Our construction company is engaged in the installation of sheet piling walls for any purpose in the Moscow region and in other regions of the Russian Federation.

The cheapest option for installing a sheet piling wall is to use boards as part of a sheet piling fence.

In this case, the fence is thin walls between the sheet piling posts, enclosing and strengthening the walls of the pit, and also protecting it from moisture, snow, etc.

What are dowels needed for?

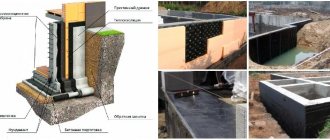

Sheet piling is a continuous wall made of sheet piles connected by tongue-and-groove locks. Sheet piling walls are used:

- to strengthen the walls of pits: they prevent the collapse of the soil, the penetration of groundwater into the site, and also localize the construction zone and stop the movement of soil around the pit;

- for strengthening unstable slopes, railway embankments, highways. Prevents slope destruction, landslides, etc.;

- to strengthen coastlines, prevent sloughing and erosion;

- for installation of various hydraulic structures: dams, bridges, dams, berths;

- for fencing underground communications;

- for creating collectors, fencing landfills, etc.

You can order work on installing a sheet piling wall from our company

The cost of installing sheet piling for a pit and transporting pile driving and drilling equipment is the lowest in the region.

For any questions call:8 800 707-72-09

Types of sheet piling walls

Sheet piling fences differ in the material used to make the sheet piling:

- wooden;

- reinforced concrete;

- PVC and composite;

- metal.

Metal ones, in turn, are divided into profile (Larsen tongues) and tubular. Tubular – high strength with increased stability, used in particularly difficult conditions. In most cases, Larsen tongues are used, most often trough-shaped.

Wooden tongues are almost never used today: they are cheap, but disposable. They deteriorate in the ground and cannot be removed without damage. Reinforced concrete has high strength. Theoretically, they can be dismantled, but this is never done because the process of removing them from the ground is too difficult and expensive. Reinforced concrete walls are left at the immersion site and included in the foundation design.

Plastic and composite sheet piles can be reused many times, but they are most often also left in the ground: due to their aesthetic appearance and resistance to corrosion, they are used as an integral part of the design when strengthening embankments. In terms of strength characteristics, they are inferior to metal piles.

Metal tongue and groove piles are used almost everywhere. They successfully combine high strength, stability, relatively low weight and dimensions. Up to 20 cycles are used, providing customers with a number of savings opportunities:

- you can rent sheet piles;

- buy used ones, their price is lower;

- sell after use. Our company buys back used sheet pile and returns up to 80 percent of the cost to the customer.

Picking up Larsen is also a way to save money, more on that below.

What is a pick-up from boards for a pit?

On water-saturated unstable soils, sheet piles are installed as a continuous wall. The profile piles are rotated 180 degrees relative to each other and connected with locks. In plan, the structure resembles a sinusoid - in this form, the stability of the wall is maximum. The pipe piles are not unfolded, but they are also installed closely.

On dense soil, in which stability is higher and the pressure on the wall is correspondingly lower, sheet piles can be placed not closely, but at intervals. The gaps are covered with boards, steel sheets, etc. This is the rebate. It allows you to save money (fewer tongues will be needed). Subsequently, the backfill is used as formwork when pouring the foundation.

If the soil is dense but saturated with water, this measure is not enough: the intake is permeable. In this case, water reduction measures are necessary, that is, additional costs. Calculation will show which will be more economical in your case.

We not only do sheet piling, but also design fencing. If necessary, we conduct soil tests. If you contact us, we will together with you choose the option that is suitable in terms of hydrogeological conditions and the most economical in cost.

We know everything about sheet piling

Work experience - 10 years. More than 270 completed projects. Not a single negative review. For any questions call: 8 800 707-72-09

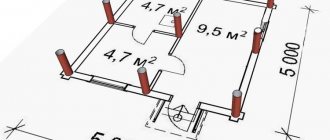

Options for installing a fence in a house on a columnar foundation

The installation of a columnar foundation can vary depending on the technical prerequisites of the building site and the parameters of the future building, as well as on the personal wishes of the owner. It is important to discuss the future design in detail with the project architect.

Now in housing construction there are several options for fences that provide owners with the necessary practical characteristics.

Cement bonded particle board

Picking up the foundation from the CBPB

This type is made from specially prepared cut boards of a specified size. They are mounted on pre-installed guide bars. The construction speed of this option is high. But the thermal insulation characteristics are reduced, which requires additional insulation of the space with expanded clay and other materials.

Brick and stone

Sand bedding is poured into a previously prepared trench. After this, a concrete pad is poured, on which a stone backing is already laid. Carrying out the work requires precision and adherence to certain rules, which forces it to be handed over to a specialist mason.

Concrete pick-up

Removing the concrete base

This design also requires the creation of a sand bedding in the trench. The pick-up itself is approximately 30 cm thick. This option requires precision and is quite fast.

Use of corrugated asbestos cement sheets

The sheets are placed in a vertical position. The cost-effectiveness and speed of construction of this option is especially beneficial for garden houses and outbuildings. And when applied with hot drying oil, it creates additional strength and aesthetics of the structure.

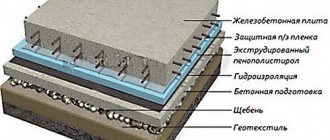

Insulation made from thermal insulation sheets

If the support pillars have a height of more than 70 cm, then the insulation process must be approached especially carefully. The production technology of the pick-up is a step-by-step process that begins with the creation of a frame from a metal profile. Sheets of the selected insulation are attached to the inside of the frame, and on the outside, corrugated sheeting provides protection for the insulation. To fill the space between the surface of the earth and the lower surface of the house, thermal insulation backfill is used.

One of the popular and profitable ways to make a practically valuable and cost-effective pickup is the use of profiled sheets. It combines quick installation, aesthetic appearance and reliable insulation.

Types of pickups

The pick-ups differ in the material they are made of. The cheapest and simplest option is a pit with a fence made of boards. For installation we use boards 5 centimeters thick. Installation example (I-beams as load-bearing elements):

- We lay the boards in layers of 0.5-1 m, starting from the bottom and moving up, along the entire height of the tongue.

- To install the I-beams behind the shelves, we make a groove of the same height as the width of the board (10 cm). The depth of the groove is different: 6 cm to one edge, 10 to the other.

- We insert the board into the groove, place it behind the I-beam shelves, and center it.

If pipes are used as load-bearing elements:

- We weld a corner to the pipe, the length is equal to the thickness of the soil layer, 5 or 10 cm. The weld seam is 5 millimeters.

- We place the boards to be installed at one end by a corner, and fasten the other with the same corner 8 cm long (welded to the next pipe).

An option designed for higher loads is a device for collecting from pipes or steel sheets.

Materials for collection

Collection materials can be:

- board (grooved or regular);

- logs;

- natural stone:

- bricks, building blocks;

- concrete;

- basement siding;

- cement-bonded particle boards and other sheet materials for finishing facades.

Wooden fences

Quite often, the fence is made from the same materials as the foundation pillars. And although logs for poles are now used mainly only for temporary structures, timber for wooden houses is not uncommon, even if they stand on brick or concrete supports.

With the classical technology of making a wooden plinth, it is made from short logs placed vertically between the ground and the first crown. For this purpose, the “groove-tenon” principle of connecting elements is used. The process looks like this:

- between the pillars they dig a trench with a depth of 30 to 50 cm;

- For sandy soils, the bottom is compacted; for clay soils, a sand cushion 15 cm thick is additionally filled and compacted;

- between the pillars, logs with the groove upward are placed and secured to the bottom - jams;

- prepare short logs to the height of the pick-up, cut out tenons at both ends;

- the logs are inserted with a tenon into the groove of the jam;

- On top of the tenons of the logs, horizontal logs are “planted” with a groove - plantings that are connected to the lower crown.

The same technology can be recommended for houses made of timber, where short timber is used instead of logs for picking.

In the modern version, a tongue-and-groove board, block house or imitation timber is used for wooden girders. This type of false base is classified as lightweight - hinged. In this case, installation of the sheathing is carried out on a wooden frame made of a 100x50 mm or 50x50 mm bar, attached to pillars and foundation beams (analogous to the grillage of a pile foundation). And the lower edge of the fence “rests” against the covering of the blind area. This technology is similar to making a fence from basement siding.

For wooden scaffolding, it is important to treat each element with antiseptics before carrying out work.

Covering the base with siding

When making a columnar foundation with your own hands, PVC base siding is the easiest to work with. In addition to simple installation, its list of advantages includes resistance to moisture and mechanical stress.

The manufacturing process has the following sequence:

- Galvanized profiles or wooden blocks impregnated with an antiseptic are vertically attached to the pillars and foundation beams.

- All elements of the sheathing are placed in the same plane. If a wooden block is used, and the pillars are made of reinforced concrete, then pieces of roofing felt (or similar material) must be laid between them.

- Just above the level of the blind area, a starting strip is attached to the sheathing.

- The panels are installed in accordance with the manufacturer's instructions.

- The ebb is attached along the top line of the base.

What does the cost of a collection device consist of?

The cost of collection depends on the material of manufacture, volume, urgency and working conditions, on the need for additional operations (water reduction, etc.)

Arctic Hydro Stroy carries out fencing installation work (including turnkey) in all regions of Russia. Our services:

- hydrogeological assessment of soil;

- testing of soils and piles;

- wall design;

- drawing up estimates and technological maps;

- transportation of material and equipment;

- leader drilling;

- immersion of sheet piles;

- collection device;

- strengthening of finished walls (reinforced belt, spacer systems, etc.);

- dismantling and removal of sheet piles after completion of work.

From us you can buy or rent sheet piles (new and used), as well as rent piling equipment.

Important!

To apply, call us or fill out the form. Our specialist will contact you by phone, with whom you can discuss the terms of the order and preliminarily determine the price. Next, our employee will come to your site to review the working conditions and documents. Based on the results of the trip, a final agreement with prices and terms is drawn up.

At your service:

- high-quality and maneuverable equipment;

- large assortment of tongues;

- skilled workers;

- SRO approval;

- fast deadlines;

- low prices;

- preparation of all necessary documents;

- work guarantee.

Sheet piling fencing for a pit in Sheremetevo, made by specialists from ArktikGidroStroy

Sheet piling in Moscow, made by specialists from ArktikGidroStroy

Sheet piling fencing for a pit made from Larsen sheet piles with spacers, made by specialists from ArktikGidroStroy

Indentation of the sheet pile performed by specialists from ArktikGidroStroy

Vibration driving of pipes and sheet piles during the construction of a temporary bridge, performed by specialists from ArktikGidroStroy

How to insulate a fence

Additional insulation of the columnar base can significantly improve performance characteristics and make the house much warmer. Otherwise, a large amount of the heat generated by the boiler will go into the space under the lower plane of the house.

To insulate the fence, do the following:

- Fastening steel sheets to base supports.

- The frame is covered with polystyrene foam or simple polystyrene foam.

- The outer side is covered with corrugated board.

- Be sure to fill the free space with slag or other materials.

- Leave openings for passing communications.

- Equipped with ventilation holes that rise 20-30 cm above the ground.

Insulation of the foundation backfill

The efficiency of creating a fence is very high and will become noticeable at the first frost, when you will have to spend less time and money on heating the house.