Historical reference

Roads have been paved with natural stone since the “beginning of time” - they were simply laid unprocessed, in large pieces. Later they began to give it the shape of a flat cube and the first granite paving stones appeared. For centuries, there was no alternative to this material, until the industrial boom of the last century began to dictate its conditions. The preparation of stone and small-format paving itself have ceased to “keep pace” with rapidly growing cities. And in our country, granite has been replaced everywhere by asphalting not only roads, but also pavements and walking alleys. However, asphalt also had enough disadvantages, and over time it became clear that paving stones had been written off early. A compromise between asphalt and stone paving stones has become concrete paving slabs, also known as concrete paving slabs or concrete paving stones.

Physical characteristics of paving slabs

The main quality parameters that you first need to pay attention to when choosing, purchasing and laying paving slabs are:

- Strength of the product material. This parameter characterizes how durable the tile is and how well the product will withstand loads and not break. The strength should be at least 30-40 MPa.

- Water absorption of the material. For modern products, this parameter should be minimal. After all, the less moisture a product can absorb, the better for its performance characteristics. And excess water in paving slabs can freeze and significantly damage the internal structure. The water absorption rate should not exceed 6%.

- Abrasion. This property directly depends on the manufacturing method. Often, in order to reduce the price of products, the manufacturer adds dye only to the top layer of the product. Such material will quickly lose its original appearance. In this case, a coating made from a material of one color will retain its color throughout its entire service life. Abrasion resistance should be about 0.7 g/cm2.

- Frost resistance grade. This parameter is one of the most important indicators that you should pay attention to when purchasing and laying paving slabs . Good quality products should be designed for a period of about 250-300 cycles (1 cycle - freezing and subsequent thawing). Typically, approximately 5 such cycles occur during the winter. And based on this, the full service life of tiles, professionally and efficiently laid by specialists, is 50-60 years.

- Characteristics of the product surface (glossy or matte). Laying paving slabs with a glossy surface looks more beautiful, but gloss indicates a large amount of water in the product, which is a negative factor for the overall service life.

Advantages of paving slabs

Paving slabs, widely used for paving both in cities and in the private sector, are attractive for many characteristics. But just as a person is “met by his clothes,” the path, first of all, attracts attention with its appearance, and paving slabs provide it with this attractiveness.

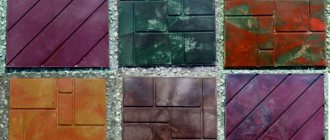

1. Highly decorative

Manufacturers offer a huge selection of formats and several texture options, coupled with a wide range of colors and ColorMix technology for mixing shades. This variety allows you to implement any design ideas without restrictions, harmoniously combining paving with the surrounding architecture and landscape style. If you want to imitate ancient pavements, you can use the corresponding collections for paving.

Roman ChizhovChief technologist of the Steingot plant

Classic and small square shapes really resemble stone paving stones. But in recent years, comfort and safety have been in trend, so preference is often given to medium format tiles with minimal bevels or no bevels at all.

The original shade of paving slabs practically does not change over time (for high-quality materials), thanks to which paths remain one of the basic elements of landscape design for a long time.

2. Ease of installation and maintainability

Laying paving slabs, even large format ones, does not require complex preparation of the base using heavy construction equipment. If necessary, you can easily replace one or more cracked elements without completely dismantling the coating. It happens that under an already laid path it is necessary to install or repair communications; to do this, it is also enough to disassemble the tiles and put them back when the work is completed.

3. Operational safety

If paving technology is followed, puddles do not form on the surface of the path, and the tile itself does not slip even when wet and remains comfortable and safe when moving.

Roman ChizhovChief technologist

Sprinkling the seams and then thoroughly compacting the sand in the seams with a vibrating plate is primarily necessary to ensure that the bulk of the water is drained along the surface of the tile into the drainage system. Therefore, the slope of the paving surface is also required. It is understood that very little water should get through the seams under the surface of the tile - a small amount will have time to escape through the tightly compacted layers of the base.

4. Comfort

Paths are a functional and decorative element of landscaping and should not only decorate the area, but also be as comfortable as possible for its inhabitants. It is quite possible to achieve this effect if you use modern collections of paving slabs.

Roman ChizhovChief technologist

Today, comfort in conjunction with paving slabs is understood to mean a flat surface with minimal seams and chamfers. The trend was set several years ago by city architects and now we all know the “Comfortable Environment” program.

5. Eco-friendliness

The climate is changing and hot summers are no longer uncommon even in the central regions and to the north, not to mention areas where above 30˚C has long been considered “cool”. And some coatings, for example, asphalt, begin to release harmful chemicals into the atmosphere already at 25 ˚C. Whereas concrete, even with strong heating, does not change from one state of aggregation to another and does not release anything into the air. And the composition of concrete paving slabs, in principle, does not imply the presence of any potentially harmful additives.

6. Durability

Properly laid tiles, coupled with proper preparation of the base, will provide decades of service without the need for repairs. High-quality paving slabs do not fade, do not wear out and do not require complex care or periodic renewal. The service life of concrete paving stones is from 15 years, which is due to high frost resistance (F100-200 cycles). Even taking into account the initial investment, in the long run it is much more profitable to spend money on paving with good concrete paving stones once and for many years, rather than redoing the paths every few years.

7. Practicality

Concrete paving slabs are characterized by minimal permeability - they practically do not absorb moisture, and therefore do not absorb dirt either. If necessary, it is enough to periodically wash off the surface of the paths with water from a garden hose with a spray nozzle. In extreme cases, cleaning with a pressure washer may be necessary, but this is rare under normal operating conditions.

Frost resistance as a quality criterion for paving slabs

Of the few characteristics of concrete products, the most mysterious for the inexperienced consumer is frost resistance. This review will briefly examine what frost resistance is and compare this indicator in injection molded and vibration-pressed products.

Frost resistance is the ability of a product in a water-saturated state to withstand repeated alternating freezing and thawing without visible signs of destruction and without a significant decrease in strength. Frost resistance is indicated by the letter “F” with numbers from 50 to 1000 (example - F200), indicating the number of freezing-thawing cycles.

From the above definition it is clear that the frost resistance of concrete products depends on its internal structure, in particular, on porosity, since this feature determines the volume of water (ice) and its distribution in the concrete body. Increasing frost resistance, in turn, is possible by increasing the density of concrete, reducing the volume of macropores and their permeability to water.

High frost resistance is very important in St. Petersburg and the Leningrad region, where climatic conditions (high humidity, multiple temperature changes relative to zero) test paving slabs annually.

GOST 17608-91 indicates that the frost resistance of paving slabs should be no lower than F100, and for the northern regions, which include St. Petersburg, no less than F150 and F200. Vibropressed paving slabs, having a high concrete density, have a frost resistance of at least F200. Paving slabs made using casting technology, and, accordingly, with a low density of concrete, do not meet these requirements and have frost resistance indicators that are several times lower than vibrocompressed ones.

As a result of such gross non-compliance with GOST, cast tiles have a short service life - almost everywhere you can observe that relatively recently laid tiles begin to crumble and crack after just a few years. In areas with heavy traffic this occurs after several years. As a result, a material that is supposed to serve for a long time, after a short period of time, already needs repair, and often a complete replacement. Let us remind you that replacing paving elements is a much more complex and time-consuming procedure than installation.

Main types and technologies for the production of paving slabs

Today, the two main types of concrete paving slabs are most in demand – vibro-cast and vibro-pressed. Typically, the first is used mainly in the private sphere, the second is actively used on an industrial scale, along with granite paving stones. Product characteristics directly depend on the raw material base and production technology.

Vibration casting technology is the prerogative of small private enterprises, as it involves manual labor with minimal involvement of equipment. The mortar for making tiles is a mixture of cement, sand and water, with a fairly liquid consistency. Also, the solution may contain plasticizing additives and pigment, mainly of organic origin, since it is cheaper and gives a brighter shade. The solution is poured into molds installed on a vibrating table, where the concrete is compacted under the influence of vibration for a certain time. After two days, the tiles are removed from the molds and sent to the racks for natural maturation and strength gain.

Vibrocompression is a technology for large factories, as it requires a complex, expensive, automatic production line. The raw material mixture includes not only cement and sand, but also crushed stone, which is due to the direct relationship between the strength of concrete and the strength of its largest filler. As with vibration casting, during vibrocompression, modifying additives are introduced into the solution, but minimal water is added, just enough for hydration. The mixture is not poured into molds, but filled in, as it is a homogeneous semi-dry mass. The molds (matrices) enter the press, where the concrete is compacted under double influence: vibration and high pressure. This is followed by stripping, and the pallets with tiles are sent to the holding chamber, where high temperature and humidity are maintained. This stage allows the concrete to quickly gain grade strength under optimal conditions. The bulk of collections of vibropressed tiles today are produced using double pressing technology - the main layer is a mixture of cement, sand and crushed stone; facial – cement, sand and pigment (inorganic).

Roman ChizhovChief technologist

Concrete components: cement, sand, crushed stone, water. According to the current GOST 17608-2017, crushed stone must be used in everyday life. Special additives have a much smaller effect on strength and durability than high-quality raw materials and strict adherence to production technology.

Two types of pigments are used for concrete:

- organic (acid-based) - cheap and bright, but fade quickly.

- inorganic (based on oxides of iron, titanium, cobalt and chromium) - more expensive, but durable and not affected by organic solvents.

Different production technology and appearance

The main difference between these types of flooring is the composition and production technology.

Cement versus clay, press versus kiln firing. Vibropressed paving slabs are made from a mixture of cement, sand, crushed stone and pigments. The composition is filled into a matrix - a mold - and compacted under the influence of vibration and pressure, hence the name. After this, the tiles gain strength in special chambers where a certain air temperature and humidity are maintained.

Clinker paving stones are made from refractory types of clay and fired in a kiln at a temperature of 1200-1300°C until the surface is sintered.

Due to production technology, the appearance of vibropressed tiles and paving stones varies greatly. While clinker has a more glossy, shiny surface, vibropressed tiles have a slightly rougher surface.

The difference here is not only in the surface of the products, but also in the shape. Clinker is most often rectangular, and among vibropressed paving slabs there is a huge selection of shapes: square, zigzag, coil, wave, multi-format “Old Town”.

Characteristics of concrete tiles

The properties of concrete paving slabs directly depend on the raw material base and the production cycle - the denser the structure, the stronger and more durable the material.

| Characteristics | Indicators | |

| Vibration pressing | Vibrocasting | |

| Strength of concrete (compression) | B30 | Up to B22.5 |

| Abrasion | 0.5-0.7 g/cm² | From 0.8 g/cm² |

| Water absorption | Until 6% | From 7% |

| Frost resistance | F200 | Up to F100 |

However, it is worth clarifying that the specific parameters of vibrocast tiles may differ from the average ones due to the characteristics of production.

Roman ChizhovChief technologist

It is important that there is no GOST for vibrocast tiles, and therefore the raw materials for its production are not regulated. Therefore, it is a priori unclear what quality should be, but in fact, it varies greatly for each manufacturer. And the characteristics of the tile may be worse than in the table.

Technical characteristics of paving slabs GOST 17608-2017

| No. | Characteristic | Description of technical requirements and characteristics in accordance with GOST 17608-2017 |

| 1. | Compressive strength of concrete | Concrete strength is the most significant parameter of concrete quality. Designation: B25, where B is the strength class, 25 - the tile can withstand a load of at least 25 MPa, or 254 kgf/cm2. For concrete paving slabs it is characterized by strength classes - B22.5 - B40. In the laboratory of the Stellard plant, strength parameters are checked after the production of each batch of paving elements. To do this, selected samples are placed under a laboratory press and the upper limit of its compression endurance is determined. In order for the products to be shipped, the strength of the slabs must be at least 90% of the compressive strength class declared by the manufacturer (70% is allowed as agreed with the client). |

| 2. | Concrete grade for frost resistance | Frost resistance grade is a very important indicator of concrete products, showing how many freezing and thawing cycles (one cycle – freezing and thawing of the sample at temperatures from -20 to +20) the sample can withstand without losing its strength. The grade of concrete for paving slabs in terms of frost resistance according to GOST 17608-2017 must be at least F200. Designation: F200, where F is the frost resistance grade, 200 is the number of cycles. |

| 3. | Abrasion of concrete | Abrasion is one of the indicators of the service life of paving slabs, which shows how much the product changes in volume and weight when exposed to friction forces. The abrasion properties of concrete are tested in laboratory conditions by performing tests on an abrasion wheel. GOST requirements for abrasion of concrete slabs: G1 – not > 0.7 g/cm2; G2 – not > 0.8 g/cm2; G3 – not > 0.9 g/cm2; All products of the Stellard plant correspond to the G1 abrasion grade. |

| 4. | Operations group | Depending on the impacts and loads during operation, all concrete paving slabs are divided into 4 groups: A - street sidewalks, pedestrian paths and areas of private houses, which are not accessible even by passenger vehicles. B – sidewalks of heavily trafficked streets, city squares, bicycle paths, public stops. transport. B- low-intensity roads, parking areas, gas stations. D – areas with particularly high load (container terminals, ports, warehouse areas). |

| 5. | Water absorption | Water absorption is the ability of concrete slabs to absorb water, a characteristic on which the service life of the products directly depends. Concrete, which absorbs a small amount of water, will not collapse from internal pressure when the moisture frozen in it thaws. Water absorption according to GOST should not exceed by weight, %: 5 – for slabs made of heavy concrete; 6 – for slabs made of fine-grained concrete. All Stellard paving slabs have a water absorption rate of no more than 5% This indicator means that with a paving stone 6 cm thick weighing 2.7 kg, it will not absorb more than 135 g of water. |

| 6. | Marking of paving slabs | Plates are designated by grades according to GOST 23009-78 For example, consider the markings of one of the forms of Stellard paving stones: New city V.15.Psm.6, where

|

| 7. | Thickness of the facing concrete layer for two-layer slabs | The thickness of the facing layer must be at least 10% of the nominal thickness of the slab. For slabs less than 50 mm thick, the thickness of the textured layer must be at least 5 mm. For slabs with a thickness of more than 100 mm, a textured layer of 10 mm is allowed. |

In addition to technical characteristics, the new standard specified requirements for paving slabs, such as

- Requirements for materials;

- Requirements for manufacturing accuracy;

- Requirements for surface quality and appearance.

You can download GOST 17608-2017 in pdf format.

Properties of different types of tiles

The choice of paving slabs should be approached comprehensively, taking into account the technical, operational, and aesthetic properties of the material, which is laid not for one year, but ideally for more than one five-year period.

Texture - vibro-cast tiles are smooth, on the one hand, they become less dirty, on the other hand, like granite, it is easier to slip on them after rain or in icy conditions. Vibration-pressed tiles with a rough surface win in this regard.

Aesthetics - initially vibropressed tiles were produced in the form of rectangular paving stones in a very limited range, including several shades of gray. Whereas the vibrocast one was replete with a large number of complex shapes and bright, saturated colors and attracted gloss. However, today manufacturers have not only expanded the palette many times and diversified the forms, but also learned to mix shades, obtaining different visual effects. A brick press can imitate different types of natural stone and clinker, and the collections are replete with pastel and bright colors. In addition, due to the durability of inorganic pigments and minimal abrasion, the original color of the tiles remains virtually unchanged over the years, and the paths do not lose their presentability.

Ease of use - both vibro-cast and vibro-pressed tiles are now laid primarily using a dry method without the use of mortar. But due to the ideal geometry, it is easier to work with vibropressed, an even plane and identical seams are obtained without additional effort.

Availability - at first glance, vibro-cast tiles are the leader in this parameter, since their price is much lower, which is most important for large paving areas. For comparison, the cost of a vibration-casting square starts from 350 rubles for a simple gray mold, and a vibration-pressed square starts from 800 rubles. If we look at exclusive collections of brick making machines, then the cost is already around one and a half to two thousand rubles. Vibrocasting, in principle, is not exclusive, but more complex forms in bright colors will cost about 600 rubles per square. However, not everything is so simple, given that the cost-effectiveness of paving needs to be considered in the long term, large initial investments will be “repaid” due to the increased strength and durability of vibro-pressed tiles.

Paving slabs

What it is? These are solid flat piece materials of relatively small thickness, made using various technologies and intended for paving sidewalks and areas. Depending on the source materials used, the following types of paving slabs are distinguished:

- vibro-compressed, vibro-cast and pressed, from ordinary and colored concrete mixtures;

- sawn, from natural natural stone;

- clinker, from specially prepared clay;

- polymer sand, obtained as a result of high-temperature sintering of polymer materials and sand;

- rubber, from recycled car tires.

Due to its affordable cost, simple manufacturing technology and good performance characteristics, such concrete “outdoor floor tiles” have found a wide response in private and contract construction.

Common shapes and sizes

The variety of paving tiles produced today has long gone beyond the limits of GOST 17608-91, which determined the technical requirements only for concrete slabs.

Shapes and sizes of slabs.

The range of modern paving materials can include not only rectangular and square paving slabs, but also products in the form of a wide flat wave, rhombus, polygon, clover, or in the form of a set of several elements that make up a figured pattern.

Also, in the process of choosing paving slabs, you should pay attention to the “collection series”. These include “Old Town”, “English Cobblestones”, “California”, “Florida” and some others. All of them differ in their appearance from traditional products due to a special design approach to manufacturing.

An important dimensional characteristic of paving slabs is their thickness. This characteristic largely determines the scope of its application. The thickness range of products is from 30 to 80 mm. The thinnest types can only be used for paving garden paths with low pedestrian traffic. The average thickness is for street sidewalks and squares, and the thickest is in places where cars are parked and for roadways with light traffic.

Speaking about the geometric dimensions in the plane of piece products, the most popular length is in the range of 200-400 mm with a width of 140-250 mm.

Marking

Modern production conditions and changes in paving slab manufacturing technologies have led to the fact that most factories label this road material in accordance with their own specifications. At the same time, the State Standard specifies that the marking of tiles must indicate:

- the material from which it is made;

- its geometric shape;

- length, width and thickness in cm.

- square concrete paving slabs 50x50x30 mm are designated as B K 5.5.3;

- rectangular made of granite measuring 300x200x40 mm - G P 30.20.4;

- clinker hexagonal size 120x180x50 mm - K Ш 12.18.5;

- wave paving slabs 50x150x40 made of concrete - B B 5.15.4.

One way or another, this format is quite difficult to understand, and therefore a person without a construction education may have difficulties during the purchasing process. Therefore, on store price tags the name is usually indicated without using markings, and its explanation is immediately given in terms and quantities that are understandable to the buyer.

Popular slab sizes.

Material Specifications

The performance characteristics of paving slabs depend on the quality of the material from which they are made, as well as the manufacturing technology. For example, the most popular tile made from colored concrete mixtures, depending on the method of its molding, may have the following characteristics:

- compressive strength 0.40-0.60 kg/cm2;

- frost resistance 200-350 cycles;

- density or specific gravity of paving slabs 1800-2200 kg/m 3;

- water absorption 2-5%;

- abrasion 0.15-0.55 g/cm 2 ;

- estimated service life up to 25 years.

Granite, marble, clinker and polymer sand tiles have higher performance indicators, which are determined in each case separately and depend on many factors.

Tile selection

The solution to the problem of how to choose paving slabs depends on the combination of answers to the following questions:

- purpose of the road surface;

- expected pedestrian and weight load on the surface;

- desired type of pattern and color shade;

- financial opportunities.

Granite or clinker tiles are stronger and more durable, but the high cost of this material forces many developers to choose cheaper products made from colored concrete.

Before choosing paving slabs, pay attention to the absence of cracks and chips on the surface, check the correct geometric dimensions and color uniformity.

High-quality tiles should produce a fairly clear sound when tapped. Muffled returns indicate high humidity of the products and low quality of the initial mixture.

On average, manufacturers place 10 to 14 square meters on a pallet. meters of tiles depending on its thickness. As a result, the weight of one pallet can range from 680 to 1120 kg. Therefore, when purchasing in bulk, special attention should be paid to those tiles that bear all this weight, being at the very bottom.

Cost of material and installation work

The cost of factory-made paving slabs depends on the materials used, thickness and method of their manufacture. Average price per sq. meter in large cities of Russia is:

- vibro-cast colored concrete - 300-480 rub/m2;

- vibropressed concrete - 530-750 rub/m 2;

- granite, depending on the type, - 1700-3500 rubles/m2;

- polymer sand - 410-480 rub/m2;

- rubber - 800-1700 rub/m2.

The cost of vibro-cast concrete tiles made independently at home is 160-200 rubles/m2.

The cost of laying paving slabs by a construction organization largely depends on the complexity of preparing the base. But on average the price ranges from 30 to 50% of the cost of all materials used (about 900 rubles per sq.m. including preparation of the base).

So which tile should you choose?

As with everything, there is no definite answer to this question; everything depends not only and not so much on the type of tile, but on its quality. There are quite a few conscientious manufacturers of vibro-cast tiles on the market, using high-quality raw materials and observing the water-cement ratio. And the characteristics of their products are quite capable of satisfying all the requirements for paving with low loads. Another thing is that there are plenty of outright handicrafts that will fall apart after the first season, but playing Russian roulette with your own money is a thankless task. Vibropress is, in principle, produced only by large factories that provide a guarantee for their products, and there is much less chance of getting caught with it. And most importantly, the tiles must be selected according to the operating conditions. According to GOST, the thickness of sidewalk tiles is at least 50 mm; in practice, tiles from 40 mm are used, but manufacturers recommend a thickness of 60 mm. If not only pedestrian traffic is expected, but also vehicular traffic (parking, entry), according to GOST the minimum is 80 mm, in practice – 60-80 mm. Regardless of what tile will be used, how long the paving will last depends on compliance with the base preparation and installation technology.

GOST paving slabs - key features

Considering that the material in question is used for finishing outdoor surfaces, it is important to pay attention to the type of its application, hence the basic requirements. Particular attention is paid to thickness, weight and size, which vary greatly depending on the specific type of stone and type of coating. Taking into account the expected load, the following categories are classified:

- 30 mm - material used for courtyard areas and paths;

- 40 mm – can be used as a pedestrian zone;

- 60 mm – such vibropressed tiles are used for highways and light vehicle parking;

- 80 mm - unlike a thinner coating, it can also withstand freight transport.

The standards do not regulate the size of one product, but in general some standards are common. For example, you will always find paving slabs 300x300x30 in stock and with a similar ratio, but if you need something exclusive, then such stones are usually made to order. Please note that curb stones also have their own interstate standard, which is also mandatory for road construction.

| Name of works | Unit change | Price, rub. |

Turnkey laying of paving slabs with materials

| sq. meter | Negotiable |

Laying paving slabs without materials

| sq. meter | Negotiable |