPS lamp in illuminating everything

… and so:

HPS lamps illuminate almost 100% of roads

As, again, already mentioned, luminaires for HPS lamps are produced all over the world by hundreds (maybe thousands) of companies. In Russia, housing and communal services have become the most common. This is also terminology dating back to Soviet times, when everything, including product names, was standardized and regulated. ZHKU stands for “ZH” Console Street. “F” is not deciphered in any way, because this letter is simply assigned to designate sodium lamps. Why "F"? There is probably some explanation for this, but it certainly doesn’t fit with ordinary logic. GKU - “G”, metal halogen lamp - understandable. RKU - “R”, Mercury lamp - understandable. DKU - “D”, LEDs - understandable. Housing and communal services... it’s not clear. Let’s simply associate this with a color close to DNAT – Yellow.

A very typical housing and communal services lamp for a DNAT 150 lamp

There are a lot of options for housing and utility services and their manufacturers in Russia. But the leader in the production of Russian utility lamps is Galad, Reflax and Lighting Technologies. How are the leaders? No one thought this, they were just on everyone’s lips. Moreover, Reflux also produces HPS lamps. But we'll talk about this below. There are also countless other manufacturers who import utility housings from Asian countries and sell them in Russia under their own brand.

HPS lamps for additional illumination of plants

By the way, this is a huge, vast topic for holivars on these Internets of ours. What is better for lighting parsley or tomatoes - sodium light or LED? Perhaps we will drop this topic now. But let us note: without exception, all greenhouses in the world, with the exception of experimental ones, and also without taking into account the manual labor of home gardeners, are illuminated with sodium and only with it.

Light for plants

Moreover, greenhouse lamps designed for HPS lamps, as a rule, do not require any serious bodywork in the form of tempered glass, IP housings and other clutter. As a result, a lamp with ballasts, base and reflector weighs 2 times less than their street counterparts.

HPS lamps guard the greenhouse economy

So that you understand what an LED lamp looks like, replacing HPS 1000 lamps, the CREE company has released an analogue of 1 kW HPS. Now there is a lot of discussion on the forums - will the load-bearing structure of the greenhouse withstand such a load, and in general, is it analogous? To be fair, we note that this is the so-called. Reference design is an attempt to show the capabilities of LEDs using a specific example with measurements and calculations, and not a finished product.

Experimental farms for illuminating seedlings with LEDs

The main advantages of sodium aggregates

The most interesting, important and noteworthy characteristics of sodium-type light sources are the following:

- unprecedentedly high level of light output - up to 150 lm/W for high-pressure modules and about 200 lm/W for low-pressure lamps;

- long operating period - from 12,000 to 32,000 hours without loss of quality and light intensity;

- economical operation - reduction in basic energy consumption and 1.5-2 times reduction in maintenance costs for the lighting installation;

- wide range of operating temperatures – the products function absolutely correctly in the range from -60°C to +40°C.

Sodium light sources are twice as efficient as conventional fluorescent lamps of the same power.

NLs are capable of providing excellent illumination of space with minimal electrical energy consumption, generating a soft and pleasant luminous flux

This is due to the design features of the products and the compact, small-sized emitter, which can very easily and without delay direct light rays in the required directions.

DNAZ lamps

DNAZ, by the way, is one of those domestic products that we (our entire editorial team) are sincerely proud of. No seriously. You will not find a more erotic solution in lighting technology in its simplicity and brevity.

DNAZ lamp 600 W with IP68 socket

Engineers have been struggling for years with the problem of the high temperature of the protective flask, with simple ways of forming the CSC, with minimizing losses in the lamp, and with reducing the weight of the lighting device. And voila - Soviet engineer Vladimir Pchelin makes a lamp with internal mirror coating, opens the Reflax company, patents this business and puts it into mass production. Profit.

Schematically, this is roughly how it works

DNaZ lamps are easily used in the plant supplementary lighting sector by such global giants as Osram and Philips. And they are especially popular among Dutch plant growers, which seems to hint.

Vladimir Pchelin and his invention: a DNaZ lamp in a street lamp housing

Returning to the previous point, these lamps have gone viral not only among agronomists, but also among road workers, and their popularity is just beginning to grow. Most of all, we had the opportunity to see DnaZ lamps in the vastness of the Republic of Belarus, although more in rural areas. In Moscow they really like to put them in courtyards. And just a few months ago they illuminated one of the streets of Dolgoprudny, despite the fact that LED lights were being installed on the neighboring street. Pilot comparison?

Street lamp with DNaZ lamp

As part of the Verified-Lumen section, we were able to test one street lamp using a DNaZ lamp. Because Since the lamp has a built-in reflector to form a wide axial reflector, and its bulb simultaneously serves as protective glass, we can safely say that the measured characteristics of the lamp = the measured characteristics of the lamp (except for power). And, for a second, we got an honest 114 lm/W with a lamp weight of 2.5 (!) kg, a luminous flux of 30,000 (!) lumens and a cost of 7,500 rubles . Actually here it is.

In general, the DNAZ lamp, together with its inventor, deserve a separate article. And we will definitely write it. No. Seriously. Apart from the company's own website, you will find almost no information about this lamp. So we'll fix this.

How to choose a lamp

The main criteria when selecting sodium lamps for your home greenhouse are power and base. The lamp power should be in the range of 75-400 watts - this is the optimal range in order not to burn the plants. The base depends on the power. For lamps with a power of up to 150 watts you can find an E27 base, for all higher power lamps only E40. We also recommend paying attention to the color rendering index and luminous flux markings: the higher it is, the better the light of the device will be.

By the way, for installation you will need a choke, a lighter and ballasts.

Summary

HPS lamps are a reliable, time-tested type of lamp that is used throughout the world to illuminate streets, highways and greenhouses. Its main advantage is high energy efficiency and low price. Thanks to this, this type of lamp will compete with all innovative light sources, including LEDs, for a long time.

HPS lamps

Ballasts (ballasts) for low-pressure heat pumps

To start sodium lamps, special ballasts are used to ignite a discharge (arc) in the lamp and limit the avalanche-like increase in current, which can lead to failure of the operating lamp. By analogy with fluorescent lamps, two types of ballasts are used: electromagnetic ballasts (EM ballasts) and electronic ballasts (electronic ballasts). In addition, sometimes the use of a pulsed ignition device (IZD) is required. Start-up time is 3–5 minutes, and full power is achieved within 10 minutes. The ballast consists of:

- an inductive choke, which serves to limit the electric arc current;

- IZU, the need for which is due to the creation at the moment of switching on a voltage of several kilovolts for ignition. This device is similar to the starter in fluorescent lamps;

- a phase-compensating capacitor, which allows you to reduce the load and reduce the risk of wiring burnout.